Overview

The article highlights the critical role of PCNA (Process Control and Network Analysis) in achieving success within the equipment manufacturing sector by enhancing operational efficiency and quality control.

It begins by addressing the prevalent challenges faced by the industry, emphasizing the need for innovative solutions.

Through systematic integration, continuous evaluation, and comprehensive staff training, PCNA provides practical strategies that lead to improved productivity and defect detection.

For instance, organizations that have adopted these practices report significant gains in operational performance.

However, it is essential to recognize that overcoming challenges such as resistance to change is vital for maximizing the benefits of PCNA.

By addressing these obstacles head-on, manufacturers can fully leverage the transformative potential of PCNA, paving the way for a more efficient and quality-driven manufacturing process.

Introduction

In the rapidly evolving landscape of equipment manufacturing, the integration of advanced systems like Process Control and Network Analysis (PCNA) is not just beneficial but essential for operational success. As manufacturers face increasing pressures to optimize efficiency and elevate product quality, PCNA emerges as a transformative force, enabling organizations to streamline processes and enhance customer satisfaction.

However, the journey towards adopting these innovative solutions is fraught with challenges—ranging from inadequate training to resistance to change.

How can manufacturers effectively navigate these obstacles to fully leverage the benefits of PCNA? This article explores these critical issues and offers insights into overcoming the hurdles associated with PCNA implementation.

