Overview

Have you ever wondered how manufacturers keep everything running smoothly? Well, order management system software is like a secret weapon for them! It brings a whole host of benefits that not only streamline processes but also boost efficiency and, guess what? It makes customers happier too.

For example, imagine a world where errors are minimized, workflows are automated, and real-time tracking is at your fingertips. Sounds great, right? These features help create a more responsive and cost-effective manufacturing operation.

So, if you're in the manufacturing game, it might be time to consider how this software can transform your business. Think about the potential improvements in customer satisfaction and operational efficiency! Why not explore how you can implement these solutions today?

Introduction

Have you ever thought about how order management system software is changing the game in manufacturing? It’s pretty amazing! This technology is packed with benefits that can really boost operational efficiency. By automating workflows, centralizing data, and streamlining processes, manufacturers can cut down on errors, enhance customer satisfaction, and ultimately drive profitability.

But as the industry keeps evolving, a key question pops up: how can manufacturers tap into these systems to tackle challenges and grab growth opportunities in such a competitive market? Let’s dive into this together and explore how we can make the most of these innovative tools!

Equip360: Streamline Order Management for Enhanced Efficiency

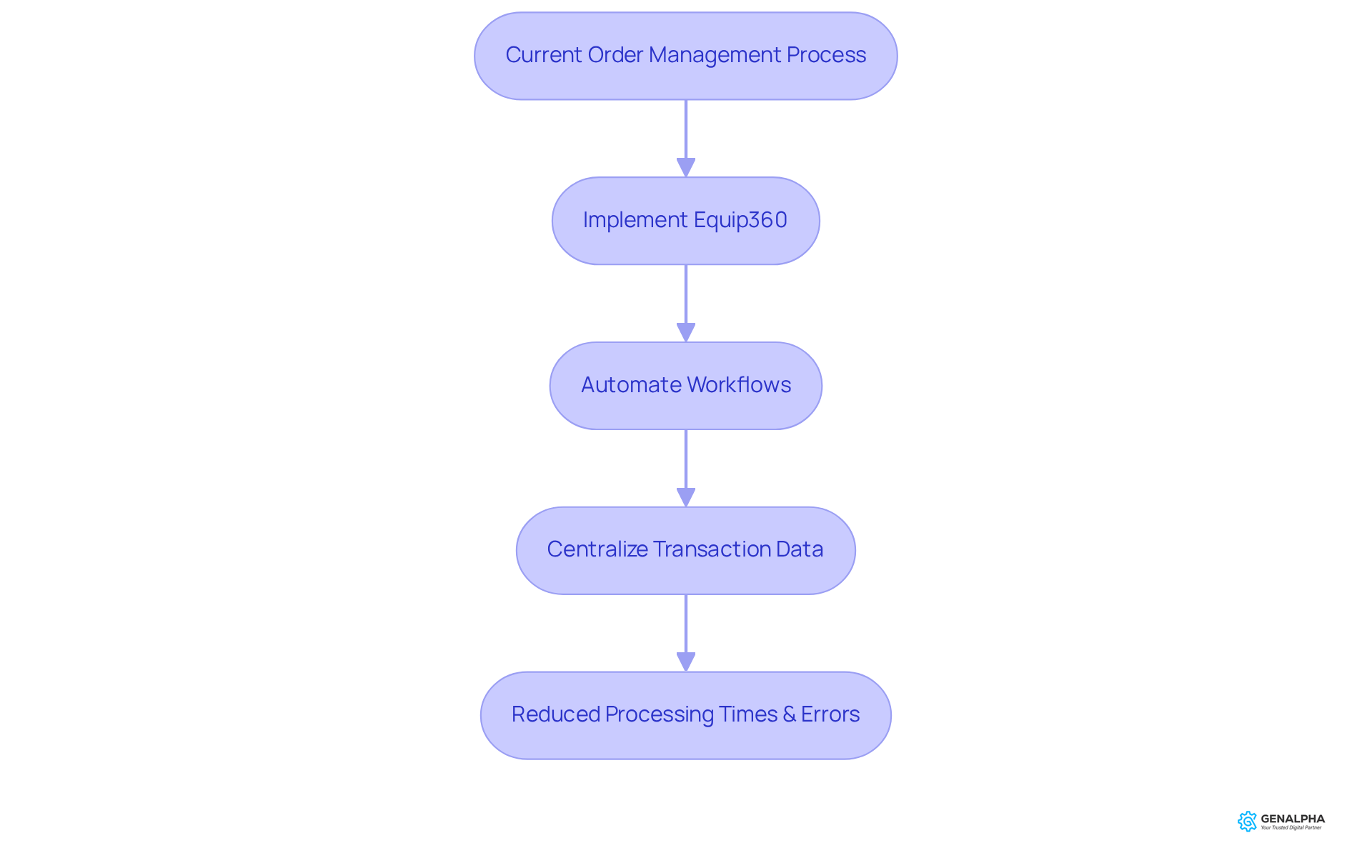

Have you ever felt overwhelmed by managing requests? Equip360 is here to change that! This platform is designed to streamline management processes for producers like you. By utilizing order management system software to automate workflows and centralize transaction data, you can cut down processing times significantly and reduce errors. Imagine how much smoother your operations could be, leading to happier clients who appreciate quicker and more accurate service.

Success stories from producers using Equip360, such as those highlighted in the case study 'Equip360: Optimizing B2B eCommerce,' really showcase its effectiveness. These narratives reveal how it enhances processing, , and strengthens customer relationships. Kristina Harrington, CEO of GenAlpha Technologies, sums it up perfectly: "Efficiency and accuracy in parts ordering are vital for producers striving to succeed in a competitive environment."

So, if you want to stay ahead in this ever-changing market, incorporating sophisticated order management system software such as Equip360 is essential. Why not take the next step towards a more efficient future? Your clients—and your bottom line—will thank you!

Digital Warranty Management: Improve Customer Satisfaction and Reduce Costs

Have you ever felt overwhelmed by warranty claims? Digital warranty management systems are here to save the day! They empower manufacturers to effectively. By automating these tasks, companies can cut down on administrative expenses and respond to client inquiries much faster.

