Overview

Have you ever thought about how digital transformation can change the game in manufacturing? It’s pretty exciting when you consider the significant benefits it brings, like boosting efficiency and enhancing operational processes. Imagine improved product quality and better customer engagement—sounds great, right?

For example, think about real-time data monitoring. This isn’t just a buzzword; it’s a tool that allows manufacturers to keep a close eye on their operations. Then there’s predictive maintenance, which helps prevent costly breakdowns before they happen. And let’s not forget personalized customer experiences that make every buyer feel valued. These digital solutions not only lead to increased productivity but also help cut costs and ramp up customer satisfaction.

So, what do you think? Isn’t it time to explore how these innovations could transform your own manufacturing processes? Let’s dive into this digital journey together!

Introduction

Digital transformation is shaking things up in the manufacturing world, opening doors to incredible opportunities for efficiency and growth. Imagine manufacturers harnessing innovative digital solutions to streamline operations, boost product quality, and cut costs—all while keeping customers happy.

But as the industry continues to evolve, a big question looms: how can manufacturers not just keep up with the competition but also stay ahead of market demands?

In this exploration, we’ll dive into the many benefits of digital transformation in manufacturing, uncovering strategies that can help organizations move toward a more efficient and sustainable future.

So, are you ready to see how these changes can impact your business?

GenAlpha Technologies: Streamline Operations with Digital Solutions

At GenAlpha Technologies, we truly shine when it comes to providing digital solutions that cater specifically to producers and distributors. Our flagship product, Equip360, is a game-changer—it seamlessly integrates eCommerce capabilities with your existing systems. This means you can streamline operations and supercharge your online sales processes. How cool is that?

Imagine enhancing user experiences while boosting operational efficiency! Equip360 allows producers to adapt to the fast-paced digital landscape effortlessly. With features like interactive parts catalogs and secure ordering, online selling becomes a breeze, helping manufacturers meet client demands and optimize inventory management.

Take, for instance, our success story with De Klok Dranken, which achieved an impressive 80% adoption rate after upgrading to Equip360. This transformation has led to higher sales and increased client loyalty, proving just how effective this platform can be in revolutionizing manufacturing operations.

As the industry continues to evolve, embracing innovative solutions like Equip360 is essential for staying competitive. Did you know that B2B eCommerce outpaces B2C by nearly seven times? This fact really underscores the benefits of digital transformation in manufacturing. Industry leaders agree that selling the right products to the right customers at the right time is crucial for profitability. So, why not explore how Equip360 can make a difference for you?

Increased Operational Efficiency: Optimize Manufacturing Processes

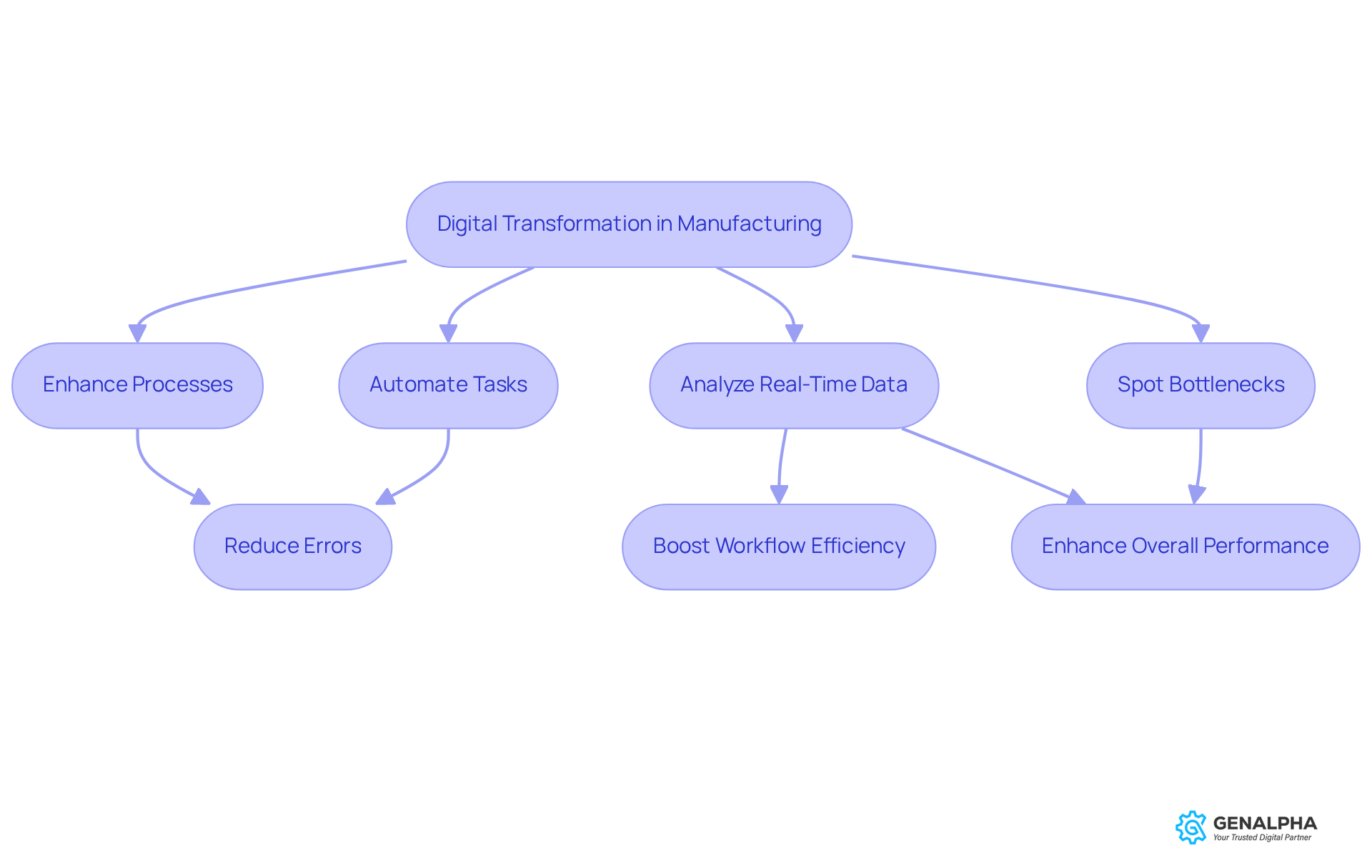

Have you ever considered the benefits of digital transformation in manufacturing and how it can really shake things up for manufacturers? Enhancing processes through automation and smart information analysis highlights the benefits of digital transformation in manufacturing. By diving into digital solutions, companies can wave goodbye to tedious manual tasks, cut down on errors, and fully realize the benefits of digital transformation in manufacturing to boost workflow efficiency.

