Overview

So, what's the big deal about B2B inventory management? Well, this article dives into some essential strategies that can really help you succeed. Picture this: effective inventory management isn’t just a checkbox on your to-do list; it’s a game changer! By employing methods like:

- real-time tracking

- demand forecasting

- optimizing those all-important supplier relationships

you can boost your operational efficiency and keep your customers happy.

Think about it: when you have a clear view of your inventory, you can make smarter decisions. For example, real-time tracking helps you understand what’s in stock and what’s running low, which means you can avoid those frustrating stockouts. And let’s not forget about demand forecasting—it’s like having a crystal ball for your inventory needs!

So, are you ready to take your inventory management to the next level? By implementing these strategies, you’ll not only streamline your operations but also enhance customer satisfaction. It’s time to embrace these tools and watch your business thrive!

Introduction

In the fast-paced world of B2B commerce, effective inventory management isn’t just about logistics; it’s a strategic advantage that can really make a difference to your company’s bottom line. With advanced technologies and new methodologies on the rise, businesses now have the chance to refine their inventory practices like never before.

So, what’s in store? This article dives into nine essential strategies that can transform B2B inventory management. We’ll explore how companies can:

- Optimize their stock levels

- Enhance supplier relationships

- Leverage data for smarter decision-making

But as the landscape keeps evolving, what challenges do organizations need to tackle to ensure their inventory management practices stay competitive and efficient? Let’s find out together!

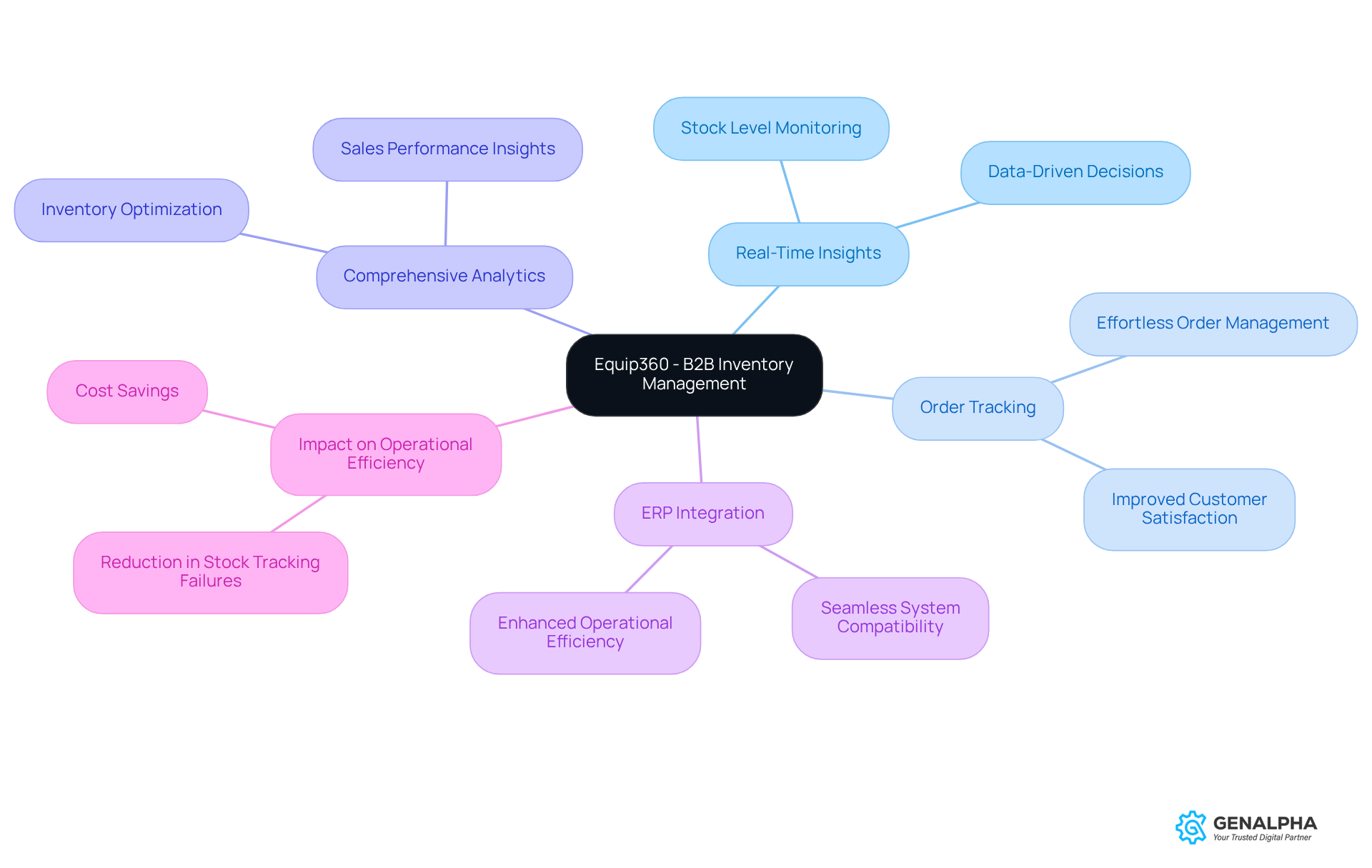

GenAlpha Technologies: Optimize Your B2B Inventory Management with Equip360

Hey there! Have you heard about Equip360 from GenAlpha Technologies? It’s a game-changing B2B eCommerce platform that prioritizes B2B inventory management to simplify stock management for manufacturers and distributors. Imagine having real-time insights into your stock levels, tracking orders effortlessly, and accessing comprehensive analytics—all in one place! This means you can streamline your operations and boost your sales performance.

What’s really cool is how Equip360 integrates seamlessly with your existing ERP systems. This enables organizations to effectively, ensuring they meet customer demands without the headache of excess supplies and unnecessary expenses. Did you know that 62% of business finances are affected by stock tracking failures? That’s a pretty big deal and highlights the need for effective solutions like Equip360.

Companies that have successfully implemented Equip360 are seeing significant improvements in operational efficiency. It’s clear that this platform plays a crucial role in enhancing B2B inventory management practices for manufacturers. As the B2B eCommerce landscape continues to evolve, adopting platforms like Equip360 isn’t just a good idea—it’s essential for staying competitive.

