Overview

Have you ever wondered how manufacturers can keep up with the fast-paced world of production? The article titled "10 Benefits of PLM Product Lifecycle Management for Manufacturers" dives into the many perks that Product Lifecycle Management (PLM) systems bring to the table. From enhanced collaboration to improved operational efficiency and better sustainability practices, these tools are game-changers. They not only streamline processes but also boost overall productivity and customer satisfaction in the manufacturing sector.

Imagine a world where teams work seamlessly together, sharing insights and ideas effortlessly. That’s the magic of PLM! By fostering collaboration, manufacturers can tackle challenges head-on and innovate like never before. Plus, with improved operational efficiency, businesses can save time and resources, allowing them to focus on what truly matters—delivering quality products to their customers.

Sustainability is another crucial aspect that PLM addresses. As more companies aim to reduce their environmental footprint, these systems help implement better practices that benefit both the planet and the bottom line. It’s a win-win situation!

So, if you’re in the manufacturing game, it might be time to consider how PLM can transform your operations. What are you waiting for? Dive into the world of Product Lifecycle Management and unlock your company’s potential!

Introduction

Manufacturers today are navigating a landscape filled with challenges and opportunities. Efficiency and innovation are key, right? That's where Product Lifecycle Management (PLM) comes into play. It’s not just a fancy term; it’s a vital strategy that can really transform how companies manage their products from start to finish.

In this article, we’ll dive into ten compelling advantages of PLM. You’ll see how it streamlines processes, enhances collaboration, and even supports sustainability while speeding up time-to-market. As the industry evolves, you might be wondering: how can manufacturers harness these benefits to stay competitive and meet the ever-changing demands of their customers? Let’s explore together!

GenAlpha Technologies: Streamline Product Lifecycle Management with Digital Solutions

At GenAlpha Technologies, we’re all about providing digital solutions that really make a difference in PLM product lifecycle management for producers. Imagine having Equip360 at your fingertips, along with handy tools like:

- Digital 2D and 3D bills of materials catalogs

- RMA

- Warranty

- Configurator tools

With these resources, managing item data becomes a breeze! This means that PLM product lifecycle management ensures every stage of the lifecycle is optimized for maximum efficiency, leading to happier customers.

And guess what? Our recent collaboration with Optessa takes this commitment to the next level! It’s all about boosting operational efficiency, helping producers adapt quickly and stabilize their supply chains. This integration not only streamlines workflows but also by providing timely and accurate information throughout the purchasing journey.

As industry leaders often point out, using digital tools in managing goods can significantly impact efficiency and customer engagement. The result? A major boost in productivity and customer satisfaction, empowering producers to thrive in today’s competitive landscape. So, how are you planning to leverage these tools in your own operations?