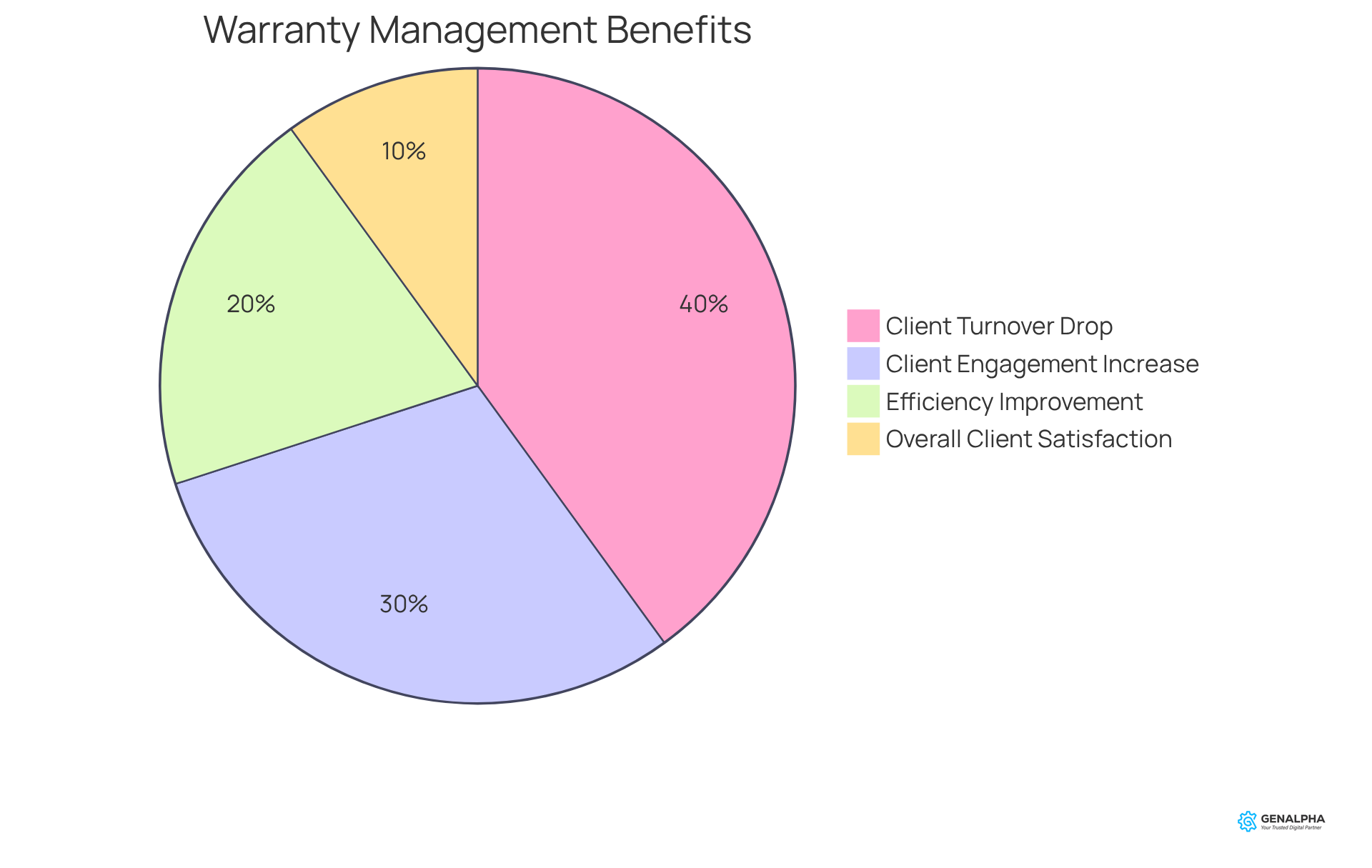

This boost in efficiency doesn’t just make life easier for businesses; it can also enhance client satisfaction—potentially increasing it by 5-10%! When clients feel appreciated and supported throughout their purchasing journey, trust is cultivated. For instance, businesses using digital warranty management have reported up to a 20% drop in client turnover and a 15% increase in client engagement. Isn’t that impressive?

But wait, there’s more! Proactive client engagement through automated reminders about warranty expirations can further enhance brand loyalty. Imagine a well-implemented warranty tracking system that reassures customers about their purchase protection, leading to improved loyalty and repeat business.

As more producers embrace these digital solutions, they not only update their operations but also gain a competitive edge in a rapidly changing market. Take GenAlpha Technologies, for example. Their flagship product, Equip360, showcases how customized digital solutions can effectively tackle warranty issues. So, why not consider how these systems could work for you?

