Overview

Let’s dive into some key strategies for rocking B2B commerce in equipment manufacturing!

-

Understanding customer needs.

Have you ever thought about how knowing what your customers really want can change the game? -

Leveraging technology for operational efficiency.

Imagine how much smoother your processes could be with the right tools at your fingertips. -

Data analytics.

Utilizing data for informed decision-making isn’t just a fancy term; it’s about making choices that truly benefit your business. -

Fostering strong relationships with partners and customers.

Building those connections can lead to amazing opportunities.

Each of these strategies is backed by solid evidence. For example, customer feedback can significantly impact retention rates. Plus, technology plays a vital role in boosting productivity. It’s clear that manufacturers need to adapt and innovate to stay competitive.

So, what are you waiting for? Let’s get started on these strategies and take your business to the next level!

Introduction

In the bustling world of equipment manufacturing, have you ever stopped to think about how B2B commerce is changing? It’s a fascinating landscape, and understanding its dynamics is more important than ever. Manufacturers now have a golden opportunity to boost their operations by focusing on what customers really want, embracing new technologies, and building strong relationships. But here’s the kicker: the real challenge is weaving these elements together to not just meet, but truly exceed client expectations.

So, how can manufacturers successfully navigate this intricate terrain? What steps can we take to ensure sustainable growth and success as we look toward 2025 and beyond? Let’s dive into this together!

