Overview

Have you ever wondered how equipment manufacturers can keep their quotation costs in check? It’s a common challenge, but there are some smart strategies that can really make a difference.

-

Adopting automated quoting tools can save time and reduce errors. Imagine how much smoother things would run if teams could focus on what really matters instead of getting bogged down in paperwork!

-

Integrating ERP systems can streamline processes even further. This means better communication among teams, which is crucial for keeping everyone on the same page.

-

Fostering open lines of communication is important. When teams work together seamlessly, it not only reduces mistakes but also helps to lower costs associated with quotations.

So, why not take a closer look at these strategies? By embracing automation and enhancing collaboration, you can not only control costs but also improve efficiency across the board. It’s time to make quoting a breeze!

Introduction

Manufacturers today are facing a tough challenge: how to manage quotation costs effectively in an ever-competitive landscape. But guess what? With the rise of digital solutions and automated tools, there’s a golden opportunity for equipment producers to not only streamline their quoting processes but also to cut down on errors and boost customer satisfaction. Sounds great, right? But here’s the kicker: how can manufacturers tackle the tricky world of pricing strategies, communication, and tech integration to achieve the best quotation efficiency possible?

In this article, we’re diving into seven actionable strategies that can completely transform how manufacturers handle quotation costs. These insights will help ensure they stay profitable and gain that all-important competitive edge. Ready to explore? Let’s get started!