So, why not take a moment to evaluate your current stock management practices? Consider incorporating Equip360 into your operations to see how it can help you thrive!

Prioritize Accurate Inventory Tracking for Enhanced Efficiency

Keeping a close eye on stock is super important for cutting down on discrepancies and making sure that what you see truly reflects what's available. Have you ever thought about how barcode scanning and RFID tech can really up your tracking game? Take the 52nd Logistics Readiness Squadron at Spangdahlem Air Base, for instance. They jumped on the RFID bandwagon, and it's projected to save them over 7,000 man-hours every year just in stock management!

Regular audits and cycle counts are key to ensuring effective b2b inventory management, helping to dodge both shortages and excess inventory. By maintaining accurate stock records, companies can improve their b2b inventory management, which helps boost order fulfillment rates and ramp up overall efficiency. As Senior Airman Julius Pruitt shared, "The RFID scanner enables the Airmen to perform stock assessments without having to tally each item separately, conserving over 7,000 man-hours." This really shows the real-world benefits of these , paving the way for smarter decision-making and real-time tracking.

So, how are you tracking your stock? It might be time to consider these innovative tools to streamline your processes!

![]()

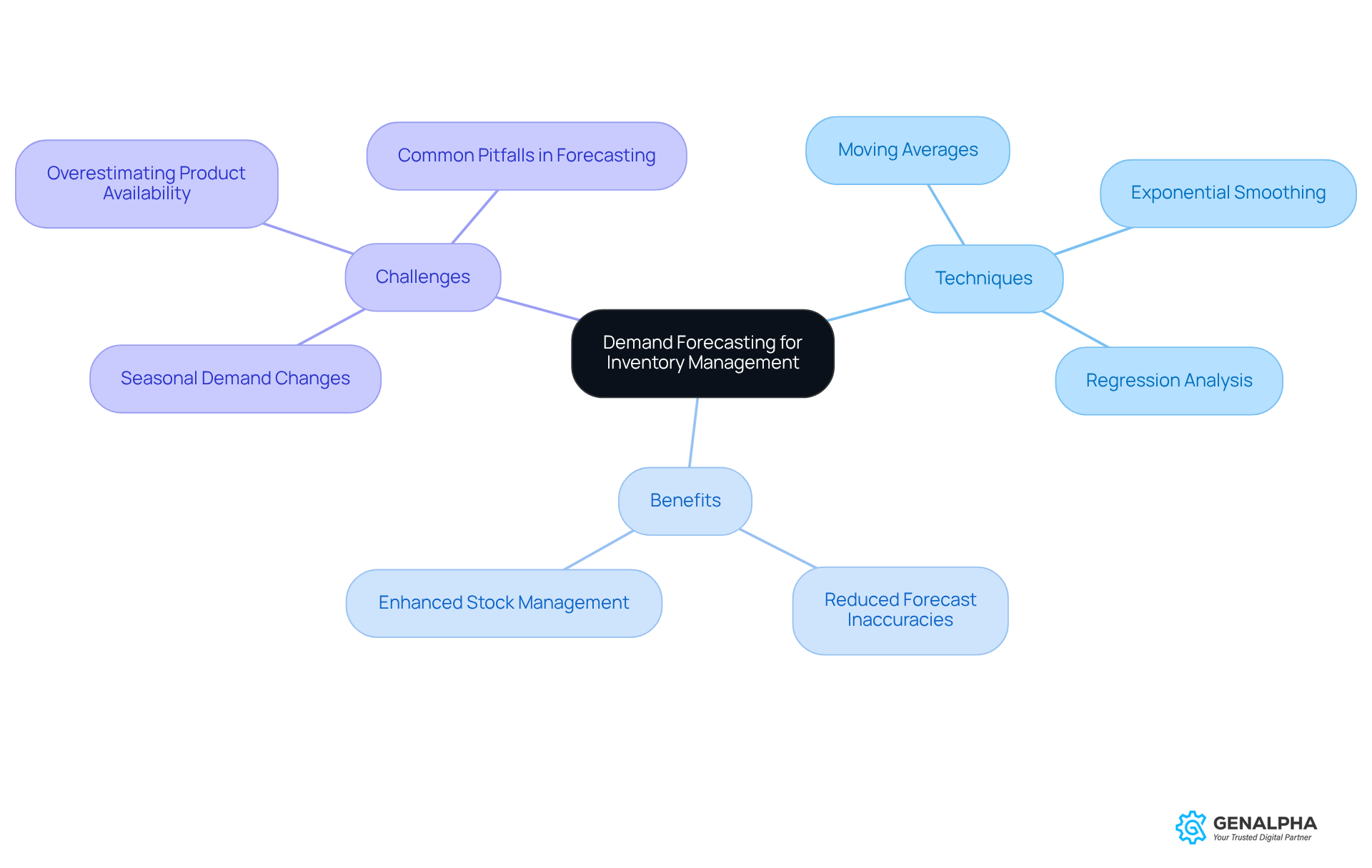

Utilize Demand Forecasting to Anticipate Inventory Needs

Effective demand forecasting methods are key for companies looking to enhance their B2B inventory management and stay ahead of their stock needs. By tapping into historical sales data, market trends, and seasonal variations, businesses can really fine-tune their inventory levels. This means having the right products available just when customers are looking for them.

Let’s think about it: techniques like moving averages, exponential smoothing, and regression analysis play a big role in improving forecasting accuracy. They help identify customer demand trends by directly utilizing past sales data. For instance, a global energy company saw a whopping 65% drop in forecast inaccuracies after it automated its demand planning models. This shows just how beneficial into B2B inventory management can be!

Similarly, Procon Products brought together several software platforms to boost demand visibility. This led to smarter stock management decisions and enhanced B2B inventory management planning precision. But, it’s not all smooth sailing—companies need to watch out for common pitfalls in forecasting, like overlooking seasonal demand changes.

So, by embracing these strategies and being mindful of potential challenges, businesses can meet customer demand effectively while cutting down on surplus stock. This not only enhances operational efficiency but also keeps customers happy. What steps are you considering to improve your demand forecasting?

