Overview

Have you ever wondered how equipment makers can stand out in a crowded market? Well, engineer to order manufacturing offers some fantastic benefits! Think about it:

- Enhanced customization

- Improved quality control

- Increased operational efficiency

- Stronger supplier collaboration

These advantages not only boost customer satisfaction but also give companies a competitive edge.

So, how do they achieve all this? It’s all about leveraging advanced technologies and smart strategies. For example, integrating digital solutions and fostering innovation can make a world of difference. Plus, building long-term partnerships leads to greater responsiveness to client needs and market demands.

Isn’t it exciting to see how these elements come together? By focusing on these strategies, equipment makers can truly enhance their offerings and better serve their customers. What steps can you take today to explore these benefits further?

Introduction

Have you ever wondered how some manufacturers seem to have a magic touch when it comes to meeting their clients' needs? Engineer to Order (ETO) manufacturing is at the forefront of modern production, offering a unique approach that caters specifically to what clients want in an increasingly competitive landscape. In this article, we’ll explore the numerous benefits of ETO manufacturing, showing how it empowers equipment makers to streamline operations, enhance customer satisfaction, and spark innovation.

But here’s the big question: as businesses navigate this complex terrain, how can they effectively leverage ETO strategies to not just meet, but exceed client expectations while keeping that competitive edge? Let’s dive in and find out together!

GenAlpha Technologies: Streamline Online Sales for Engineer to Order Manufacturing

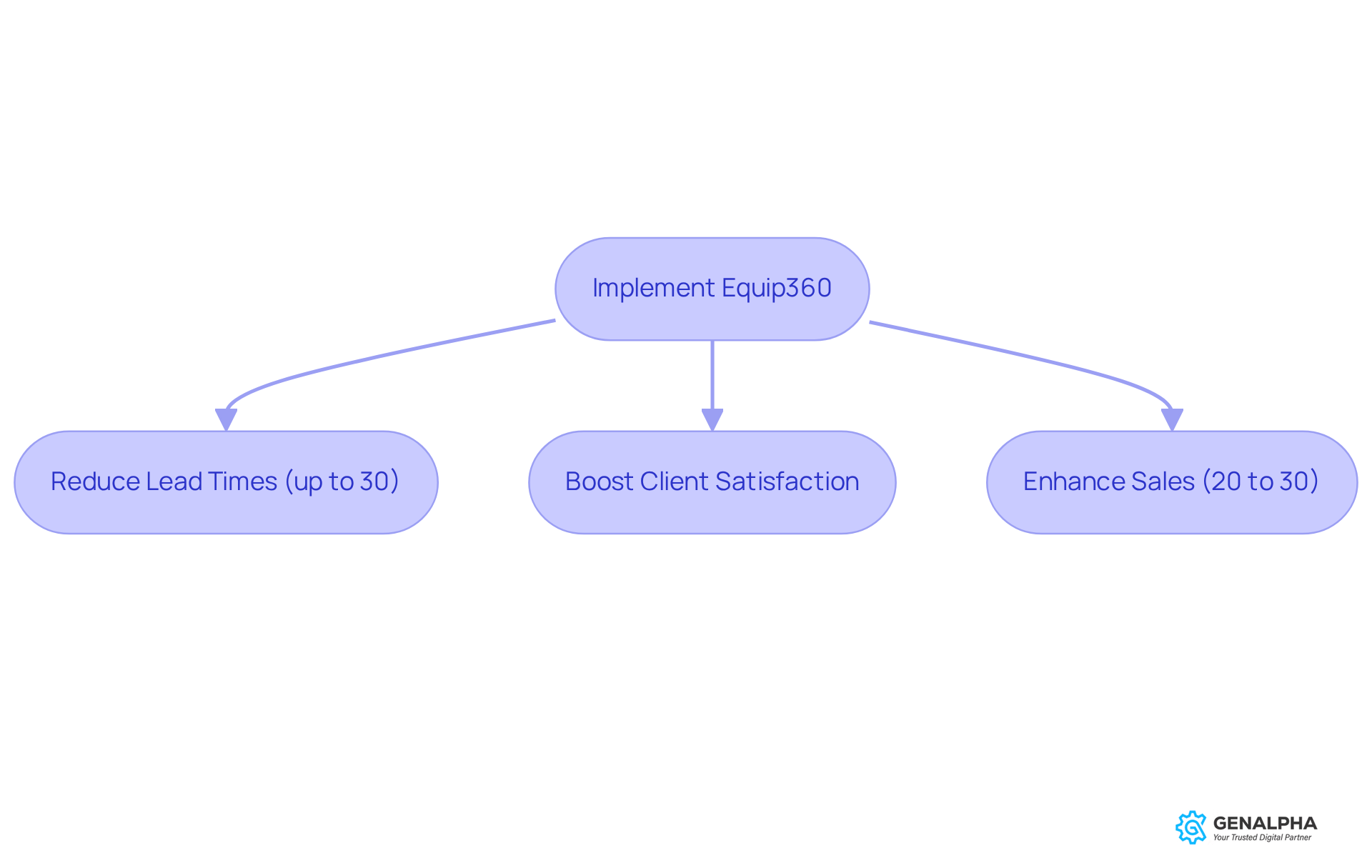

At GenAlpha Technologies, we're all about providing specialized digital solutions that truly benefit Engineer to Order (ETO) producers. Take our flagship product, Equip360, for example. It integrates seamlessly with existing ERP systems, helping producers manage those complex orders with ease. By streamlining the sales process, Equip360 not only reduces lead times but also boosts client satisfaction—something we all know is crucial in today’s competitive marketplace.

