Overview

Have you ever wondered how effective BOM management can really transform manufacturing? It all starts with a few smart strategies!

- By setting up a hierarchical structure,

- Standardizing naming conventions,

- Integrating BOM with inventory management systems,

manufacturers can make a world of difference. These practices not only enhance clarity but also reduce errors and ramp up operational efficiency. And guess what? This ultimately leads to better product management and happier customers. So, why not take a step towards improving your BOM management today?

Introduction

In the intricate world of manufacturing, the Bill of Materials (BOM) is like a critical blueprint that outlines every component necessary for production. Have you ever thought about how effective BOM management can streamline operations? It not only enhances quality control but also reduces waste and fosters collaboration across departments. Yet, the journey to mastering BOM management isn’t without its challenges. From data inaccuracies to the complexities of multi-level structures, manufacturers face hurdles. So, how can we navigate these challenges and leverage best practices to optimize our BOM processes?

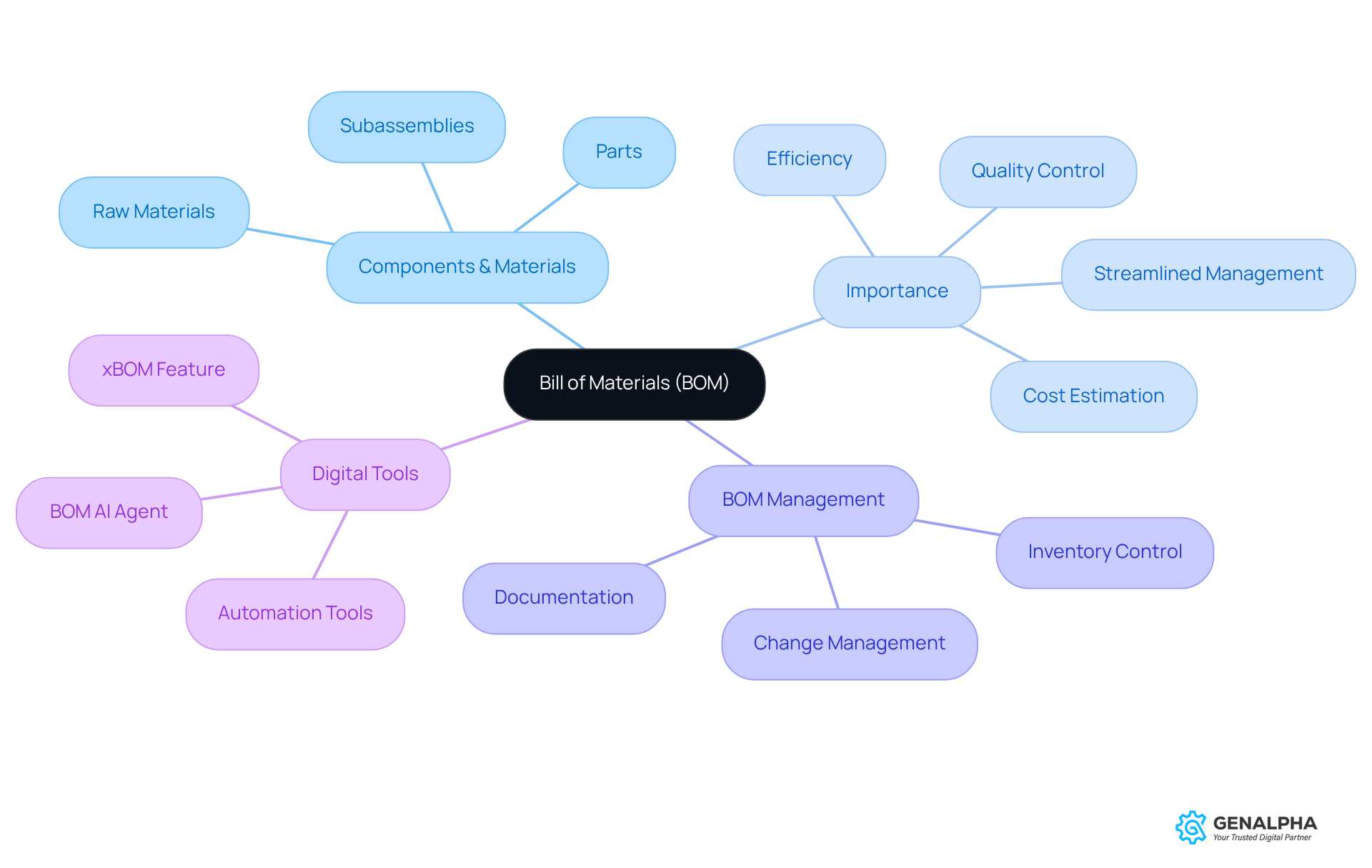

Define the Bill of Materials (BOM) and Its Importance