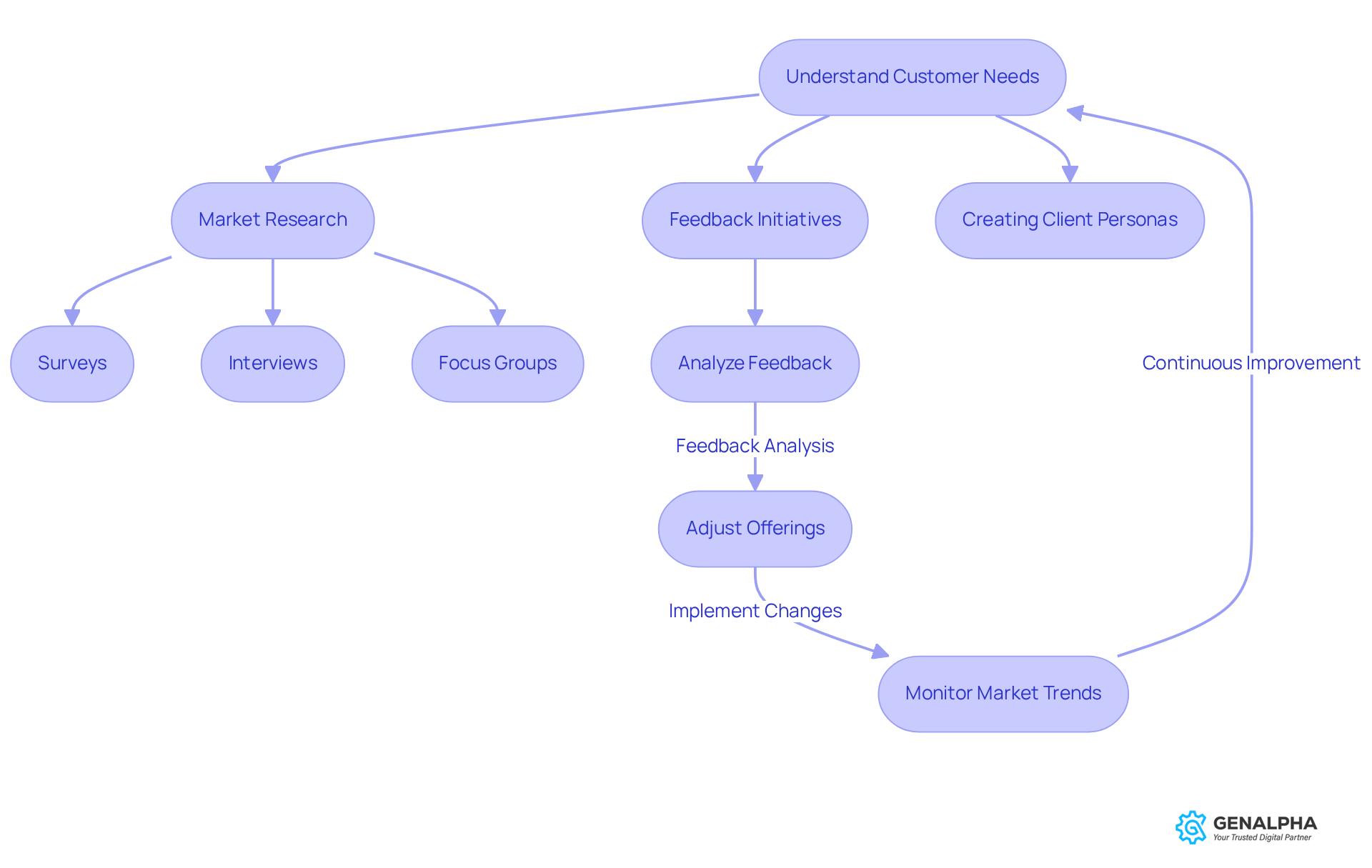

Understand Customer Needs and Market Dynamics

To truly grasp what clients need, manufacturers should really make regular market research and feedback initiatives a top priority. Think about it: this can involve various methods like surveys, interviews, and focus groups that dig into the specific challenges and requirements clients face. For example, creating detailed client personas can really help clarify what the target audience prefers and values. You might even find that clients care more about quick delivery times than about costs, which could lead to a strategic shift in logistics operations.

Staying on top of market trends and client feedback is crucial. Why? Because it allows companies to tweak their offerings in response to changing demands. In fact, organizations that actively use client feedback often see a 25-30% boost in retention rates. That really highlights how important client insights are for staying competitive in the marketplace.

As we look ahead to the complexities of 2025, incorporating customer feedback into market research strategies can lead to a whopping 40% reduction in research expenses. This means businesses can make adjustments more frequently and nimbly. So, why not start integrating client feedback into your strategy today? It could make all the difference!