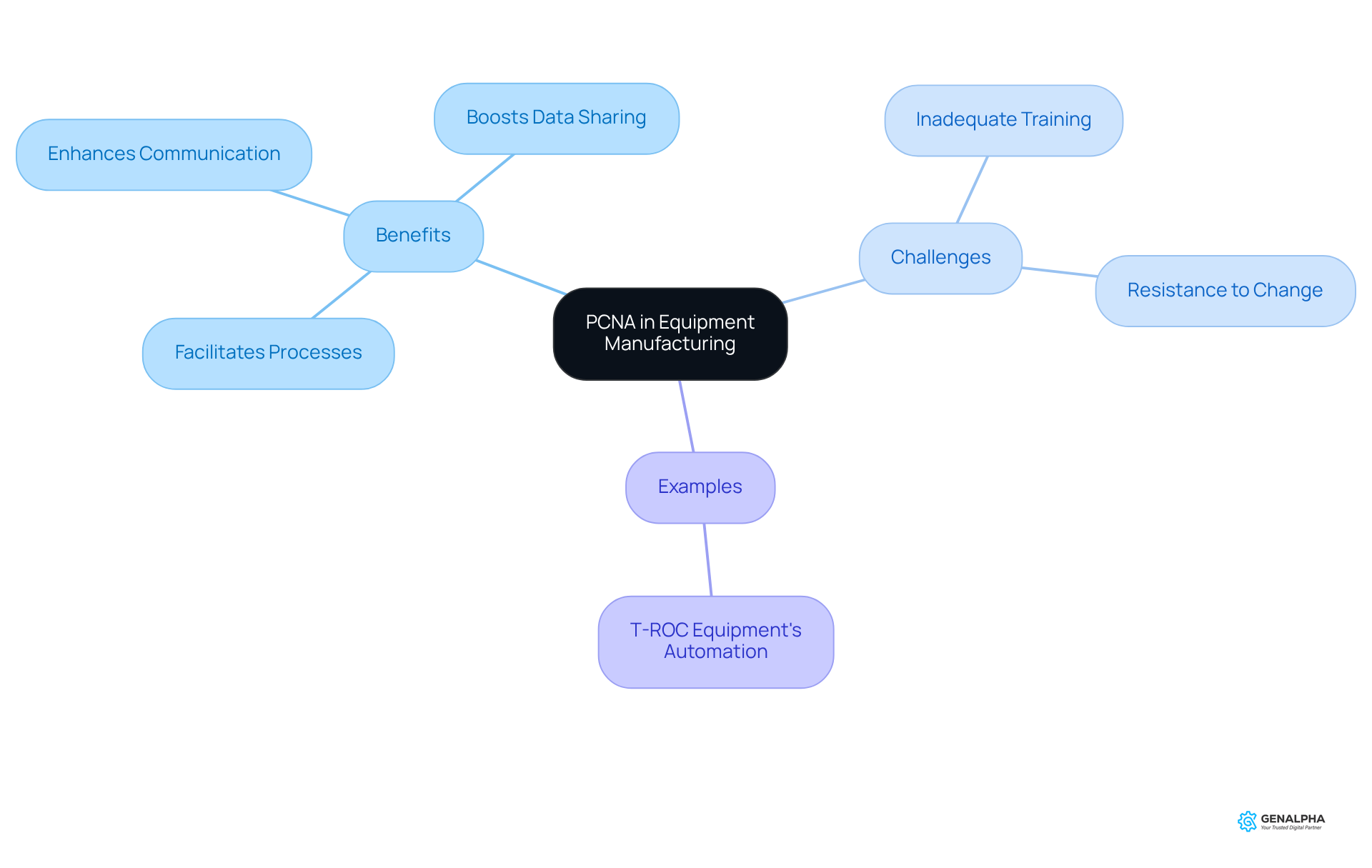

Understand the Role of PCNA in Equipment Manufacturing

The role of PCNA is pivotal in the manufacturing sector as it acts as a facilitator for various processes. It serves as a critical component in ensuring that manufacturing operations run smoothly and efficiently. By comprehending how PCNA operates within the manufacturing ecosystem, organizations can identify opportunities for enhancement in their workflows. For instance, the system facilitates communication among departments, boosts data sharing, and increases overall transparency in operations.

The manufacturing sector is anticipated to expand by 20.1% over the next decade, underscoring the importance of enhancing processes. As Ron Cowell, CEO, noted, "The Mitsubishi iQ-F PLC was the exact fit for our control needs on the Automated Box Sizer and helped us meet our customer’s needs within their budget," emphasizing the significance of effective automation in enhancing operational efficiency.

A practical example of the organization's impact is evident in T-ROC Equipment, which notably enhanced shipping efficiencies by adopting automated solutions that align with its principles.

However, producers must be vigilant about common pitfalls when implementing process control and network analysis, such as:

- Inadequate training

- Resistance to change among staff

By addressing these challenges, organizations can fully leverage the system to enhance their processes and achieve greater success in a competitive environment.