Imagine this: successful implementations have shown that producers can cut lead times by up to 30%. That means they can respond to client demands much faster! And with 92% of B2B purchases starting with a search, our platform’s advanced search functionality ensures that customers can quickly find the parts they need, driving those all-important conversions.

But that’s not all! Our strategic alliance with Optessa enhances operational efficiency, allowing producers to tap into digital trends like cross-selling, which can elevate sales by 20% to 30%. As the industry evolves, embracing innovative solutions like these is key for producers who want to thrive in the digital landscape.

As Kris Harrington, President of GenAlpha Technologies, puts it, "We saw the need to provide a solution to empower dealers to accelerate business growth." So, are you ready to take the leap and explore how Equip360 can ?

Customization: Tailor Products to Meet Unique Client Requirements

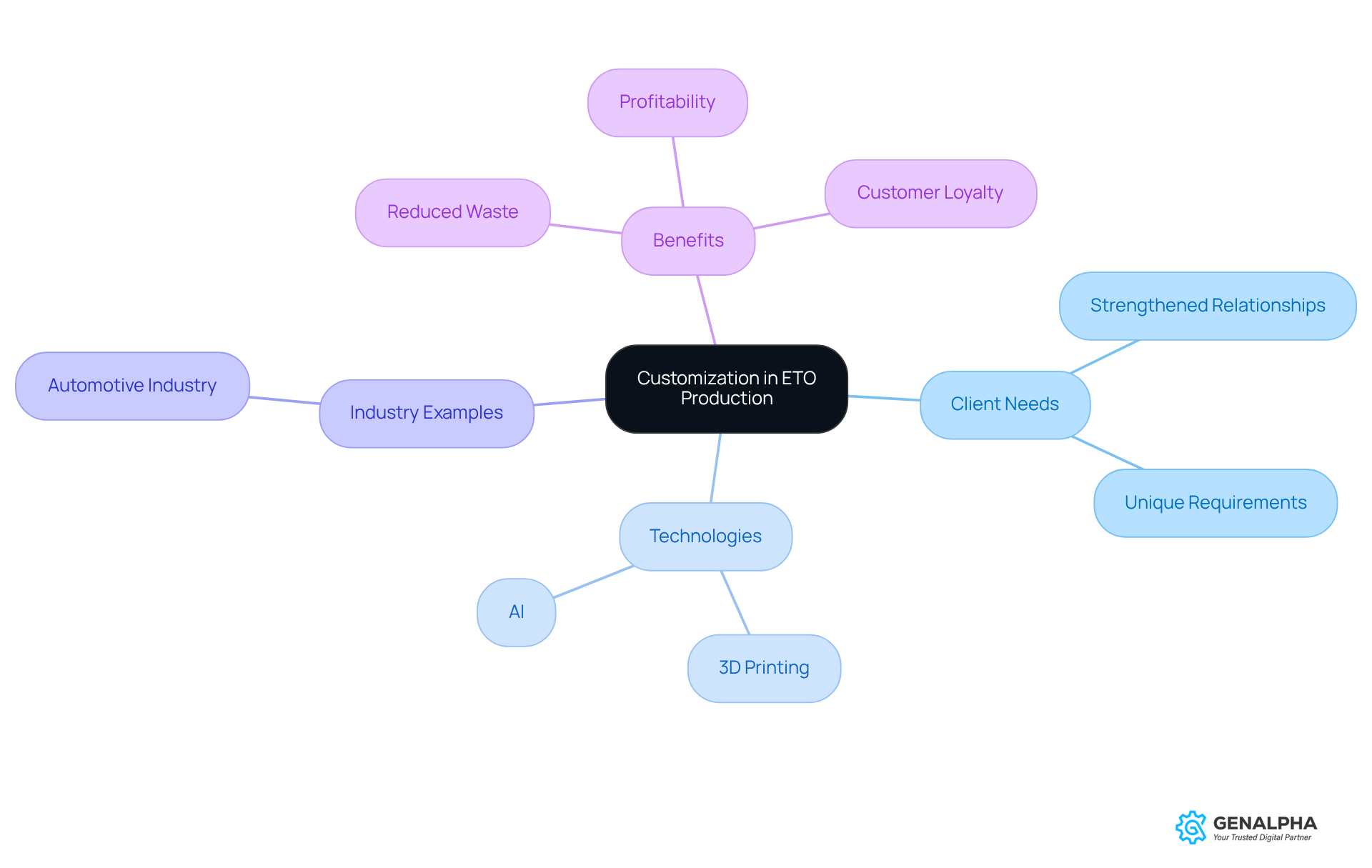

Customization is central to the concept of engineer to order (ETO) production. It allows producers to create products that fit perfectly with what clients want. This flexibility not only meets diverse client needs but also strengthens relationships, as customers appreciate the focus on their unique requirements, particularly when solutions are engineer to order.