Leverage Technology for Operational Efficiency

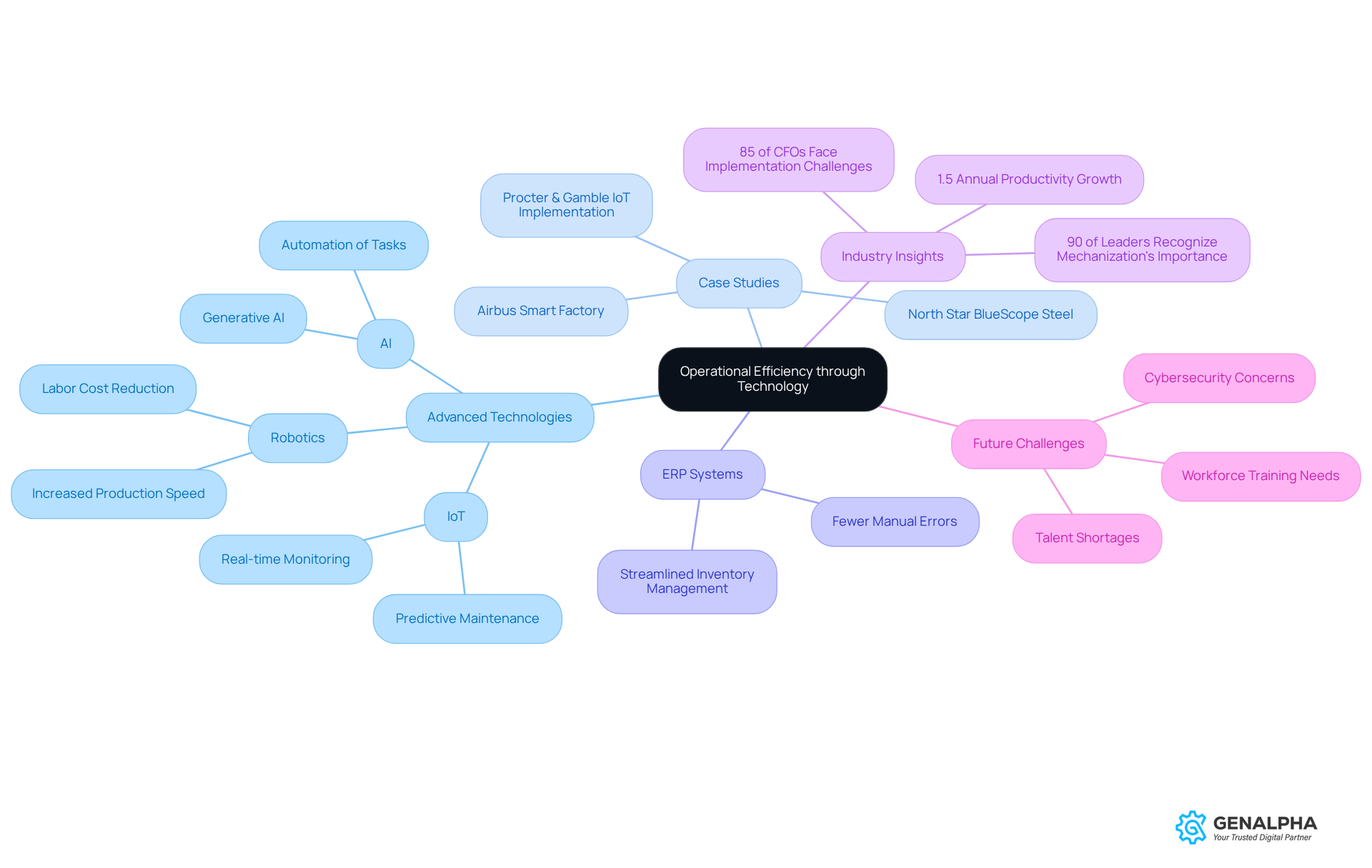

Investing in advanced technologies like robotics, IoT, and AI is crucial for boosting operational efficiency in equipment manufacturing. Have you ever thought about how IoT systems can enable real-time monitoring of equipment performance? This not only helps with predictive maintenance but also significantly cuts down on downtime. For instance, a recent case study highlighted that a well-known manufacturer achieved a remarkable 30% increase in production speed and reduced labor costs by incorporating mechanization into their assembly line.

Additionally, leveraging ERP systems can streamline inventory management and order processing. This means fewer manual errors and quicker response times. Isn’t it fascinating that mechanization is expected to enhance global productivity by 1.5% each year? This growth will only strengthen the broader economic impact of these technologies.

Moreover, 90% of leaders in the field recognize that mechanization is vital for their future success in manufacturing. However, it’s worth noting that 85% of CFOs are grappling with challenges in effectively utilizing technology and automation. This highlights the need for workforce training, as those displaced by automation will require new skills to fill gaps in skilled labor.

By embracing these technologies, producers not only enhance efficiency but also prepare themselves for scalable growth in an increasingly competitive landscape. So, what do you think? Are you ready to take the plunge into the future of manufacturing?

