Overview

Have you ever thought about how crucial product data management is in manufacturing? It’s all about getting the data right, working together, and using analytics to boost efficiency and keep customers happy. Imagine a world where your decisions are backed by accurate data, and your team collaborates seamlessly! That’s the power of effective strategies in this space.

For instance, consider how ERP integration and automated validation tools can transform your operations. These approaches not only streamline decision-making but also ensure compliance, which is vital in today’s competitive market. Plus, they help build stronger relationships with clients. Who wouldn’t want that?

So, what’s stopping you from diving into these strategies? By embracing these tools, you can enhance your market competitiveness and create a more satisfying experience for your customers. Let’s start the conversation about how we can implement these changes together!

Introduction

In the fast-paced world of manufacturing, effective product data management isn't just a necessity; it's a strategic advantage that can really push businesses ahead of the competition. As manufacturers face growing pressure to streamline operations and enhance customer experiences, implementing solid data management strategies becomes crucial. But here’s the kicker: navigating the complexities of data accuracy, regulatory compliance, and team collaboration can be quite the challenge.

So, how can producers tap into the power of data to not only tackle these challenges but also drive significant improvements in efficiency and customer satisfaction? This article dives into ten essential strategies that can transform product data management in manufacturing, setting the stage for success in an ever-evolving marketplace.

Equip360: Streamline eCommerce Operations for Enhanced Sales Performance

Imagine a world where managing your eCommerce activities is as easy as pie. That’s exactly what Equip360 is here to do! This platform is designed to revolutionize product data management for producers, enabling them to handle their inventory, process orders, and interact with clients—all in one powerful tool. By tackling those pesky operational bottlenecks, Equip360 not only enhances user experience but also boosts sales performance. With its intuitive interface, navigating the platform feels like a breeze, allowing users to quickly discover and purchase products. In today’s competitive market, where it’s estimated that 21% of retail purchases will happen online by the end of 2025, that’s a game changer!

But wait, there’s more! Equip360 aligns with the latest eCommerce trends, where producers are increasingly utilizing dedicated sites for product data management to showcase their entire product catalogs. This approach not only ramps up visibility but also keeps clients happy—after all, did you know that 99% of online shoppers check reviews before clicking that buy button? Equip360 streamlines ordering processes, helping producers minimize administrative tasks so they can focus on what really matters: engaging with their clients through product data management. Many success stories from producers using Equip360 highlight its effectiveness in enhancing sales performance, with reports of increased efficiency and improved client interactions.

As industry experts say, "dedicated eCommerce sites enhance operational efficiencies for producers by simplifying ordering processes." By embracing Equip360, producers can set themselves up for success in the ever-evolving digital landscape, paving the way for higher sales and stronger customer relationships. So, are you ready to take the plunge and transform your eCommerce experience?