Analytics Tools: Unlock Data-Driven Insights for Operational Optimization

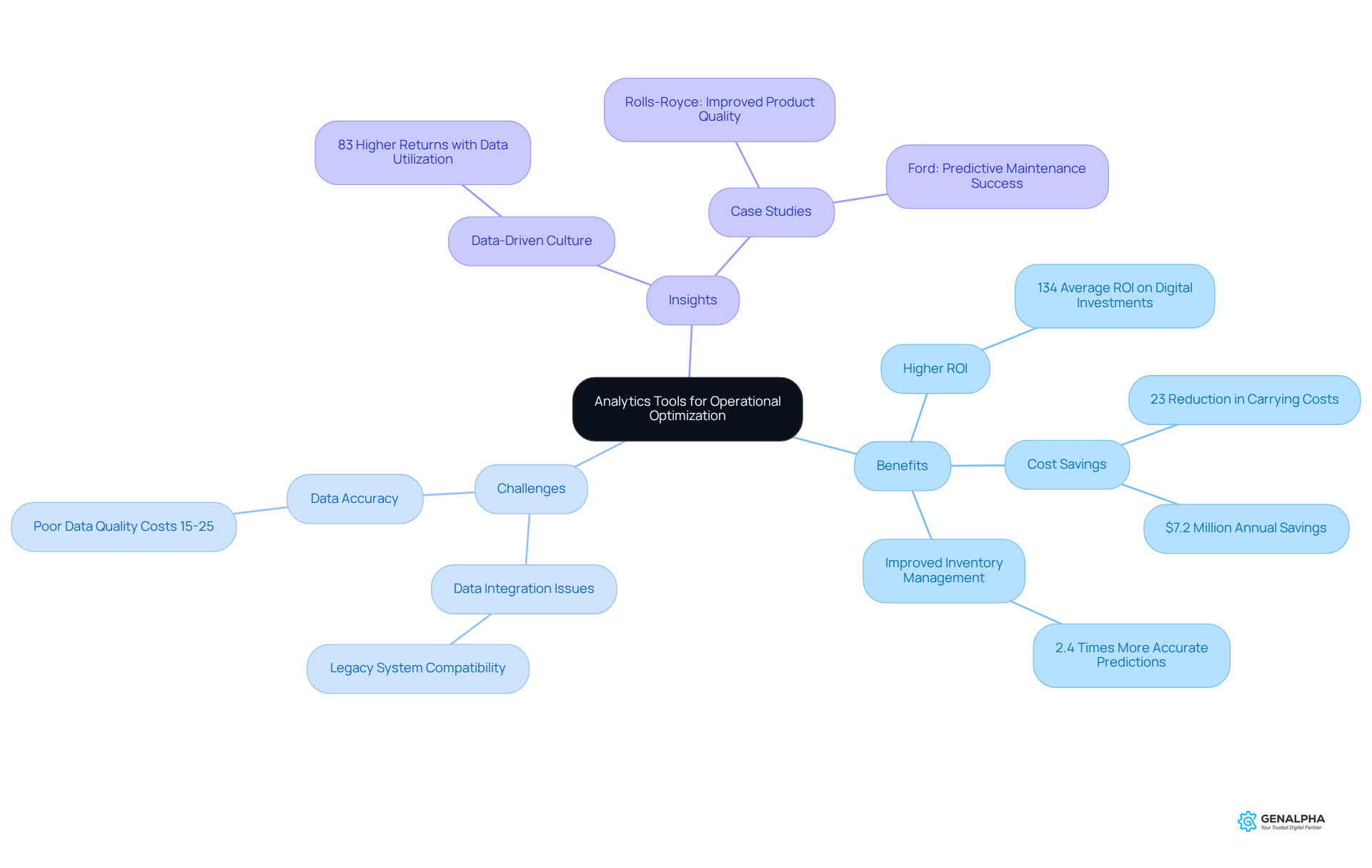

Have you ever thought about how analytics tools within order management system software can really change the game for producers? These tools help businesses gather and analyze crucial data about sales, inventory, and customer behavior. By tapping into these insights, companies can make smart decisions that boost their operational efficiency. For instance, those using advanced analytics report an impressive average return on investment of 134% on their digital spending, as seen in various industry case studies.

But it doesn’t stop there! Effective inventory optimization through analytics can lead to significant cost savings. Did you know that producers with integrated data systems are 2.4 times more likely to accurately predict production outcomes? This directly impacts how they manage their inventory. Take, for example, an electronics producer that managed to cut carrying costs by 23% while maintaining a 99.8% service level, resulting in annual savings of $7.2 million (Supply Chain Management Review).

Additionally, industry analysts point out that organizations where employees truly understand and utilize data effectively see 83% higher returns on their analytics investments (Deloitte). This really underscores the importance of creating a within manufacturing operations. By leveraging analytics tools alongside order management system software, producers can not only fine-tune their inventory levels but also tailor their marketing strategies to better meet customer needs, ultimately driving growth and enhancing customer satisfaction.

However, it’s important to acknowledge the hurdles in implementing manufacturing analytics, like integrating data with legacy systems and ensuring data accuracy. Tackling these challenges is key to successful execution, allowing producers to fully harness the benefits of data-driven insights. So, what steps can you take to start embracing these analytics tools in your operations?