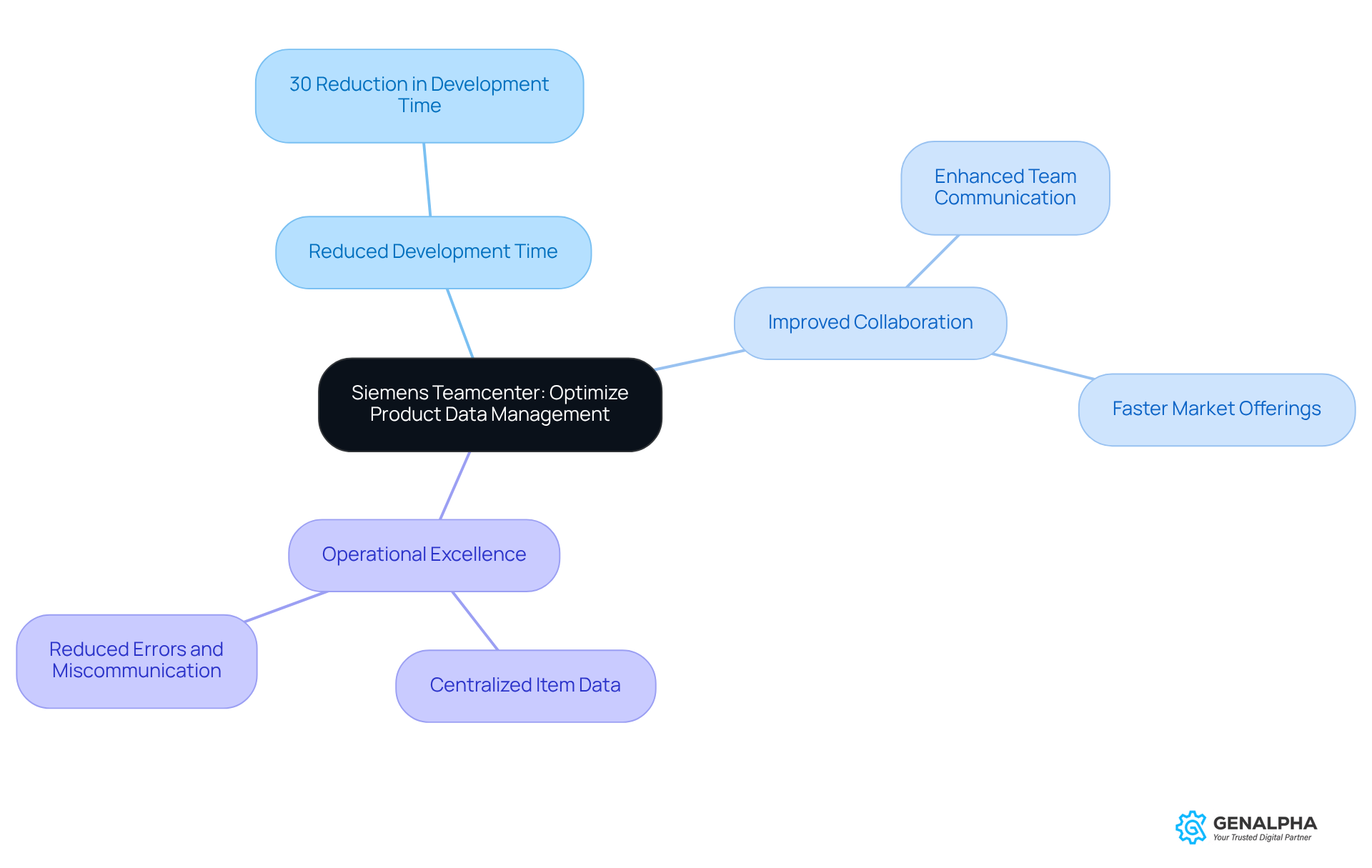

Siemens Teamcenter: Optimize Product Data Management for Enhanced Efficiency

Have you ever felt overwhelmed by the sheer volume of information your team has to manage? Siemens Teamcenter is here to help! It’s a powerful PLM (Product Lifecycle Management) solution that simplifies information management, enabling producers to maintain accurate and up-to-date details across all departments. By centralizing item data, Teamcenter cuts down on errors and miscommunication, which means quicker decision-making and better quality. This kind of optimization is crucial for producers looking to stay ahead in a fast-paced market.

Recent studies from Siemens Digital Industries Software reveal that can lead to a whopping 30% reduction in development time. That’s a big deal! It really shows how Teamcenter contributes to operational excellence. For equipment manufacturers facing challenges in innovation and adaptation, implementing PLM through Teamcenter can significantly boost efficiency and results. Imagine improved collaboration among teams and getting new offerings to market faster.

So, why not consider Teamcenter for your organization? It could be the game-changer you’ve been looking for!

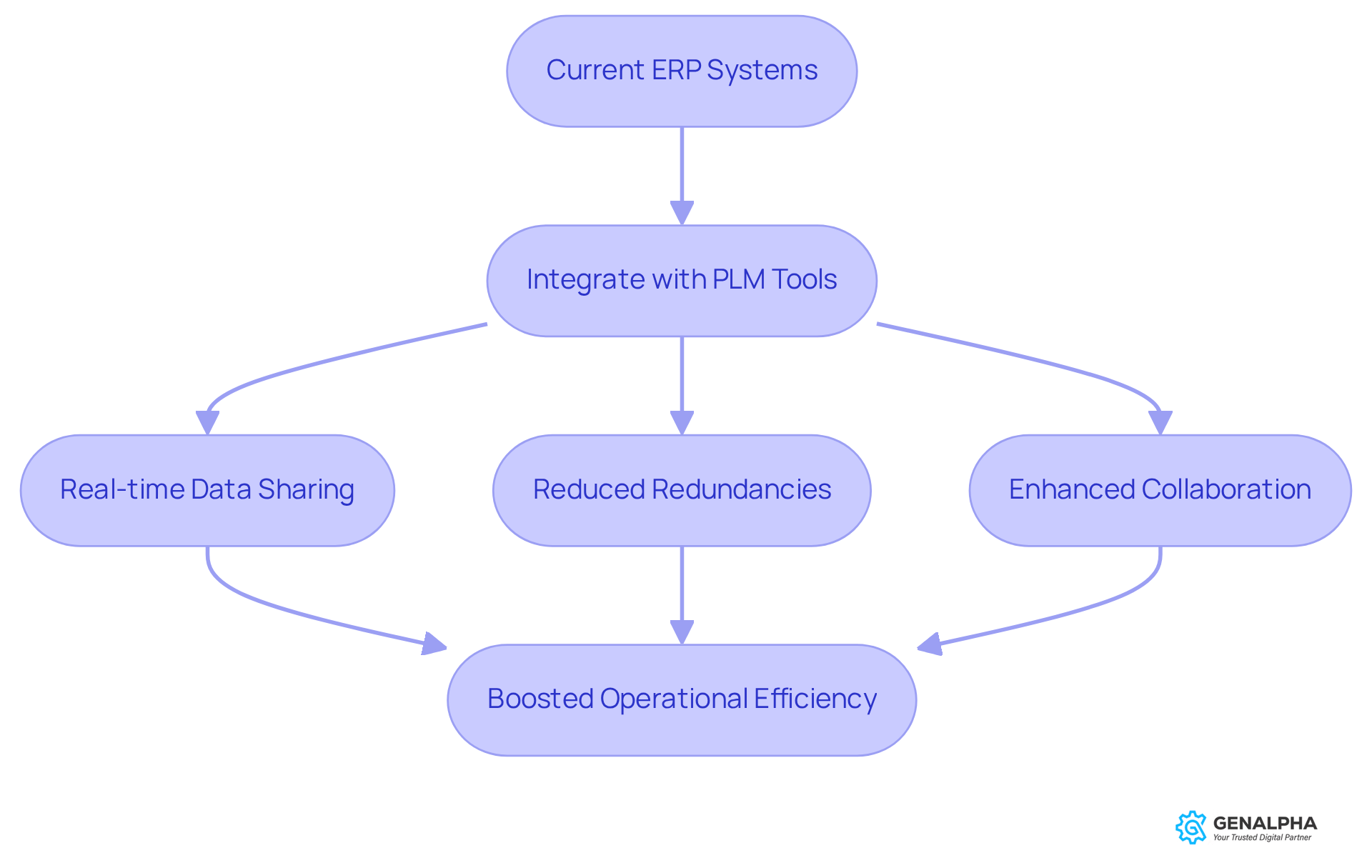

Integration with ERP Systems: Enhance Operational Efficiency through PLM

Are you integrating your current ERP systems with PLM product lifecycle management tools? That's a game changer for boosting operational efficiency! Imagine this: real-time data sharing between departments. It’s like having a well-oiled machine—reducing redundancies and enhancing collaboration.

Manufacturers can really tap into this synergy provided by PLM product lifecycle management to streamline workflows, cut down on delays, and keep every team in sync with the latest info about offerings. This isn’t just about efficiency; it’s about and satisfaction. So, why not explore how this integration can work for you?