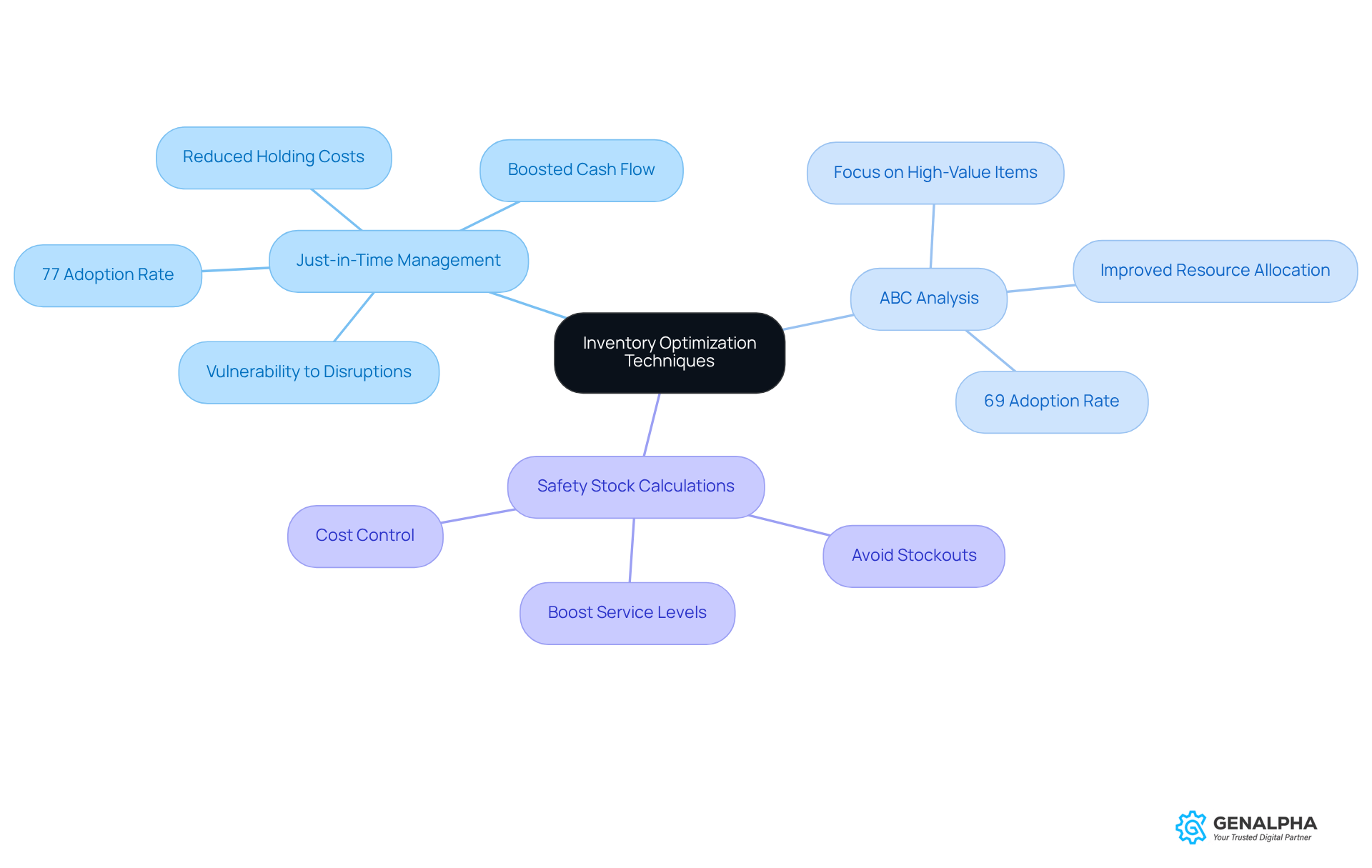

Adopt Inventory Optimization Techniques to Reduce Costs

Have you ever thought about how stock optimization techniques can really change the game for businesses? Techniques like Just-in-Time (JIT) management, ABC analysis, and safety stock calculations can lead to some serious cost savings. JIT stock management, for instance, helps cut down on holding costs by ensuring that supplies are ordered only when needed. This not only reduces excess stock but also boosts cash flow. But, let’s be real—JIT strategies can also make businesses vulnerable to disruptions, especially with the supply chain challenges we've seen recently. Did you know that 77% of supply chain decision-makers are using JIT strategies? It’s clear that this approach is pretty popular in today’s stock control scene.

Now, let’s talk about ABC analysis. This method takes stock control up a notch by categorizing items based on their importance and how quickly they sell. This way, businesses can focus on high-value items, making sure resources are used wisely. In fact, around 69% of organizations are on board with ABC analysis, showcasing how effective it is at improving b2b inventory management by directing efforts where they’re needed most.

And what about safety stock levels? Calculating these is vital for avoiding stockouts when demand unexpectedly spikes. This proactive approach ensures that customer needs are met without racking up unnecessary costs, ultimately boosting service levels. After all, understocking can put service level agreements and customer expectations at risk, leading to those costly expedited shipments we all dread. By embracing these strategies, companies can deftly navigate the complexities of supply chain operations while keeping efficiency and customer satisfaction in check. To really make these methods work, it’s crucial for companies to regularly and tweak their strategies based on the ever-changing market landscape.