Seamless ERP Integration: Enhance Digital Capabilities Without Disruption

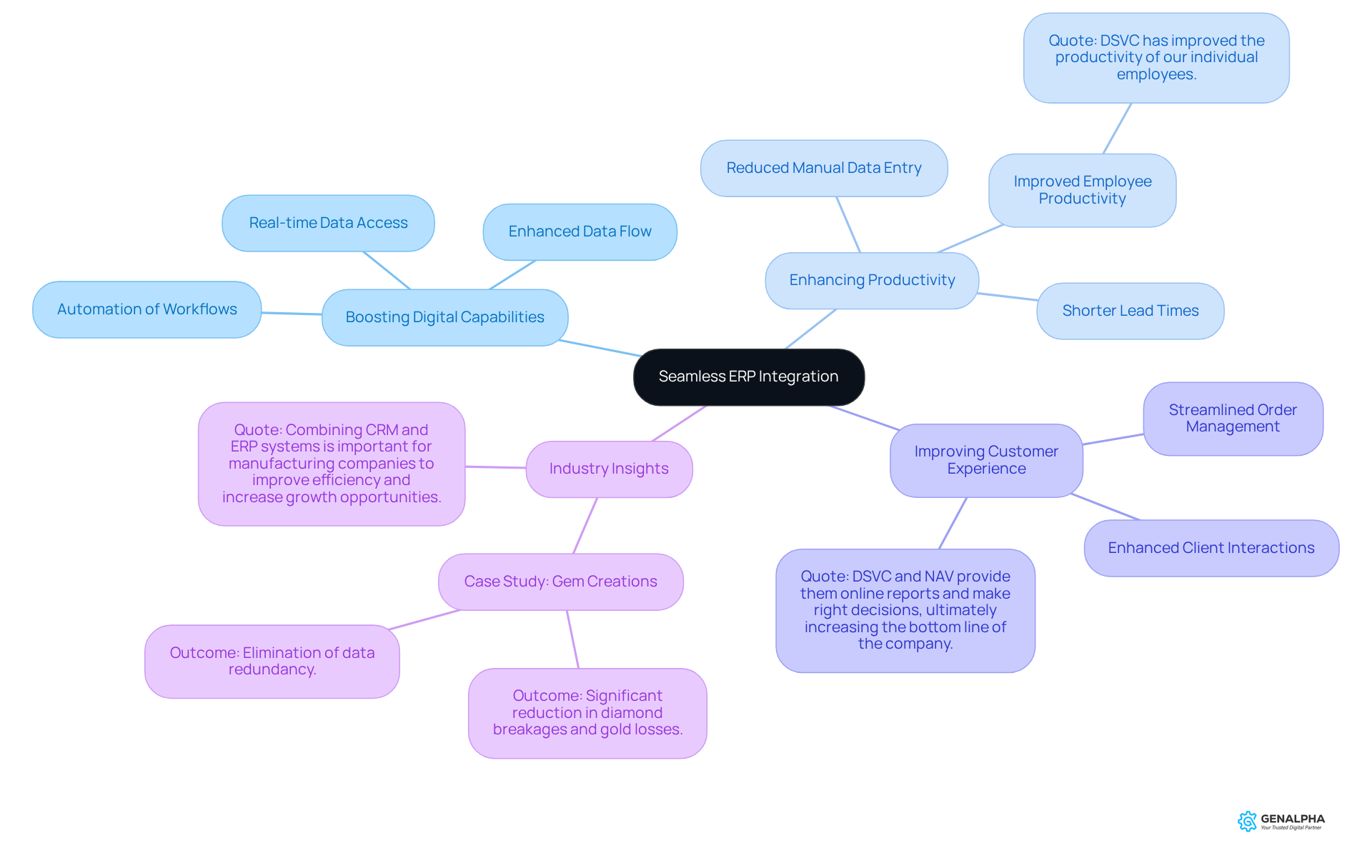

Have you ever wondered how combining inventory control systems with current ERP solutions could transform your operations? Well, it turns out that this seamless integration not only boosts digital capabilities but also keeps everything running smoothly. Imagine a world where data flows effortlessly between systems, cutting down on errors and ramping up efficiency. Sounds good, right?

According to industry insights, integrated ERP systems can significantly enhance productivity by minimizing the need for manual data entry and reconciliations. By leveraging their existing infrastructure, producers can tap into advanced order management system software features that simplify processes and elevate client experiences. For instance, companies like Gem Creations, which implemented DSVC and MS Dynamics NAV, have reported impressive gains in production efficiency and inventory control. This has led to shorter lead times and happier customers.

As Mr. Chotiwat Lattapanit put it, 'DSVC has improved the productivity of our individual employees.' This ability to maintain operational continuity while enhancing digital capabilities means producers can swiftly respond to market needs, paving the way for growth and profitability. So, why not explore how these integrated solutions can work for you?

Improved Inventory Management: Maintain Quality Control and Meet Demand

Order control systems are like the secret sauce for producers, giving them essential tools to keep an eye on inventory in real-time. Imagine never having to worry about running out of stock or having too much on hand—sounds great, right? This capability is crucial for meeting customer demand while keeping quality standards in check. When businesses have , they can make smarter purchasing decisions, which really boosts supply chain efficiency.

Did you know that the inventory control software sector is expected to reach a whopping $2,191.2 million by the end of 2024? That just shows how vital these systems are becoming for producers who want to thrive in a competitive landscape. Plus, a staggering 62% of business finances take a hit because of inventory tracking issues. This really highlights why strong inventory oversight solutions are a must-have.

By embracing order management system software, producers can streamline their operations, reduce costs associated with inventory errors, and ultimately enhance customer satisfaction. So, why not take that step toward optimizing your inventory control? It could be the game-changer you’ve been looking for!

![]()