Have you ever thought about how advanced technologies, like AI and 3D printing, help manufacturers manage engineer to order custom orders? These tools make it easier to deliver personalized items quickly, ensuring they arrive on time and meet high-quality standards. For instance, businesses that utilize engineer to order solutions often see happier clients because these tailored offerings resonate more deeply with individual preferences.

Look at the automotive industry; successful examples show that engineering to order customization can boost customer loyalty and enhance brand reputation. Customers are naturally drawn to products that reflect their specific desires. Additionally, when producers collaborate strategically, they can improve production flexibility, allowing them to optimize operations and respond swiftly to market changes.

By prioritizing customization, producers also reduce waste and promote sustainability. This not only but also positions them as leaders in a rapidly evolving market. So, what steps can you take to embrace customization in your own business?

Quality Control: Enhance Product Standards and Compliance

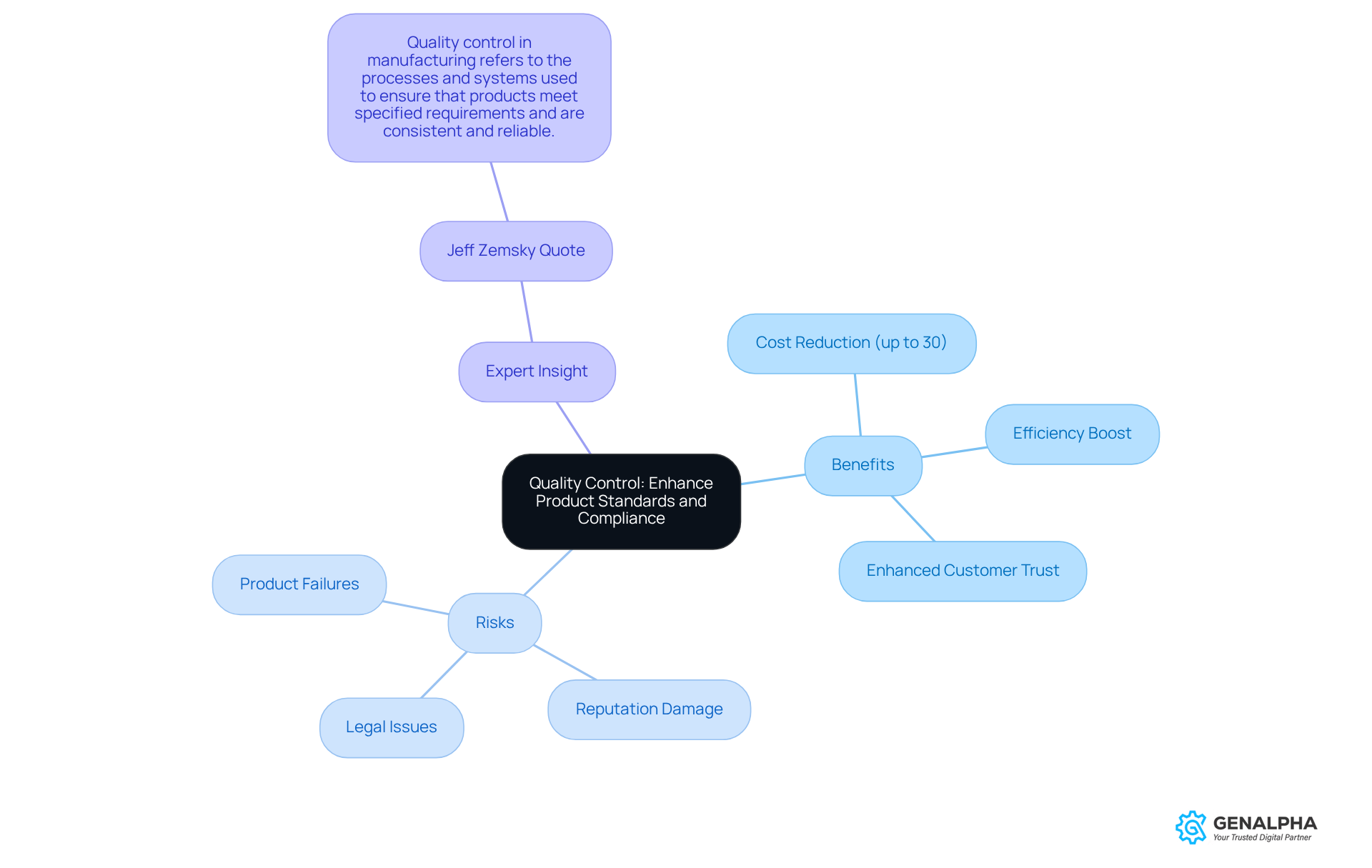

In Engineer to Order (ETO) manufacturing, have you ever considered how essential it is to implement strict control measures? They’re essential for ensuring that products meet client specifications and industry standards. A well-organized management system, like a Quality Management System (QMS), helps producers spot potential issues early in the production process. This proactive approach can greatly .