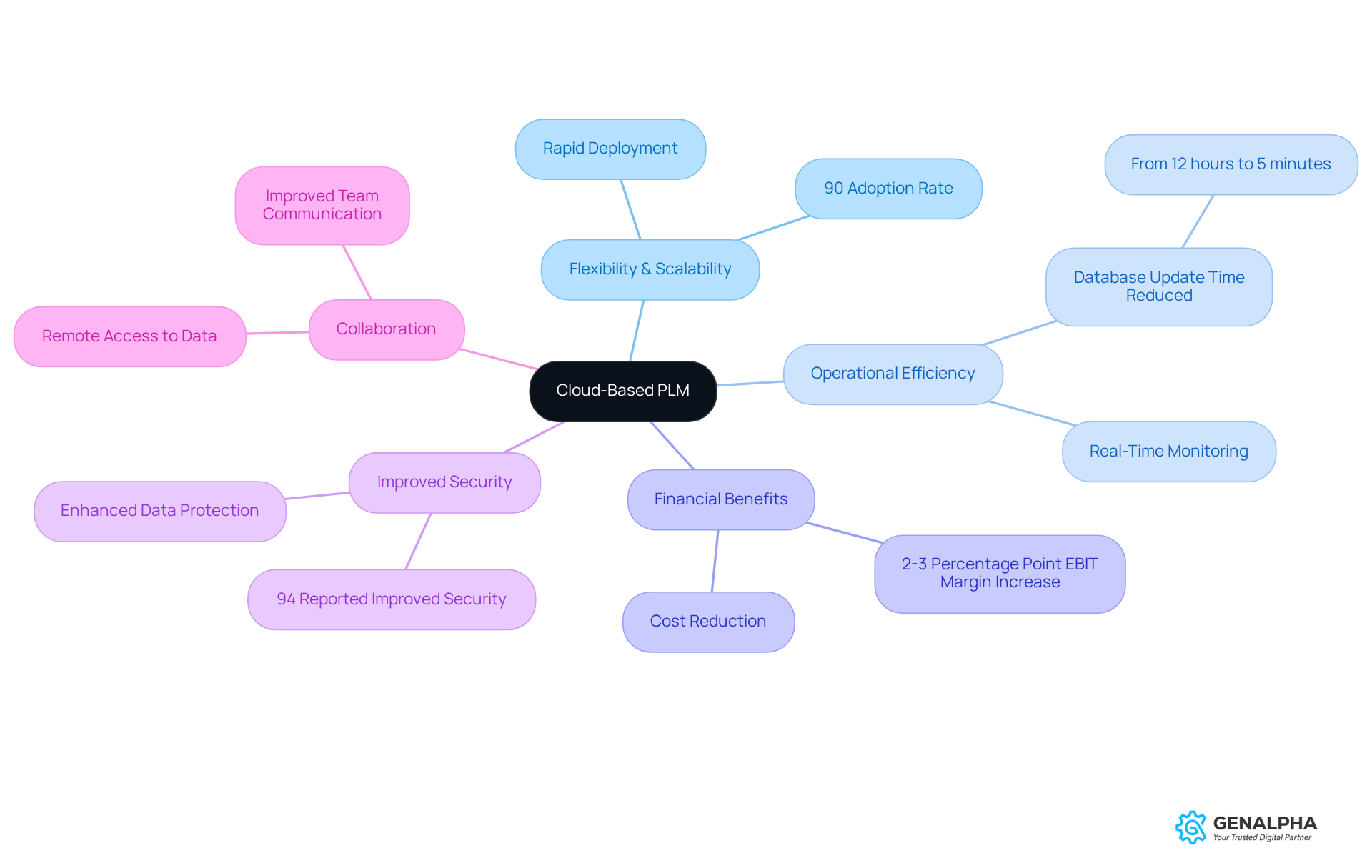

Cloud-Based PLM: Achieve Flexibility and Scalability for Modern Manufacturing

Cloud-based PLM product lifecycle management solutions are a game-changer for producers, offering the flexibility and scalability needed to thrive in today’s fast-paced market. Imagine being able to access crucial item data from anywhere—how much easier would that make remote collaboration and decision-making? This adaptability allows businesses to quickly scale operations, whether they're launching new product lines or venturing into new markets, all without hefty infrastructure costs.

Take, for instance, a global manufacturing client managing 700 warehouses and 235 factories across 60 countries. They managed to cut down database update times from over half a day to just about five minutes thanks to a cloud-based system. That’s a clear demonstration of the operational efficiencies that cloud technology can bring!

But it doesn’t stop there. Cloud computing can boost EBIT margins in manufacturing by 2 to 3 percentage points, highlighting the financial perks of adopting these technologies. As more producers jump on the cloud bandwagon—about 90% have either set up or are in the process of setting up cloud computing—they’re finding better collaboration and responsiveness in their operations.

And here’s a reassuring fact: 94% of businesses reported improved security after transitioning to the cloud. This just reinforces the idea that in the industry. So, are you ready to embrace the cloud and unlock these advantages for your business?