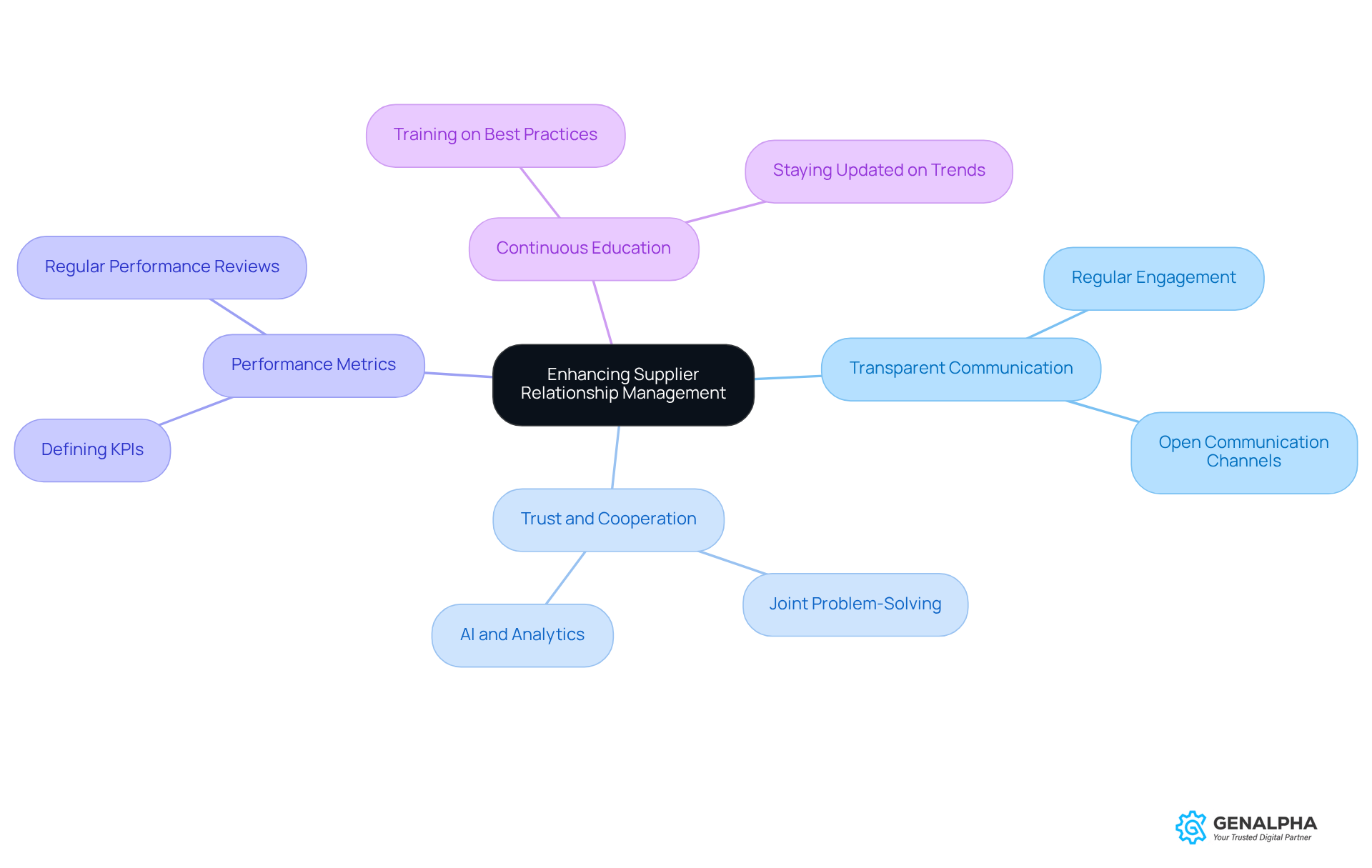

Enhance Supplier Relationship Management for Better Inventory Control

Improving supplier relationships is key to optimizing stock control, and it all starts with transparent communication, trust, and cooperation with your key suppliers. Have you ever thought about how setting clear expectations and performance metrics can help ensure that suppliers meet stock requirements effectively? Regular performance reviews and joint planning sessions not only enhance lead times but also significantly cut down on stockouts that can disrupt your operations. For instance, a major electronics company saw great results when they involved key suppliers in product development, leading to a 20% reduction in time-to-market and a 15% decrease in production costs, as noted in the case study "Success Through SRM."

But it doesn’t stop there! Strong supplier connections allow companies to and conditions, which further boosts stock management efficiency. Did you know that 98% of CEOs recognize the immediate benefits of using AI and advanced analytics in supplier collaboration, according to the C-Suite Global AI Indicator Report? This can lead to improved forecasting and stock optimization. By fostering a cooperative atmosphere, organizations can anticipate demand fluctuations and adjust stock levels accordingly, ultimately enhancing cash flow and customer satisfaction.

Continuous education and training on collaboration best practices are essential to keep both parties updated on the latest trends and techniques. This not only reinforces the partnership but also builds the mutual trust necessary for long-term success. Plus, defining key performance indicators (KPIs) to evaluate the effectiveness of supplier collaboration is crucial for tracking progress and pinpointing areas for improvement. So, what steps can you take today to strengthen your supplier relationships?