Did you know that effective quality management can cut operational costs by up to 30%? That’s a significant boost to efficiency, making it a strategic asset for producers. Regular audits and compliance checks not only enhance quality integrity but also ensure that manufacturers consistently deliver high-quality solutions that are engineer to order.

As Jeff Zemsky, VP for Windchill Digital Thread, puts it, "Quality control in manufacturing refers to the processes and systems used to ensure that items meet specified requirements and are consistent and reliable." This commitment to excellence fosters trust and loyalty from clients—key ingredients for sustained success in a competitive market.

On the flip side, neglecting quality management can expose businesses to serious risks, such as product failures and damage to their reputation. So, why take that chance? Maintaining high standards isn’t just a good practice; it’s essential for thriving in today’s marketplace.

Customer Satisfaction: Deliver Tailored Solutions That Meet Expectations

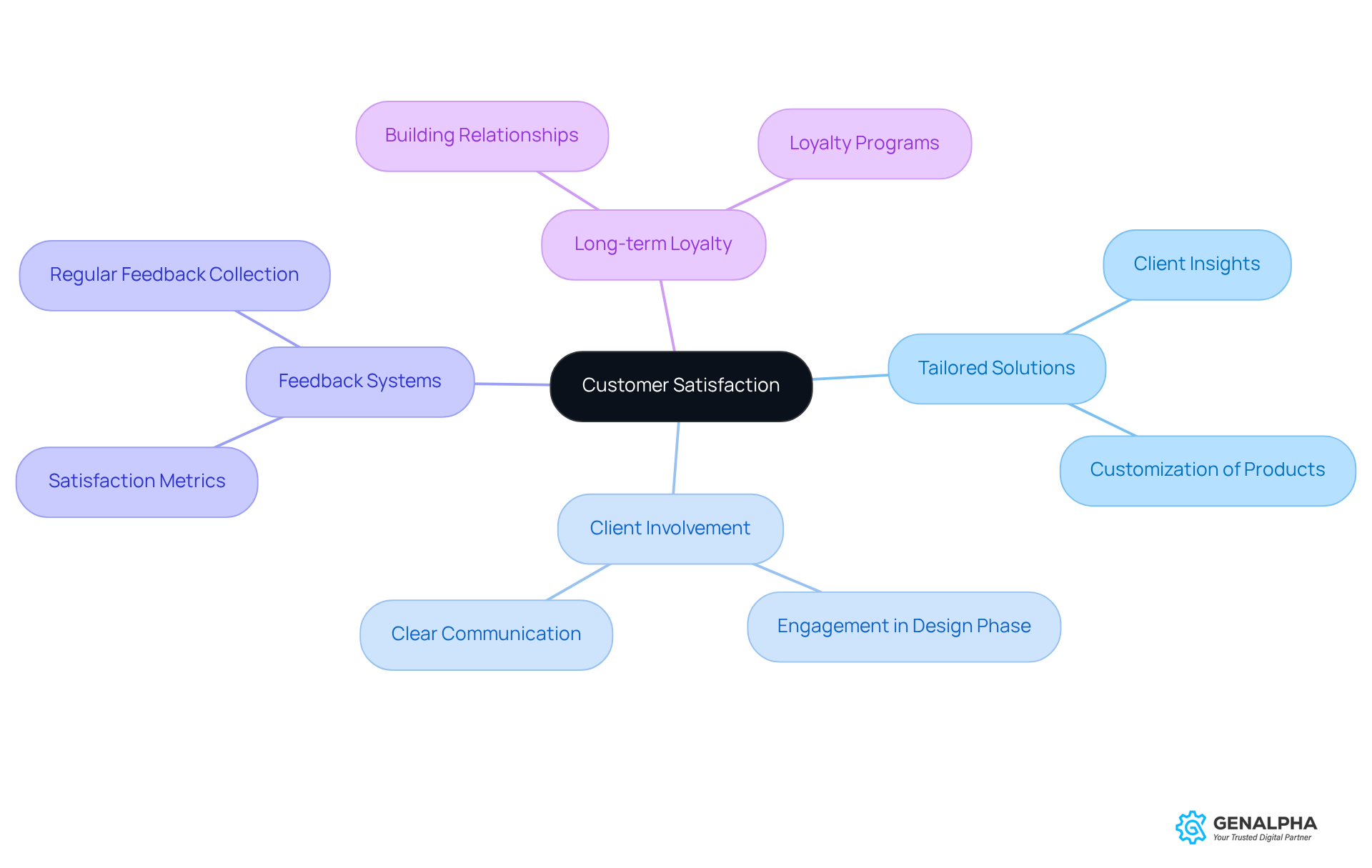

Customizing solutions is key to keeping our clients happy in engineer to order manufacturing. The engineer to order process can be quite complex and requires extensive hands-on engineering and design to meet specific client needs. By getting clients involved in the design and production journey, manufacturers can make sure their products hit the mark. Setting up feedback systems and using satisfaction metrics helps businesses continually improve what they offer. This proactive approach not only aligns products better with client expectations but also builds and encourages repeat business.

Did you know that companies that excel in client experience can see revenue growth of 4% to 8% above their market average? That really highlights the financial perks of focusing on tailored solutions! Effective strategies include:

- Bringing in client insights early in the design phase

- Keeping communication clear throughout the project

- Showcasing quality assurance

Together, these steps lead to better client satisfaction and retention. So, how are you thinking about enhancing your client interactions today?

