Overview

Have you ever wondered how to take your maintenance processes to the next level? The article "10 Key Strategies to Enhance Your Maintenance Infrastructure" dives into some effective methods that can really make a difference in organizations. It highlights the importance of:

- Integrating digital solutions

- Quality control

- Preventive maintenance

- Employee training

Why are these strategies so crucial? Well, evidence shows they can significantly reduce downtime, boost operational efficiency, and lead to cost savings—all while increasing customer satisfaction.

Imagine a scenario where your team is trained to handle issues before they escalate, or where digital tools streamline your processes. Sounds appealing, right? By embracing these strategies, you’re not just enhancing your maintenance infrastructure; you’re setting your organization up for success.

So, why wait? Let’s explore these strategies together and see how they can transform your approach to maintenance!

Introduction

In today’s world, where operational efficiency is key to success, organizations are facing a whole new level of scrutiny regarding their maintenance infrastructure. It’s becoming clear that embracing innovative strategies isn’t just a nice-to-have—it’s essential for survival in this competitive landscape.

So, what if we explored ten key strategies that could really enhance maintenance practices? From digital solutions to preventive maintenance techniques, there’s a lot to dive into.

But as we look to improve, one pressing question remains: What are the best ways to weave these strategies into our existing frameworks while tackling the complexities of modern industry demands? Let’s find out together!

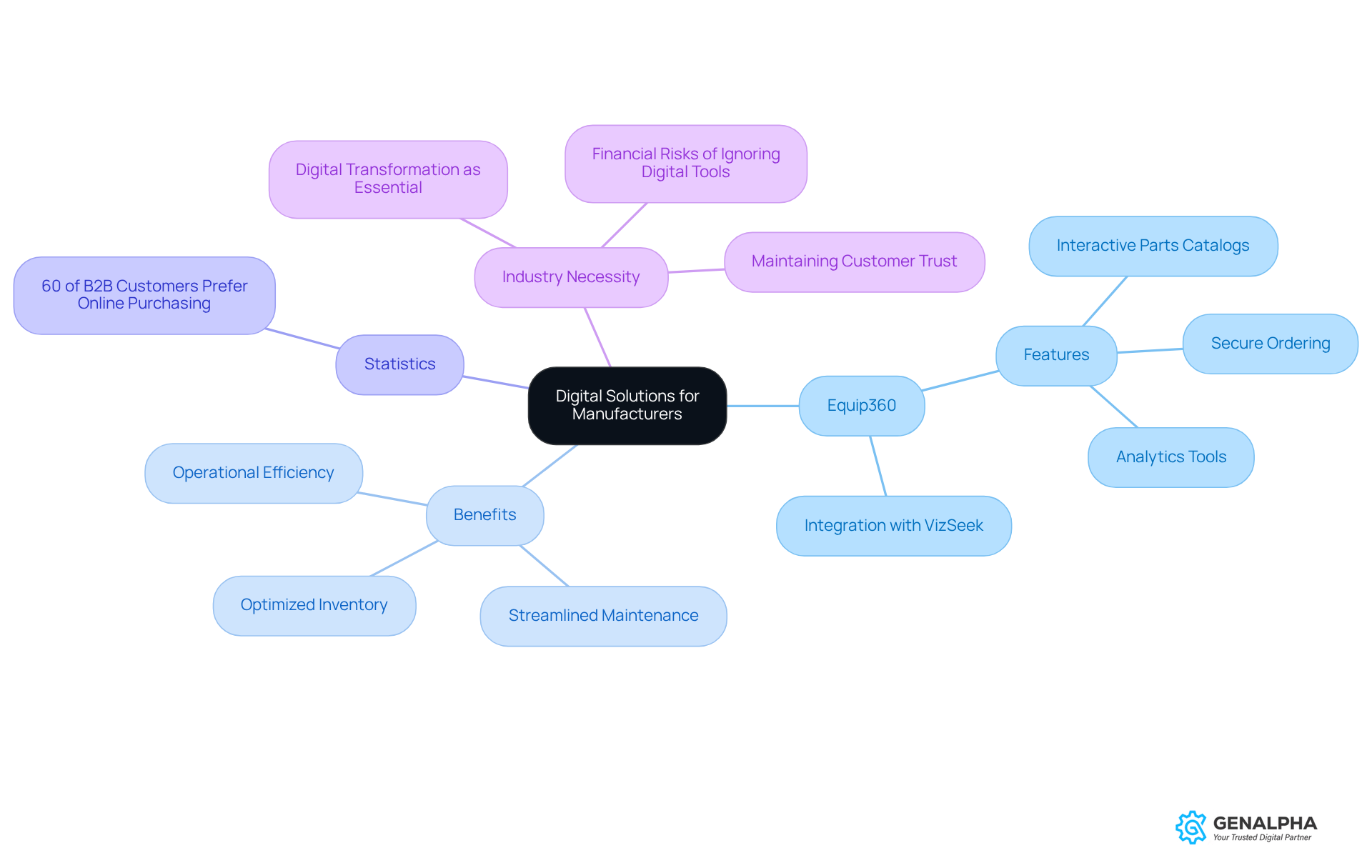

GenAlpha Technologies: Streamline Maintenance with Digital Solutions

At GenAlpha Technologies, we’re all about providing cutting-edge digital solutions tailored for manufacturers and distributors in the equipment and aftermarket parts sectors. Our flagship product, Equip360, is a game-changer when it comes to optimizing inventory management and boosting online sales capabilities. By seamlessly integrating digital warranty management and advanced analytics tools, we empower businesses to enhance their maintenance infrastructure, streamline upkeep processes, minimize downtime, and improve overall operational efficiency.

In today’s competitive landscape, digital transformation isn’t just a nice-to-have; it’s essential. Companies that embrace these innovations can monitor operations in real-time and adopt proactive upkeep strategies, leading to improved service delivery and happier clients. Did you know that 60% of B2B customers prefer online purchasing over traditional methods? This trend underscores the urgency for manufacturers to adapt.

Moreover, ignoring digital tools can expose businesses to significant financial risks. So, it’s crucial to embrace these advancements. Recently, we announced an exciting , which takes our platform’s capabilities to the next level.

As our co-founder and CEO, Kristina Harrington, puts it, 'Embracing digital tools is not just an option — it’s a necessity for anyone looking to thrive in the ever-evolving business landscape.' What are you waiting for? Let’s dive into the digital age together!