Have you ever wondered what goes into making a product? A Bill of Materials (BOM) is your go-to document that lays out all the components, materials, and subassemblies needed for manufacturing. Think of it as a comprehensive game plan that ensures everything is in place when it’s time to produce. The significance of BOM management can't be overstated; it streamlines material management, keeps inventory in check, helps estimate costs, and ensures consistency in the manufacturing process.

When a is meticulously maintained, it not only boosts quality control but also supports change management and ensures all departments are on the same page. For example, companies that prioritize BOM management often see less waste and improved efficiency, which ultimately leads to happier customers and increased loyalty.

Recently, there’s been a buzz about digital BOM oversight tools. Take the xBOM feature launched by OpenBOM on July 18, 2024, for instance. These tools leverage automation and real-time data to make workflows smoother. As the BOM management software market is expected to grow from $9.1 billion in 2024 to $9.64 billion in 2025 at a CAGR of 5.9%, it’s clear that manufacturers are recognizing the importance of BOM management in achieving operational excellence and staying competitive.

Now, let’s not forget that an incorrect BOM can cause costly delays in manufacturing. This really highlights the need for precision. As Melanie Chan wisely points out, "Always keep records and supporting documents, such as CAD drawings, part data sheets, and work instructions up to date and attached, with their specific BOM level components for easy reference and to ensure accuracy." So, are you prepared to elevate your BOM management to the next level?