For example, think about real-time data analysis. It’s like having a superpower that spots bottlenecks in production before they become a big deal. This means companies can jump in quickly and make changes that really enhance the benefits of digital transformation in manufacturing, boosting overall performance. So, why not explore how these digital tools can work for you? It might just be the game-changer you’ve been looking for!

Improved Product Quality: Enhance Customer Satisfaction

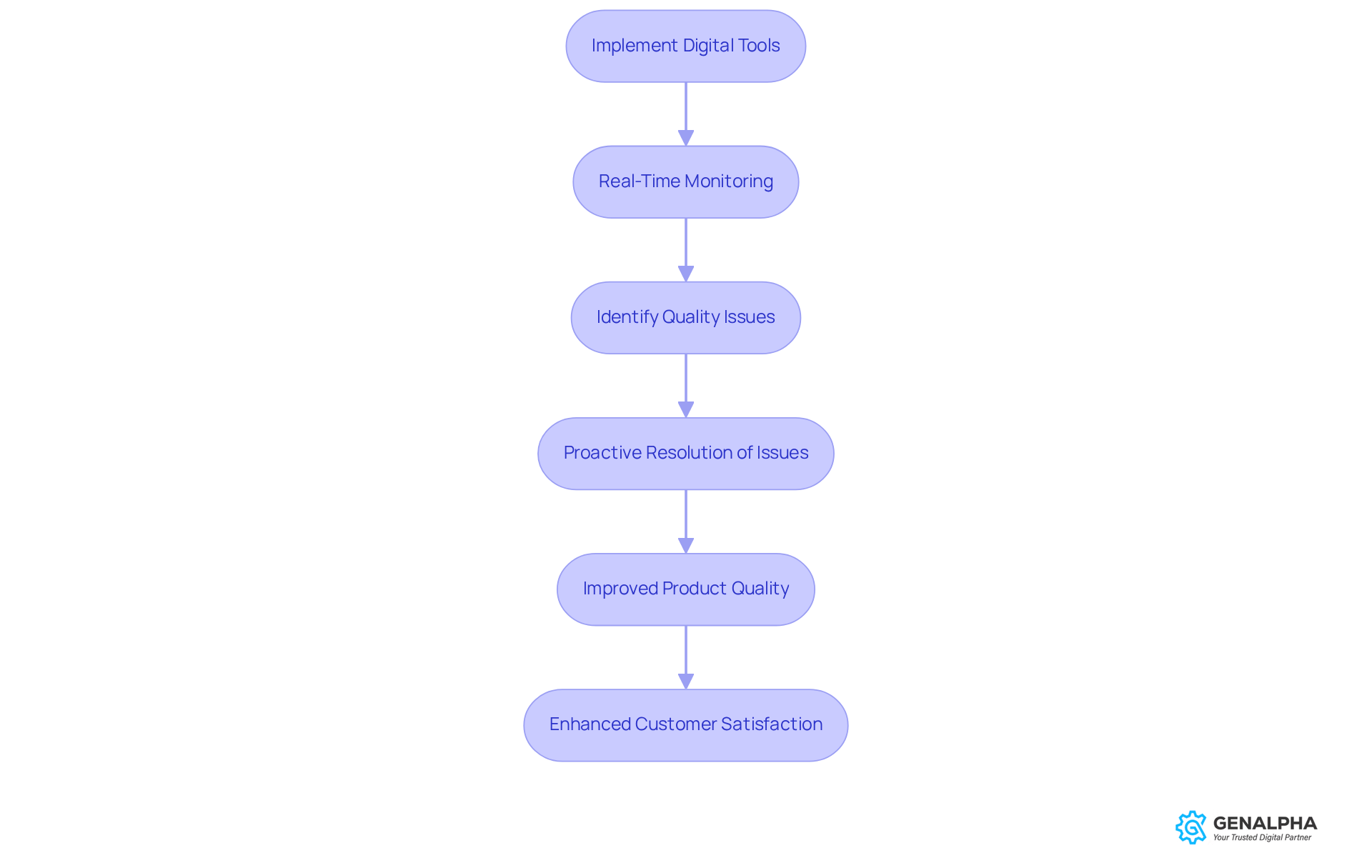

Digital tools really boost quality control, highlighting the benefits of digital transformation in manufacturing through advanced monitoring and analytics. Think about systems like Opcenter Intelligence and Manufacturing Execution Systems (MES) that let producers keep an eye on product quality in real-time. This means any issues with set standards can be tackled right away. How great is that? Not only does this proactive approach improve product quality, but it also makes customers happier since they get reliable, high-performing products.

For instance, producers using real-time monitoring have noticed a bump in overall product quality and customer satisfaction. The clear visibility into operations and insights into key performance metrics like defect rates and production efficiency highlight the benefits of digital transformation in manufacturing. Additionally, the benefits of digital transformation in manufacturing include the use of advanced data analysis, which helps spot potential bottlenecks and provides decision-makers with the tools they need to make smart choices for continuous improvement.

This holistic approach, grounded in Manufacturing Operations Management (MOM), ensures that companies meet industry standards while keeping compliance risks at bay. Ultimately, this not only strengthens customer relationships but also showcases the benefits of digital transformation in manufacturing, setting producers up for long-term success in a competitive market. So, how are you leveraging digital tools in your quality control processes?