GenAlpha Technologies: Streamlined eCommerce Solutions for Quotation Efficiency

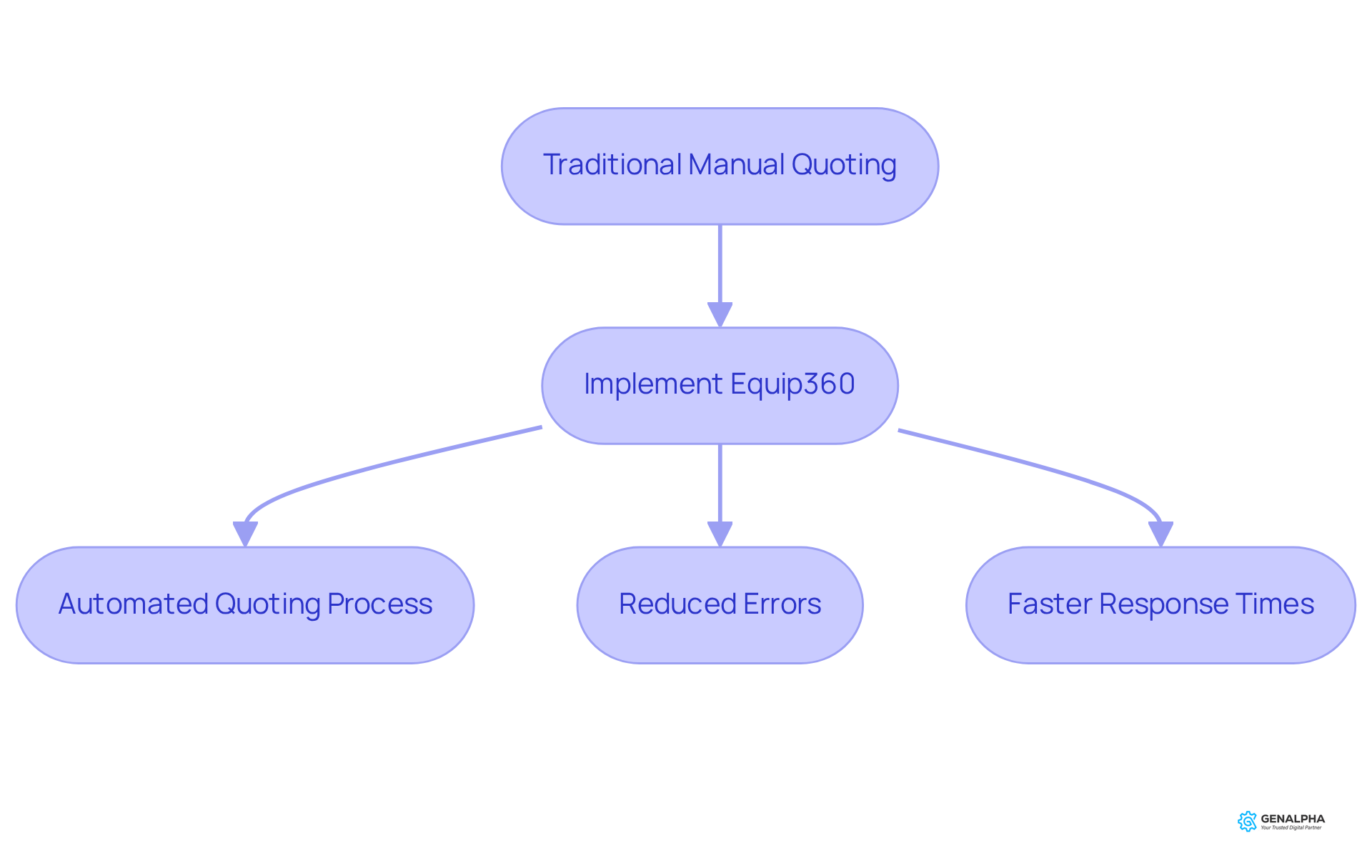

At GenAlpha Technologies, we’re all about making eCommerce solutions that really work for equipment producers. Take our flagship product, Equip360, for example. It fits right in with your existing ERP systems, giving you real-time access to crucial data and helping to streamline your workflows. By automating the quoting process, you can cut down on errors and speed up response times, resulting in lower quotation costs compared to traditional manual quoting methods.

This shift not only makes your operations run smoother but also keeps your customers happy with accurate and timely quotes. Kristina Harrington, our co-founder and CEO, puts it perfectly: "Embracing digital tools is not just an option — it’s a necessity for anyone looking to thrive in the ever-evolving business landscape."

And here’s something to think about: reports show that 80% of parts orders can shift to digital channels within just a year of implementing eCommerce. With Equip360, you can meet the , giving you a real edge in the market.

So, why not take a moment to evaluate the quotation cost of your current quoting processes? Consider bringing in digital tools like Equip360 to supercharge your operational capabilities. After all, it’s about making your life easier and your customers happier!