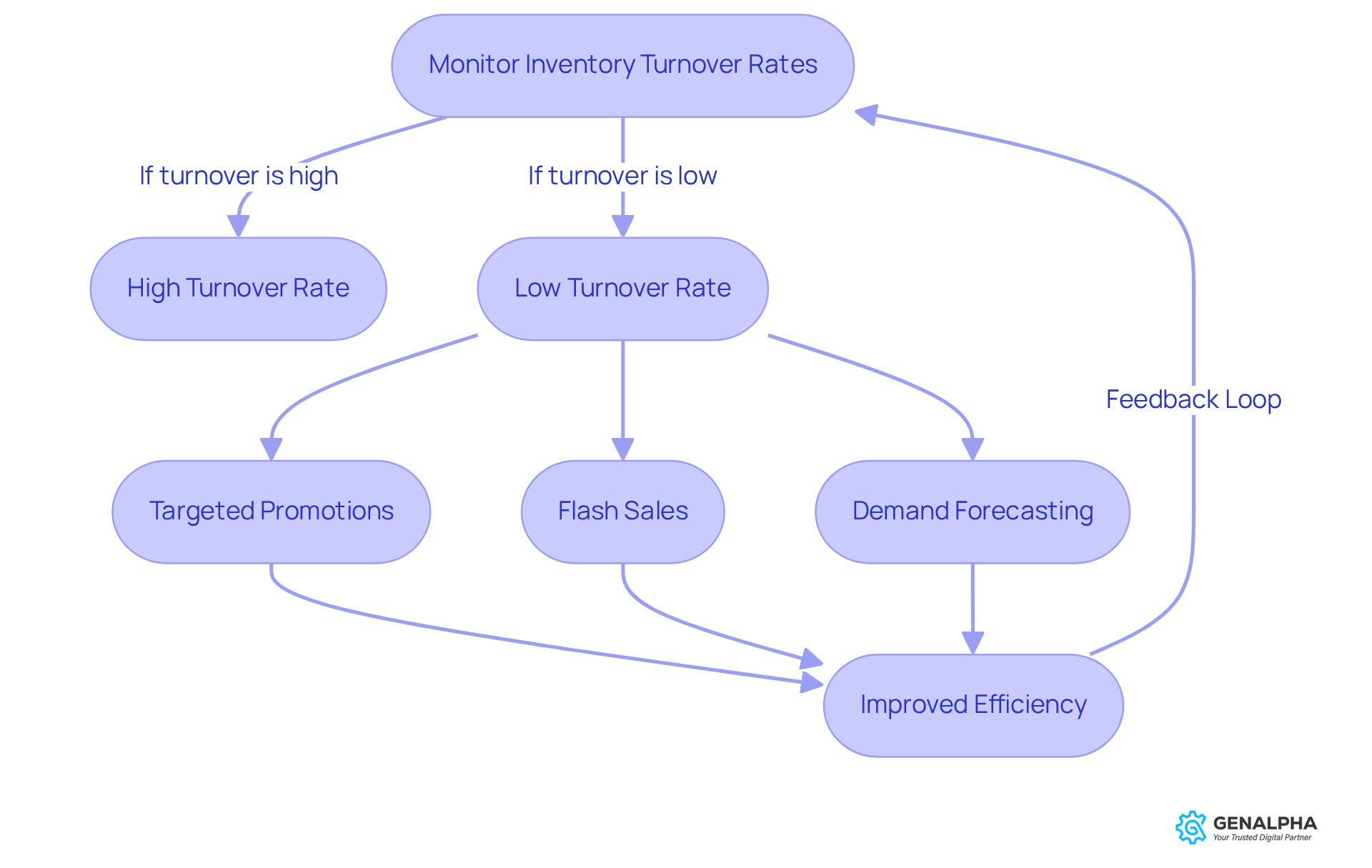

Monitor Inventory Turnover Rates for Improved Efficiency

Tracking is super important for companies that want to get a handle on their supplies. Think about it: a high turnover rate usually means that stock management is on point, showing that products are flying off the shelves. On the flip side, a low turnover rate can signal overstocking or sluggish sales, which can tie up cash and jack up storage costs.

So, how can businesses boost their stock efficiency? It starts with regularly checking those turnover ratios and adjusting stock levels accordingly. You might want to consider strategies like targeted promotions—flash sales or volume discounts for those slow-moving items can really do wonders for turnover rates.

For example, look at companies like Grayton. They’ve successfully adopted lean manufacturing strategies and saw a whopping 70% increase in cash flow in just one year! By focusing on quick-selling items and using precise demand forecasting, companies can align their stock with what the market truly needs. This approach not only enhances profitability but also boosts operational efficiency.

So, what do you think? Are you ready to take a closer look at your stock turnover rates and see how you can make improvements? Let's dive in and make those numbers work for you!