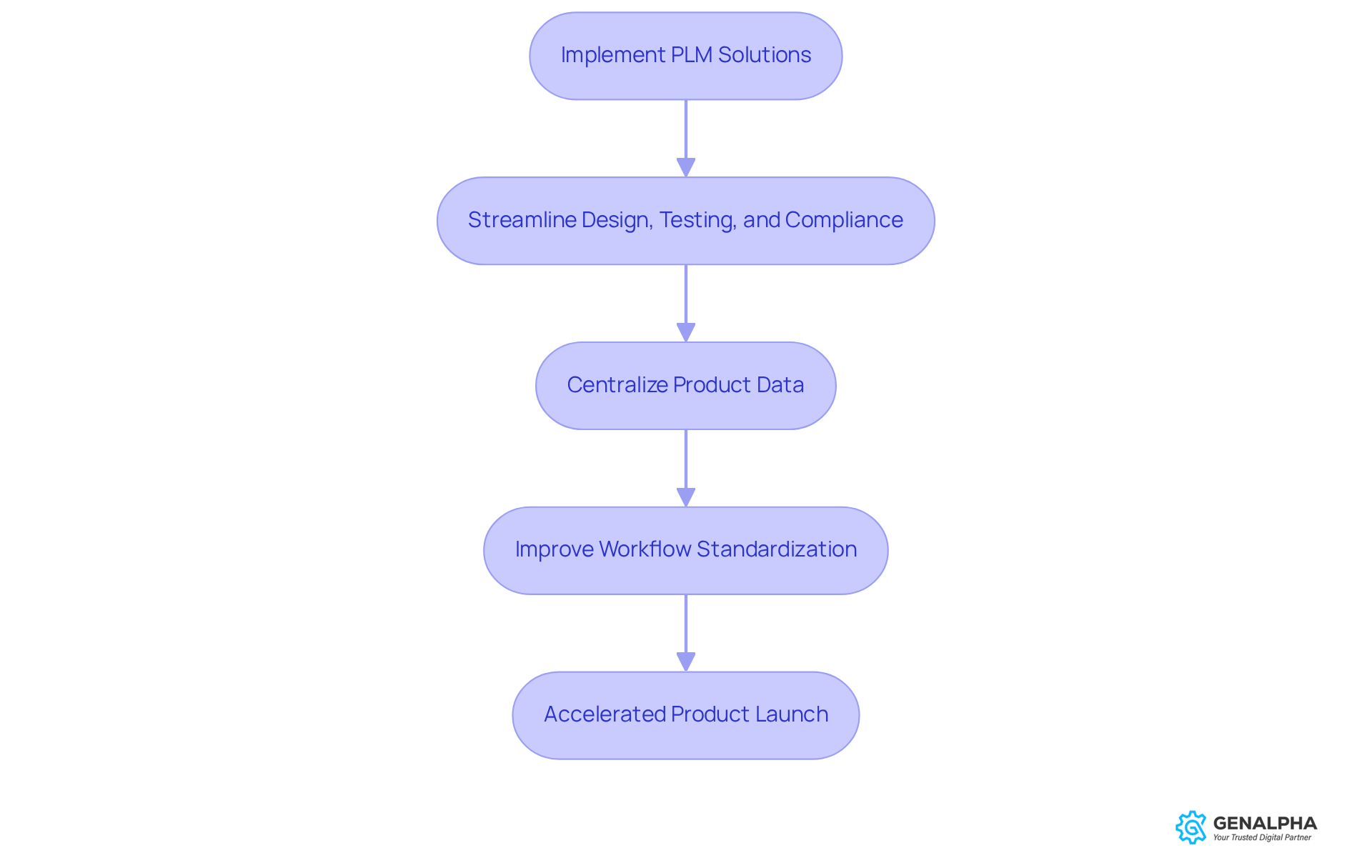

Reduced Time-to-Market: Accelerate Product Launches with PLM

Have you ever thought about how quickly businesses need to get their products to market? Implementing PLM (Product Lifecycle Management) solutions can significantly accelerate processes by streamlining essential activities such as design, testing, and compliance. This means manufacturers can jump on market opportunities faster, which ultimately boosts customer satisfaction with timely deliveries that meet consumer needs.

Take Petroleum Geo-Services (PGS) as an example. They successfully integrated Aras Innovator to tackle their complex PLM processes. This move not only gave them a unified bill of materials but also centralized all product-related data. The result? A significant improvement in workflow standardization and revision control.

Additionally, PGS's extensive MultiClient data library made data management and accessibility a breeze, leading to more efficient launches. So, when it came time to deploy their seismic survey equipment, they did so with greater efficiency. This really highlights how can lead to quicker launches and provide a competitive edge in the market. Isn’t it fascinating how technology can transform the way we work?