Data Accuracy: Ensure Quality Control and Compliance with Industry Standards

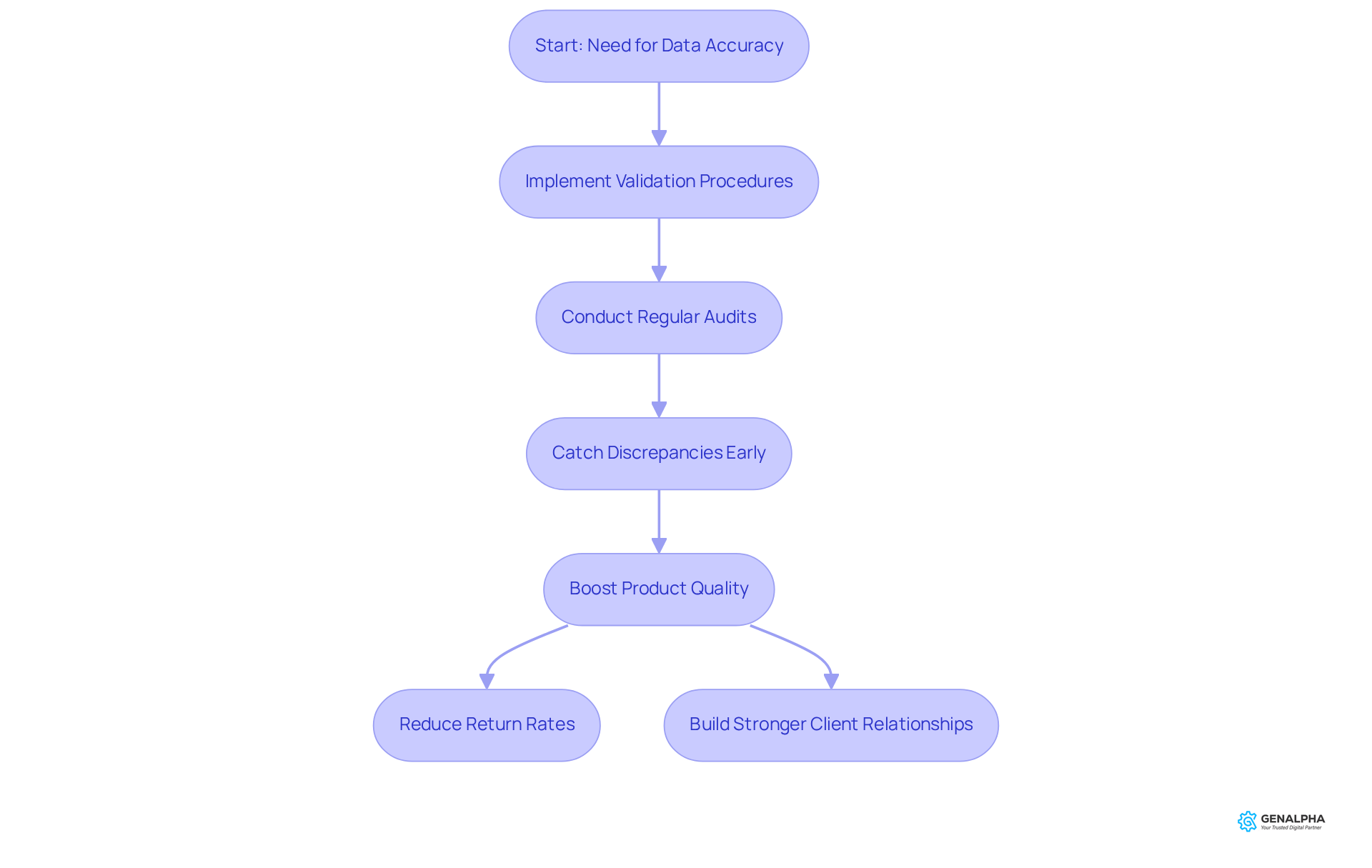

Ensuring information accuracy is super important for producers who want to keep their quality control in check and meet industry standards. Think about it: strict validation procedures and regular audits are key to catching discrepancies early on, helping to nip potential issues in the bud before they become bigger problems. When producers focus on precision, they don’t just boost product quality; they also reduce return rates and build stronger relationships with clients who appreciate reliability.

This dedication to information integrity in product data management is increasingly recognized as a best practice in the industry. Many manufacturers are now turning to advanced technologies, like automated testing tools, to make their validation processes smoother. For example, Boeing's Satellite Development Center saw a significant improvement in accuracy and saved around $200,000 in the first year alone by rolling out a PDA-based torque verification system.

Organizations that have automated their validation testing often report impressive gains in efficiency and precision. This ultimately leads to better compliance and product quality. As the manufacturing landscape evolves, maintaining high standards of product data management will be crucial for staying competitive and meeting regulatory requirements. So, why not consider implementing automated data validation tools? They could really help enhance your accuracy and efficiency!

Collaboration: Foster Teamwork to Adapt Designs and Manage Supply Chains

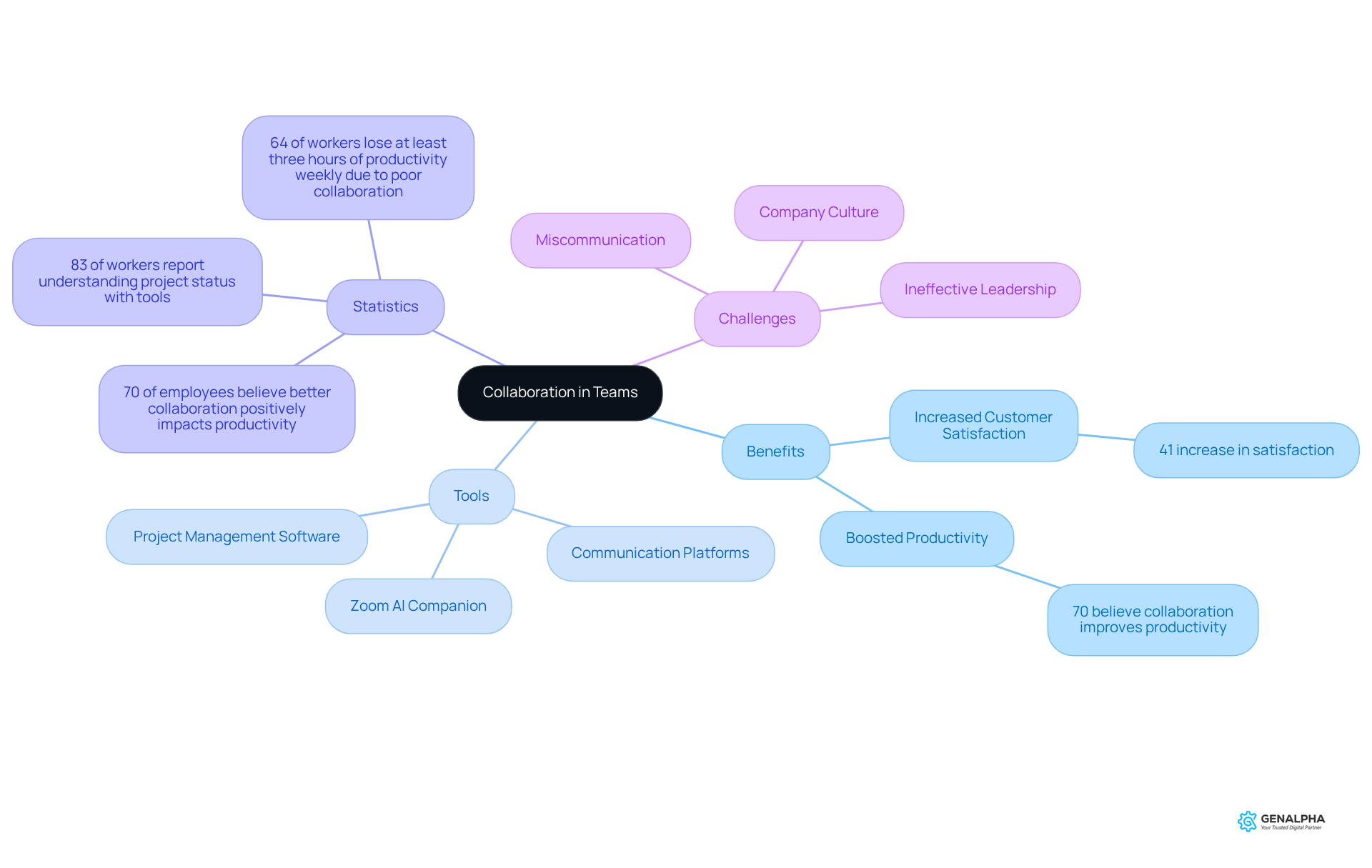

Collaboration among teams is absolutely vital for adapting designs and managing supply chains effectively. Have you ever thought about how using collaborative tools and platforms can really boost communication? When manufacturers embrace these tools, they simplify information sharing, which allows teams to react swiftly to market changes and client demands. A culture that champions collaboration not only sparks innovation but also streamlines operations, leading to happier clients. For instance, organizations that invest in team-building initiatives often see a whopping 41% increase in customer satisfaction. This really underscores the connection between effective teamwork and positive business outcomes.