Lower Production Costs: Maximize Profit Margins

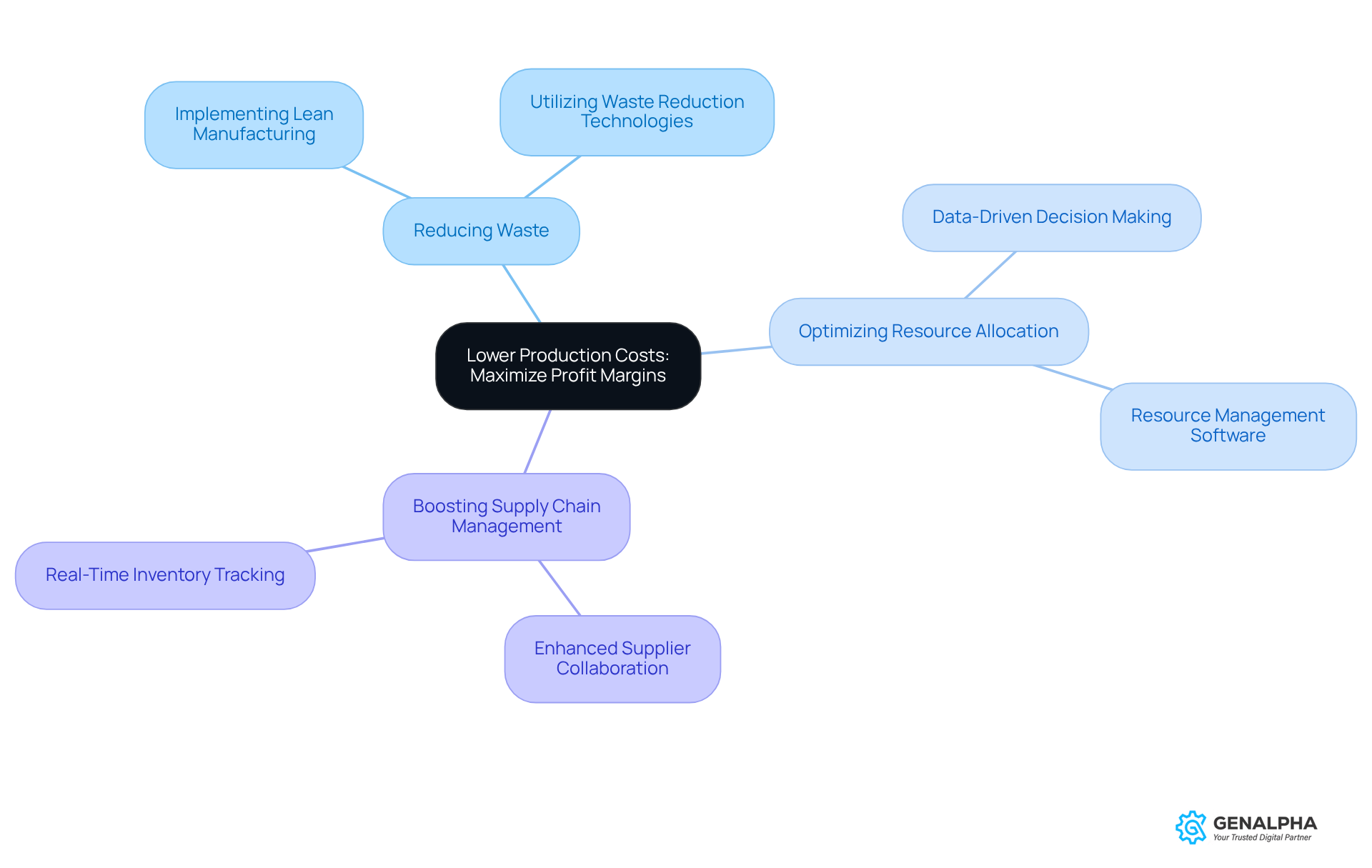

Have you ever thought about how much producers could save just by automating their procedures? By using statistical analysis, they can really cut down on production expenses. The benefits of digital transformation in manufacturing include:

- Reducing waste

- Optimizing resource allocation

- Boosting supply chain management

The benefits of digital transformation in manufacturing lead to lower operational costs, allowing businesses to maximize their profit margins and stay competitive in the market. Isn't that a win-win? So, if you're looking to streamline your operations, now might be the perfect time to consider these changes!