Automated Order Processing: Reduce Errors and Increase Efficiency

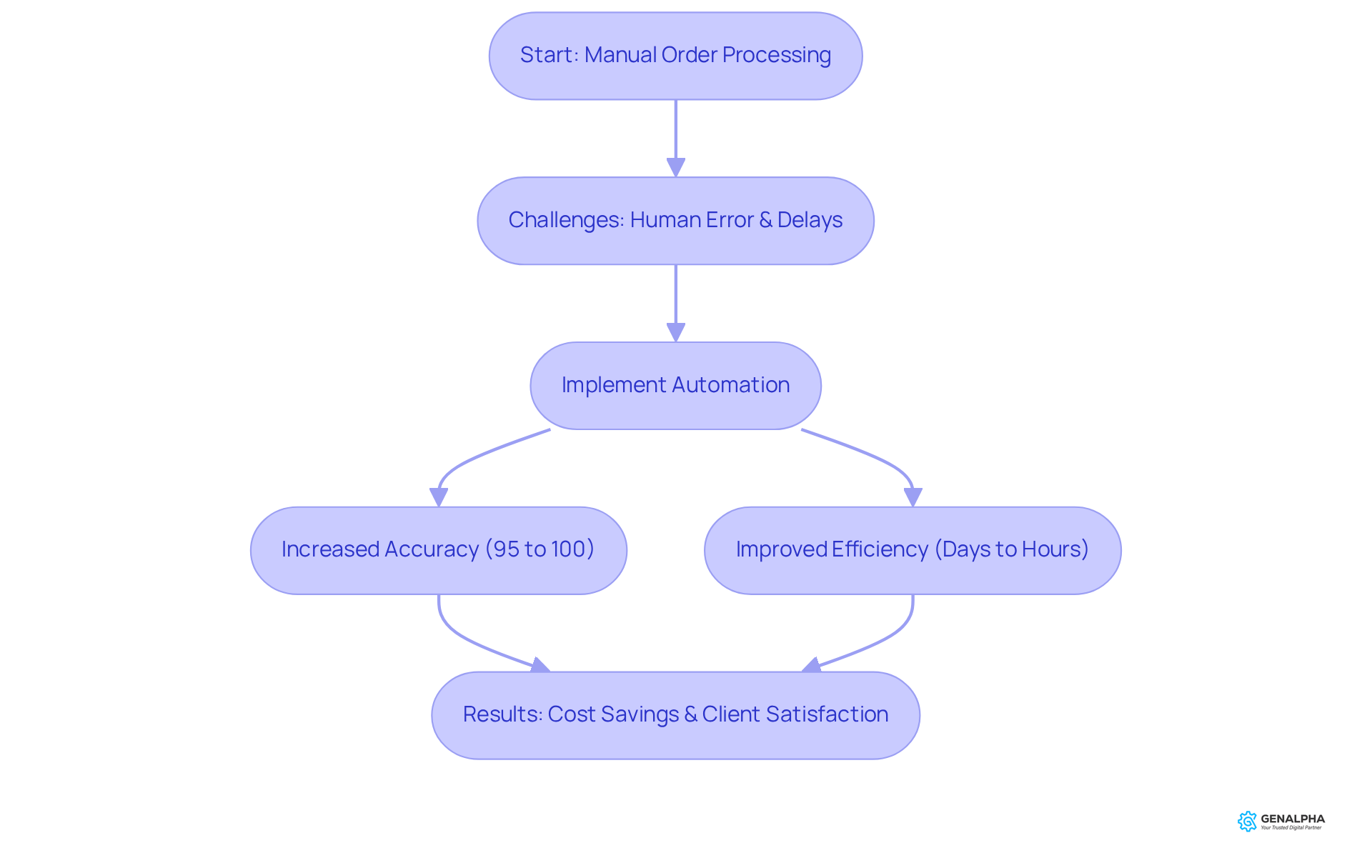

Have you ever thought about how automated processing can really change the game? It’s amazing how it significantly reduces the risk of human error by streamlining everything from receipt to fulfillment. When manufacturers automate those repetitive tasks, they not only boost efficiency but also ensure that requests are handled with precision and speed.

Take Van Meter, for example. They faced some real challenges with accuracy as their transaction volume surged. But once they embraced automation, their accuracy in processing requests jumped from 95% to a perfect 100%! That’s a clear win that shows the tangible benefits of this technology.

And it gets better! Organizations that have integrated order management system software into their workflow often report impressive efficiency gains. Imagine processing times shrinking from days down to just hours. Not only does this save precious time, but it also enhances the overall client experience. Customers get their items promptly, without any unnecessary delays.

In fact, industry insights reveal that automated systems can save companies about $30 for every manually processed sales transaction. That’s a significant boost to , especially when dealing with large volumes of requests. As producers strive to meet growing demand, implementing order management system software for automated processing isn’t just a nice-to-have; it’s essential for staying competitive and ensuring client satisfaction. So, why not consider how automation could work for you?

Enhanced Customer Engagement: Build Stronger Relationships with Clients

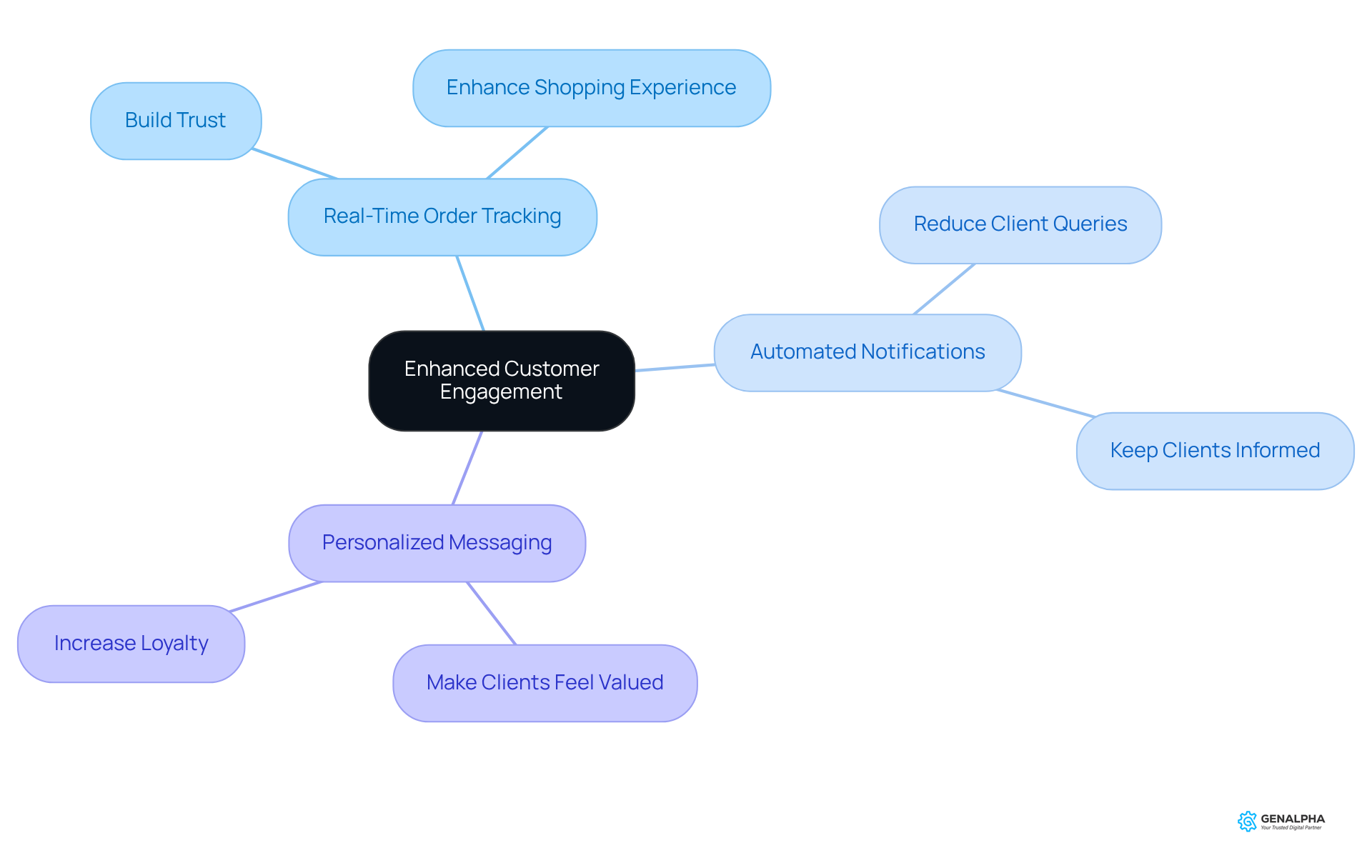

Order management system software is a game-changer when it comes to improving client interaction. They provide manufacturers with essential tools for effective communication throughout the transaction process. Think about it: features like real-time order tracking, automated notifications, and personalized messaging play a huge role in building stronger relationships with clients. For instance, real-time tracking allows customers to see their shipments from processing to delivery. This not only builds trust but also enhances the overall shopping experience. Did you know that 96% of clients consider experience crucial to their loyalty? This really highlights how important it is to keep them informed and engaged.