Additionally, did you know that 70% of employees believe better collaboration positively impacts productivity and saves time? Tools like project management software and integrated communication platforms can significantly enhance collaboration, ensuring that everyone on the team is aligned and informed. In fact, 83% of workers report having a solid understanding of project status when using these tools. However, it's important to acknowledge that challenges like miscommunication and ineffective leadership can get in the way of collaboration. That’s why it’s crucial for managers to actively nurture a collaborative environment.

As the manufacturing landscape continues to evolve, embracing these collaborative strategies will be key to keeping a competitive edge. So, what steps can you take today to foster a more collaborative culture in your organization?

Data-Driven Insights: Enhance Decision-Making for Operational Efficiency

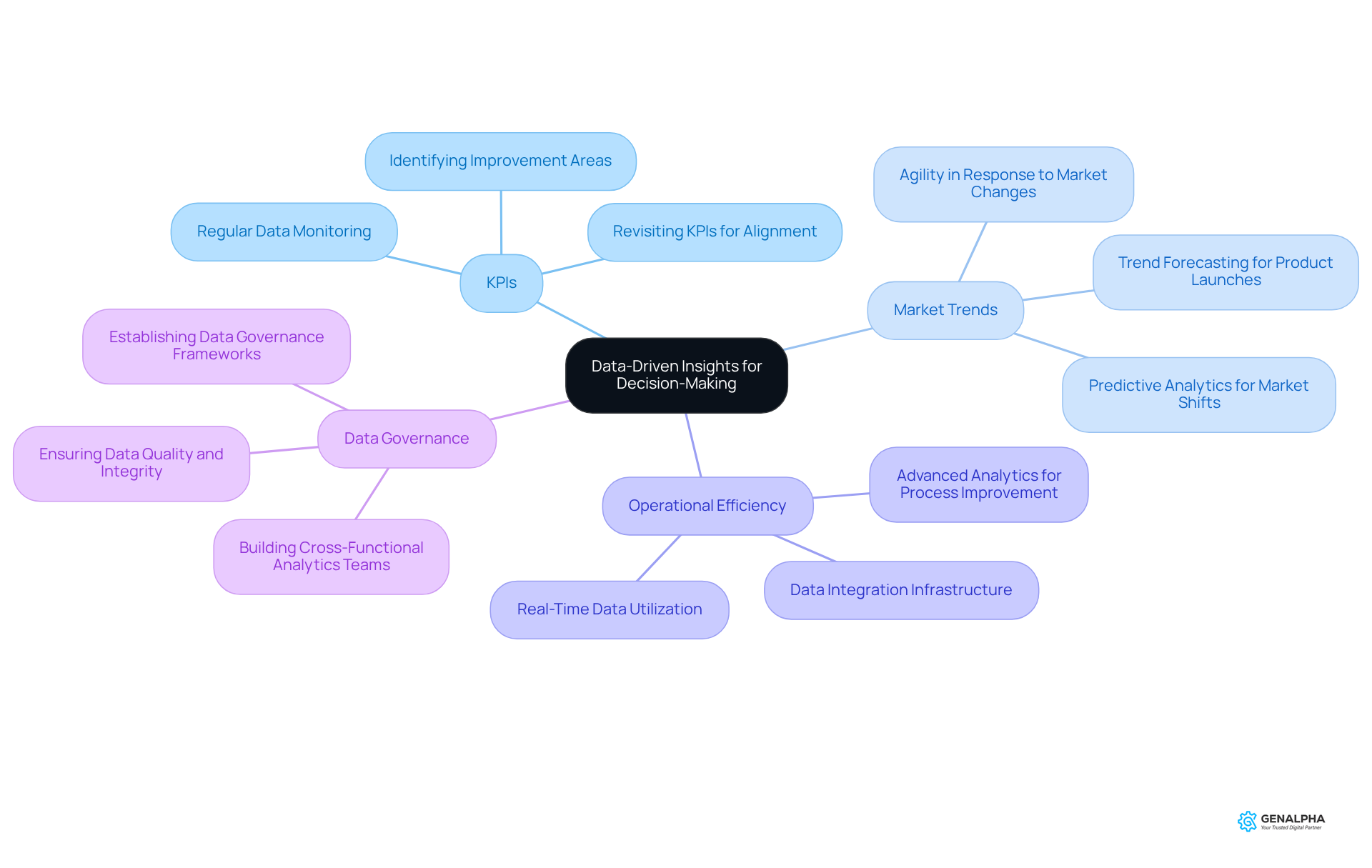

Have you ever wondered how some manufacturing operations seem to make decisions effortlessly? Harnessing product data management can truly elevate decision-making processes. By diving into key performance indicators (KPIs) and market trends, producers can spot areas that need a little TLC and roll out strategies that boost efficiency.

Regularly checking in on product data management is akin to having a pulse on the market—it enables organizations to adapt quickly to any changes that arise. This agility not only keeps them relevant but also ensures they stay competitive. So, why not take a closer look at your data and see what improvements you can make? It could be the game-changer you’ve been waiting for!