Utilize Data Analytics for Informed Decision-Making

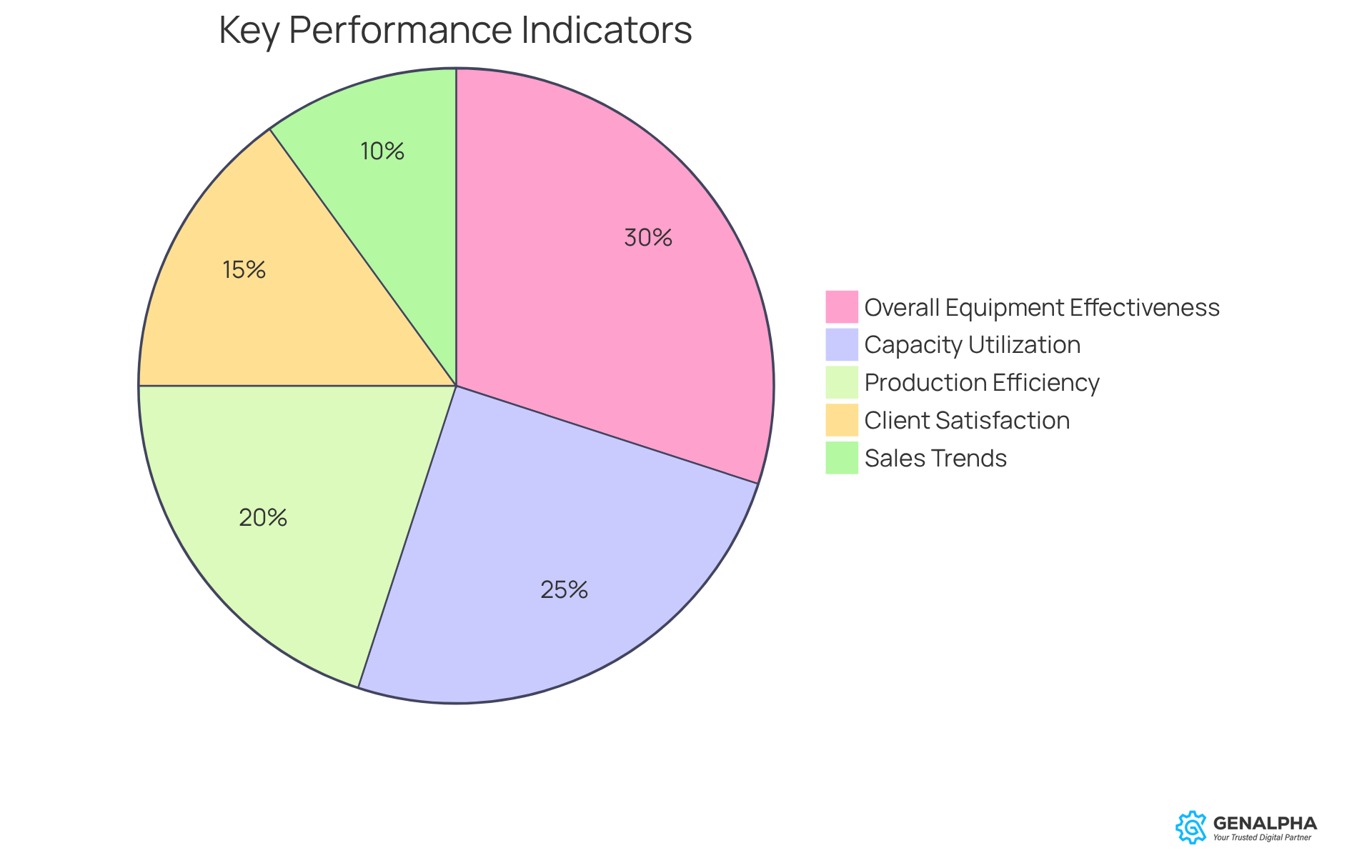

To really tap into the power of analytics, manufacturers need to set up solid systems for collecting and analyzing data that includes both historical and real-time insights. This means keeping an eye on key performance indicators (KPIs) like:

- Overall Equipment Effectiveness (OEE)

- Capacity Utilization

- Production efficiency

- Client satisfaction scores

- Sales trends

By digging into this data, companies can spot trends and proactively refine their strategies.