Operational Efficiency: Optimize Resource Allocation and Reduce Waste

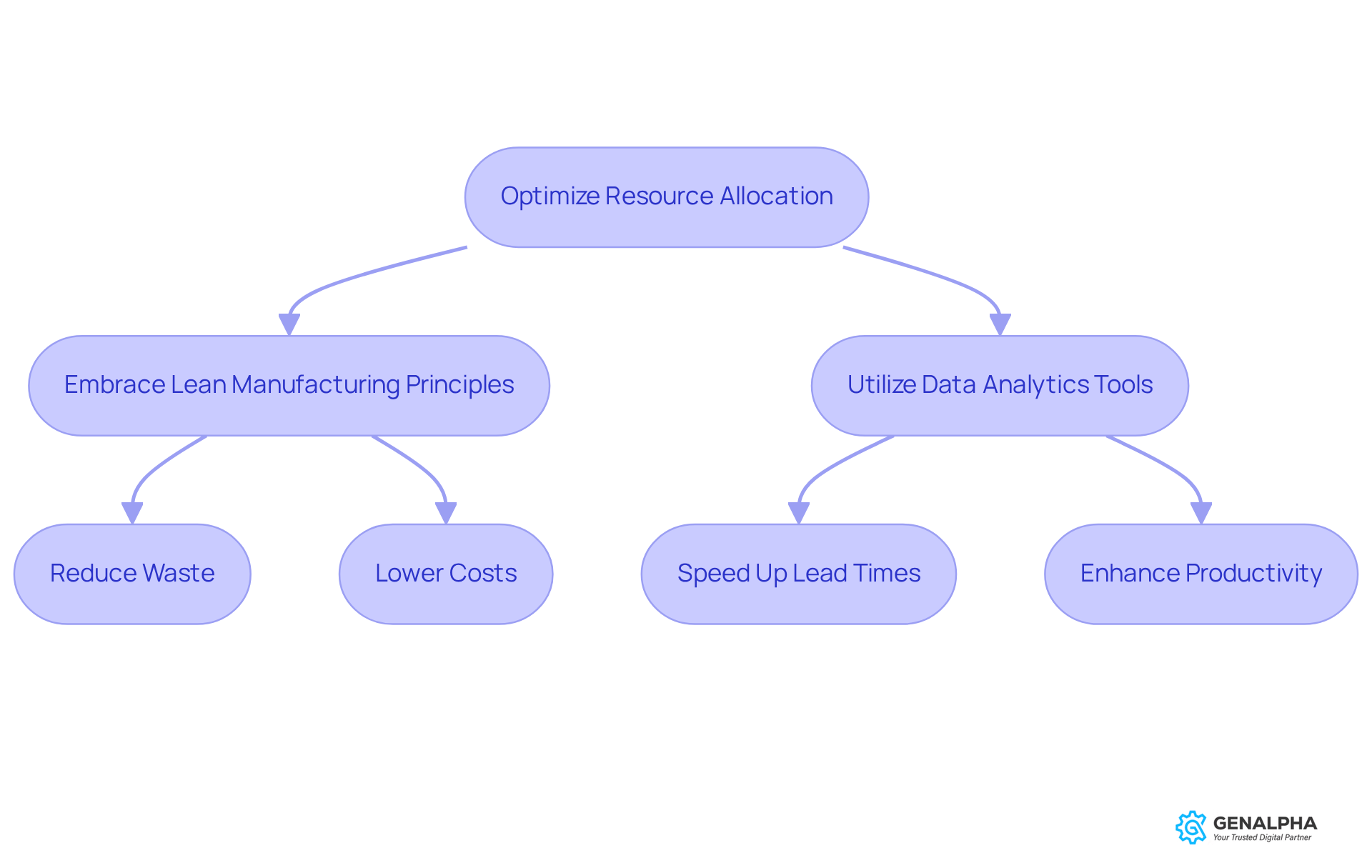

Have you ever thought about how optimizing resource allocation can really boost efficiency in engineer to order manufacturing? By embracing lean manufacturing principles, businesses can spot and cut out waste throughout the production process. This not only helps to but also speeds up lead times and enhances overall productivity.

For example, using data analytics tools can be a game-changer. They help in making informed decisions about resource distribution, ensuring that everything runs smoothly. So, why not take a closer look at how these strategies can transform your operations? Let's dive in and explore the benefits together!