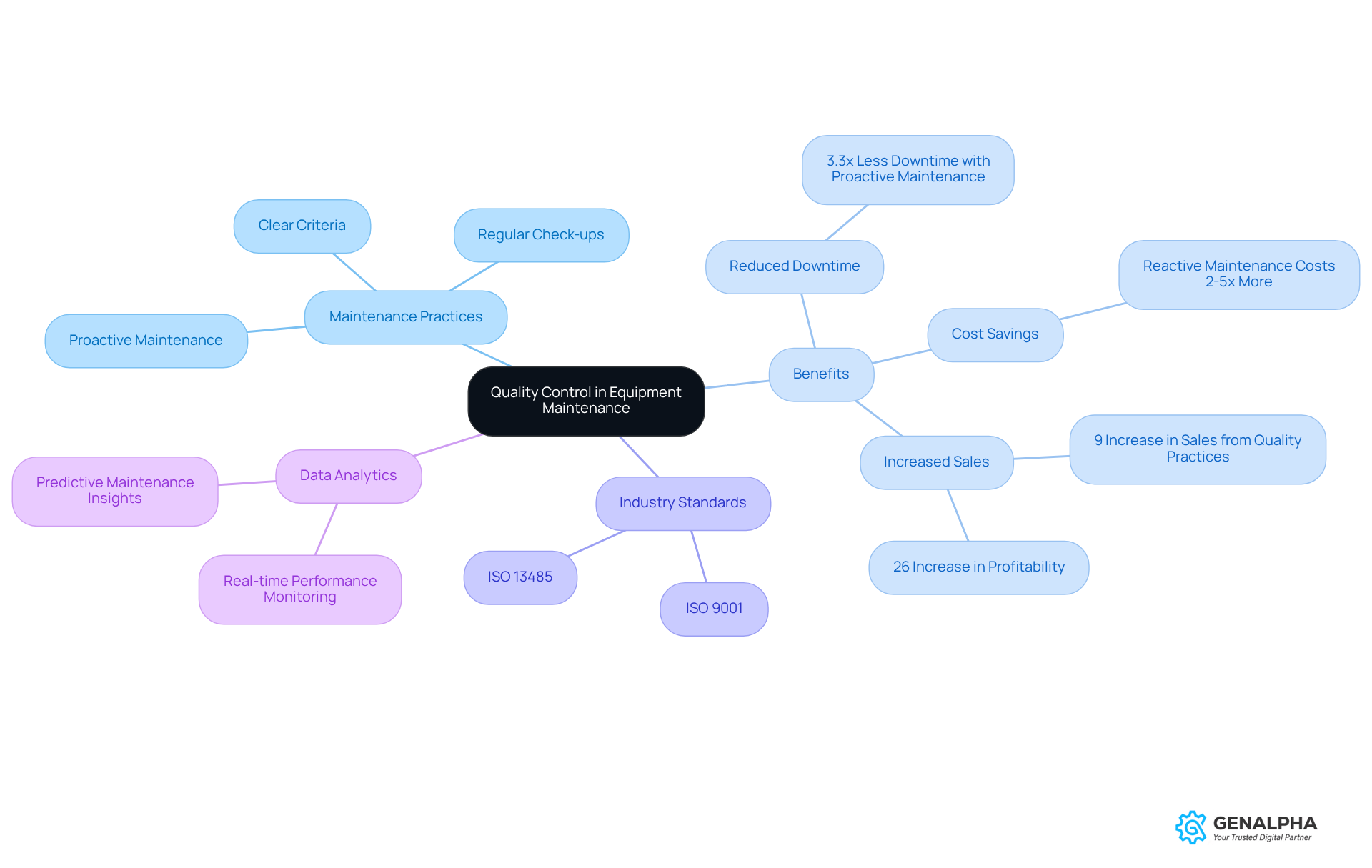

Quality Control: Ensuring Reliability in Equipment Maintenance

Let’s talk about why establishing strong quality control practices is crucial for keeping our machinery in top shape. Imagine establishing clear criteria for our maintenance infrastructure activities, conducting regular check-ups, and utilizing data-driven methods to monitor the performance of our machines. These are key components of a successful strategy. When organizations put , they can significantly cut down on the risk of equipment failures. In fact, studies show that proactive maintenance can reduce unplanned downtime by up to 3.3 times compared to reactive approaches, which can be 2-5 times more costly. This not only lowers costs related to maintenance infrastructure but also boosts customer satisfaction by enhancing service reliability.

Now, effective quality management ensures we stick to industry standards like ISO 9001 and fosters a culture of continuous improvement within our support teams. Companies that embrace robust quality management systems often see an average 9% increase in sales and a 26% boost in profitability. That’s a clear win for prioritizing quality! By leveraging data analytics, organizations can gain real-time insights into machine performance, which makes it easier to manage their maintenance infrastructure proactively. This further cuts costs and improves operational efficiency.

So, when we implement effective quality management practices—like regular performance evaluations and holding suppliers accountable—we not only enhance equipment reliability but also improve our maintenance infrastructure, leading to reduced costs. Ultimately, this sets the stage for long-term success in the competitive manufacturing landscape. How can we start applying these practices in our own operations today?