For example, if a manufacturer notices a dip in customer satisfaction, they can investigate the root causes—just like what’s shown in the Customer Returns Rate Analysis—and make targeted improvements in how they deliver service. Plus, predictive analytics can help with demand forecasting, making inventory management and resource allocation smoother. Did you know that effective analytics implementation can boost operational efficiency by up to 20%? That’s according to a recent study in the manufacturing sector, which really highlights how crucial this is for performance improvement.

However, it’s important for producers to be mindful of the potential challenges that come with KPI implementation. Sometimes, there can be initial confusion about how to use KPIs effectively, which can limit their impact. By addressing these hurdles, manufacturers can unlock the full potential of data analytics.

So, what steps can you take today to start leveraging analytics in your operations?

Foster Strong Relationships with Partners and Customers

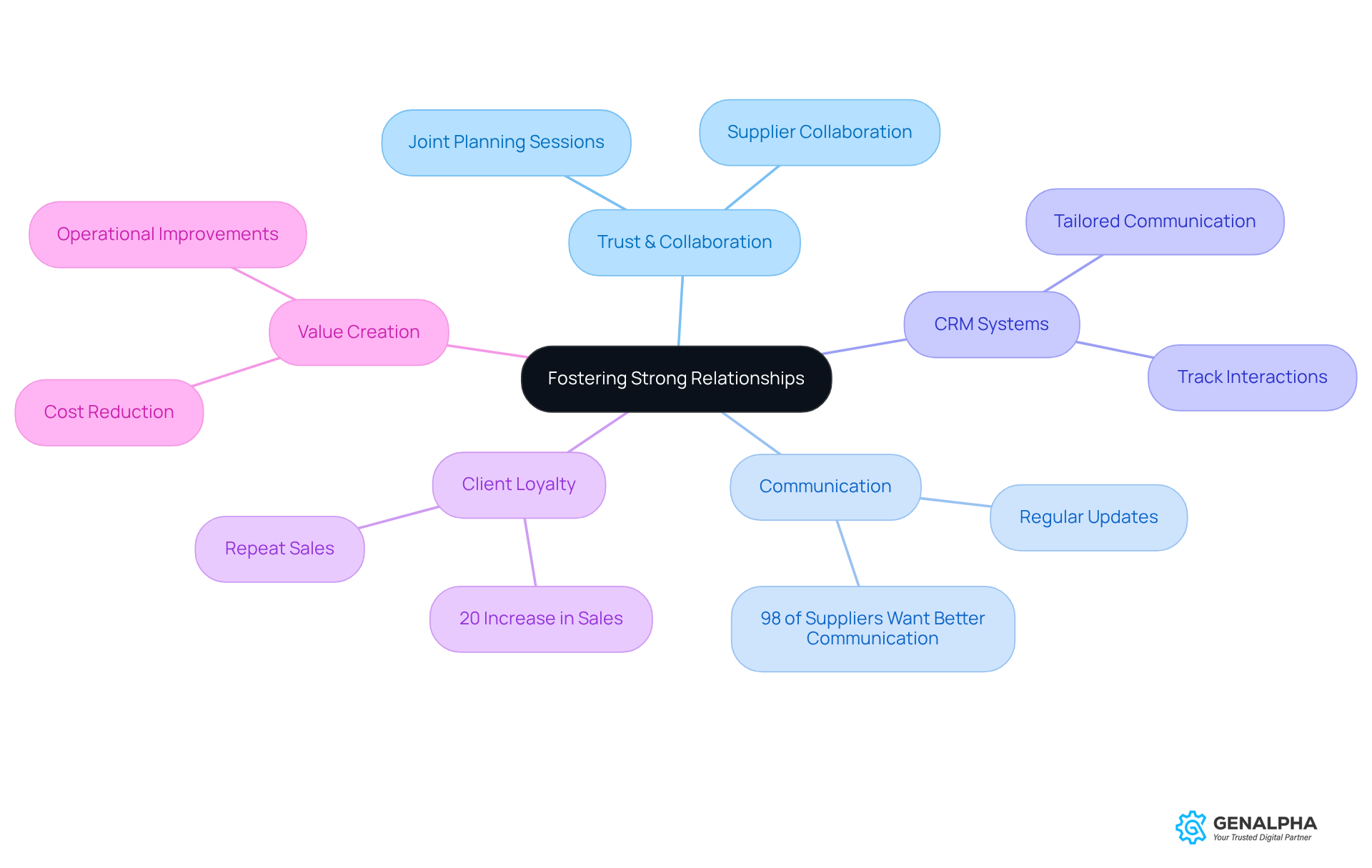

Let’s talk about something that really matters in business: building strong relationships. Manufacturers should make it a priority to develop strategies that foster trust and collaboration with both clients and suppliers. Have you ever thought about how regular communication and transparency in operations can create a supportive environment? It’s essential for delivering real value.

For example, hosting joint planning sessions with suppliers can really enhance alignment on production schedules and inventory management. This not only reduces lead times but also cuts costs. And here’s where it gets interesting: adopting a client relationship management (CRM) system allows producers to keep track of interactions and preferences. This tailored communication can significantly boost client loyalty.

Did you know that studies show producers focusing on relationship management often see a considerable rise in repeat sales? Happy clients are much more likely to return and recommend the firm to others. In fact, statistics reveal that boosting client loyalty can lead to a 20% increase in sales. That’s a big deal! It really highlights how strong partnerships contribute to business success.

Additionally, it’s worth noting that 98% of suppliers wish for better communication from their largest customers. This just goes to show how important effective communication is in fostering loyalty. So, what are you waiting for? Let’s prioritize those relationships and watch the benefits unfold!

Conclusion