Adaptability: Quickly Respond to Market Changes and Client Needs

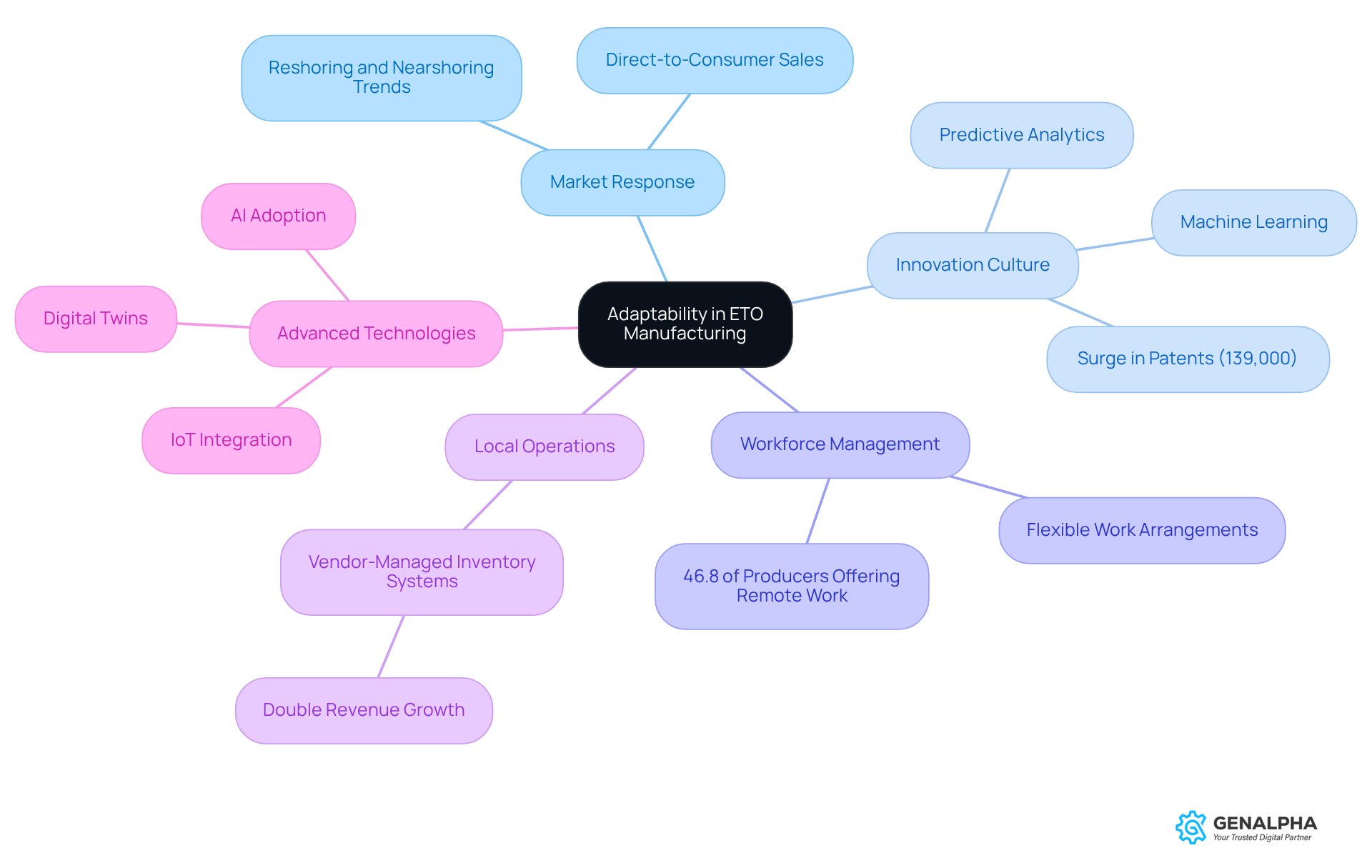

In the fast-evolving world of engineer to order (ETO) manufacturing, adaptability is key to success. Have you ever noticed how quickly things change in the market? Manufacturers need to respond rapidly to these shifts and the changing needs of their clients. By fostering a culture of innovation and continuous improvement, businesses can adopt agile practices that allow them to tweak production processes on the fly.

For example, companies that use predictive analytics and machine learning have seen a significant drop in product defects, which boosts overall quality and responsiveness. This adaptability not only makes customers happier but also in their fields.

Looking ahead to 2025, as reshoring and nearshoring trends pick up speed, many producers are focusing on localizing operations to strengthen their supply chains. Take a look at firms that have implemented vendor-managed inventory systems; they’ve experienced more than double the revenue growth compared to those that haven’t.

Additionally, with 46.8% of producers offering remote work and compressed workweek options to attract talent, adaptability extends beyond production processes to workforce management, addressing labor shortages. The manufacturing sector's filing of 139,000 new patents highlights the ongoing innovation needed for continuous improvement.

As producers navigate these changes, incorporating advanced technologies like IoT and AI will help them engineer to order market demands and enhance their operations. This way, they can stay competitive in a rapidly changing landscape. So, how is your business adapting to these trends?

Supplier Collaboration: Strengthen Relationships for Better Sourcing

Effective cooperation with suppliers is crucial for those who operate Engineer to Order (ETO) production, as they need the right materials and components for their custom projects. By building strong relationships, manufacturers can negotiate better terms, ensure timely deliveries, and maintain high-quality standards. Have you ever thought about how consistent communication and collaborative planning meetings can align objectives and expectations? This ultimately leads to a more efficient supply chain and improved outcomes.

Research from a McKinsey survey shows that companies with strong supplier relationships tend to grow faster and incur lower operating costs. Organizations that prioritize collaboration often enjoy significant cost savings and enhanced product quality. Plus, setting up service-level agreements (SLAs) is key; they help establish realistic delivery expectations and nurture good relationships, paving the way for performance improvements.