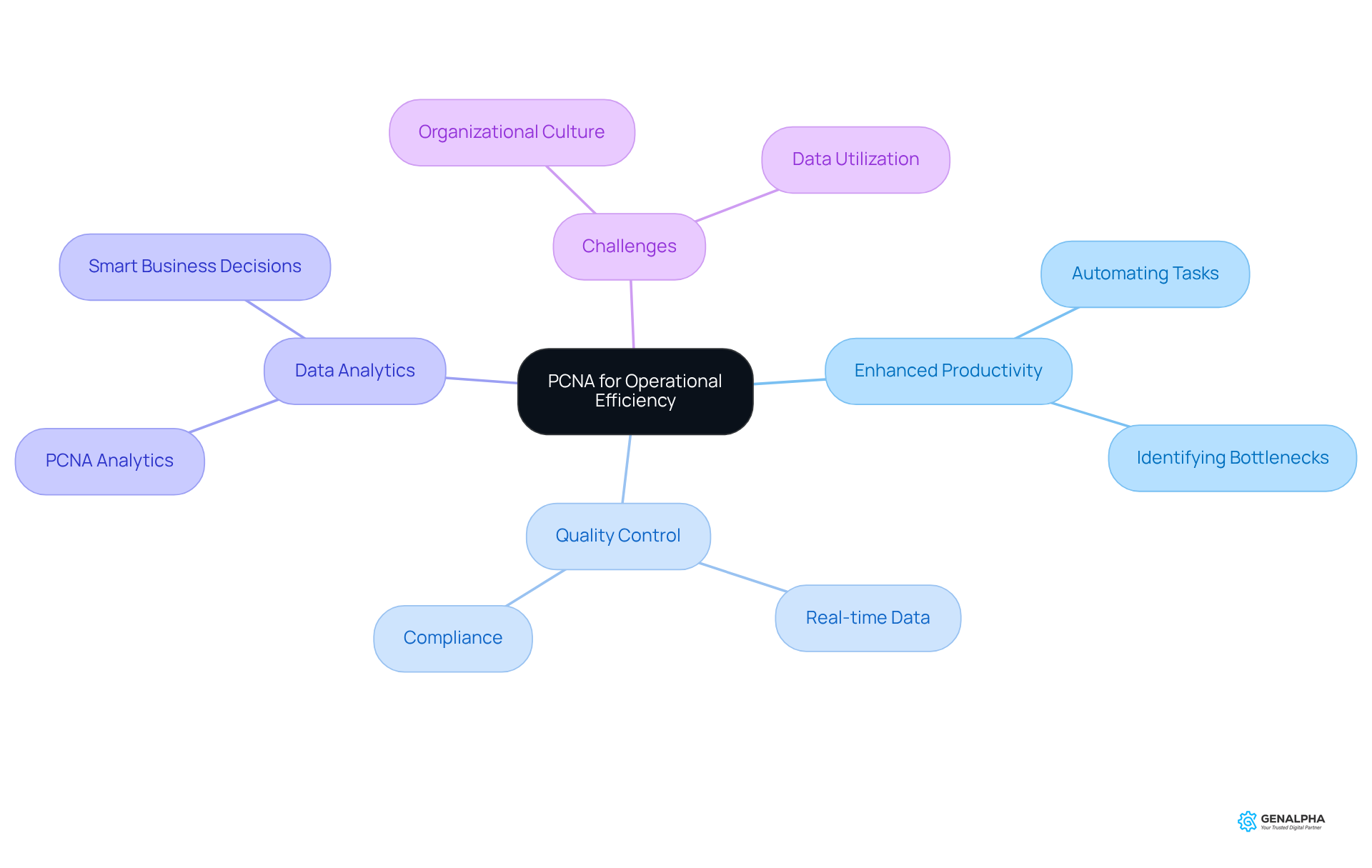

Leverage PCNA for Enhanced Operational Efficiency and Quality Control

To address the pressing challenges within the industry, producers must seamlessly integrate advanced technology into their operational frameworks. This integration is pivotal; not only minimizes human error but also significantly enhances productivity. For instance, the application of PCNA analytics allows for the identification of bottlenecks in production lines, enabling timely interventions that improve workflow efficiency.

As Geoffrey Moore aptly states, "data is absolutely crucial to making smart business decisions," highlighting the vital role of analytics in manufacturing. Moreover, organizations can greatly improve quality control by leveraging real-time data on product specifications and compliance, ensuring that all outputs consistently align with industry standards.

Notably, '67% of analytics leaders stated that organizational culture is the greatest obstacle to becoming a data-oriented company,' which underscores the challenges producers face in effectively adopting PCNA strategies. By embracing these practices, producers can enhance operational efficiency and elevate product quality, ultimately fostering greater customer satisfaction.

Additionally, case studies such as that of GenAlpha Technologies exemplify how digital solutions empower manufacturers and distributors, further validating the effectiveness of PCNA analytics.