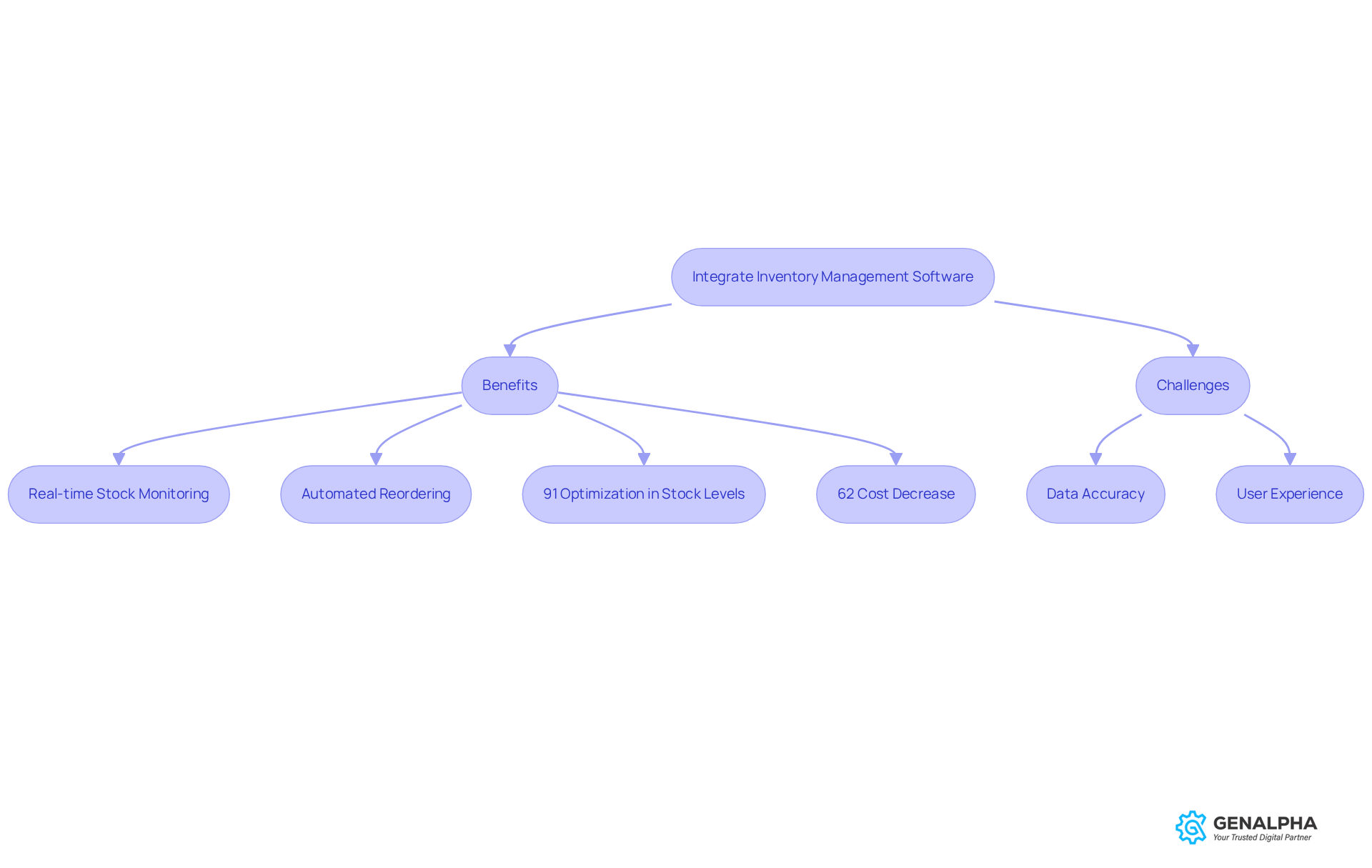

Integrate Inventory Management Software for Seamless Operations

Have you ever thought about how integrating stock management software with your existing systems, like ERP and eCommerce platforms, can really enhance b2b inventory management? It’s all about streamlining operations and boosting data accuracy. When you connect these systems, you get and automated reordering, which means fewer manual errors and better reporting. Companies that have made this leap have seen a whopping 91% optimization in stock levels—pretty impressive, right? Plus, 62% of businesses reported cost decreases, especially in procurement and stock control, which highlights the financial perks of b2b inventory management integration.

By tapping into advanced technology for b2b inventory management, you gain better visibility into stock levels, which empowers you to make informed decisions based on accurate data. But let’s not ignore the challenges, like data accuracy and user experience, that can pop up during the integration process. On the bright side, automating reordering helps avoid those pesky stockouts and overstocking issues that many face.

Choosing the right software that fits your specific business needs is key to maximizing the benefits of integration. Ultimately, this leads to improved operational efficiency and happier customers. So, what are you waiting for? It’s time to explore how integration can work wonders for your business!

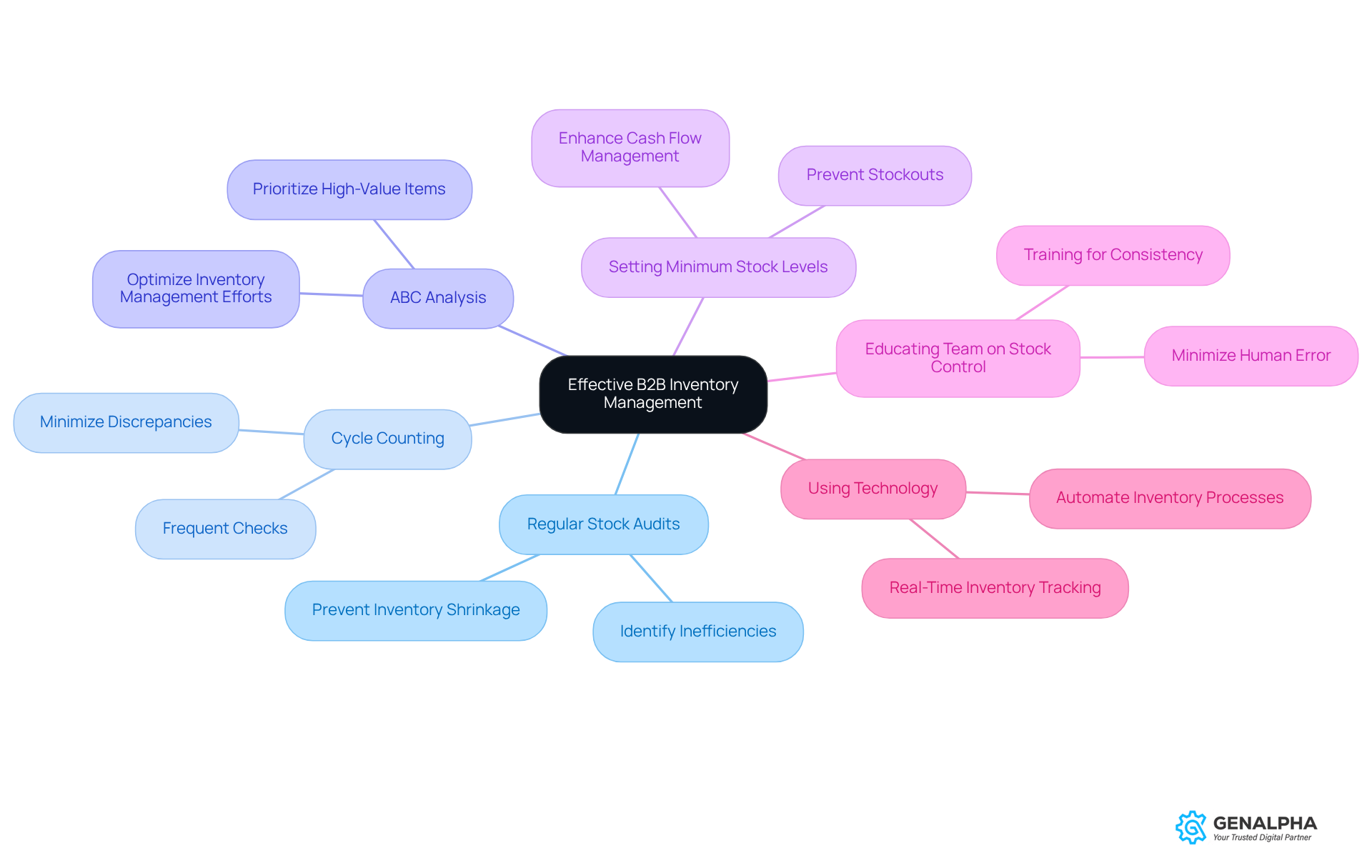

Follow Best Practices for Effective B2B Inventory Management

When it comes to b2b inventory management in the B2B world, there are some best practices that really make a difference. Have you ever thought about how:

- Regular stock audits

- Cycle counting

- ABC analysis

can help? Setting minimum stock levels is another smart move to prevent shortages, and effective b2b inventory management policies can keep everything on track.

It’s also super important to educate your team about stock control processes. Plus, using technology for b2b inventory management can significantly boost efficiency. By embracing these best practices, you can not only enhance your stock oversight processes but also elevate your overall performance. So, why not take a closer look at how you can in your organization?