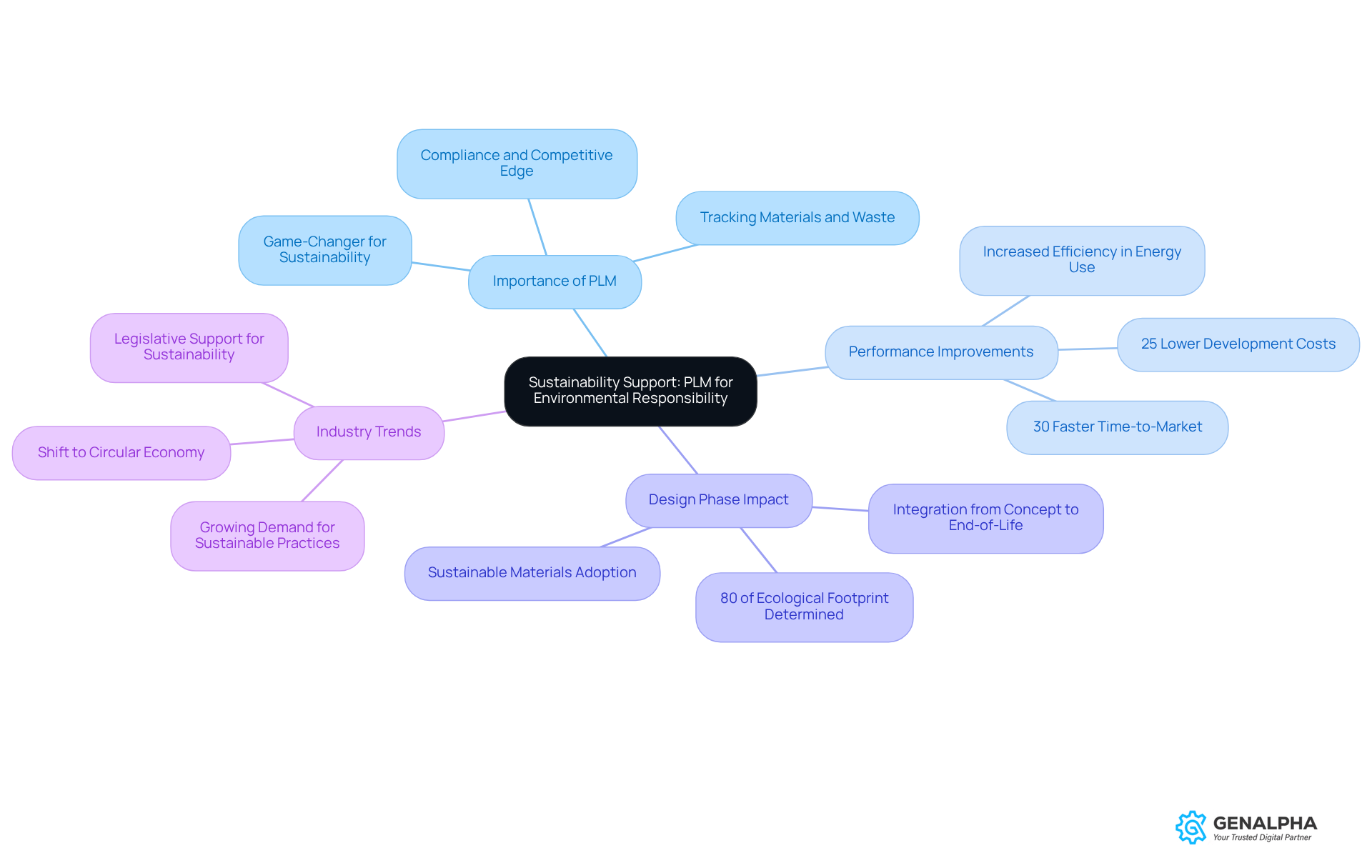

Sustainability Support: Leverage PLM for Environmental Responsibility

Have you ever thought about how important PLM (Product Lifecycle Management) solutions are for achieving sustainability in manufacturing? They’re not just tools; they’re game-changers! By helping producers keep a close eye on materials, energy use, and waste throughout a product's lifecycle, these systems empower informed decisions that can significantly reduce environmental impact. This proactive approach doesn’t just tick off regulatory boxes; it aligns perfectly with what customers expect from responsible businesses.

For instance, producers using PLM have reported up to 30% faster time-to-market and a 25% drop in development costs. Talk about a win-win for both operational efficiency and sustainability! As Joseph Prock, a Sr. Marketing Content Writer for PTC, puts it, "No longer is going green a nice thing to have as a marketing incentive—it’s become a necessity."

As we see the industry leaning towards a circular economy, integrating sustainability right from the design phase is crucial. Did you know that 80% of a product's ecological footprint is determined during this stage? That’s why it’s exciting to note that 67% of C-suite executives are increasingly opting for sustainable materials. This trend reflects a broader .

By harnessing PLM tools, producers can effectively track and enhance their sustainability initiatives. This not only ensures compliance with evolving standards but also helps build a competitive edge in the marketplace. So, how are you planning to integrate sustainability into your processes?