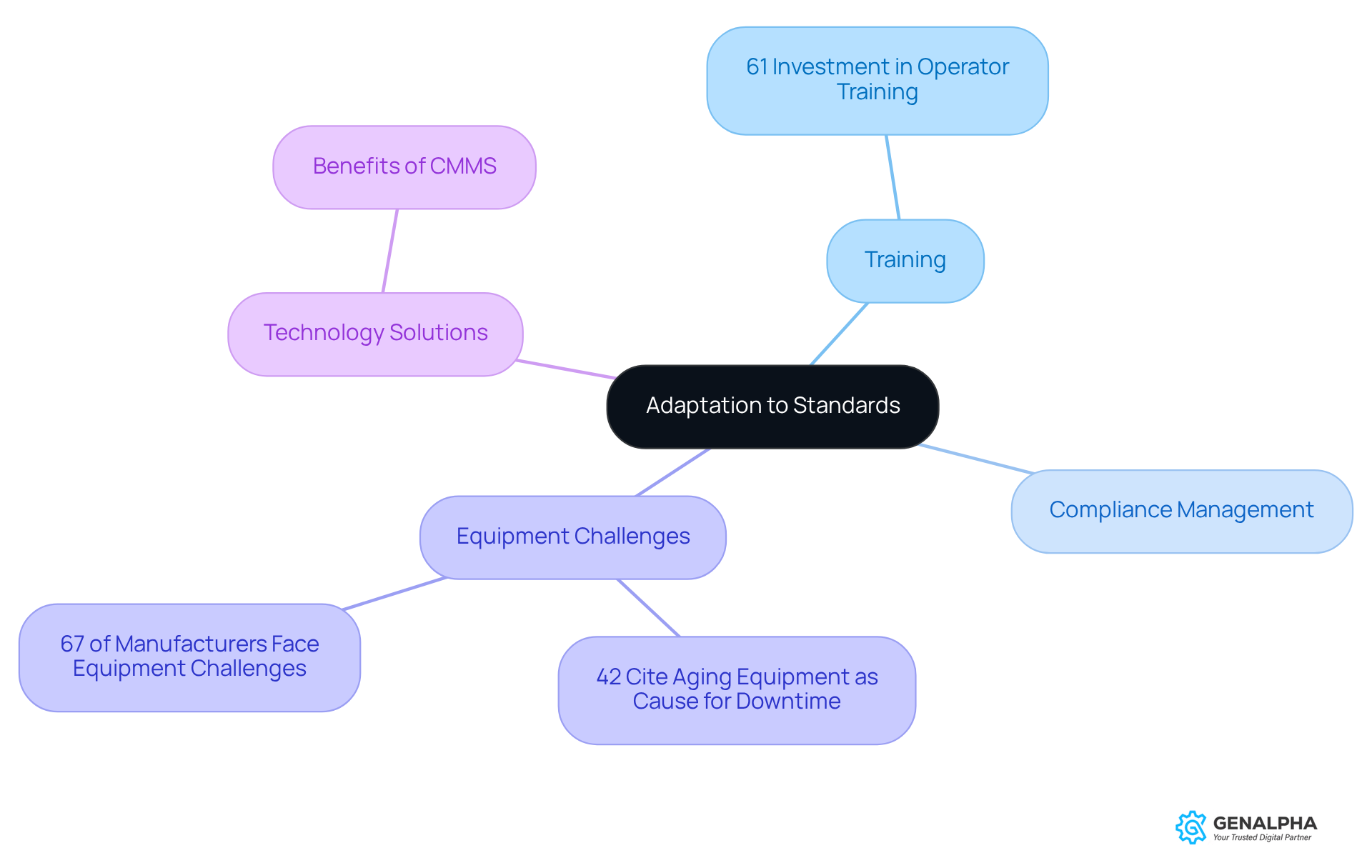

Adaptation to Standards: Meeting Evolving Industry Requirements

In today’s ever-changing regulatory landscape, it’s crucial for organizations to keep improving their maintenance infrastructure practices. Why? To stay compliant and maintain that competitive edge! Staying on top of new regulations isn’t just about tweaking operational protocols; it’s also about providing thorough training for your staff on these updates. Did you know that 61% of companies are investing in operator training to reduce downtime? That’s right! Proactive compliance management can help avoid costly penalties, enhance your reputation, and ensure the safety and reliability of your operations.

Frequent audits and evaluations are essential tools for spotting compliance gaps, allowing for quick adjustments to your upkeep strategies. Interestingly, 42% of facilities say that aging equipment is the top reason for unplanned downtime. With 67% of manufacturers citing it as a significant challenge, it’s clear that can boost both operational efficiency and compliance adherence.

Additionally, leveraging technology like CMMS can make documentation a breeze. As LLumin points out, "a well-executed CMMS solution not only lessens the administrative load but also guarantees that every upkeep action is recorded and verifiable." This means smoother audits and a stronger commitment to regulatory standards. Remember, non-compliance can lead to serious financial consequences, including hefty fines, loss of market share, and increased downtime costs.

So, what steps are you taking to ensure compliance and keep your operations running smoothly?