Industry leaders stress that solid supplier relationships encourage open communication and teamwork. As one expert pointed out, "Reliable suppliers understand your specific quality standards and are committed to meeting them consistently." By viewing suppliers as partners rather than just vendors, producers can tap into new value sources and continuously improve their processes. Regular meetings with suppliers to discuss improvement initiatives are also vital for effective relationship management.

In summary, investing in supplier relationships not only boosts sourcing efficiency but also plays a significant role in the success of projects that are engineer to order. By treating suppliers as partners and conducting due diligence on their cultures, manufacturers can navigate the complexities of custom manufacturing with greater agility and resilience. So, how will you today?

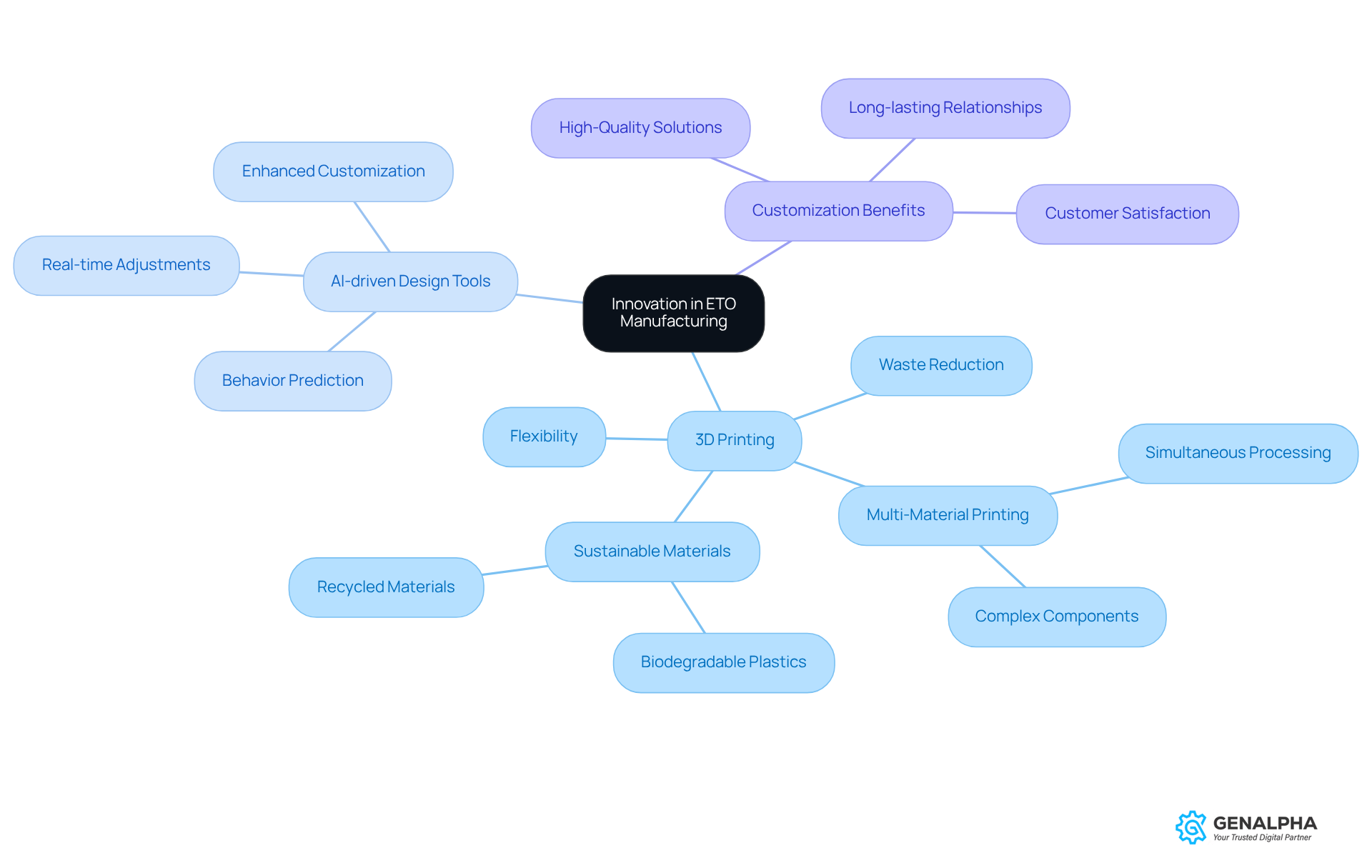

Innovation: Foster New Solutions and Technologies for Custom Products

Innovation is crucial for producers who operate as engineer to order (ETO) to keep up with changing customer demands. By focusing on research and development, these businesses can tap into exciting technologies like 3D printing and AI-driven design tools. Did you know that by 2025, the use of 3D printing has really taken off? Manufacturers are using this technology more and more to create custom products that not only boost flexibility but also cut down on waste. For example, advancements in multi-material printing let us process different materials at the same time, making it possible to produce complex components that are tailored to specific needs.