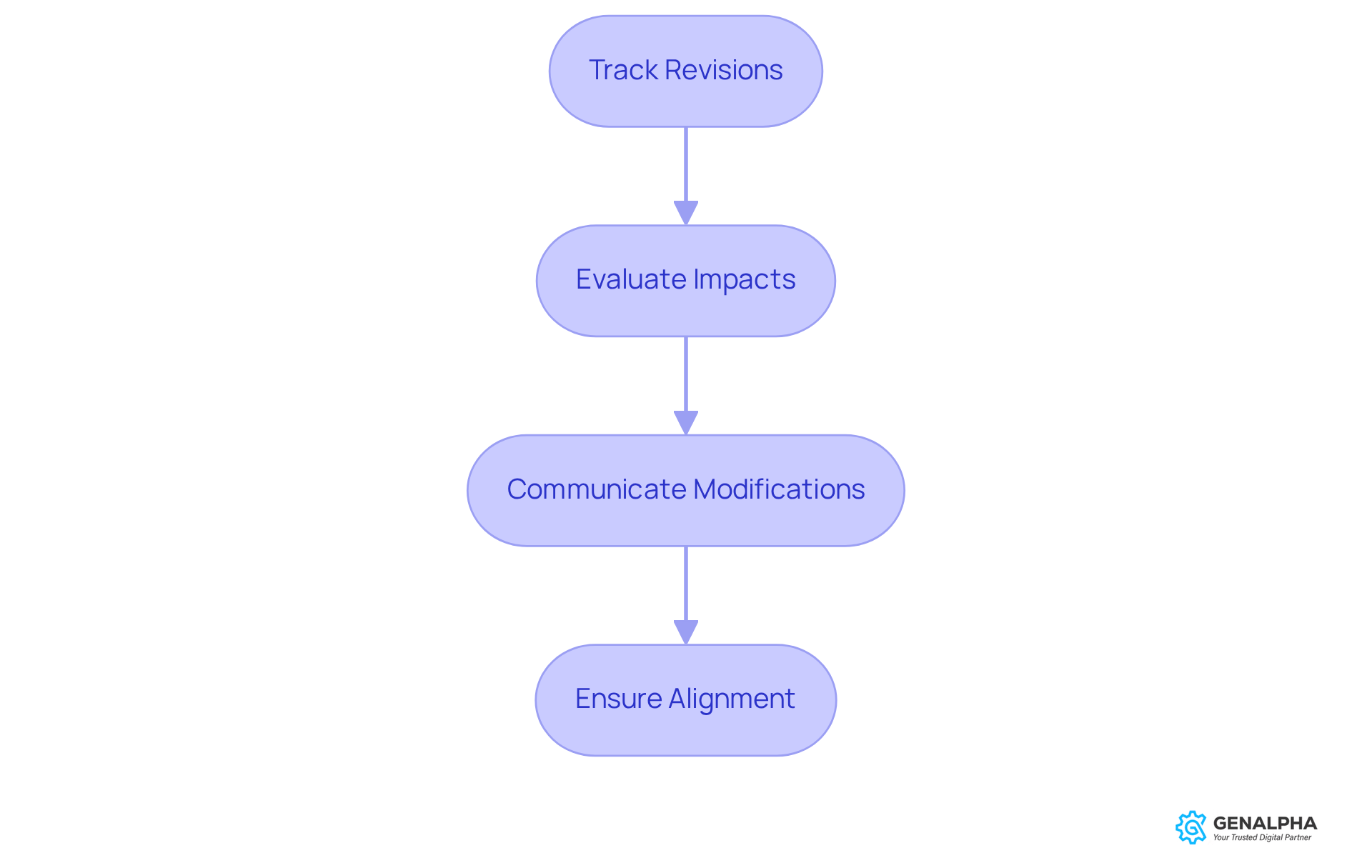

Change Management: Navigate Design Changes with PLM Solutions

Have you ever thought about how crucial PLM solutions are in managing change effectively? They provide a structured framework that helps teams handle design changes with ease. Imagine manufacturers being able to track revisions meticulously, evaluate impacts, and communicate modifications seamlessly across teams. This kind of ensures everyone stays informed and aligned, which is key to minimizing mistakes and maintaining quality—something every customer values.

For example, companies that embrace strong PLM systems often see a drop in costly rework and experience better collaboration among departments. This leads to improved operational efficiency. As industry leaders emphasize, mastering design change management is essential in today’s complex manufacturing landscape. After all, timely and precise communication can make a huge difference in development outcomes. So, how are you managing design changes in your organization?

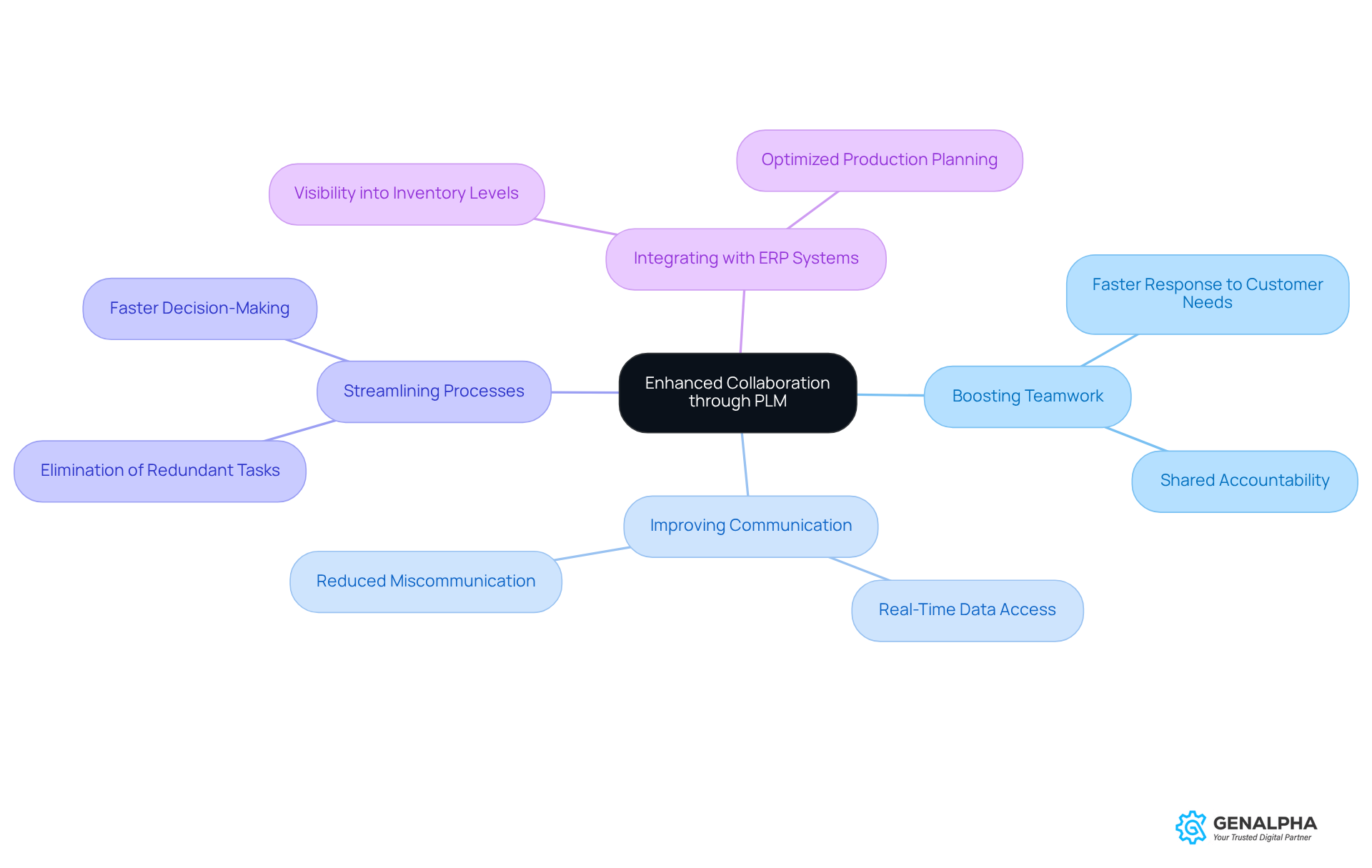

Enhanced Collaboration: Foster Team Alignment through PLM

Have you ever thought about how teamwork can truly make or break a project? PLM product lifecycle management solutions are a game changer in this regard, significantly boosting collaboration among teams by providing a centralized platform for sharing information and resources. This not only enhances communication but also fosters the kind of collaboration that's essential for innovative development. When teams come together effectively, they can respond swiftly and accurately to customer needs, leading to greater satisfaction and loyalty.

As Phil Jackson wisely said, "The strength of the team is each individual member. The strength of each member is the team." This really highlights how is for achieving shared goals. Just look at real-world examples: organizations that have embraced PLM product lifecycle management software in various industries have seen remarkable improvements in team alignment. Take, for instance, the case study on PLM product lifecycle management software in discrete industries. It shows how this integration streamlines processes, cuts down on miscommunication, and eliminates redundant tasks, ultimately leading to a more efficient workflow.