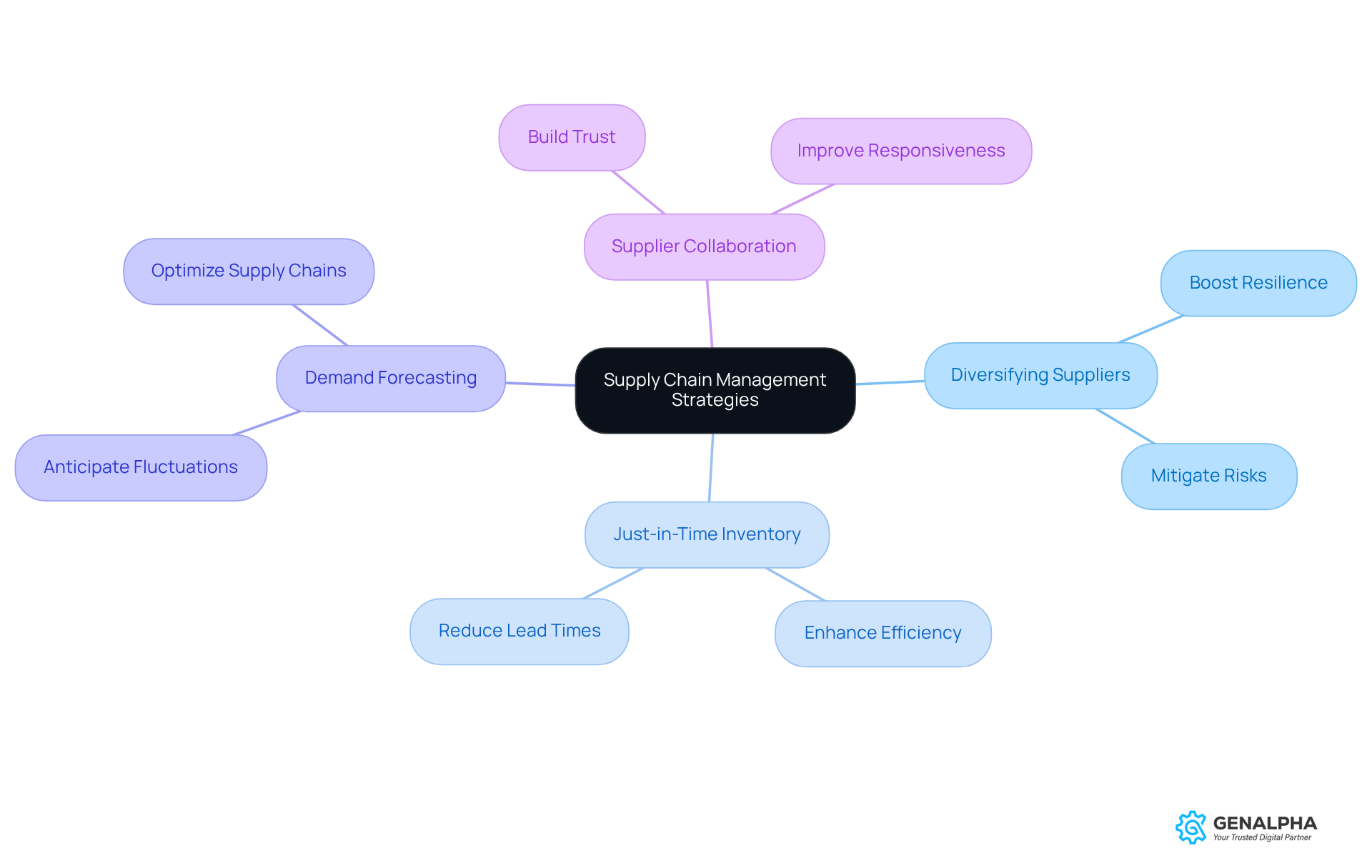

Supply Chain Management: Mitigating Disruptions for Infrastructure Stability

Mitigating supply chain disruptions is crucial for keeping our infrastructure stable and ensuring that operations run smoothly. Have you ever thought about how diversifying suppliers can really boost resilience against unexpected shortages? Plus, adopting just-in-time inventory methods can enhance efficiency within the maintenance infrastructure. These strategies can significantly cut down lead times for essential upkeep materials, thereby enhancing the maintenance infrastructure and allowing organizations to respond quickly to operational needs. Additionally, leveraging advanced analytics for demand forecasting helps businesses anticipate fluctuations and adjust their supply chains accordingly.

Collaboration with suppliers and keeping those lines of communication open are vital for strengthening supply chain relationships. This proactive approach not only to changing demands but also builds a culture of reliability and trust. Did you know that 52% of manufacturing leaders see supplier quality and reliability as major challenges? By diversifying supplier bases, we can mitigate risks associated with relying on a single source. By implementing these approaches, organizations can enhance their operational efficiency and ensure strong maintenance infrastructure stability even in the face of ongoing supply chain challenges.

Preventive Maintenance: Minimizing Downtime for Optimal Performance

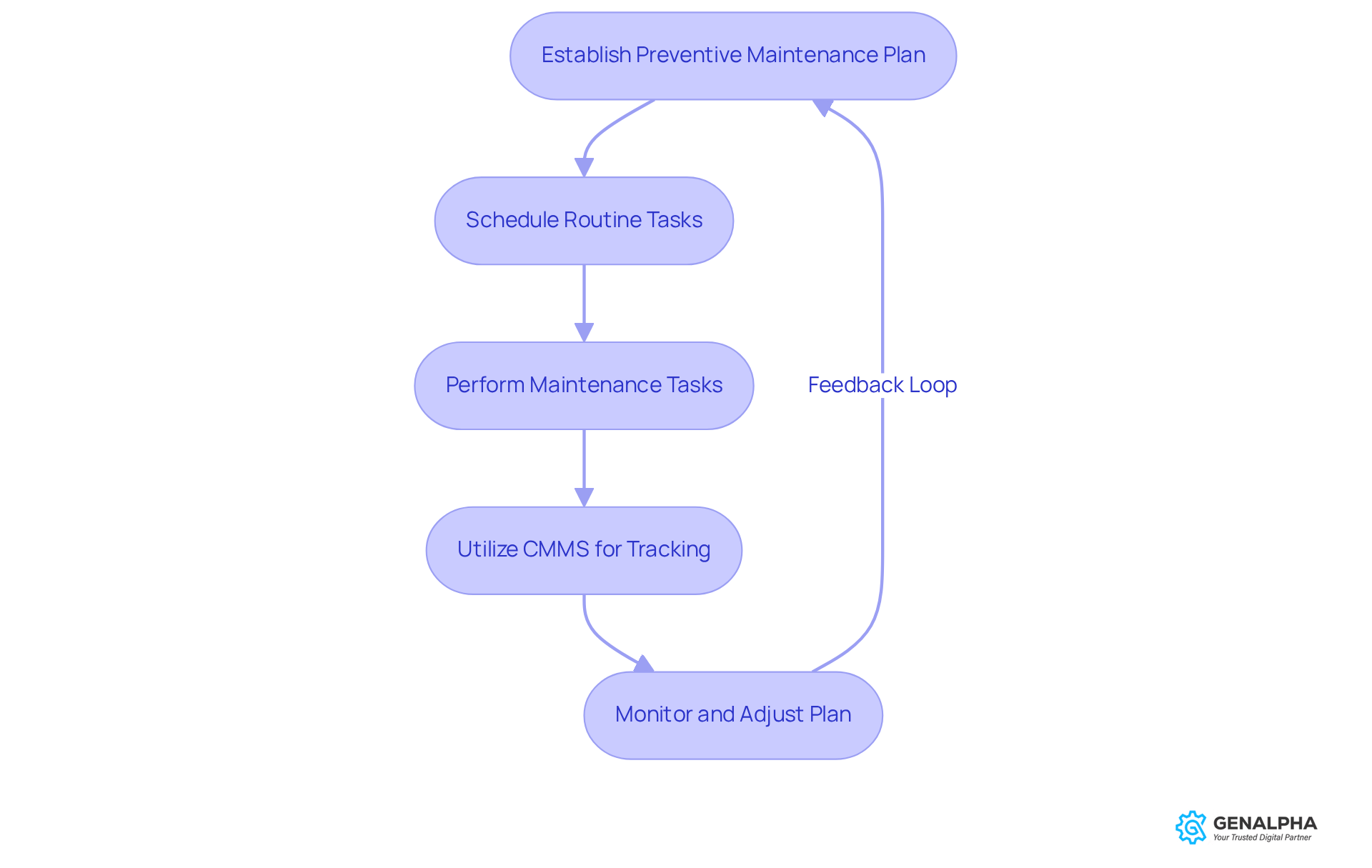

Have you ever thought about how much downtime can cost your business? Establishing a preventive upkeep plan is key to keeping your machinery running smoothly and efficiently. By planning routine upkeep tasks based on usage or time frames, you can spot potential issues before they become major headaches. This not only helps in extending the lifespan of your equipment but also cuts down on repair costs and boosts overall productivity.

Imagine being able to tackle maintenance before it disrupts your workflow! By prioritizing preventive care, you’re not just saving money; you’re enhancing your team’s efficiency. Plus, with technology like Computerized Management Systems (CMMS), scheduling and tracking upkeep tasks becomes a breeze, ensuring everything gets done on time.

So, why wait? Start thinking about how you can implement a preventive upkeep plan today. Your machinery—and your bottom line—will thank you!