Enhanced Forecasting Accuracy: Anticipate Market Demands

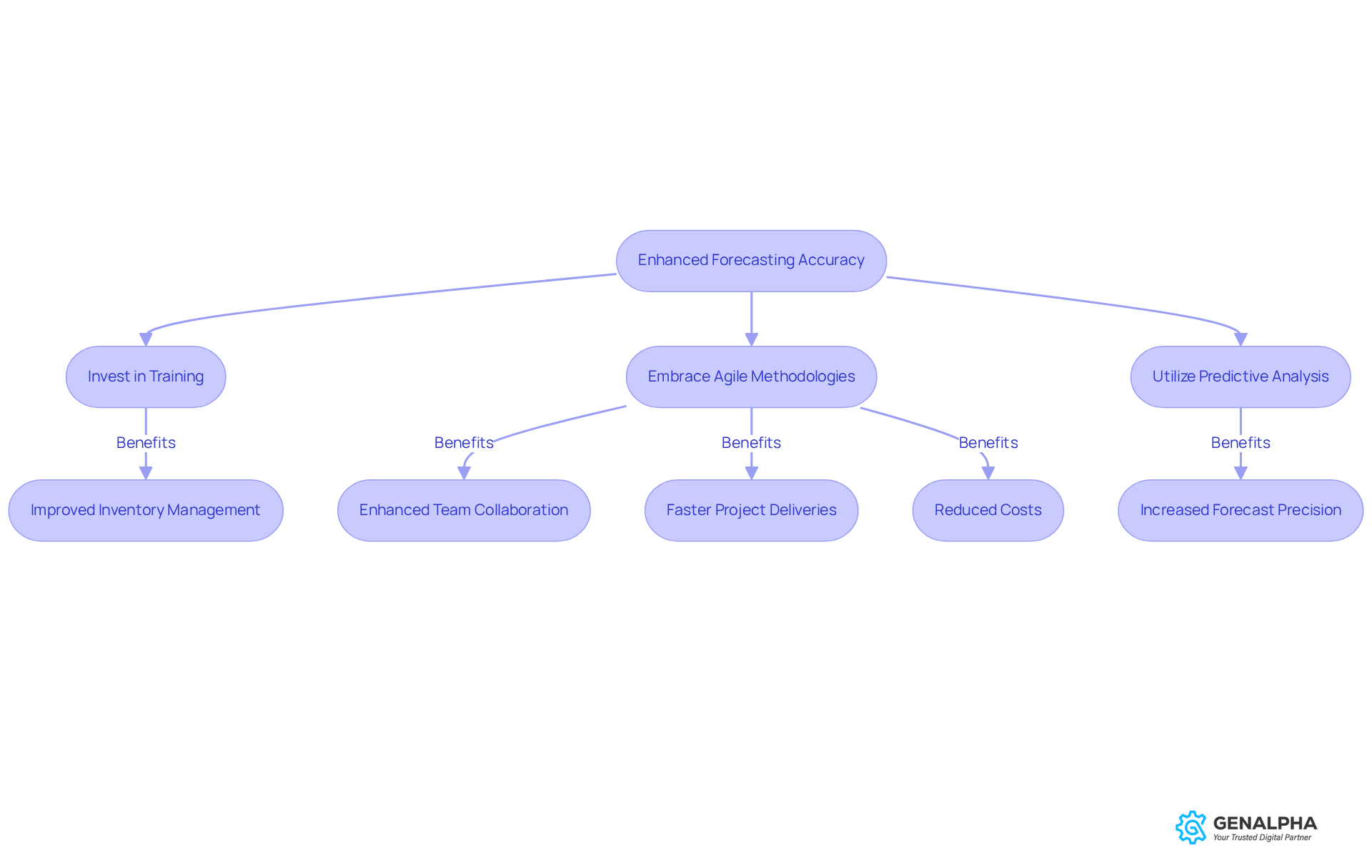

Digital transformation acts as a superpower for manufacturers by using advanced forecasting tools that utilize historical data and market trends, highlighting the benefits of digital transformation in manufacturing. Imagine being able to predict client demands more accurately, showcasing the benefits of digital transformation in manufacturing by allowing production to sync perfectly with what the market needs. With this capability, companies can dodge the pitfalls of excess inventory and stockouts, showcasing the benefits of digital transformation in manufacturing, which ultimately boosts customer satisfaction. Research shows that organizations using predictive analysis can enhance their inventory management by up to 20%. That's a tangible benefit of digital transformation in manufacturing provided by these digital tools! For instance, businesses that effectively harness predictive insights have experienced a 15% bump in forecast precision, allowing them to pivot quickly when market conditions change.

Industry leaders are echoing a crucial point: embracing predictive analysis is key to staying competitive. It empowers producers to make informed decisions that ramp up efficiency and profitability. But to truly unlock these benefits, manufacturers should think about weaving agile methodologies into their ERP systems. Agile methods can supercharge the use of predictive insights by fostering flexibility and collaboration among teams, ensuring these tools are put to good use.

However, it's important to keep in mind the challenges that might crop up during the post-implementation phase of ERP systems. Continuous management and the ability to adapt to shifting business needs are essential. To get the ball rolling with predictive analytics, manufacturers can start by investing in training for their teams. This way, everyone can learn how to interpret data and make informed, data-driven decisions. By embracing these strategies, manufacturers can leverage the benefits of digital transformation in manufacturing to sharpen their forecasting accuracy and get a better handle on market demands. What steps will you take to enhance your forecasting today?