Moreover, automated alerts keep clients updated at every step of their order, reducing the need for them to ask for updates. This proactive approach to communication can significantly boost client satisfaction. Take PartsSource, for example; they improved their Estimated Ship Date (ESD) coverage and saw a 10% increase in on-time shipping accuracy. Such improvements not only meet client expectations but also encourage repeat business, especially since 69% of consumers are likely to stop buying from brands that don’t deliver on time. This underscores the essential role of order management system software in ensuring , which is vital for maintaining client loyalty.

By leveraging the features of order management system software, manufacturers can create a seamless fulfillment process that prioritizes client communication. This not only reduces order errors but also makes clients feel valued and informed, ultimately leading to greater loyalty and stronger relationships. As industry leaders often say, effective communication is key to building trust and satisfaction. So, choosing a scalable and integrative order management system software isn’t just a smart move; it’s a strategic decision for manufacturers looking to enhance their customer engagement.

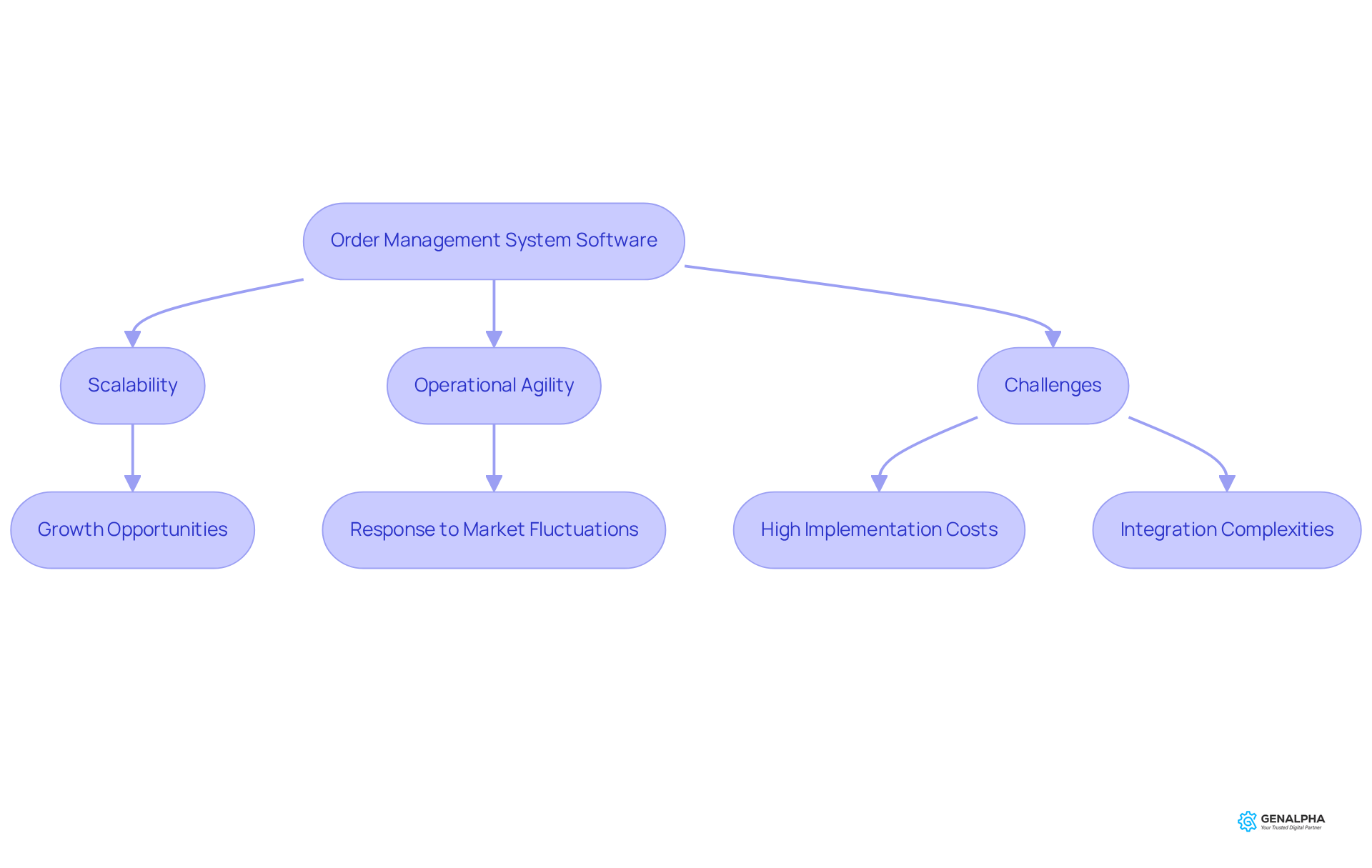

Scalability: Adapt to Market Changes and Grow Operations

Order management system software is pretty amazing when you think about it! They’re designed to scale up effortlessly, allowing producers to quickly adjust to market changes and grab growth opportunities. As businesses grow, these systems can easily manage more orders and add new product lines without missing a beat. This kind of flexibility is crucial because producers are facing increasing .

Did you know that the global Order Management Software market is expected to jump from around USD 3.2 billion in 2023 to about USD 6.1 billion by 2032? That’s a compound annual growth rate (CAGR) of roughly 7.4% during that time! Companies that are using order management system software in a cloud-based environment have seen some impressive boosts in their operational agility, which helps them respond to market fluctuations like pros.

However, it’s not all smooth sailing. Producers do have to deal with challenges like high implementation costs and integration complexities when they adopt OMS. But here’s the good news: by implementing a strong order management system software, producers can not only meet client demands but also strategically position themselves for future growth in a constantly changing marketplace. So, why not consider how an OMS could work for you?