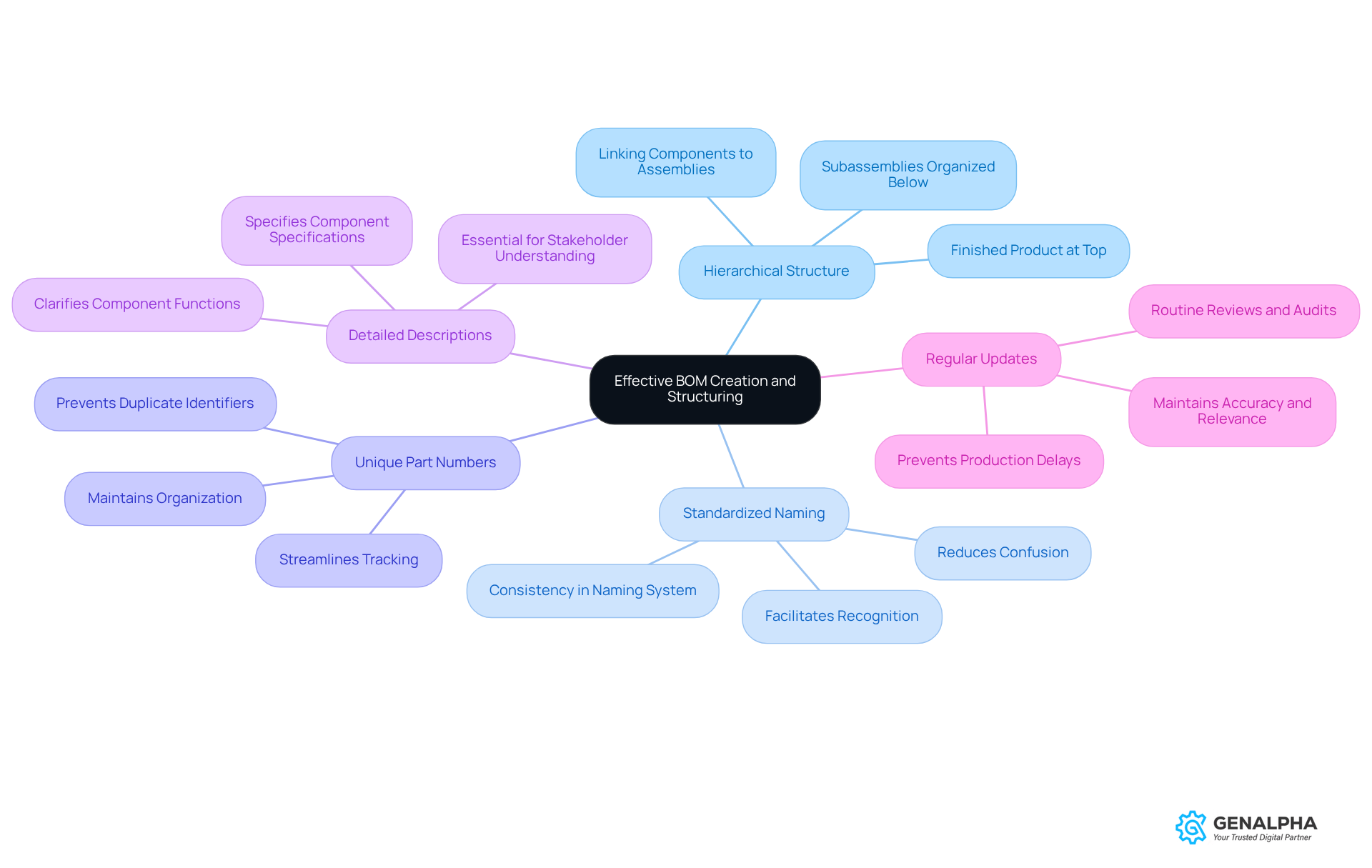

Establish Effective BOM Creation and Structuring Processes

Creating an effective Bill of Materials (BOM) through BOM management can feel like a daunting task, but it doesn’t have to be! Let’s explore some best practices that can make this process smoother and more efficient for manufacturers.

First off, - think about using a hierarchical structure. Picture your finished product at the top, with subassemblies and components neatly organized below. This setup not only makes everything clearer but also helps everyone across departments stay on the same page. It’s like having a common reference point that everyone can understand. Plus, linking lower-level components directly to higher-level assemblies is key to improving clarity in BOM oversight.

Next, let’s talk about - standardizing naming conventions. Consistency is crucial here! When everyone uses the same naming system, it cuts down on confusion and makes it easy for team members to . This can really help maintain precision in operations and inventory management.

Another important step is to - assign unique part numbers. Each component should have its own identifier to streamline tracking. This practice keeps your BOM organized and helps prevent errors that can pop up from duplicate or unclear identifiers.

Don’t forget to - provide detailed descriptions for each item. Including comprehensive descriptions clarifies what each component does and its specifications. This level of detail is essential for ensuring that all stakeholders understand the components involved, which is vital for effective project execution.

And here’s a big one: - regularly update the BOM. Establishing a routine for reviewing and updating the BOM is essential to keep up with any changes in materials or processes. Regular audits and updates help maintain accuracy and relevance, reducing the risk of production delays and ensuring that the BOM remains a reliable source of information throughout the project lifecycle.

By incorporating these strategies, you can significantly enhance your BOM management oversight processes, leading to improved operational efficiency and reduced costs. However, it’s also important to be aware of common pitfalls in BOM oversight, like challenges with version control and the need for effective collaboration among teams. By addressing these issues, you can further optimize your BOM practices. So, are you ready to take your BOM game to the next level?