Cost Implications: The Financial Risks of Poor Maintenance

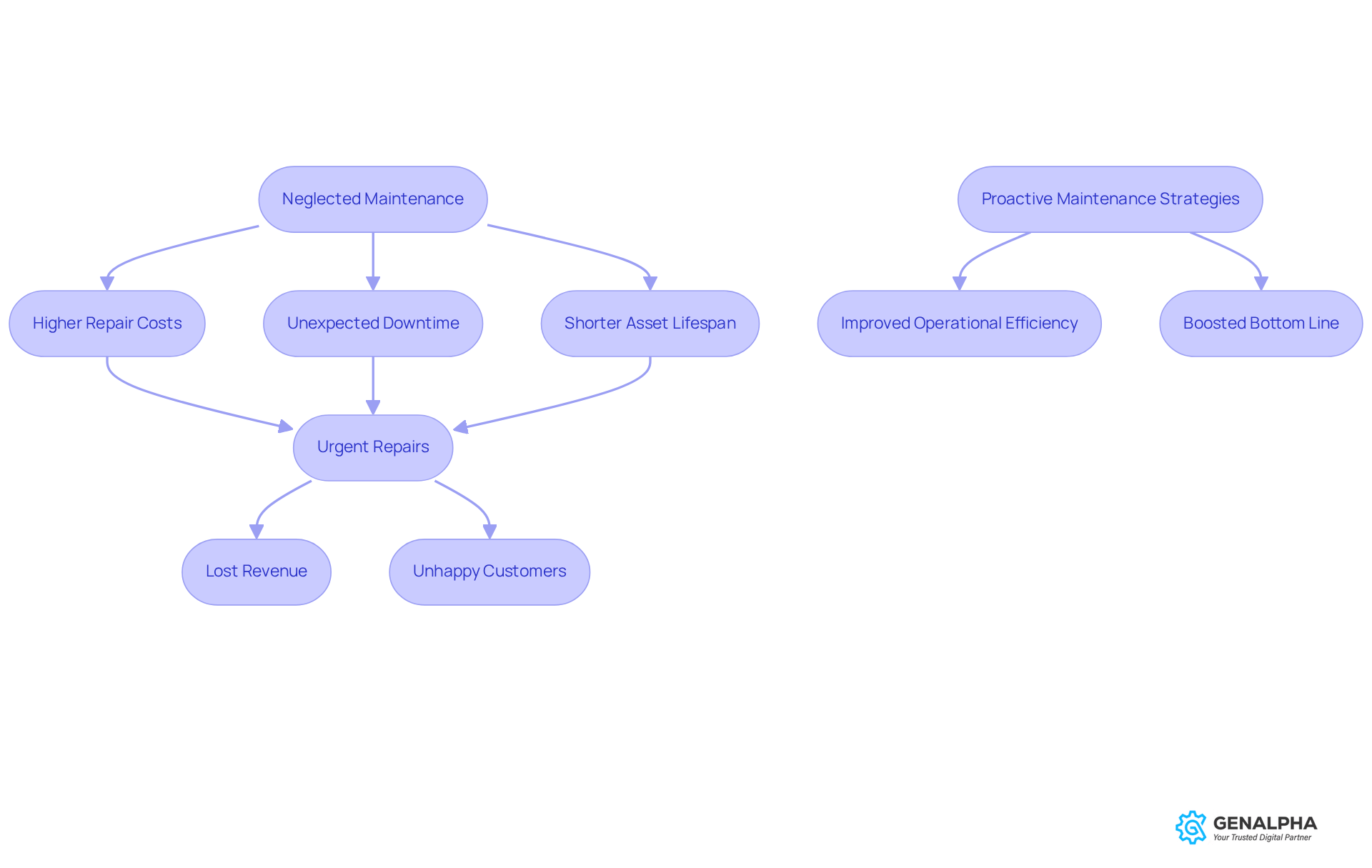

Have you ever thought about what happens when we ignore upkeep? It can lead to some serious financial pitfalls for organizations. We’re talking about higher repair costs, unexpected downtime, and even a shorter lifespan for our assets. When maintenance gets neglected, it often leads to that can end up costing way more than regular servicing. Plus, equipment failures can throw a wrench in operations, causing lost revenue and unhappy customers.

But here's the good news: by investing in proactive maintenance strategies, we can dodge these financial bullets. Not only do we improve operational efficiency, but we also give our bottom line a nice boost. Ever considered performing a cost-benefit analysis? It’s a great way to justify those necessary investments in upkeep programs. So, what do you think? Ready to take action on maintenance?