Regulatory Compliance: Navigate Legal Requirements to Stay Competitive

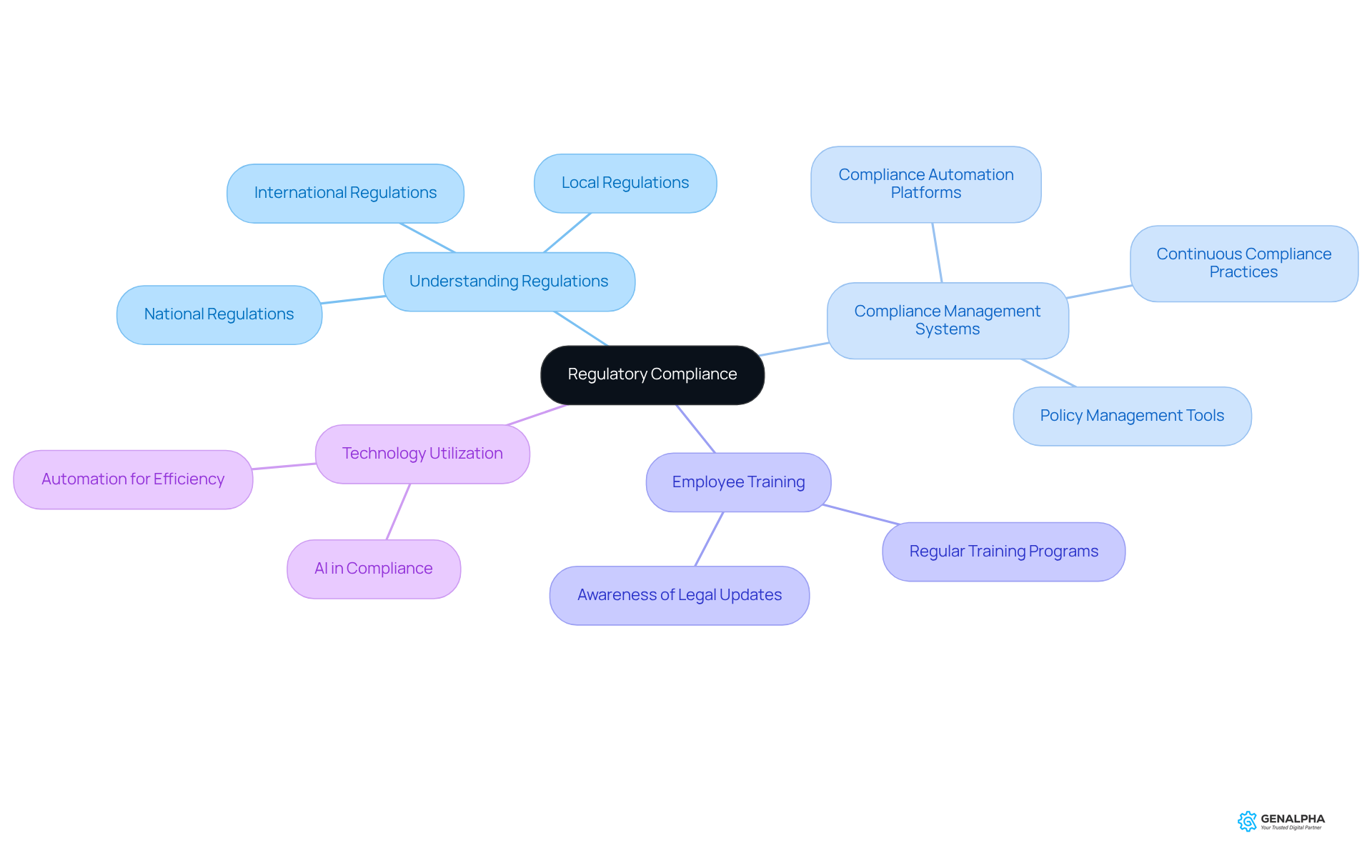

Manufacturers, have you ever felt overwhelmed by the maze of regulations out there? Staying on top of regulatory compliance is crucial for successfully navigating legal requirements. It’s all about having a solid understanding of local, national, and international regulations that impact your operations. By implementing strong compliance management systems, you not only streamline adherence to legal standards but also significantly cut down on the risks tied to non-compliance. And let’s not forget about regular employee training—this is key to fostering a culture of compliance and keeping your team informed about the latest legal updates.

For example, organizations that embrace continuous compliance practices often see a boost in operational efficiency and a drop in compliance costs. A recent survey found that 89% of users of compliance automation platforms sped up their time-to-compliance across multiple frameworks. This really shows how effective these systems can be in enhancing compliance management.

Moreover, successful producers demonstrate that proactive compliance strategies can give you a competitive edge. Take Lifearc, for instance; they achieved an impressive 87.5% attestation rate for their compliance processes. This highlights how effective policy management tools can help you stick to stringent regulations. By prioritizing compliance and leveraging technology, you can not only minimize risks but also enhance your overall operational performance, positioning yourself advantageously in a competitive marketplace. So, why not take that next step towards better compliance today?