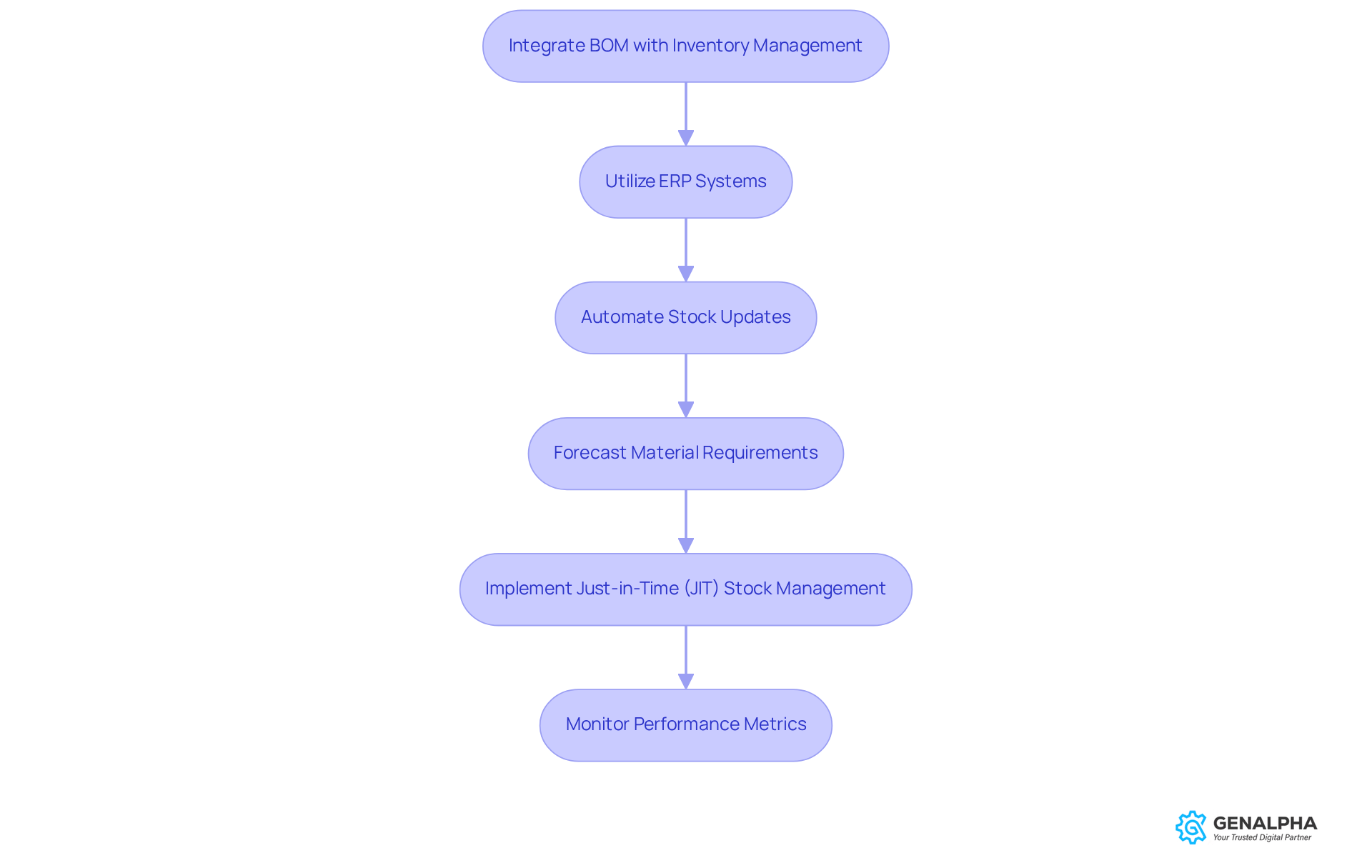

Integrate BOM with Inventory Management for Enhanced Efficiency

Integrating the Bill of Materials (BOM) with BOM management systems can really boost operational efficiency. So, how can we make this integration happen? Here are some key strategies to consider:

- Utilize ERP Systems: Have you thought about implementing an ? It connects BOM management data with stock levels, enabling real-time tracking of materials and components. This means better visibility and coordination across departments, ensuring production schedules align with what you have on hand. In fact, 91% of organizations reported improved stock levels after implementing ERP systems—pretty impressive, right?