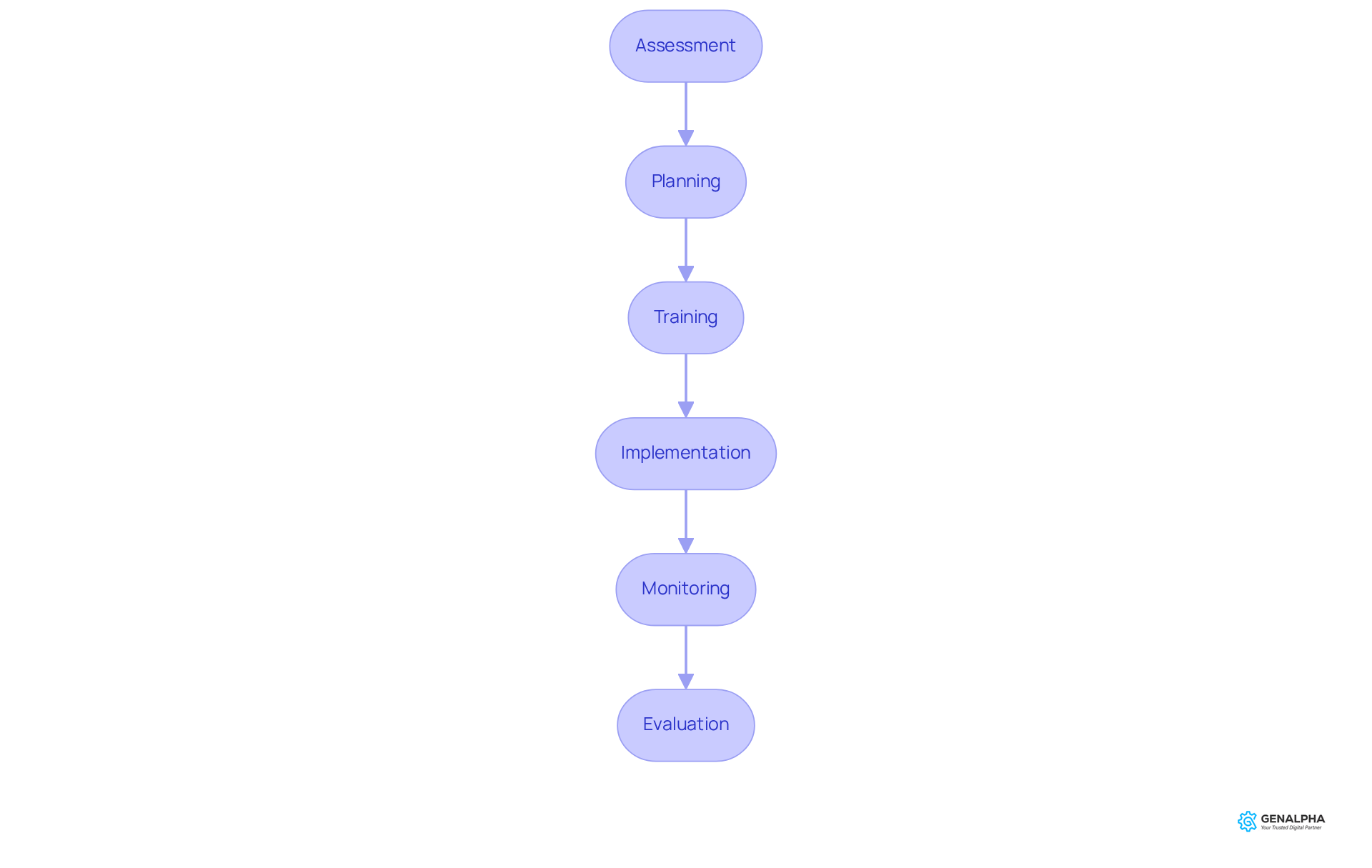

Implement PCNA: Step-by-Step Integration Strategies

Incorporating this component into current manufacturing processes presents significant challenges that require a systematic approach. To navigate these complexities effectively, follow these essential steps:

- Assessment: Conduct a thorough evaluation of current processes to pinpoint areas where this initiative can deliver substantial value.

- Planning: Develop a comprehensive integration plan that clearly defines objectives, timelines, and resource allocation, ensuring clarity and direction.

- Training: Implement development programs for staff, equipping them with the necessary skills to utilize the system effectively and fostering a culture of continuous improvement.

- Implementation: Initiate the integration process with pilot projects, allowing for testing and refinement of the system's functionality before full-scale deployment.

- Monitoring: Continuously oversee the integration process, collecting feedback from users to identify challenges and make necessary adjustments.

- Evaluation: After complete implementation, assess the program's impact on operational efficiency and quality control, utilizing key performance metrics to measure success.