ERP Integration: Enhance Data Accessibility and Streamline Operations

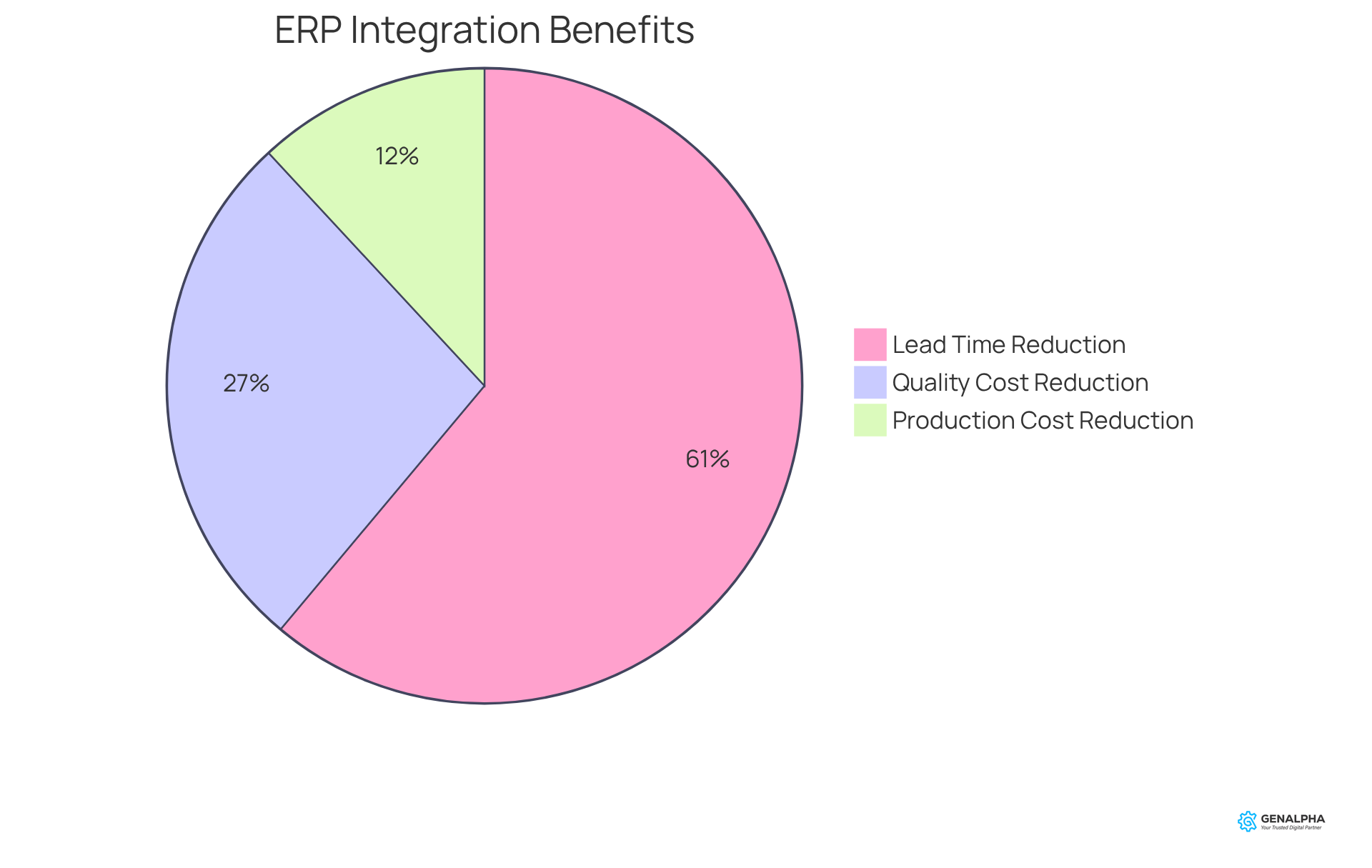

Integrating Enterprise Resource Planning (ERP) systems is super important for making information more accessible and streamlining operations in manufacturing. Imagine having real-time data at your fingertips across all departments—this can really boost collaboration and help everyone make better decisions. Plus, this integration not only optimizes inventory management and order processing but also takes customer service to the next level, which means greater operational efficiency and happier customers.

For example, a medical device producer implemented in-line quality monitoring with real-time analytics. The result? A whopping 42% reduction in quality-related costs, saving the company $12 million every year! That’s impressive, right? Manufacturers using ERP systems have reported significant reductions in lead times, with some seeing up to a 95% decrease. Brian Anderson notes, "Overall, we have seen that ERP systems can reduce manufacturing lead times by as much as 95%, a testament to their ability to transform manufacturing processes."

And there’s more! Companies that fully embrace real-time analytics can expect to cut production costs by 17-20% by 2025. Clearly, using ERP systems efficiently is a game changer, allowing producers to react quickly to market shifts and boost overall productivity. So, are you ready to explore how ERP can transform your operations?

Analytics: Optimize Processes and Boost Productivity Through Data Management

If you're a producer looking to boost your processes and productivity, employing analytics tools is a game-changer. By diving into operational data, you can spot inefficiencies and uncover opportunities to improve. This proactive approach allows you to make informed, data-driven choices that not only ramp up productivity but also cut costs and enhance overall performance. And who wouldn't want a competitive edge in the marketplace?