- Automate Stock Updates: Imagine using software that automatically refreshes stock levels based on BOM requirements. This not only reduces manual errors but also ensures that stock levels are always in sync with manufacturing needs, minimizing the risk of running out or having too much. Companies that have automated their inventory management often report a 62% reduction in costs, especially in purchasing and inventory management. That's a significant saving!

- Forecast Material Requirements: Let’s talk about using BOM data to predict material needs based on your manufacturing schedules. This proactive approach can help you avoid overstocking and shortages, making resource use more efficient. Accurate BOM management enhances planning and scheduling, aligning material needs with lead times. A case study on 'Better Cost Estimating and Tracking' illustrates how BOM management is essential for estimating and monitoring material and labor costs during manufacturing.

- Implement Just-in-Time (JIT) Stock Management: Have you considered adopting JIT principles? This strategy synchronizes deliveries with production schedules, cutting down on carrying costs and waste. With JIT, manufacturers can keep leaner stock levels while ensuring timely availability of components. Effective JIT implementation can significantly boost profitability—studies show that just a 10% reduction in lead time can lead to a 7% profit increase.

- Monitor Performance Metrics: Regularly checking performance indicators related to BOM and stock control is crucial. By monitoring metrics like turnover ratios and stockout rates, you can gain insights into operational efficiency and find ways to optimize processes. Organizations that engage in ongoing performance monitoring often see improved project metrics, with 33% reporting enhancements thanks to integrated systems.

By putting these strategies into action, manufacturers can enhance their processes for BOM management and inventory oversight, leading to greater operational efficiency and better alignment with manufacturing goals. As RubinBrown points out, having a robust ERP system is key to enhancing collaboration and boosting productivity. So, what are you waiting for? Let’s get started on optimizing your processes!

Identify and Overcome Common BOM Management Challenges

When it comes to BOM management, we often encounter some common hurdles. Let’s take a closer look at these challenges and see how we can tackle them together.

First up, we have inaccurate data entry. Ever entered a long order and thought everything was fine, only to find out there were six errors in a 300-line-item order? That’s a 99% accuracy rate, but it still leads to problems. Imagine a 3000-item order! To avoid these headaches, consider implementing validation checks and conducting regular audits of your BOM management data. It’s all about ensuring accuracy and reliability.

Next, let’s chat about the lack of version control. Without a solid versioning system, teams might be working off outdated BOMs, which can lead to confusion. Establishing a clear versioning system for BOM management helps track changes and ensures everyone is on the same page. Plus, having defined procedures for updating and revising BOMs keeps a history of changes, which is super helpful.

Now, how about poor communication? Miscommunication between departments can lead to discrepancies in BOM data. To prevent this, let’s foster a culture of collaboration! Utilizing for BOM management can significantly enhance communication and data integrity. A unified system makes a world of difference.

Then there’s the complexity of multi-level BOMs. They can be a real challenge to manage! Simplifying the structure where possible and providing comprehensive training for staff can streamline processes and improve efficiency. Everyone benefits from a little clarity.

Lastly, we can’t forget about resistance to change. It’s natural for employees to be hesitant about new BOM oversight practices. To ease this transition, why not offer training sessions that highlight the advantages of enhanced BOM management? Show how these changes can boost overall efficiency and productivity, and you might just win them over.

So, which of these challenges resonates with you? Let’s work together to overcome them and improve our BOM management!