Integrating PCA has demonstrated a remarkable increase in defect detection rates by 30%, alongside a return on investment enhancement of 40-50% for producers. As Timo Resch, President and CEO of the company, emphasizes, enhancing customer experience is crucial in today's competitive landscape. By adhering to these steps, producers can facilitate a seamless transition to the new system, unlocking its full potential to boost productivity and quality. Moreover, the challenges posed by machine inactivity in manufacturing highlight the necessity of to mitigate risks and enhance operational efficiency.

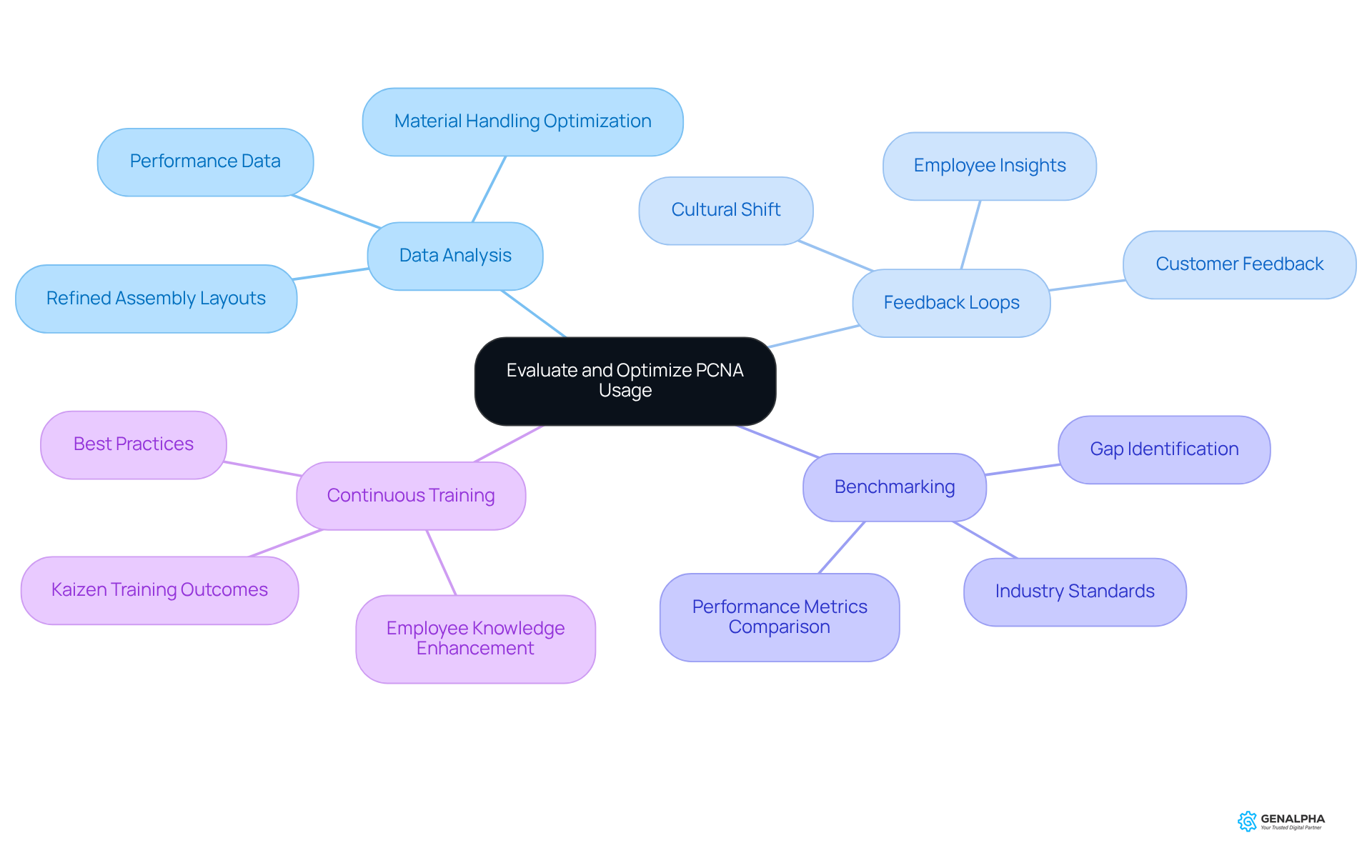

Evaluate and Optimize PCNA Usage for Continuous Improvement

To thrive in today's competitive landscape, producers must through ongoing evaluation and optimization of its application. This can be achieved through several key strategies:

- Data Analysis: Conduct regular analyses of performance data to uncover trends and pinpoint areas needing improvement, such as optimizing material handling and refining assembly layouts. This data-driven approach enables manufacturers to make informed decisions that enhance operational efficiency.

- Feedback Loops: Implement robust feedback mechanisms with both employees and customers to gather insights on the effectiveness of PCNA. This two-way communication fosters a culture of collaboration and ongoing development, as evidenced by the cultural shift where Kaizen concepts now emerge from the shop floor due to improved teamwork.

- Benchmarking: Regularly compare performance metrics against industry standards to identify gaps and opportunities for enhancement. Benchmarking not only highlights areas for growth but also inspires teams to pursue excellence, aligning with the need for continuous development in a competitive environment.

- Continuous Training: Provide regular training for staff to ensure they are knowledgeable about best practices and the latest features related to the program. For instance, the Kaizen training at Yanmar led to the generation of 135 ideas for enhancement, illustrating how equipping employees with knowledge boosts their capacity to effectively utilize PCNA, promoting operational success.

By committing to these practices, manufacturers can cultivate a culture of continuous improvement, ensuring their operations remain agile and responsive to evolving market demands. It is also crucial to acknowledge potential challenges, such as employee resistance to change and the necessity for leadership buy-in, to successfully implement these strategies.

Conclusion

Leveraging PCNA in equipment manufacturing stands as a pivotal strategy for enhancing operational efficiency and upholding high-quality standards. Understanding the integral role of PCNA within manufacturing processes allows organizations to unlock substantial improvements in communication, data sharing, and overall transparency. This foundational knowledge empowers producers to pinpoint areas ripe for enhancement, ultimately fostering a more streamlined and effective manufacturing environment.

Key insights regarding the implementation of PCNA reveal the significance of:

- Systematic integration strategies

- Ongoing training

- Cultivation of a culture centered on continuous improvement

Real-world examples from T-ROC Equipment and GenAlpha Technologies underscore the tangible benefits achievable through effective PCNA utilization, such as increased defect detection rates and enhanced customer experiences.

Embracing PCNA transcends mere technical upgrades; it embodies a transformative approach capable of redefining manufacturing success. Manufacturers are urged to adopt these strategies and nurture an agile, data-driven culture that prioritizes ongoing evaluation and optimization. By doing so, they can not only meet the demands of a competitive marketplace but also establish a foundation for sustained growth and innovation.

Frequently Asked Questions

What is the role of PCNA in equipment manufacturing?

PCNA acts as a facilitator in the manufacturing sector, ensuring that operations run smoothly and efficiently. It enhances communication among departments, boosts data sharing, and increases overall transparency.

How does understanding PCNA benefit organizations?

By comprehending how PCNA operates within the manufacturing ecosystem, organizations can identify opportunities for enhancement in their workflows, leading to improved efficiency and effectiveness.

What is the projected growth of the manufacturing sector in the next decade?

The manufacturing sector is anticipated to expand by 20.1% over the next decade, highlighting the importance of enhancing processes.

Can you provide an example of PCNA's impact in a real-world scenario?

T-ROC Equipment improved shipping efficiencies by adopting automated solutions that align with the principles of PCNA.

What are some common pitfalls when implementing process control and network analysis?

Common pitfalls include inadequate training and resistance to change among staff.

How can organizations overcome the challenges associated with PCNA implementation?

By addressing challenges such as inadequate training and resistance to change, organizations can fully leverage PCNA to enhance their processes and achieve greater success.