Employee Training: Enhancing Skills for Effective Maintenance

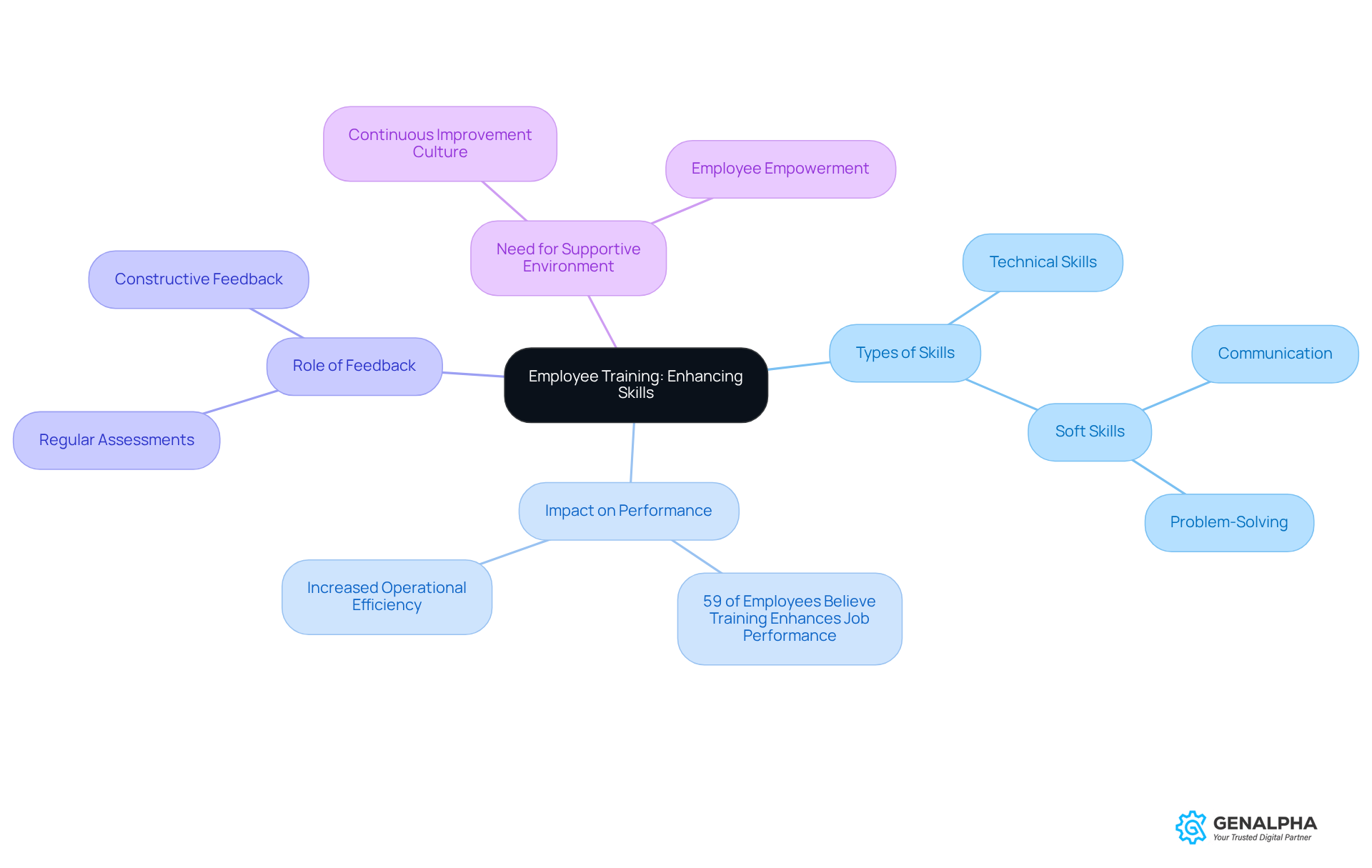

Have you ever thought about how crucial continuous employee training is for keeping our upkeep staff sharp and our operations running smoothly? It’s not just about technical skills; we need to focus on soft skills too, like communication and problem-solving. When organizations , they empower their support teams to tackle tasks efficiently, which means fewer mistakes and a boost in service quality. In fact, did you know that 59% of employees think training enhances their job performance? That really shows how effective it can be!

Regular assessments and constructive feedback play a vital role in spotting areas for improvement. After all, employees learn 70% of their skills on the job and only 10% from formal training sessions. This proactive approach not only builds employee confidence but also nurtures a culture of continuous improvement. The result? Better upkeep outcomes and improved operational efficiency rely on effective maintenance infrastructure. Plus, with the increasing pressure on support teams due to worker shortages, effective training becomes even more essential to minimize safety risks associated with untrained labor.

So, what can we do? Let’s prioritize training and create an environment where everyone feels supported and empowered to grow!

Technology Integration: Leveraging Innovation for Maintenance Efficiency

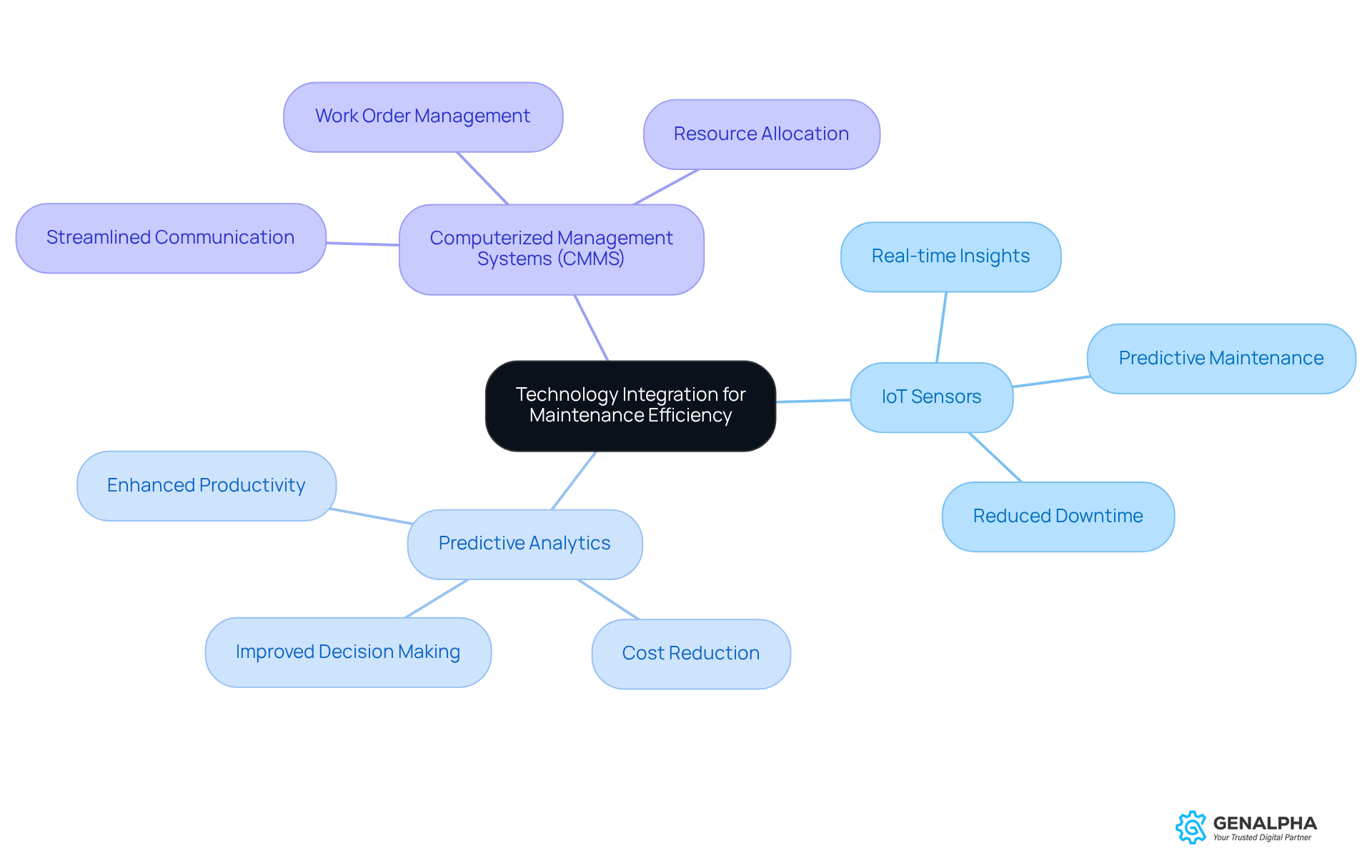

Incorporating technology into our maintenance infrastructure practices is essential for boosting efficiency and optimizing operations. Have you ever thought about how IoT sensors, predictive analytics, and Computerized Management Systems (CMMS) could transform your team's performance? These solutions provide , enabling support teams to make informed decisions that can really make a difference.

By leveraging these technologies, organizations can embrace predictive upkeep strategies that not only foresee equipment failures but can also cut unexpected downtime by up to 50%. That’s impressive, right? In fact, 55% of plants report enhanced upkeep staff productivity after adopting predictive care, which really underscores its effectiveness. And it gets better—70% of surveyed industrial companies see predictive upkeep as a strategic priority. This highlights just how significant these technologies are in today's market environment.