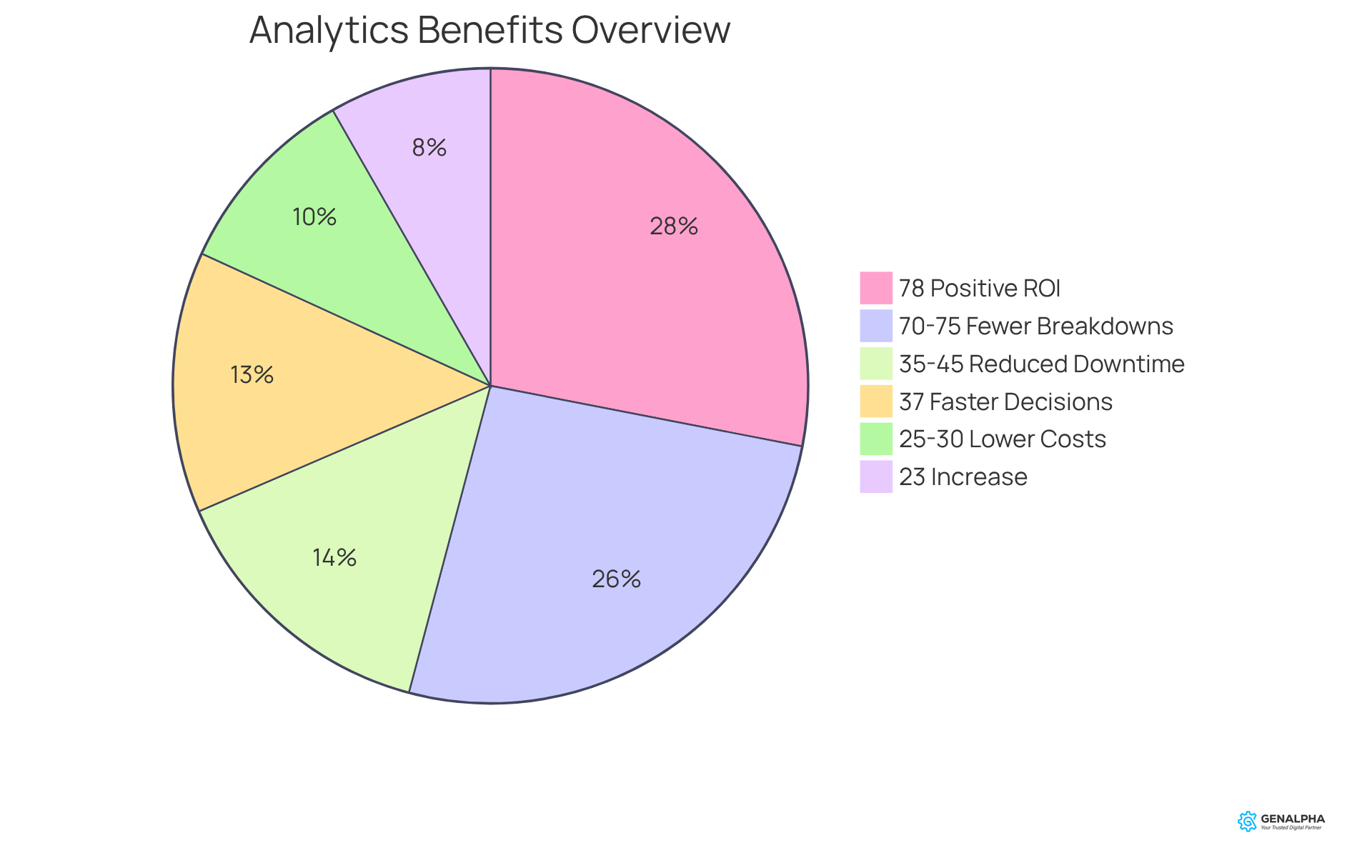

For instance, producers using augmented analytics have reported a whopping:

- 23% increase in productivity

- 37% faster decision-making process compared to those sticking with traditional reporting methods

Plus, predictive maintenance powered by analytics can reduce unplanned downtime by:

- 35-45%

- Slash maintenance costs by 25-30%

- Lower breakdowns by an impressive 70-75% compared to reactive maintenance

What’s even more exciting? A staggering 78% of producers see a positive return on investment from their augmented analytics investments within just 14 months. This really highlights how effective product data management can transform production operations.

Looking ahead, the augmented analytics market in manufacturing is set to skyrocket from $1.5 billion in 2022 to $8.26 billion by 2027. This growth underscores the increasing importance and adoption of these tools in the industry. So, are you ready to jump on the analytics bandwagon and see what it can do for your operations?

Change Management: Adapt to Evolving Market Demands Effectively

Effective change management strategies are super important for producers looking to adapt to the ever-changing market demands. So, where does it all start? It begins with getting teams ready for change, which means offering comprehensive training that gives employees the skills they need to navigate new systems and processes. Did you know that projects with great change management are nearly five times more likely to be on or ahead of schedule compared to those with poor change management? This really highlights why investing in employee development is a smart move.

Now, let’s talk about communication. It plays a key role in managing change in manufacturing environments. When messaging is clear and consistent, it helps ease employee anxiety and resistance—two common hurdles to successful transformation. In fact, about 29% of employees say that changes aren’t communicated clearly, leading to confusion and a dip in engagement. By fostering an open dialogue, producers can boost understanding and support, making transitions smoother.

But adapting to market demands isn’t just about tackling challenges; it’s also about grabbing new opportunities. For example, organizations that focus on purpose in their change initiatives are three times more likely to spark innovation and achieve long-term growth. Successful producers show flexibility by leveraging technology and analytics to enhance operations and elevate client experiences.

In summary, by creating a culture that welcomes change, investing in training, and prioritizing effective communication, producers can quickly respond to market shifts. This way, they ensure they stay competitive in a dynamic landscape. So, are you ready to embrace change and thrive?