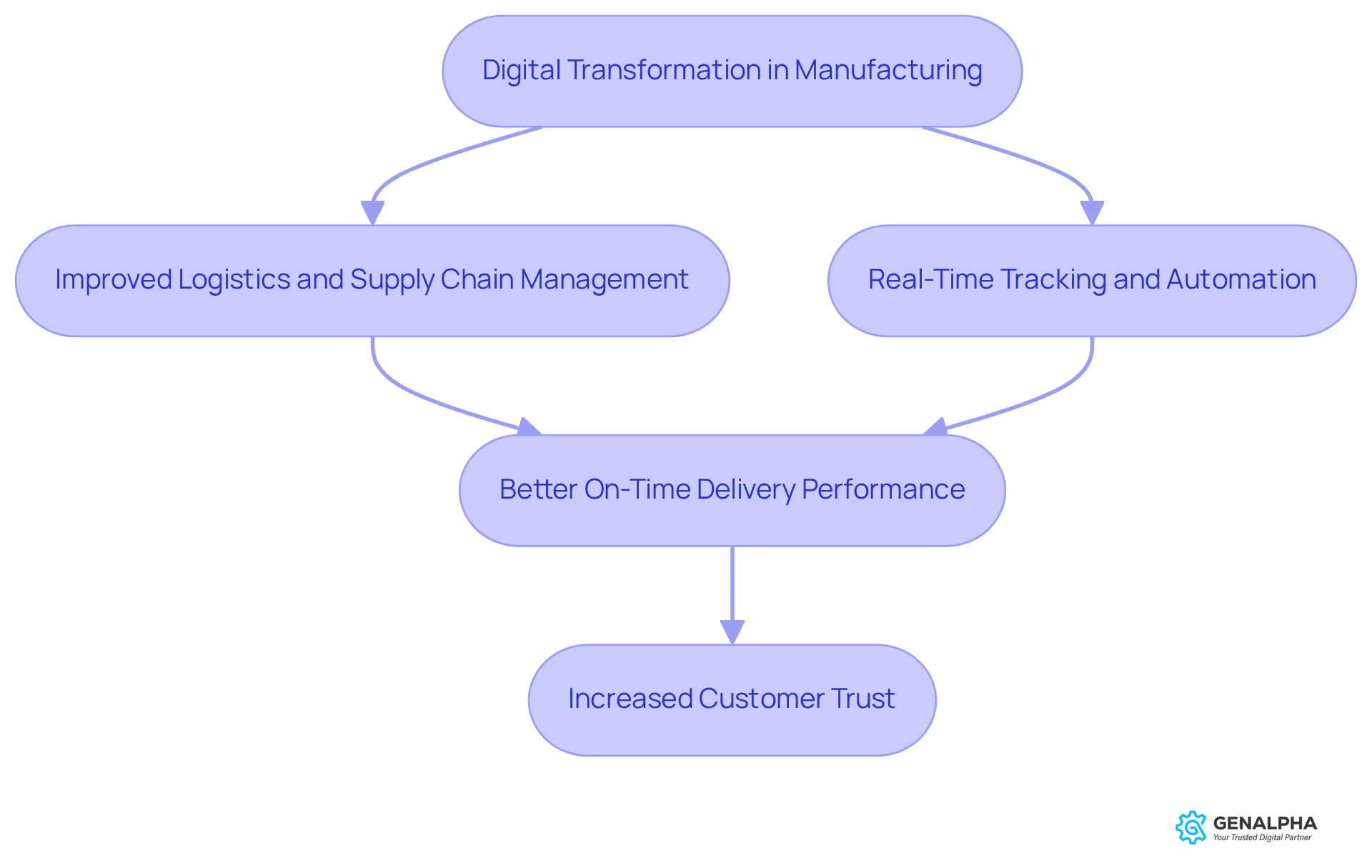

Better On-Time Delivery Performance: Maintain Customer Trust

The benefits of digital transformation in manufacturing are evident as digital solutions significantly boost logistics and supply chain management, leading to better on-time delivery performance. Imagine being able to track your products in real-time and automate scheduling—this means producers can ensure prompt delivery, which is crucial for maintaining client trust.

For example, Kaneka Corporation, a Japanese multinational chemical manufacturer, embraced AI technologies like the MathCutting solution powered by the Gurobi Optimizer. This shift not only cut down planning time but also ramped up productivity.

This reliability helps build stronger, long-term relationships with clients, as consistent delivery is key to client satisfaction. Companies that adopt advanced tracking systems often see a noticeable increase in delivery accuracy, which directly boosts customer loyalty. As Kaneka points out, "There’s still a role for humans to play in deciding how to use the output generated by these AI solutions."

As the industry evolves, recognizing the benefits of digital transformation in manufacturing will be essential for building trust and ensuring smooth operations. So, how are you planning to leverage these digital tools in your own operations?

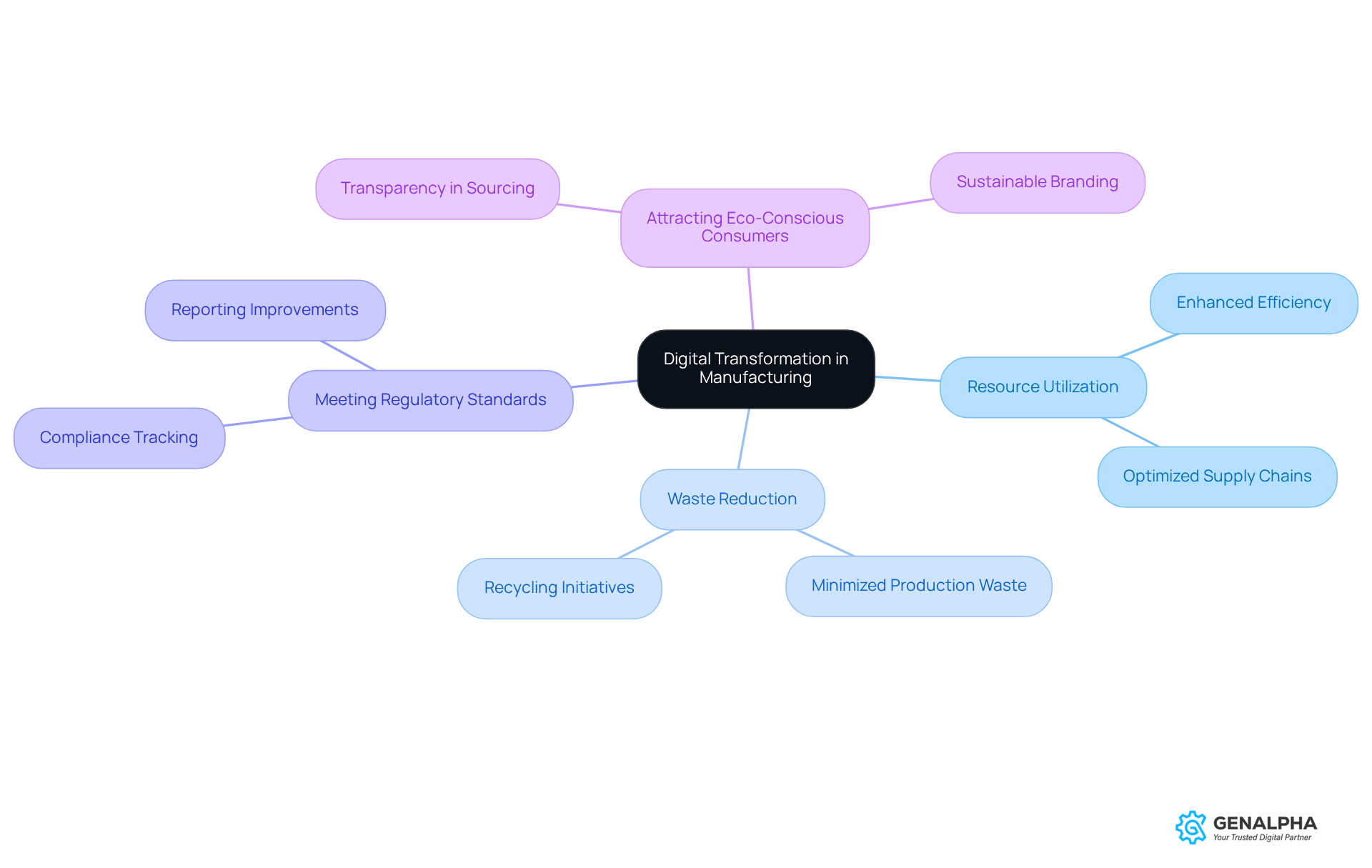

Stronger Sustainability Results: Meet Regulatory Standards

Have you ever considered the benefits of digital transformation in manufacturing for helping producers become more sustainable? It’s pretty amazing! By enhancing resource utilization and cutting down on waste, companies can effectively leverage the benefits of digital transformation in manufacturing. For example, advanced data analysis can highlight specific areas where improvements can be made. This not only helps businesses meet regulatory standards but also boosts their sustainability efforts, showcasing the benefits of digital transformation in manufacturing.