Additionally, the ability of PLM product lifecycle management software to integrate with ERP systems enhances collaboration even further. It provides visibility into inventory levels and supplier performance, which is vital for industries that need to comply with strict regulations. And let’s not forget the statistics—PLM software significantly reduces time-consuming bottlenecks and speeds up time to market. This really emphasizes its importance in the development landscape. So, why not consider how PLM solutions could transform your team's collaboration and efficiency?

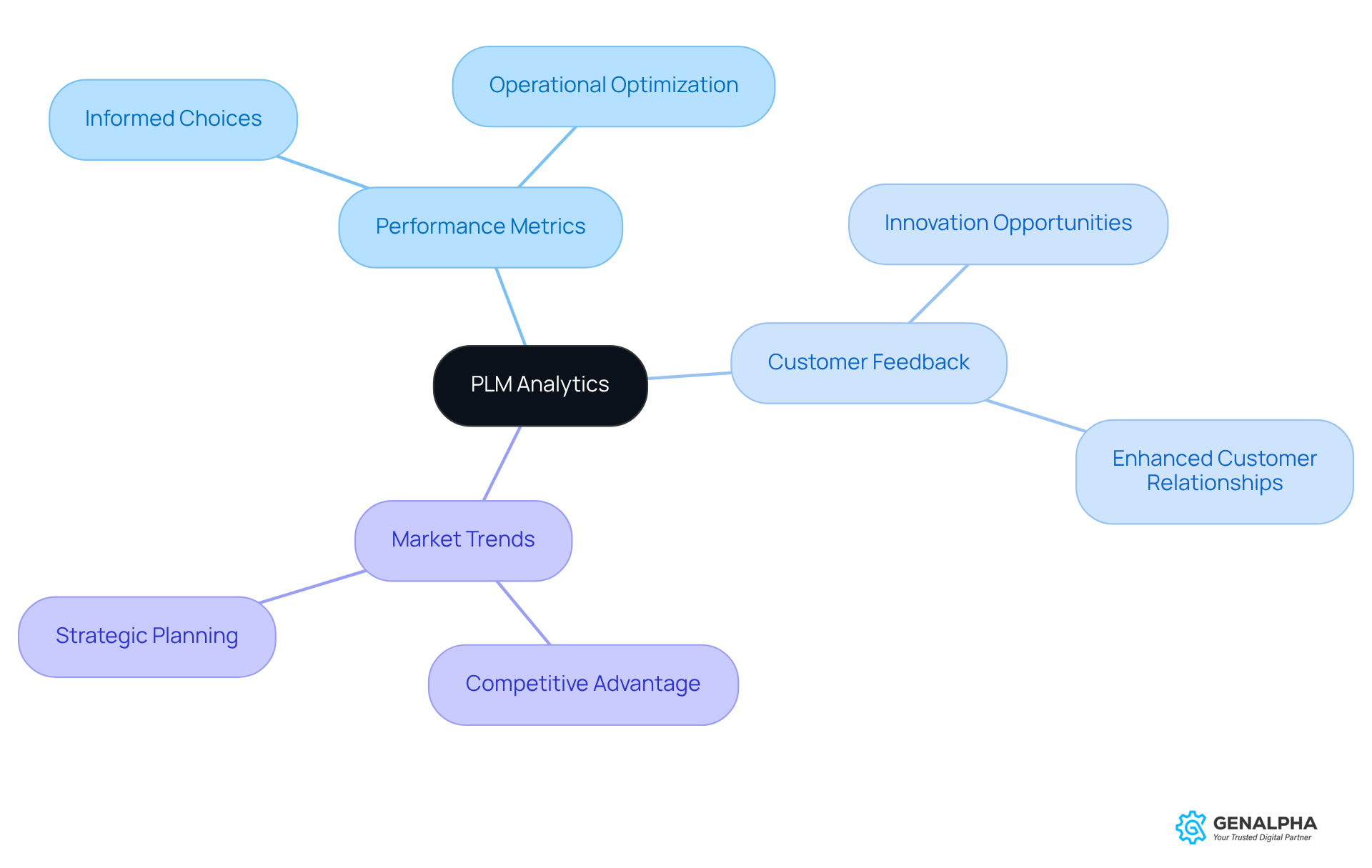

Data-Driven Insights: Improve Decision-Making with PLM Analytics

Have you ever wondered how some manufacturers seem to make all the right moves? Well, that’s where PLM (Product Lifecycle Management) analytics come into play! These tools offer producers data-driven insights that can really enhance decision-making processes. By digging into performance metrics, customer feedback, and market trends, manufacturers can make informed choices to optimize their operations.

Imagine being able to spot areas for improvement almost effortlessly! With these insights, businesses can recognize where they can innovate and ultimately deliver superior offerings to their customers. So, why not take a closer look at how PLM analytics can transform your approach? You might just find the key to !