Customer Satisfaction: Build Loyalty Through Effective Data Management

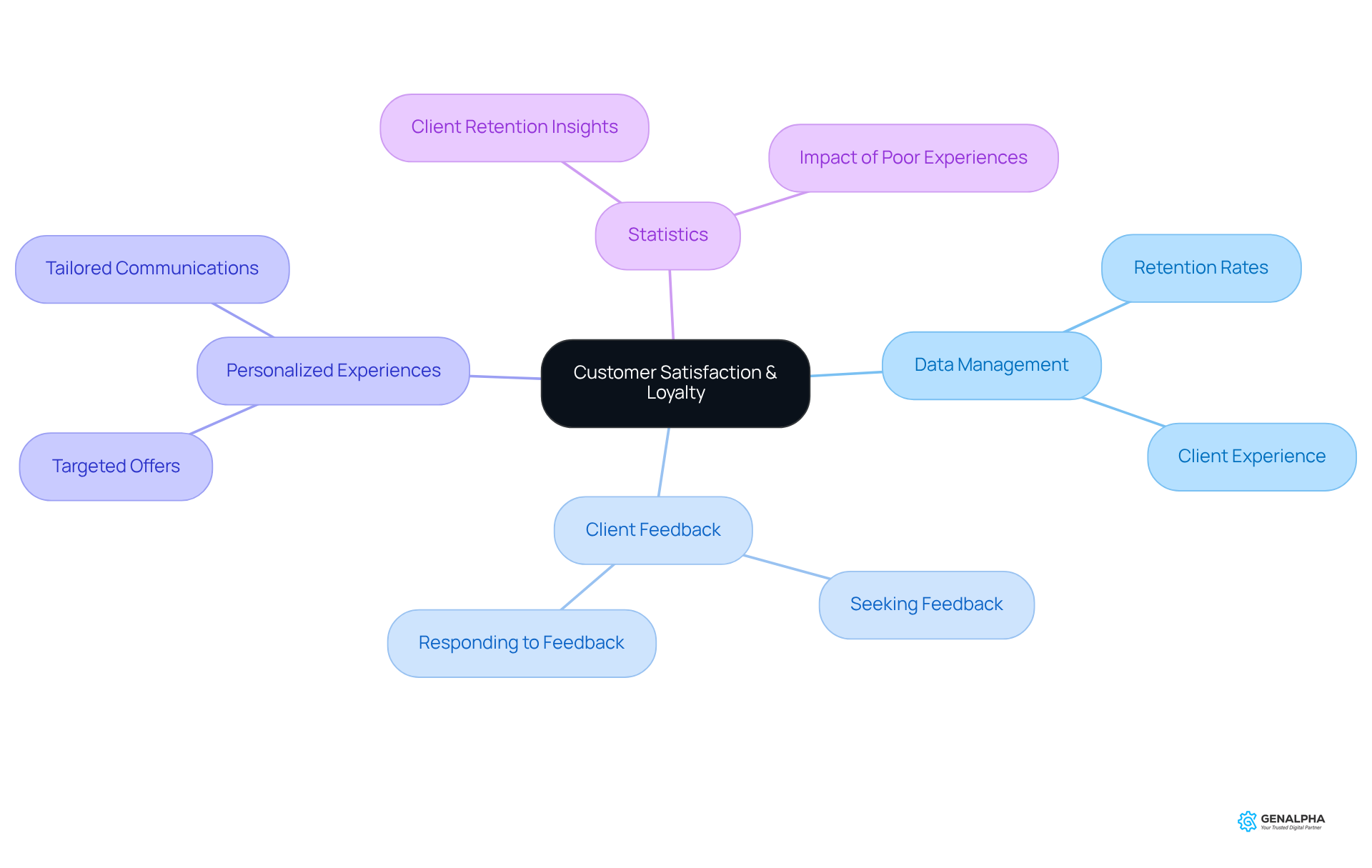

Efficient information management is super important for keeping clients happy and loyal in the manufacturing world. Imagine having precise and easily accessible client info at your fingertips—this allows manufacturers to create experiences that really resonate with individual needs. For instance, did you know that businesses using data-driven insights are six times more likely to retain clients? This really highlights the financial perks of focusing on information management.

But it doesn’t stop there! Regularly seeking and responding to client feedback not only boosts satisfaction but also builds stronger connections, leading to more repeat business. Take HNI Corporation, for example. They managed to raise client satisfaction from 72% to over 95% by adopting a client-focused approach. This shows just how impactful effective information management can be on loyalty.

Personalized experiences, like targeted offers and tailored communications, can make a huge difference in engagement too. In fact, 88% of people are more likely to stick with brands that offer personalized interactions. And in a world where 78% of clients have canceled purchases due to poor experiences, it’s clear that efficient information management is key to fostering loyalty. So, how are you managing your client information to enhance satisfaction and loyalty?