Real-Time Tracking and Reporting: Monitor Operations and Make Timely Adjustments

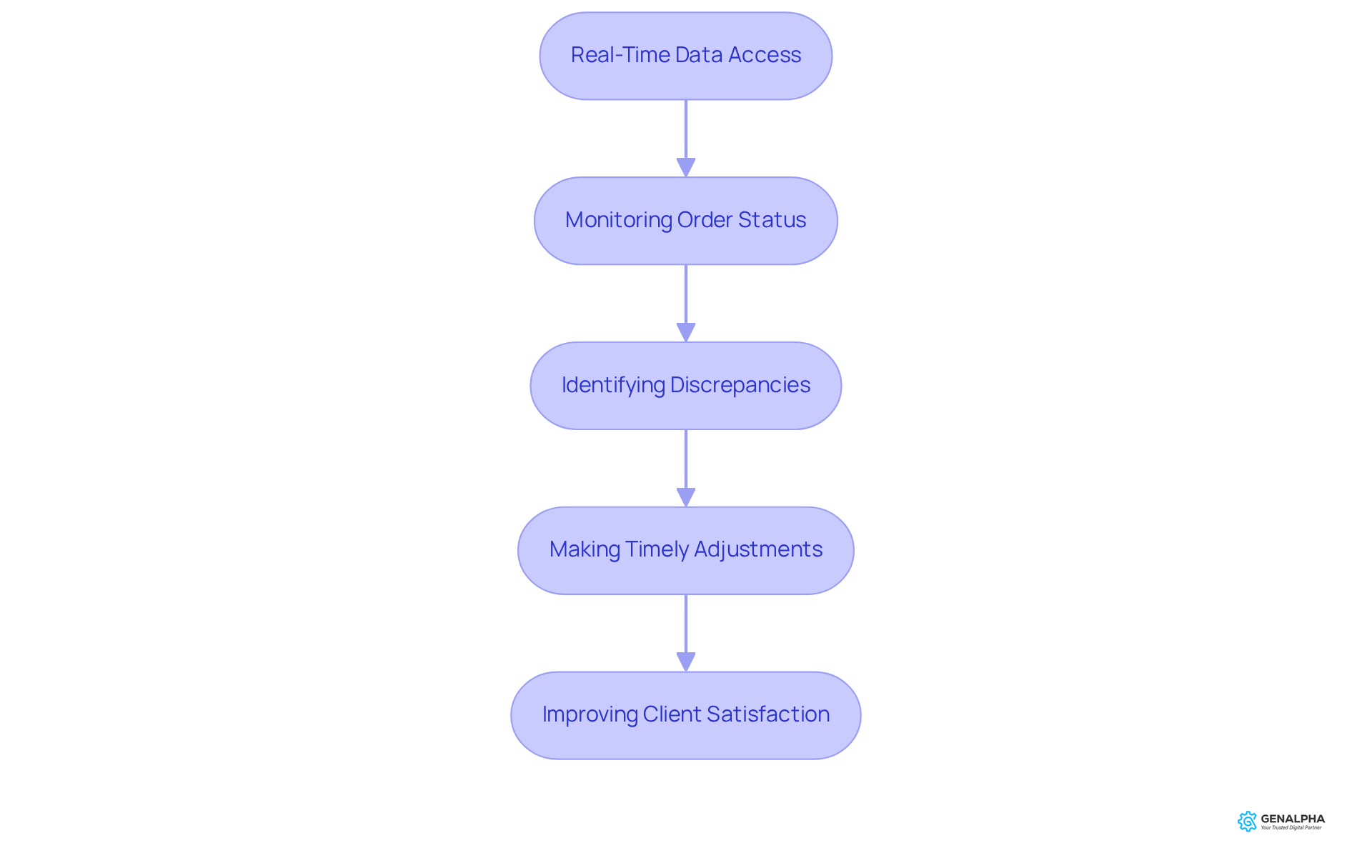

Have you ever thought about how real-time tracking and reporting features in management systems (OMS) can really change the game for producers? With on order status, inventory levels, and client interactions, businesses can make timely adjustments to their processes. For example, manufacturers who tap into real-time data can quickly spot discrepancies in their inventory. This proactive approach helps prevent costly stockouts or overstock situations, ensuring smoother operations and happier customers.

Now, let’s talk numbers. The financial impact of inefficient transaction oversight is staggering—global retailers face an annual deficit of $1.77 trillion due to inventory distortion issues. But here’s the good news: effective reporting capabilities can make a big difference. Manufacturers can analyze trends and operational metrics to fine-tune their workflows. Take Brooks Brothers, for instance. They’ve successfully harnessed advanced OMS solutions to enhance their order management and service processes by integrating real-time data, allowing them to respond more effectively to client demands.

Industry leaders emphasize that keeping a pulse on operations is crucial for adapting to market needs and ensuring a smooth client experience. By incorporating real-time tracking into their systems, producers can boost their responsiveness and operational agility, paving the way for growth and client loyalty. However, it’s also vital to tackle challenges like data gaps and inconsistencies to maximize the benefits of OMS. Plus, integrating advanced fraud detection tools is key to safeguarding against potential losses. So, what steps can you take to enhance your operations today?