And here’s the kicker: this commitment to sustainability isn’t just good for the planet; it also attracts eco-conscious consumers who care about where their products come from. So, what do you think? Isn’t it time we embraced these sustainable practices? Let’s make a positive impact together!

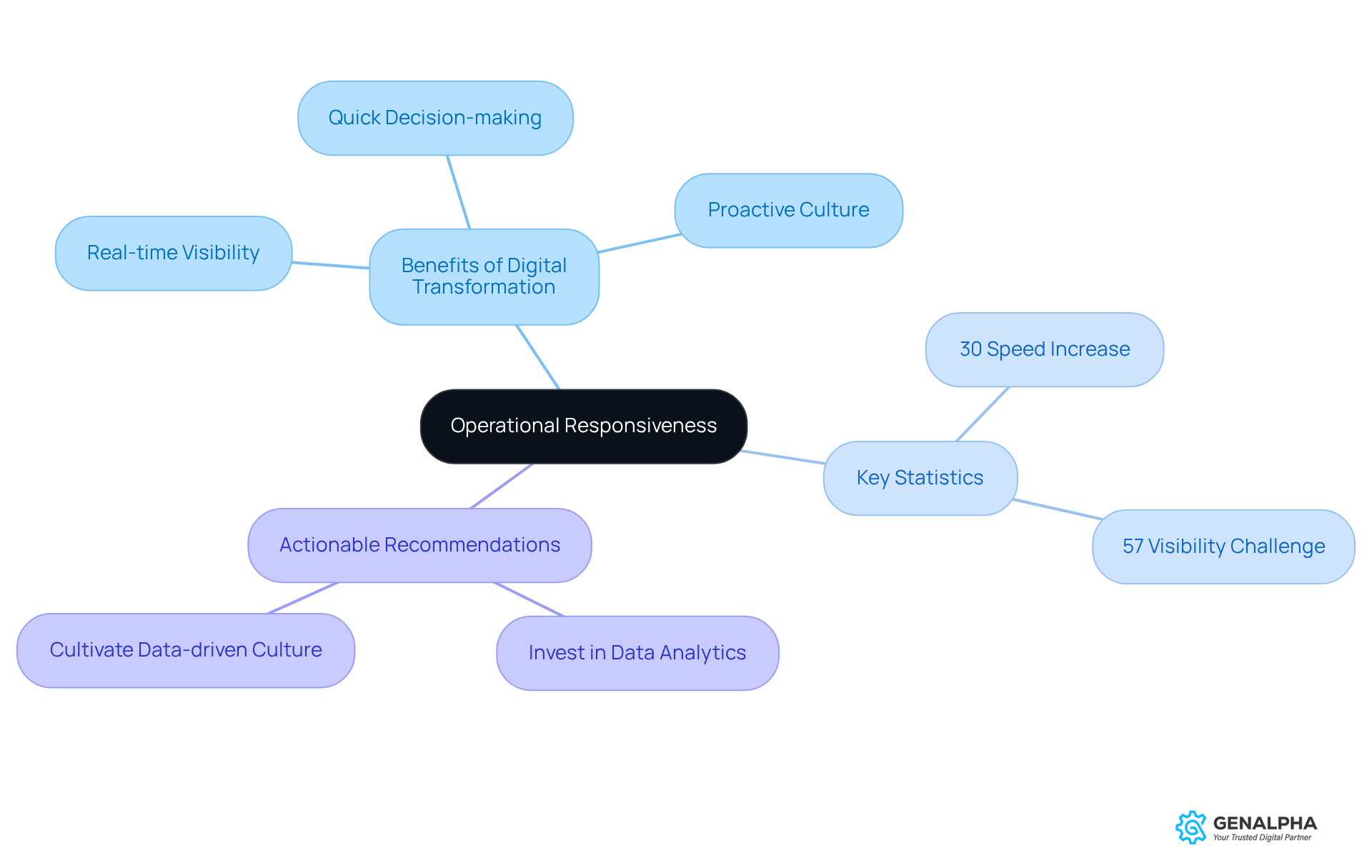

Real-Time Data Visibility: Improve Operational Responsiveness

The benefits of digital transformation in manufacturing are evident as it serves as a game changer for manufacturers, offering real-time visibility into information that helps them make quick decisions and respond nimbly to market changes. Have you ever noticed how swiftly companies can adapt? By diving into information analysis, businesses can spot new trends and tweak their strategies, keeping them competitive and aligned with what customers want. A recent study even pointed out that organizations leveraging this analysis have seen their decision-making speeds jump by up to 30%, which significantly boosts their operational responsiveness.

Interestingly, 29% of producers are now tapping into AI or machine learning at their facilities or across their networks. This trend really highlights the benefits of digital transformation in manufacturing and how it is reshaping the landscape. Industry leaders are all in on this, noting that the benefits of digital transformation in manufacturing not only streamline processes but also foster a culture of proactive decision-making. This means producers can adjust quickly to shifts in demand and tackle operational challenges head-on.

In fact, a staggering 57% of supply chain professionals say that lack of visibility is their biggest hurdle for 2025. This clearly shows the pressing need for better data-sharing capabilities to boost performance. As Steve McCrystal, Chief Enterprise Technology Officer, wisely points out, 'AI and data analysis are altering the way businesses function.' This really underscores the transformative potential these technologies hold.

So, what can producers do to enhance their operational responsiveness? It’s simple: prioritize investing in data analytics tools and cultivate a culture that embraces data-driven decision-making. Let’s take that step together—after all, the future is all about being agile and informed!