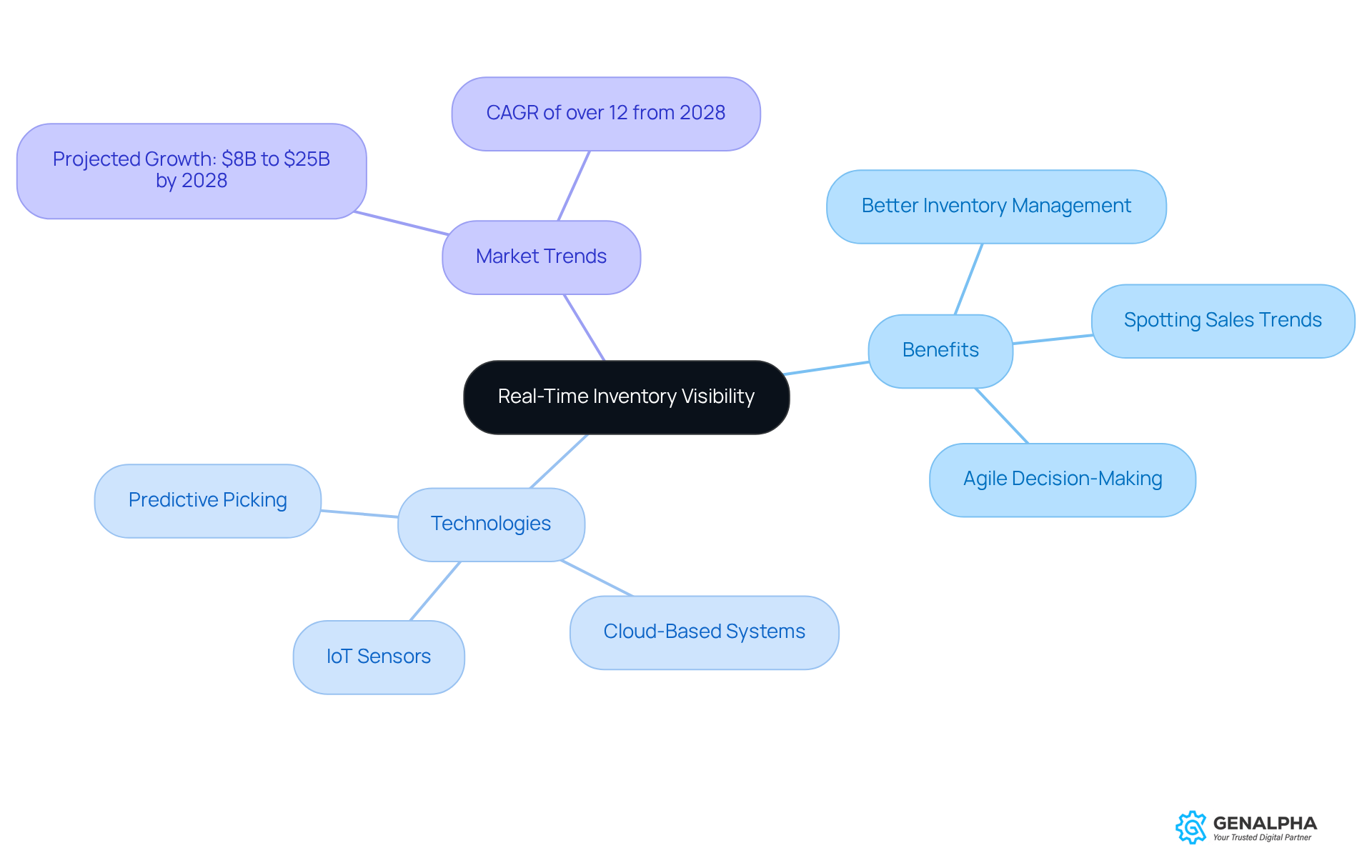

Achieve Real-Time Inventory Visibility for Agile Decision-Making

Imagine being able to see your stock levels in real-time. This kind of immediate visibility enhances b2b inventory management, helping companies manage inventory better, spot sales trends, and respond quickly to what customers want. By using IoT sensors and cloud-based inventory systems, organizations can get constant updates on their stock. This means they can make decisions on the fly, adjusting stock levels based on actual demand and reallocating resources when urgent needs pop up.

Not only does this tech improve how efficiently things run, but it also enhances b2b inventory management by ensuring that products are available when customers need them. And here’s something to think about: the Real-Time Inventory Visibility Software market is projected to hit nearly $25 billion by 2028, up from around $8 billion in 2025. This surge shows just how crucial are becoming in today’s supply chains.

Additionally, Ambient IoT technology is a game-changer for workflow and labor efficiency. It uses predictive picking to streamline b2b inventory management, showcasing how these innovations can truly transform operations. So, are you ready to embrace these changes and enhance your inventory management? Let’s dive into this exciting world together!