Additionally, AI algorithms are shaking up the design process. They analyze past data to predict how materials will behave, allowing for that enhance quality and efficiency. As Andrew Rieser points out, "The world is experiencing a transformation, one that is reshaping industries, redefining consumer experiences, and rewriting the rules of competition." Industry experts are highlighting that these innovations not only streamline production but also significantly ramp up product customization.

So, what does this mean for producers? They can deliver high-quality, customized solutions more effectively, which ultimately boosts customer satisfaction and builds long-lasting relationships. By integrating these technologies, ETO producers are stepping into the spotlight of the industry, ready to tackle the challenges of modern manufacturing with an engineer to order strategy.

Competitive Advantage: Differentiate Products in the Marketplace

Want to stand out in the crowded marketplace? For producers who specialize in engineer to order, it’s all about making your products shine. You can do this by highlighting:

- Unique features

- Top-notch quality

- Outstanding customer service

Think about it: when you leverage smart branding strategies and targeted marketing campaigns, you’re not just selling a product; you’re sharing a story that resonates with potential clients. This and helps attract new business. So, how will you make your mark?

Long-Term Partnerships: Build Trust Through Consistent Quality and Customization

Establishing long-term collaborations is super important for producers who operate on an engineer to order basis. By consistently delivering high-quality, tailored products, producers can build trust and reliability with their clients. Did you know that research from Bain & Company shows that increasing customer retention by just 5% can boost profits by 25% to 95%? That really highlights the financial perks of nurturing loyalty through exceptional service!

Regular follow-ups and feedback sessions are key for keeping those communication lines open. This way, client needs are met, and expectations are not just met but exceeded. It’s a proactive strategy that not only enhances client satisfaction but also reinforces the manufacturer’s commitment to excellence.

Take a look at successful examples in the industry, like the Customer Service Excellence at Trinity Precision. Companies that prioritize trust-building through consistent quality and personalized service see significant boosts in client retention rates. As Tom Elstner, founder and CEO of Zoo Productions, puts it, "Finding the right clients is more than just a matter of closing deals. It’s about establishing the type of enduring relationships that can transcend the usual transactional exchanges into real-life connections."

Authentic communication and transparency are the bedrock of nurturing these relationships. They ultimately lead to . So, how are you fostering those connections with your clients?

Conclusion

Engineer to Order (ETO) manufacturing brings a wealth of advantages that are crucial for equipment makers eager to succeed in today’s competitive world. By embracing customization, quality control, and operational efficiency, manufacturers can not only meet but even exceed client expectations. With the integration of cutting-edge technologies like AI and 3D printing, these capabilities are taken to the next level, allowing producers to respond swiftly to market demands while upholding high quality standards.

Throughout this discussion, we’ve seen how crucial adaptability and supplier collaboration are in ETO manufacturing. Companies that focus on building strong relationships with their suppliers often enjoy better sourcing outcomes. On the flip side, those who stay agile can quickly pivot to meet changing client needs. Plus, nurturing long-term partnerships based on trust and consistent quality can significantly boost profitability and customer loyalty.

Ultimately, the journey toward successful ETO manufacturing isn’t just about crafting custom products; it’s about establishing a resilient business model that champions innovation and values customer relationships. As the landscape continues to shift, manufacturers need to harness these benefits to stay ahead of the curve, ensuring they not only meet today’s demands but also anticipate future trends. By engaging with these strategies, businesses can not just survive but truly thrive in the ever-evolving world of engineer to order manufacturing. So, are you ready to take the leap and embrace these exciting opportunities?

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies specializes in providing digital solutions that benefit Engineer to Order (ETO) producers, with their flagship product, Equip360, designed to streamline online sales and integrate with existing ERP systems.

How does Equip360 improve the sales process for ETO producers?

Equip360 streamlines the sales process by reducing lead times and boosting client satisfaction, enabling producers to manage complex orders more efficiently.

What impact can Equip360 have on lead times?

Successful implementations of Equip360 have shown that producers can cut lead times by up to 30%, allowing them to respond to client demands more quickly.

What percentage of B2B purchases start with a search, and how does Equip360 assist in this?

92% of B2B purchases start with a search, and Equip360's advanced search functionality helps customers quickly find the parts they need, driving conversions.

How does the partnership with Optessa enhance operational efficiency?

The strategic alliance with Optessa allows producers to utilize digital trends like cross-selling, which can increase sales by 20% to 30%.

Why is customization important in Engineer to Order production?

Customization allows producers to create products tailored to client specifications, meeting diverse needs and strengthening customer relationships.

How do advanced technologies like AI and 3D printing benefit ETO manufacturing?

These technologies facilitate the management of custom orders, enabling manufacturers to deliver personalized items quickly and maintain high-quality standards.

What benefits does prioritizing customization bring to producers?

Prioritizing customization reduces waste, promotes sustainability, enhances profitability, and positions producers as leaders in a rapidly evolving market.

What role does quality control play in ETO manufacturing?

Quality control is essential for ensuring products meet client specifications and industry standards, helping to prevent costly rework and maintain high quality.

How can effective quality management impact operational costs?

Effective quality management can cut operational costs by up to 30%, making it a strategic asset for producers.

What are the risks of neglecting quality management in manufacturing?

Neglecting quality management can lead to product failures and damage to a company's reputation, which can have serious consequences in a competitive market.