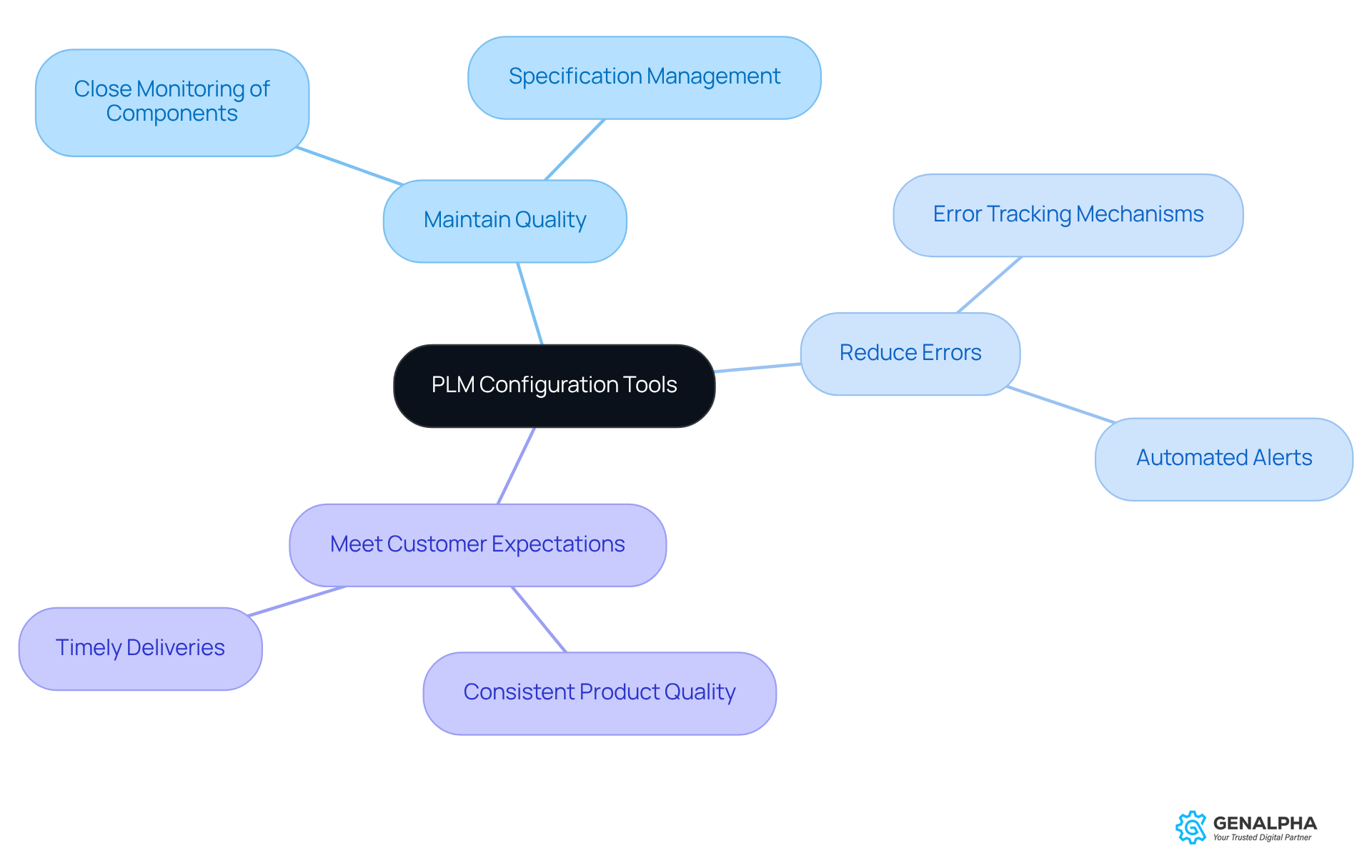

Complex Product Management: Maintain Quality with PLM Configuration Tools

Managing intricate items can feel overwhelming, right? But that's where robust configuration tools from PLM (Product Lifecycle Management) solutions come into play. These help producers maintain quality by ensuring that every component and specification is closely monitored and managed. By utilizing PLM configuration tools, manufacturers can not only reduce errors but also enhance product quality. And who doesn’t want to meet customer expectations consistently? So, why not explore how these tools can make your life easier?

Conclusion

Implementing Product Lifecycle Management (PLM) solutions is essential for manufacturers looking to boost their operational efficiency and keep customers happy. Imagine leveraging digital tools and integrations to streamline processes, cut down on time-to-market, and enhance collaboration across teams. By adopting PLM, you’re not just optimizing workflows; you’re also supporting sustainability initiatives, making it a crucial asset in today’s competitive landscape.

Throughout this article, we’ve highlighted some key benefits of PLM. For instance, think about:

- Improved data management with tools like Siemens Teamcenter

- Enhanced operational efficiency through ERP integration

- Flexibility offered by cloud-based solutions

- Importance of data-driven insights for informed decision-making and managing complex products

Each of these aspects contributes to a well-rounded approach that empowers manufacturers to adapt and thrive.

As the manufacturing industry continues to evolve, embracing PLM solutions isn’t just a nice-to-have—it’s a must. By integrating these systems into your operations, you can set your business up for success, meet customer demands effectively, and play a positive role in environmental sustainability. So, what are you waiting for? Explore how PLM can transform your processes and drive your business forward!

Frequently Asked Questions

What is GenAlpha Technologies focused on?

GenAlpha Technologies is focused on providing digital solutions for product lifecycle management (PLM) that enhance efficiency for producers.

What tools does GenAlpha Technologies offer for PLM?

GenAlpha Technologies offers tools such as Equip360, digital 2D and 3D bills of materials catalogs, RMA, warranty, and configurator tools to help manage item data effectively.

How does GenAlpha Technologies improve customer experience?

By collaborating with Optessa, GenAlpha Technologies boosts operational efficiency, enabling producers to adapt quickly and stabilize their supply chains, which enhances the customer experience with timely and accurate information.

What are the benefits of using digital tools in PLM?

Digital tools in PLM significantly impact efficiency and customer engagement, leading to increased productivity and customer satisfaction for producers.

What is Siemens Teamcenter?

Siemens Teamcenter is a powerful PLM solution that simplifies information management by centralizing item data, helping producers maintain accurate and up-to-date details across departments.

How does Siemens Teamcenter improve decision-making?

By reducing errors and miscommunication, Siemens Teamcenter allows for quicker decision-making and better quality, which is essential for producers in a fast-paced market.

What impact can effective data management strategies have according to Siemens?

Effective data management strategies can lead to a 30% reduction in development time, demonstrating how Teamcenter contributes to operational excellence.

How can integrating ERP systems with PLM enhance operational efficiency?

Integrating ERP systems with PLM allows for real-time data sharing between departments, reducing redundancies and enhancing collaboration, which streamlines workflows and improves customer service.

What is the overall goal of integrating PLM with ERP systems?

The goal is to boost operational efficiency, cut down on delays, and keep teams synchronized with the latest information about offerings, ultimately elevating customer satisfaction.