Competitive Advantage: Gain Market Share with Robust Data Management Strategies

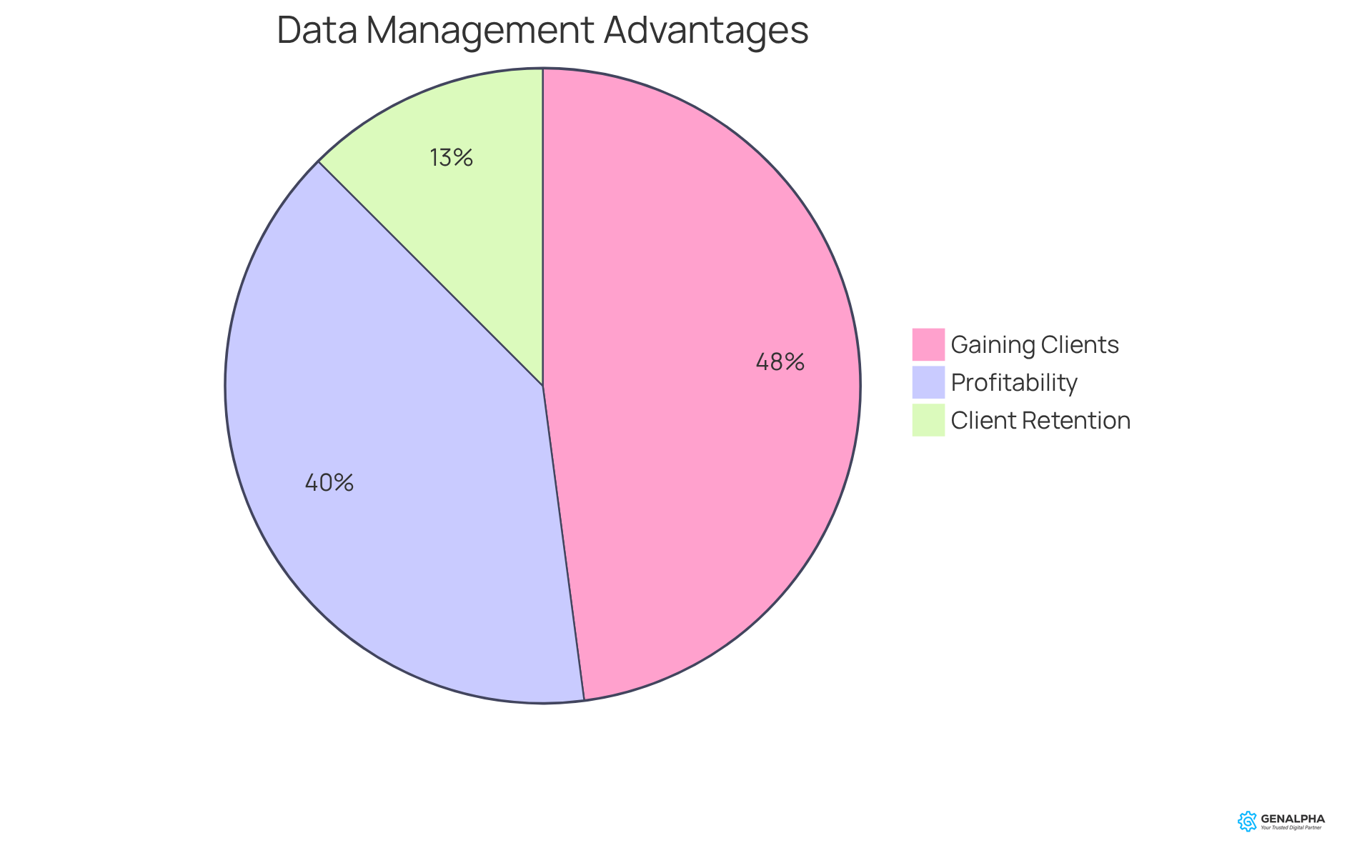

Have you ever thought about how strong information management techniques can give producers a real edge in the market? By using information wisely, manufacturers can optimize their operations, enhance client experiences, and make informed decisions. This not only sets them apart in a crowded marketplace but also boosts their efficiency. Plus, it helps them capture a bigger slice of the market and supports sustainable growth.

For example, organizations that adopt information-driven strategies are an impressive:

- 23 times more likely to gain clients

- Six times more likely to keep them

- 19 times more likely to be profitable

This really highlights how crucial information is in driving profitability. Additionally, companies that harness AI and analytics can streamline their production processes, spot bottlenecks, and even predict equipment failures, leading to better quality control and happier customers.

As Jyot Singh, a leader in data strategy, puts it, 'Data is manufacturing’s new currency, the new medium of exchange that helps shape strategy, improve operations, and ultimately get results.' This really underscores why manufacturers need to embrace data-driven methods to boost their market share and operational effectiveness. So, what steps are you taking to leverage information in your own operations?

Conclusion

In the fast-paced world of manufacturing, effective product data management isn’t just important—it’s essential for success. Imagine a scenario where manufacturers can enhance operational efficiency and boost customer satisfaction simply by prioritizing data accuracy, collaboration, and regulatory compliance. With advanced tools like Equip360, not only can eCommerce operations be streamlined, but producers can also focus on what really matters: building strong relationships with clients and quickly adapting to market demands.

Throughout this article, we've explored some key strategies. For instance,

- Data accuracy plays a crucial role in quality control.

- Collaboration can significantly improve supply chain management.

- Analytics can optimize decision-making.

- ERP integration ensures data accessibility.

- Effective change management is important in responding to the ever-evolving market conditions.

Each of these elements contributes to a holistic approach to product data management, ultimately leading to improved productivity and a competitive edge.

As the manufacturing industry continues to change, embracing these strategies is vital for staying ahead. Organizations that tap into data-driven insights and foster a culture of collaboration will not only enhance their operational performance but also secure a loyal customer base. So, what’s the takeaway? Manufacturers must prioritize effective product data management to navigate challenges and seize opportunities in this dynamic marketplace. Are you ready to take that step?

Frequently Asked Questions

What is Equip360 and what does it do?

Equip360 is a platform designed to streamline eCommerce operations for producers by managing product data, inventory, order processing, and client interactions all in one tool. It aims to enhance user experience and boost sales performance.

How does Equip360 improve sales performance for producers?

Equip360 tackles operational bottlenecks, enhances user experience, and aligns with eCommerce trends, which helps producers minimize administrative tasks and focus on client engagement, ultimately leading to increased efficiency and sales performance.

Why is data accuracy important for producers?

Data accuracy is crucial for maintaining quality control, meeting industry standards, and reducing return rates. It fosters stronger relationships with clients who value reliability.

What practices can producers implement to ensure data accuracy?

Producers can implement strict validation procedures, regular audits, and advanced technologies like automated testing tools to improve their data validation processes and enhance product quality.

How does collaboration among teams impact supply chain management?

Collaboration fosters effective communication, allowing teams to adapt designs and manage supply chains more efficiently. A collaborative culture can lead to increased innovation and improved customer satisfaction.

What tools can enhance collaboration in manufacturing?

Tools like project management software and integrated communication platforms can significantly improve teamwork and ensure that all team members are aligned and informed about project statuses.

What challenges can hinder effective collaboration in organizations?

Challenges such as miscommunication and ineffective leadership can impede collaboration, making it essential for managers to actively foster a collaborative environment.

How can manufacturers benefit from embracing collaboration?

Embracing collaboration can lead to improved productivity, faster responses to market changes, and ultimately, a competitive edge in the evolving manufacturing landscape.