But it’s not just about efficiency; technology also streamlines communication and collaboration among service teams. This is crucial, especially when you consider that 41% of manufacturers face challenges due to a lack of resources or staff. As the maintenance infrastructure landscape evolves, embracing innovation is vital for organizations that want to remain competitive in this ever-changing management realm. So, what are you waiting for? Let’s dive into the future of upkeep together!

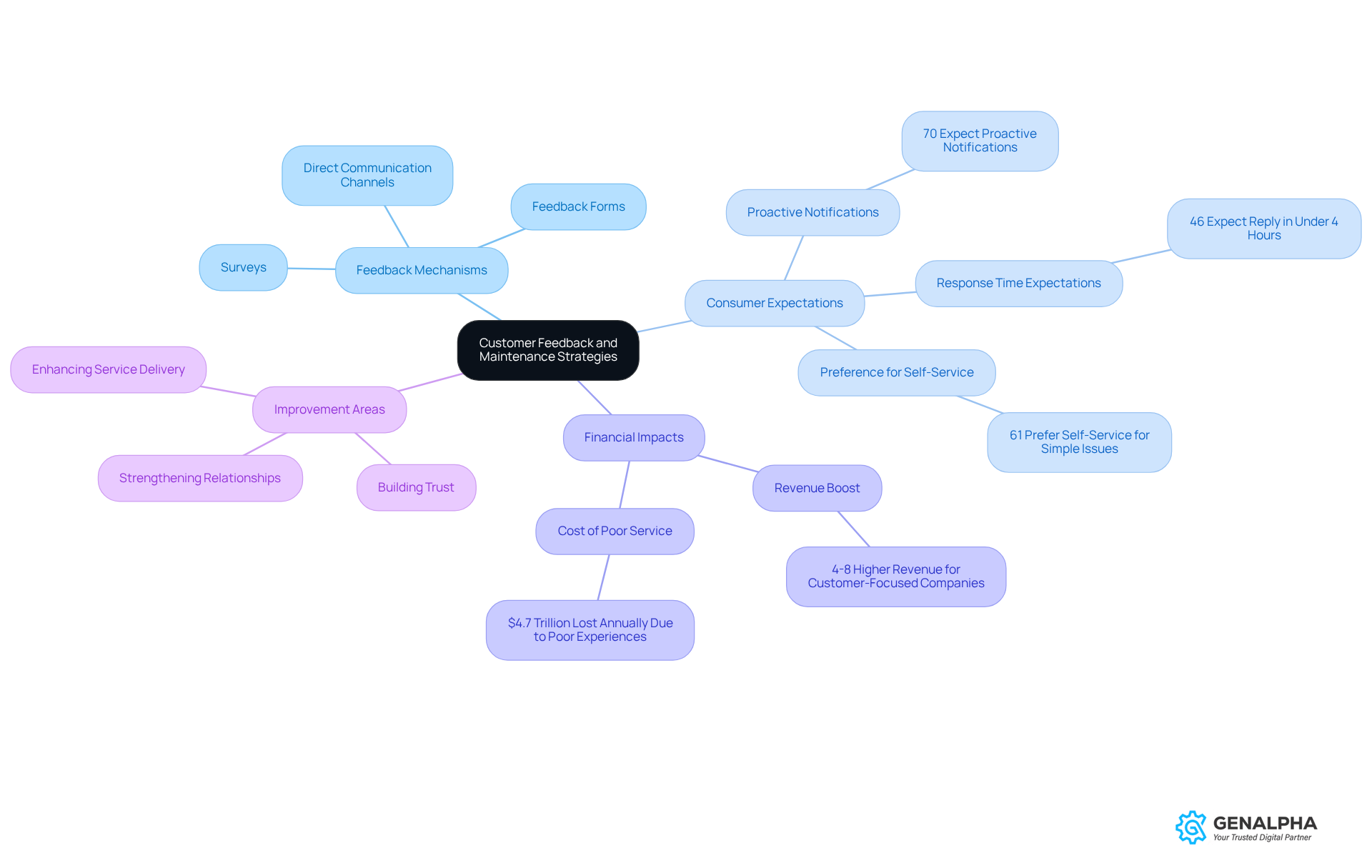

Customer Feedback: Informing Maintenance Strategies for Better Service

Integrating client feedback into maintenance strategies is a game changer for boosting service quality and client satisfaction. Have you ever wondered how organizations can really tune into what their clients need? Implementing solid mechanisms for gathering insights—like surveys, direct communication channels, and feedback forms—can help uncover those needs and expectations. Research shows that 70% of consumers expect proactive notifications from organizations. This really highlights the importance of staying connected!

Plus, companies that prioritize client experience often see a revenue boost of 4-8% compared to their competitors. That’s a big deal! Analyzing client feedback not only pinpoints areas where maintenance infrastructure can improve but also informs strategic decision-making. By actively engaging with clients and addressing their concerns, organizations can build trust and strengthen relationships, leading to better service delivery.

Let’s not forget the stakes: companies that ignore client feedback risk losing an estimated $4.7 trillion globally each year due to poor client experiences. As Ken McMahon wisely puts it, "Unifying your communication channels, supporting your agents with AI, and obtaining a coherent, clear perspective of your clients are table stakes."

And here’s something to think about—introducing self-service options can handle more than half of support requests. This really emphasizes the importance of how we . So, how can your organization start integrating feedback today?