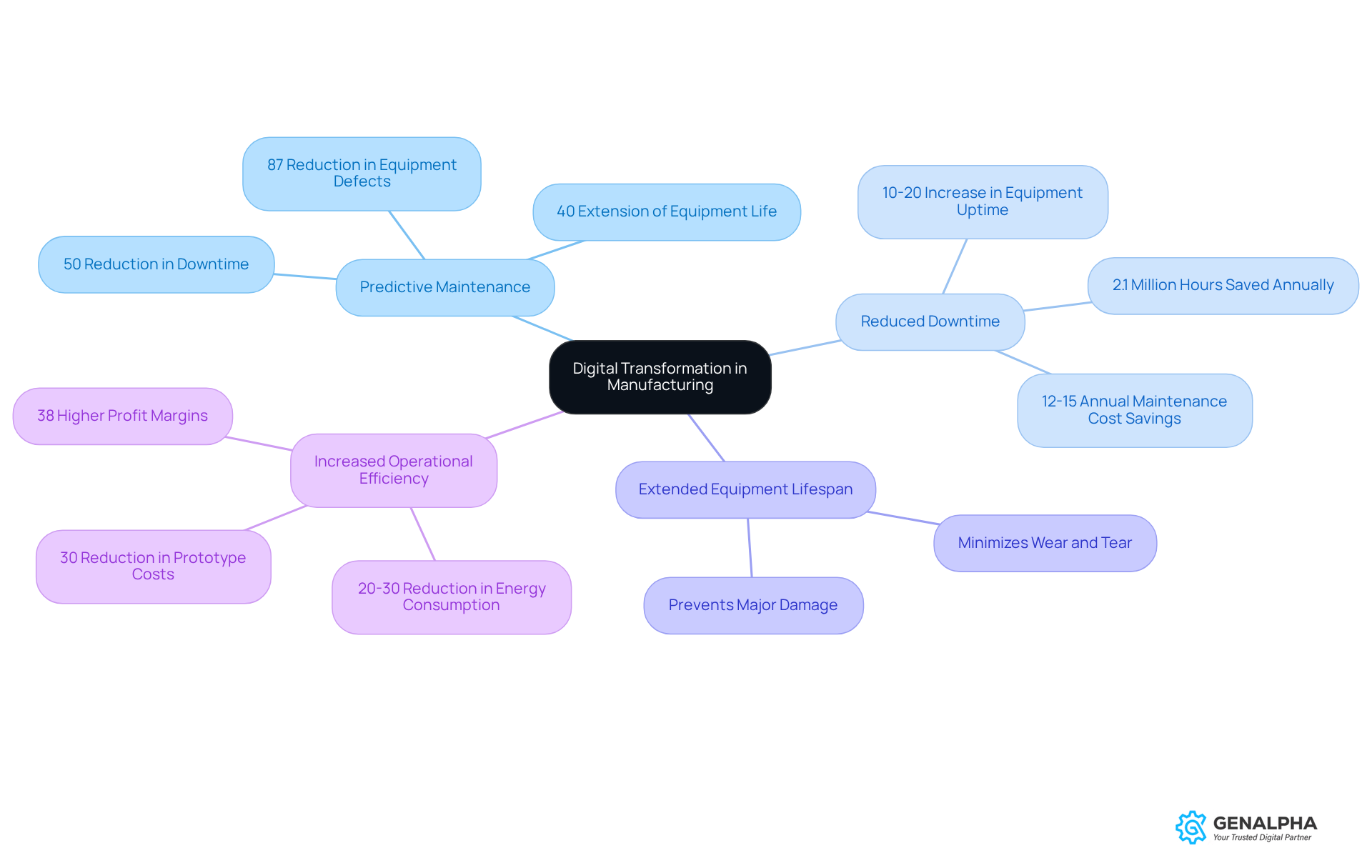

Reduced Machine Downtime: Maintain Productivity

Have you ever considered the benefits of digital transformation in manufacturing and how digital solutions can really change the game for predictive maintenance? Imagine being able to spot equipment failures before they even happen! By tapping into real-time monitoring of machine performance, companies can leverage the benefits of digital transformation in manufacturing to set up proactive maintenance schedules. This not only reduces those pesky unplanned downtimes but also showcases the benefits of digital transformation in manufacturing by maintaining productivity on track. Additionally, the benefits of digital transformation in manufacturing can even extend the lifespan of your equipment, boosting operational efficiency.

For example, did you know that predictive maintenance can slash downtime by up to 50%? That's a huge win! It can also stretch equipment life by around 40%. Industry leaders are all about this approach, emphasizing that the benefits of digital transformation in manufacturing, including smart predictive maintenance, not only save money but also guarantee timely product delivery, easing production stress.

And there’s more! The benefits of digital transformation in manufacturing are evident as organizations that embrace these digital solutions often see a noticeable bump in equipment uptime, with reports showing increases of 10 to 20%. By integrating advanced monitoring technologies, producers can realize the benefits of digital transformation in manufacturing while keeping their operational standards high and minimizing disruptions. So, why not consider how these strategies can work for you?