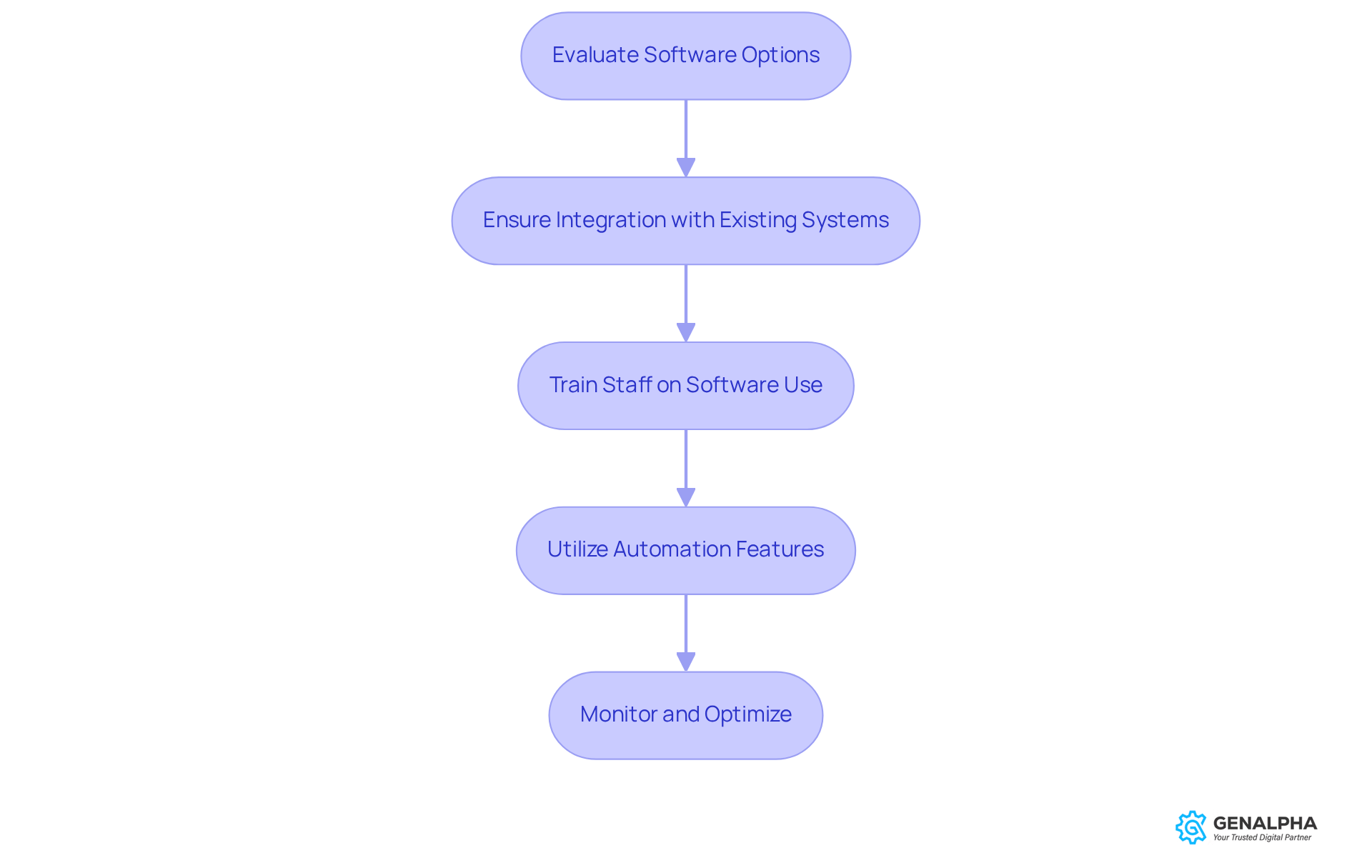

Leverage Technology: Implement BOM Management Software

Implementing BOM management software can really transform how manufacturers handle their Bill of Materials (BOM). So, how can you make the most out of this technology? Here are some key strategies to consider:

- Evaluate Software Options: Start by diving into research to compare different BOM oversight software solutions. Think about scalability, user-friendliness, and integration capabilities—these factors will help ensure that the software fits your specific operational needs.