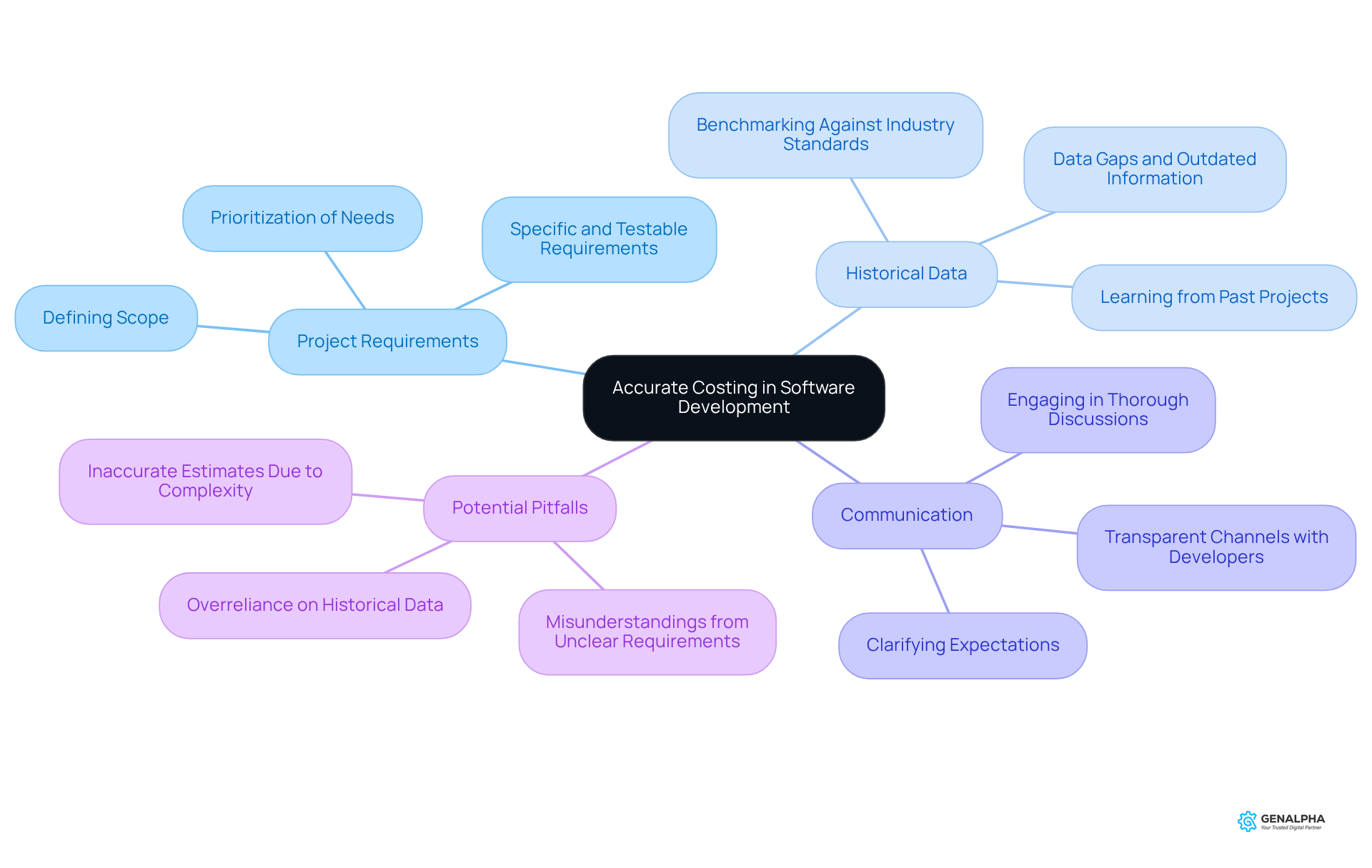

Software Development Quotes: Key Considerations for Accurate Costing

When you're diving into software development estimates, it's crucial to keep a few key factors in mind to hit that accuracy sweet spot. First off, clearly defining your project requirements is a must. This step directly and helps your development team give you those precise estimates you’re after. For example, if producers tap into historical data from past projects, they can uncover valuable insights about potential costs. This not only aids in budgeting but also makes planning a whole lot smoother. Plus, it promotes a culture of continuous improvement by highlighting patterns of risk and success. Millie Vingrys puts it well when she says that learning from both wins and losses allows teams to streamline processes and optimize workflows.

Now, let’s talk about communication. Establishing a transparent channel with your software providers is vital. This open dialogue clarifies expectations and ensures that the quotation cost accurately reflects the real costs of development. By engaging in thorough discussions about project specifics, producers can sidestep common pitfalls that stem from unclear requirements, as those often lead to misunderstandings and higher quotation costs. However, it's also important to keep in mind the challenges that can arise from relying too heavily on historical data, like data gaps and outdated information, which can throw off accurate estimations. In the end, having a well-defined project scope, backed by historical data and effective communication, gives producers the confidence to navigate the complexities of software development.