Cost Savings: Achieve Long-Term Financial Benefits with Order Management Systems

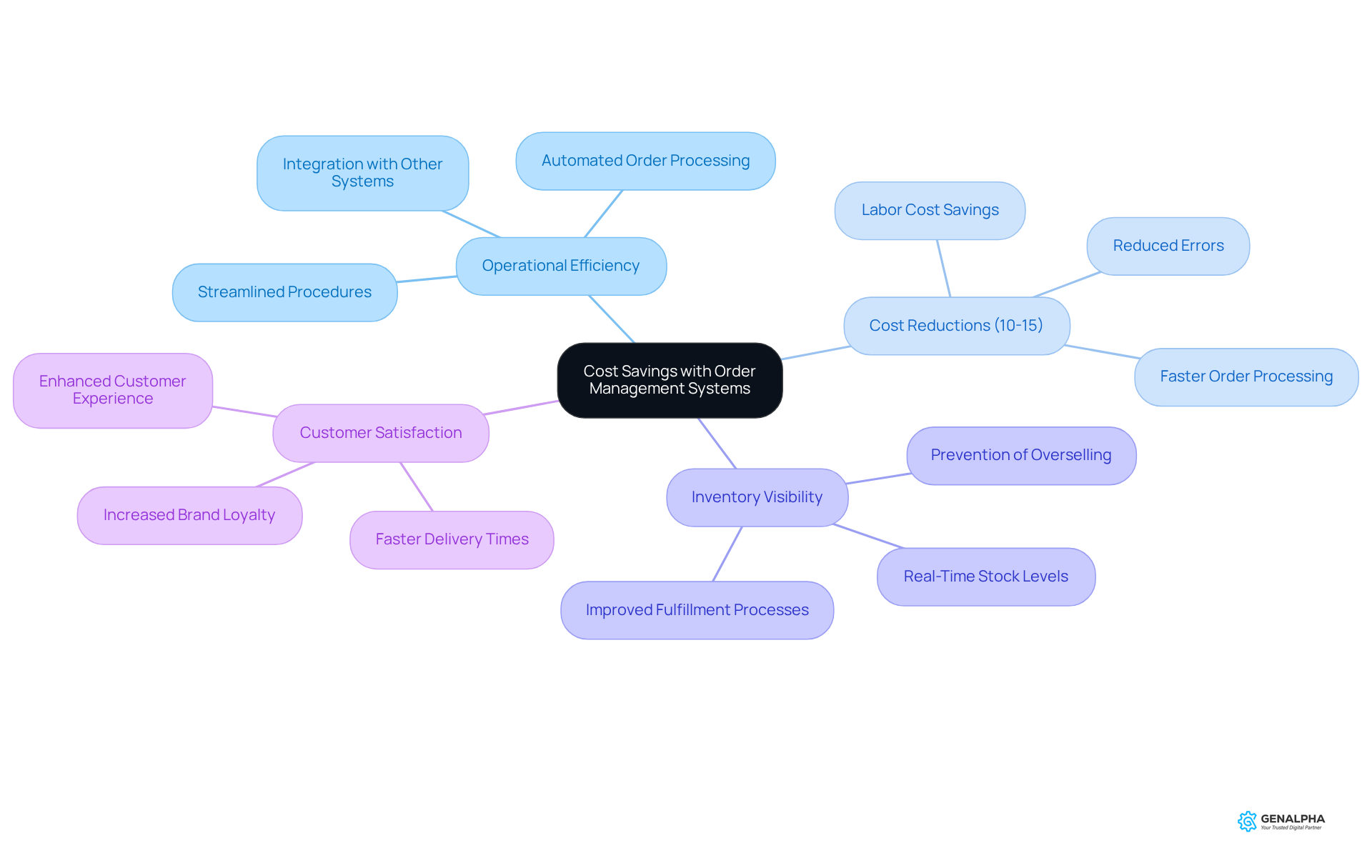

Implementing an order management system software for requests (OMS) can really save manufacturers a lot of money. By cutting down on mistakes and streamlining procedures, businesses can boost their operational efficiency and keep clients happy. For example, organizations that have embraced automation often see cost reductions of around 10-15% and faster order processing times. This kind of efficiency not only slashes operational expenses but also increases profitability. Just look at how Conexiom's automation helped a global chemical firm enhance its service and operational effectiveness.

But wait, there’s more! The long-term financial benefits of order management system software are quite impressive. With , the order management system software helps prevent overselling and underselling, which can damage client satisfaction and hurt your brand's reputation. When producers have a clear view of their stock, they can improve their fulfillment processes, leading to quicker delivery times and happier clients. As Sudhir Balebail, Product Management Leader, puts it, "Businesses require strong order management system software that can enhance customer satisfaction, boost fulfillment profitability, and support new digital and in-person customer experiences."

So, if you're thinking about the future, investing in order management system software could really strengthen your bottom line over time, especially for manufacturers eager to thrive in today's competitive landscape.

Conclusion

Implementing an order management system (OMS) software is a game changer for manufacturers looking to boost their operational efficiency and customer satisfaction. By automating processes, centralizing data, and providing real-time insights, systems like Equip360 help producers streamline their workflows and respond quickly to market demands. Plus, integrating advanced technologies not only ramps up productivity but also builds stronger relationships with clients, keeping businesses competitive in a constantly changing landscape.

Throughout our discussion, we've highlighted some key benefits of order management systems. Think:

- Improved inventory management

- Automated order processing

- Enhanced customer engagement

Companies that tap into these systems often report significant cost savings, increased accuracy, and higher client retention rates. And let's not forget the importance of analytics tools and seamless ERP integration, which really help manufacturers optimize their operations and make smart, data-driven decisions for sustainable growth.

In a world where efficiency and responsiveness are crucial, adopting order management system software isn't just a nice-to-have; it's a must. Manufacturers should definitely explore these innovative solutions—not only to tackle today's challenges but also to set themselves up for future success. Embracing these technologies can give you a competitive edge, ensuring that your business doesn't just survive but thrives in a dynamic market. So, what are you waiting for? Dive into the world of OMS and see the difference it can make!

Frequently Asked Questions

What is Equip360 and how does it help producers?

Equip360 is an order management system software designed to streamline management processes for producers by automating workflows and centralizing transaction data, significantly reducing processing times and errors.

What benefits do producers experience by using Equip360?

Producers using Equip360 experience enhanced processing efficiency, improved customer relationships, and quicker service, leading to happier clients.

Can you provide an example of a success story related to Equip360?

A case study highlighted in the article features Kristina Harrington, CEO of GenAlpha Technologies, who emphasizes the importance of efficiency and accuracy in parts ordering for producers to succeed in a competitive environment.

What is digital warranty management and how does it benefit manufacturers?

Digital warranty management systems automate the warranty claims process, reducing administrative costs and improving response times to client inquiries, ultimately enhancing client satisfaction.

How much can client satisfaction increase with digital warranty management?

Client satisfaction can potentially increase by 5-10% when businesses effectively implement digital warranty management systems.

What impact does proactive client engagement through warranty tracking have?

Proactive engagement, such as automated reminders about warranty expirations, can enhance brand loyalty and lead to improved customer retention and repeat business.

How do analytics tools within order management software benefit producers?

Analytics tools help producers gather and analyze data on sales, inventory, and customer behavior, enabling smart decision-making that boosts operational efficiency.

What is the average return on investment for producers using advanced analytics?

Producers using advanced analytics report an average return on investment of 134% on their digital spending.

How does effective inventory optimization through analytics impact costs?

Producers with integrated data systems can accurately predict production outcomes, leading to significant cost savings, such as a 23% reduction in carrying costs while maintaining high service levels.

What challenges do manufacturers face when implementing analytics tools?

Key challenges include integrating data with legacy systems and ensuring data accuracy, which are crucial for successfully harnessing the benefits of data-driven insights.