Long-Term Investment: Building a Sustainable Maintenance Infrastructure

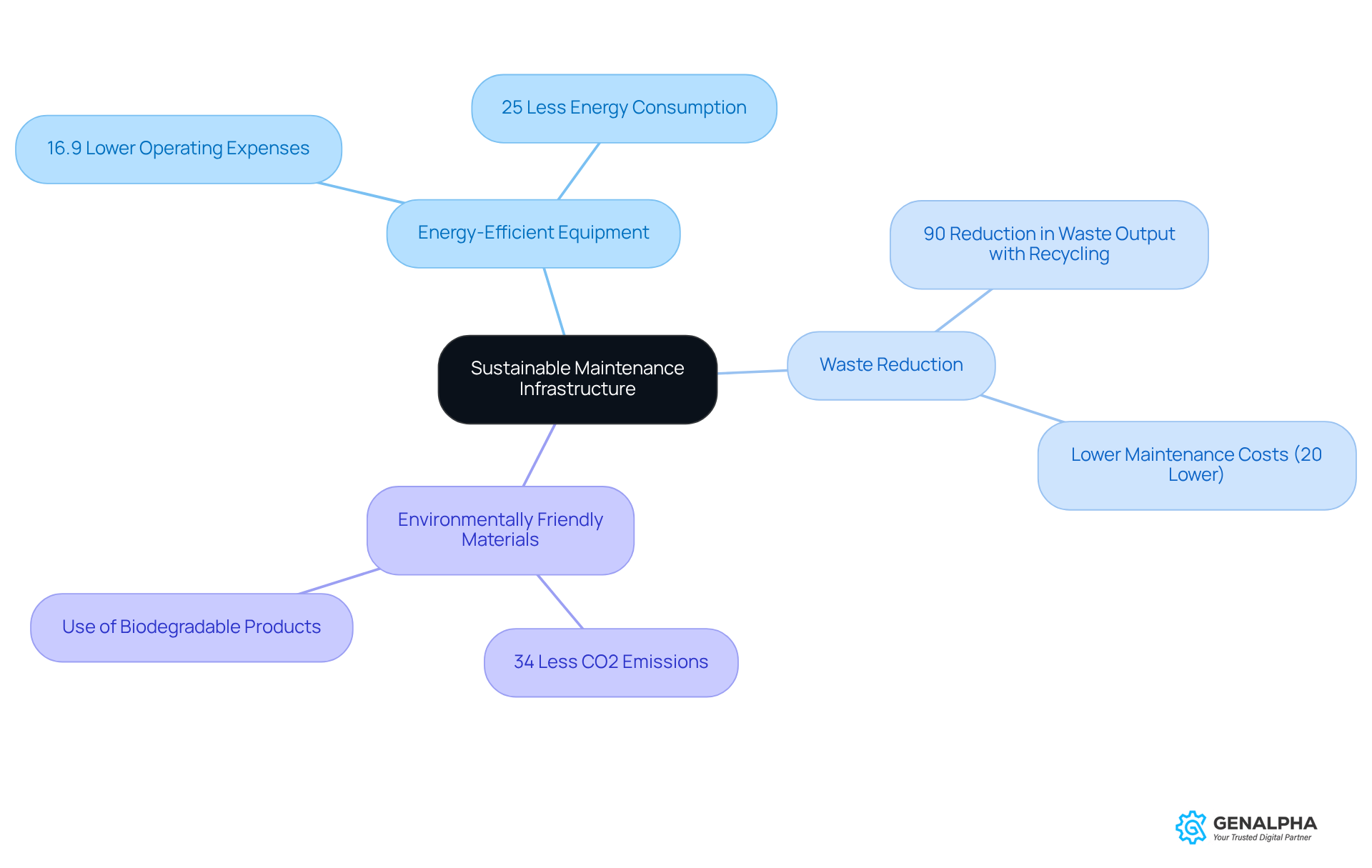

Creating a sustainable support framework is all about making a commitment to long-term investments in resources and strategies. Have you ever thought about how much our choices can impact the environment? Organizations should really prioritize practices that boost sustainability. This includes:

- Adopting energy-efficient equipment

- Reducing waste

- Using environmentally friendly materials

By putting sustainability first, companies can significantly cut down their environmental footprint while also improving operational efficiency and saving money in the long run.

For example, green buildings often see their operating expenses drop by 16.9% over five years and maintenance costs that are 20% lower than those of standard commercial buildings. Isn’t that impressive? It really shows the financial perks of embracing sustainable practices! Plus, green structures emit 34% less CO2 and consume 25% less energy, which highlights the environmental benefits of these upkeep practices.

But it’s not just about the numbers. A solid support system that focuses on sustainability can really enhance your brand's reputation, attracting customers who care about corporate responsibility. Regular evaluations and updates to maintenance infrastructure strategies are key to ensuring that sustainability goals are consistently met and improved upon. So, why not take that step towards a more resilient and efficient operational framework? Let’s make sustainability a part of our everyday conversation and actions!

Conclusion

Embracing a solid maintenance infrastructure isn’t just a nice-to-have; it’s a must for organizations looking to thrive in today’s competitive world. By adopting key strategies like:

- Digital transformation

- Quality control

- Compliance with changing standards

- Proactive maintenance

companies can really boost their operational efficiency and cut costs. These strategies not only improve machinery performance but also create a culture of continuous improvement and sustainability within the organization.

Let’s think about a few important points:

- Integrating digital tools like Equip360 can simplify processes and reduce financial risks.

- Strong quality control measures can enhance reliability and keep customers happy.

- Investing in employee training ensures that teams are ready to tackle maintenance challenges effectively.

- Addressing supply chain disruptions and leveraging technology are crucial for maintaining stability and efficiency in operations.

Ultimately, we can’t underestimate the importance of a well-structured maintenance infrastructure. Organizations that focus on these strategies will not only boost their bottom line but also position themselves as leaders in their industries.

So, here’s the call to action: take proactive steps to assess and improve your maintenance practices today. By doing this, businesses can secure a sustainable future while delivering exceptional service and value to their clients. What steps will you take to enhance your maintenance practices?

Frequently Asked Questions

What services does GenAlpha Technologies provide?

GenAlpha Technologies offers cutting-edge digital solutions tailored for manufacturers and distributors in the equipment and aftermarket parts sectors, focusing on optimizing inventory management and boosting online sales capabilities.

What is Equip360?

Equip360 is GenAlpha Technologies' flagship product that integrates digital warranty management and advanced analytics tools to enhance maintenance infrastructure, streamline upkeep processes, minimize downtime, and improve operational efficiency.

Why is digital transformation important for businesses today?

Digital transformation is essential for businesses to monitor operations in real-time and adopt proactive upkeep strategies, leading to improved service delivery and increased customer satisfaction.

What recent integration was announced by GenAlpha Technologies?

GenAlpha Technologies announced an integration between Equip360 and VizSeek Visual Search, enhancing the platform's capabilities.

What role does quality control play in equipment maintenance?

Establishing strong quality control practices is crucial for maintaining machinery, reducing the risk of equipment failures, and enhancing service reliability through proactive maintenance.

How can proactive maintenance impact costs and customer satisfaction?

Proactive maintenance can reduce unplanned downtime by up to 3.3 times compared to reactive approaches, leading to lower maintenance costs and improved customer satisfaction.

What are the benefits of implementing robust quality management systems?

Companies with strong quality management systems often see an average 9% increase in sales and a 26% boost in profitability.

Why is adaptation to evolving industry standards necessary?

Adapting to evolving industry standards is crucial for compliance, maintaining a competitive edge, and avoiding costly penalties.

What percentage of companies are investing in operator training to reduce downtime?

61% of companies are investing in operator training to reduce downtime.

How can technology like CMMS aid in compliance management?

CMMS (Computerized Maintenance Management Systems) simplifies documentation, ensuring that every upkeep action is recorded and verifiable, which facilitates smoother audits and adherence to regulatory standards.