Enhanced Customer Engagement: Thrive in a Competitive Landscape

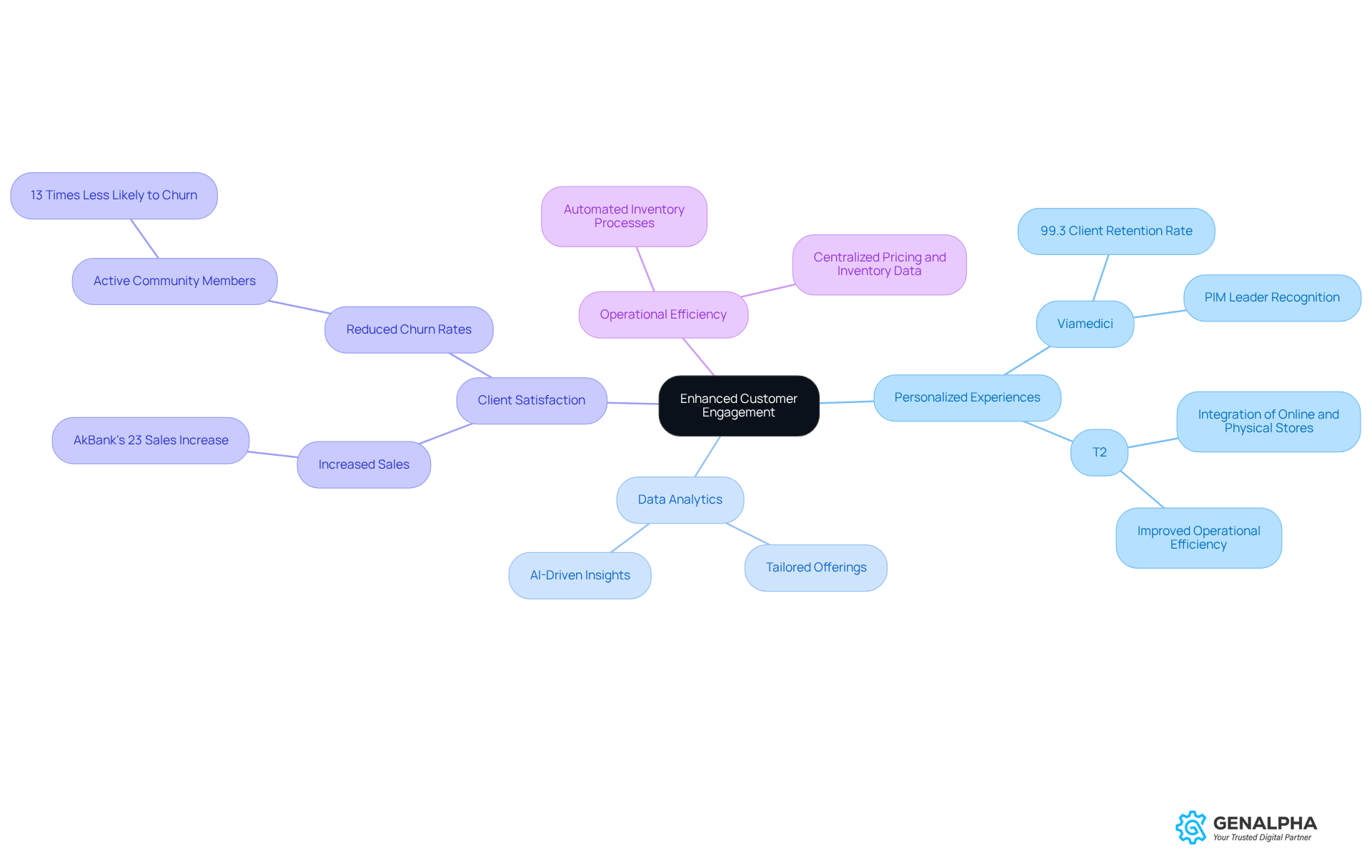

Digital transformation really amps up user engagement by creating personalized experiences and making purchasing processes smoother. Think about it: when manufacturers tap into data analytics, they can tailor their offerings to fit individual preferences. This not only builds loyalty but also drives repeat business. For instance, companies that embrace customized solutions often see a big boost in client satisfaction and retention rates. Take Viamedici, a leader in Product Information Management, which proudly boasts a 99.3% client retention rate—talk about the power of personalized engagement strategies!

Additionally, T2's clever blending of online and physical store functions during the pandemic has not only improved operational efficiency but also enhanced client satisfaction. It’s a clear example of the tangible benefits of digital transformation in manufacturing. In today's fast-paced market, where customer expectations are always changing, strong engagement is key to driving growth and keeping that competitive edge.

As industry leaders remind us, the benefits of digital transformation in manufacturing include the creation of personalized experiences, which are essential for thriving in the modern manufacturing environment. So, how are you thinking about personalizing your approach to meet those evolving expectations?

Conclusion

Digital transformation in manufacturing is a game-changer, driving efficiency, quality, and sustainability in today’s competitive landscape. By embracing digital solutions, manufacturers can streamline operations, cut costs, and boost customer engagement. This ultimately leads to better profitability and responsiveness to the market.

Let’s look at some key benefits of digital transformation:

- Increased operational efficiency through automation

- Improved product quality thanks to real-time monitoring

- Enhanced forecasting accuracy that aligns production with what customers actually want

- Maximizing profit margins by optimizing resource allocation and cutting down on waste

Just look at GenAlpha Technologies and its Equip360 platform to see how these digital strategies make a real difference in operations.

But here’s the kicker: the journey toward digital transformation isn’t just about new tech; it’s about building a culture of innovation and adaptability. Manufacturers should really take these insights to heart, using them not just to meet current market demands but also to anticipate what’s coming next. By prioritizing digital transformation, companies can stay competitive, sustainable, and responsive to the ever-changing needs of their customers. So, why wait? The time to act is now—embracing these changes is essential for thriving in the manufacturing sector of tomorrow.

Frequently Asked Questions

What is Equip360 and how does it benefit producers and distributors?

Equip360 is a digital solution from GenAlpha Technologies that integrates eCommerce capabilities with existing systems, allowing producers and distributors to streamline operations and enhance online sales processes. It features interactive parts catalogs and secure ordering, making online selling easier and helping manufacturers meet client demands while optimizing inventory management.

Can you provide an example of Equip360's impact on a company?

Yes, De Klok Dranken experienced an 80% adoption rate after upgrading to Equip360, leading to higher sales and increased client loyalty, demonstrating the platform's effectiveness in transforming manufacturing operations.

Why is digital transformation important for the manufacturing industry?

Digital transformation is essential for staying competitive in the manufacturing industry as it enhances operational efficiency, boosts workflow, and allows manufacturers to adapt to the fast-paced digital landscape. It also highlights the importance of selling the right products to the right customers at the right time for profitability.

How does digital transformation improve operational efficiency in manufacturing?

Digital transformation improves operational efficiency by automating processes and utilizing smart information analysis, which reduces manual tasks and errors. Real-time data analysis helps identify production bottlenecks, allowing companies to make timely adjustments that enhance overall performance.

What role do digital tools play in improving product quality?

Digital tools enhance product quality through advanced monitoring and analytics, allowing producers to track quality in real-time and address issues immediately. This proactive approach results in higher product quality and increased customer satisfaction.

How do systems like Opcenter Intelligence and Manufacturing Execution Systems (MES) contribute to quality control?

These systems provide real-time visibility into operations and key performance metrics, such as defect rates and production efficiency. They help producers maintain product quality standards and make informed decisions for continuous improvement, ultimately strengthening customer relationships.

What are the long-term benefits of leveraging digital tools in manufacturing?

Leveraging digital tools in manufacturing leads to improved product quality, enhanced customer satisfaction, compliance with industry standards, and reduced compliance risks. This holistic approach sets producers up for long-term success in a competitive market.