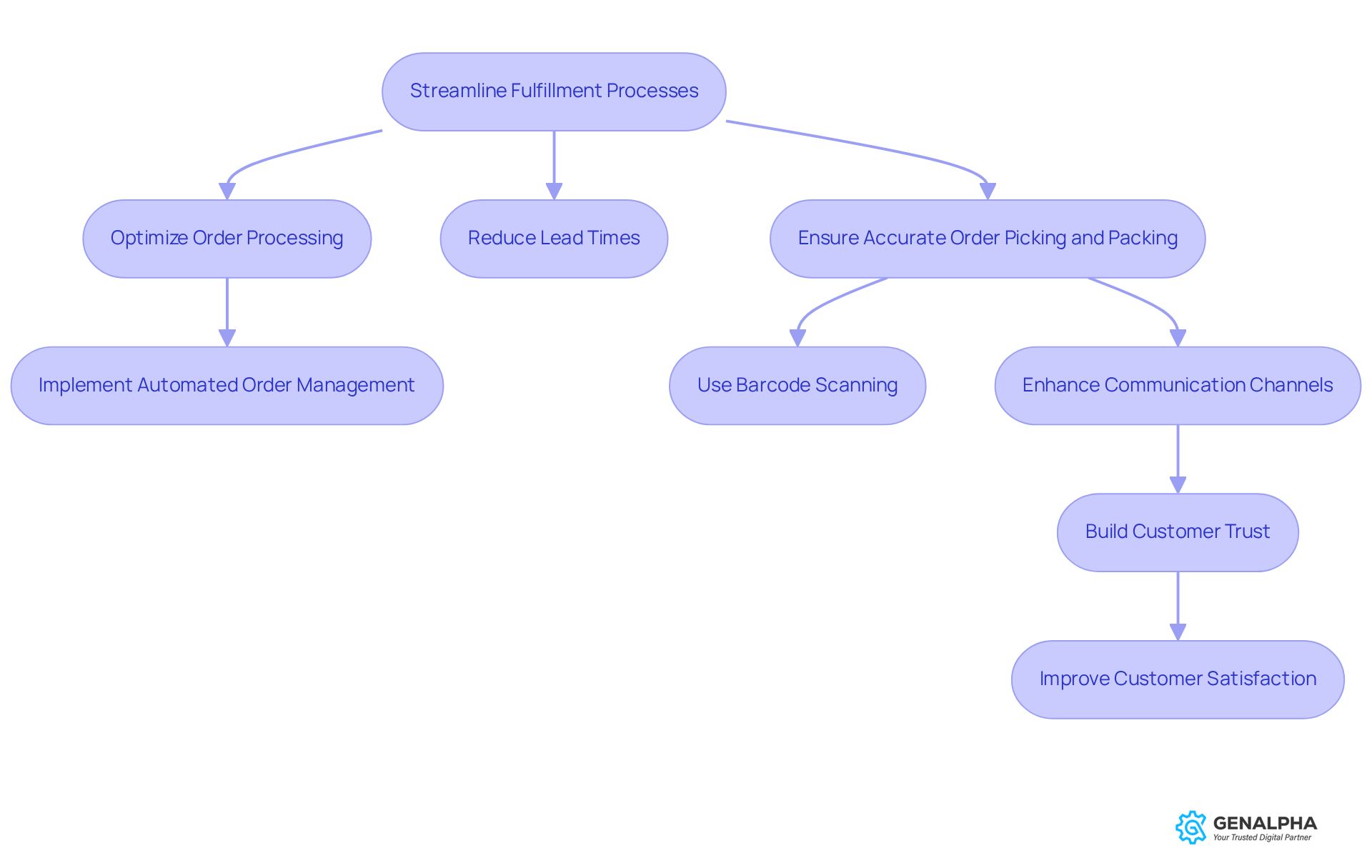

Streamline Fulfillment Processes to Enhance Customer Satisfaction

Streamlining fulfillment processes is key to boosting client satisfaction. Think about it: optimizing order processing, cutting down lead times, and ensuring accurate order picking and packing can make a world of difference. When businesses implement , they not only enhance efficiency but also reduce errors, allowing them to respond quickly to client demands.

For example, using tools like barcode scanning to eliminate mis-picks means clients receive exactly what they ordered. This is crucial for building and maintaining trust. And let’s not forget the importance of clear communication channels about order status and delivery timelines—they really enhance the client experience.

As Peoria Production Solutions puts it, "Efficient fulfillment services play a crucial role in meeting and exceeding client expectations." By prioritizing efficient fulfillment, companies can turn first-time buyers into loyal customers. So, why not take a step toward strengthening your market reputation and driving long-term success? Let's make it happen together!

Conclusion

Embracing effective B2B inventory management strategies is crucial for organizations looking to boost operational efficiency and meet customer demands. Imagine having the right tools—like Equip360—at your fingertips. By implementing these innovative solutions and best practices, you can streamline your inventory processes, keeping stock levels accurately monitored and optimized for performance. This proactive approach not only cuts costs but also positions your company to thrive in a competitive landscape.

Throughout this article, we’ve explored key strategies, such as:

- The importance of real-time inventory tracking

- Demand forecasting

- Supplier relationship management

Techniques like:

- Just-in-Time inventory management

- ABC analysis

- Regular audits

are essential for maintaining optimal stock levels and improving turnover rates. Plus, integrating advanced software solutions enhances visibility and accuracy, enabling agile decision-making that can significantly boost customer satisfaction.

Ultimately, the importance of effective B2B inventory management cannot be overstated. As the market continues to evolve, it’s vital for businesses to stay ahead of the curve by embracing these strategies and technologies. So, why wait? Taking action now to optimize your inventory management practices will lead to improved operational efficiency and foster lasting customer relationships. The time to invest in these essential strategies is now—unlock the potential of your inventory management and watch your business flourish!

Frequently Asked Questions

What is Equip360 and how does it benefit B2B inventory management?

Equip360 is a B2B eCommerce platform developed by GenAlpha Technologies that simplifies inventory management for manufacturers and distributors. It provides real-time insights into stock levels, tracks orders effortlessly, and offers comprehensive analytics, helping organizations streamline operations and improve sales performance.

How does Equip360 integrate with existing systems?

Equip360 integrates seamlessly with existing ERP systems, enabling organizations to implement effective B2B inventory management. This integration helps ensure that customer demands are met without excess supplies or unnecessary expenses.

What impact do stock tracking failures have on businesses?

Stock tracking failures can significantly affect business finances, with studies indicating that 62% of business finances are impacted by such failures. This highlights the importance of effective inventory management solutions like Equip360.

What are the advantages of accurate inventory tracking?

Accurate inventory tracking reduces discrepancies and ensures that stock levels reflect actual availability. This can lead to improved order fulfillment rates and overall efficiency, as demonstrated by the 52nd Logistics Readiness Squadron at Spangdahlem Air Base, which projected savings of over 7,000 man-hours annually through RFID technology.

How can companies enhance their demand forecasting?

Companies can enhance their demand forecasting by utilizing historical sales data, market trends, and seasonal variations. Techniques such as moving averages, exponential smoothing, and regression analysis can improve forecasting accuracy, helping businesses maintain optimal inventory levels.

What are some challenges in demand forecasting?

Common pitfalls in demand forecasting include overlooking seasonal demand changes, which can lead to inaccuracies in inventory planning. Companies need to be mindful of these challenges to effectively meet customer demand while minimizing surplus stock.

What steps can businesses take to improve their inventory management?

Businesses can evaluate their current stock management practices, consider adopting advanced tracking technologies like barcode scanning and RFID, and implement demand forecasting strategies to enhance their B2B inventory management and operational efficiency.