- Ensure Integration with Existing Systems: Look for software that connects seamlessly with your current ERP and inventory control systems. This kind of integration boosts data flow, cuts down on silos, and creates a more unified operational environment.

- Train Staff on Software Use: It’s essential to provide thorough training for your team so they can effectively use the new software. Understanding its features and benefits is key to unlocking its full potential.

- Utilize Automation Features: Don’t forget to take advantage of the within the software! Streamlining data entry, updates, and reporting processes can save you time and reduce the risk of human error, ultimately enhancing overall efficiency.

- Monitor and Optimize: Regularly check in on how your BOM control software is performing. Make any necessary adjustments to optimize its use, ensuring it continues to meet your changing business needs. This proactive approach can significantly boost your operational efficiency and product management.

By following these strategies, you’ll be well on your way to harnessing the full power of BOM management software. What steps will you take first?

Conclusion

Managing a Bill of Materials (BOM) effectively is key to optimizing manufacturing processes and achieving operational excellence. Have you ever thought about how crucial BOM management really is? By grasping its significance and applying best practices, manufacturers can streamline production, improve inventory control, and boost customer satisfaction. This article highlights just how vital a well-structured BOM is for reducing errors and maximizing efficiency.

So, what are some key strategies? First off, establishing a clear hierarchical structure and standardizing naming conventions can make a world of difference. Integrating BOM with inventory management systems not only promotes clarity but also allows for real-time tracking and forecasting of material needs. Plus, don’t underestimate the power of technology! Using BOM management software can automate processes and enhance data accuracy.

As you navigate the complexities of BOM management, embracing these strategies and technologies can lead to significant gains in productivity and cost-effectiveness. Remember, the journey toward effective BOM management isn’t just about tackling challenges; it’s a chance to innovate and elevate your operational standards. By prioritizing BOM management, you can set yourself up for success in today’s competitive landscape. So, are you ready to take the next step?

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a document that outlines all the components, materials, and subassemblies required for manufacturing a product. It serves as a comprehensive guide to ensure everything is in place for production.

Why is BOM management important?

BOM management is crucial as it streamlines material management, keeps inventory in check, helps estimate costs, and ensures consistency in the manufacturing process. It also enhances quality control and supports change management.

How does effective BOM management benefit companies?

Companies that prioritize BOM management often experience less waste, improved efficiency, higher customer satisfaction, and increased loyalty.

What are digital BOM oversight tools?

Digital BOM oversight tools, such as the xBOM feature by OpenBOM, utilize automation and real-time data to streamline workflows in BOM management.

What is the expected growth of the BOM management software market?

The BOM management software market is projected to grow from $9.1 billion in 2024 to $9.64 billion in 2025, reflecting a compound annual growth rate (CAGR) of 5.9%.

What can happen if a BOM is incorrect?

An incorrect BOM can lead to costly delays in manufacturing, highlighting the importance of precision in BOM management.

What are some best practices for creating an effective BOM?

Best practices include using a hierarchical structure, standardizing naming conventions, assigning unique part numbers, providing detailed descriptions for each item, and regularly updating the BOM.

Why is a hierarchical structure beneficial for BOMs?

A hierarchical structure organizes the finished product at the top with subassemblies and components below, making it clearer and helping departments stay aligned.

How does standardizing naming conventions help in BOM management?

Standardizing naming conventions reduces confusion and makes it easier for team members to recognize components, which aids in maintaining precision in operations.

What is the importance of assigning unique part numbers?

Assigning unique part numbers helps streamline tracking and keeps the BOM organized, preventing errors from duplicate or unclear identifiers.

Why should BOMs be regularly updated?

Regularly updating the BOM is essential to reflect any changes in materials or processes, maintaining accuracy and relevance to avoid production delays.

What common pitfalls should be avoided in BOM oversight?

Common pitfalls include challenges with version control and the need for effective collaboration among teams, which can hinder optimal BOM practices.