Understanding and implementing effective B2B strategies in equipment manufacturing is crucial for navigating the complexities of this industry, right? By putting customer needs first, leveraging technology, utilizing data analytics, and building strong relationships, manufacturers can set themselves up for lasting success and growth in a competitive market.

Throughout this article, we've explored some key strategies. Regular market research and feedback initiatives can really enhance your understanding of customer preferences. Plus, advanced technologies like IoT and AI can streamline operations and boost efficiency. And don’t forget about data analytics! It empowers manufacturers to make informed decisions based on real-time insights, ultimately driving performance improvements. The importance of nurturing relationships with clients and suppliers can't be overstated—strong partnerships lead to increased loyalty and repeat business.

So, in conclusion, embracing these best practices is not just about staying relevant; it’s about thriving in an ever-evolving landscape. As we look ahead to 2025 and beyond, taking proactive steps to understand market dynamics and invest in technology will be key. Now’s the time to assess your current strategies, enhance operational efficiencies, and cultivate valuable relationships to ensure a prosperous future in the B2B equipment manufacturing sector. What steps will you take to get started?

Frequently Asked Questions

Why is understanding customer needs important for manufacturers?

Understanding customer needs is crucial for manufacturers as it helps them identify specific challenges and requirements clients face, allowing them to tailor their offerings accordingly.

What methods can manufacturers use to gather customer feedback?

Manufacturers can use various methods such as surveys, interviews, and focus groups to gather customer feedback and insights.

How can creating detailed client personas benefit manufacturers?

Creating detailed client personas helps clarify what the target audience prefers and values, enabling manufacturers to align their products and services with customer expectations.

What impact does client feedback have on retention rates?

Organizations that actively use client feedback often see a 25-30% boost in retention rates, highlighting the importance of client insights for competitiveness.

How does incorporating customer feedback into market research strategies affect research expenses?

Incorporating customer feedback into market research strategies can lead to a 40% reduction in research expenses, allowing businesses to make adjustments more frequently and efficiently.

What is the significance of staying updated on market trends and client feedback?

Staying updated on market trends and client feedback is significant because it enables companies to adapt their offerings in response to changing demands, maintaining their competitive edge.