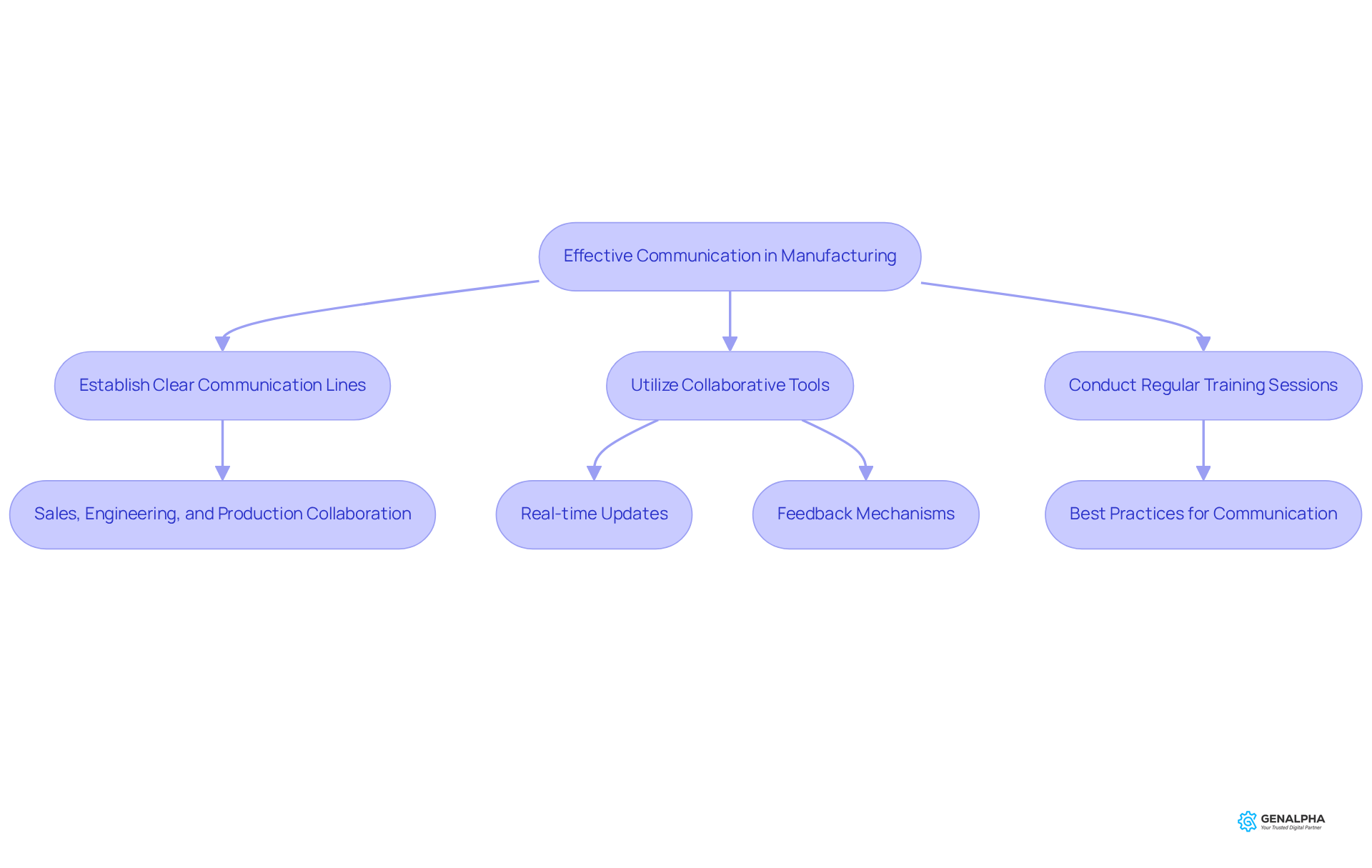

Effective Communication: A Critical Factor in Quotation Accuracy

Have you ever thought about how important effective communication is in manufacturing? It’s absolutely crucial for getting those accurate quotes we all strive for. Imagine this: manufacturers really need to create clear lines of communication between sales, engineering, and production teams. Why? Because when everyone is on the same page, all the relevant information gets considered when determining the quotation cost.

Using like project management software and messaging platforms can really make a difference. They allow for real-time updates and feedback, which can significantly cut down on errors. For example, businesses that have jumped on board with integrated communication systems often report a big drop in miscommunication, leading to much more accurate estimates.

And here’s a thought: regular training sessions focused on communication best practices can take team collaboration to the next level. They help create an environment where information flows seamlessly. By prioritizing these strategies, producers can boost their quotation cost accuracy while also enhancing overall operational efficiency. Isn’t that something worth considering?

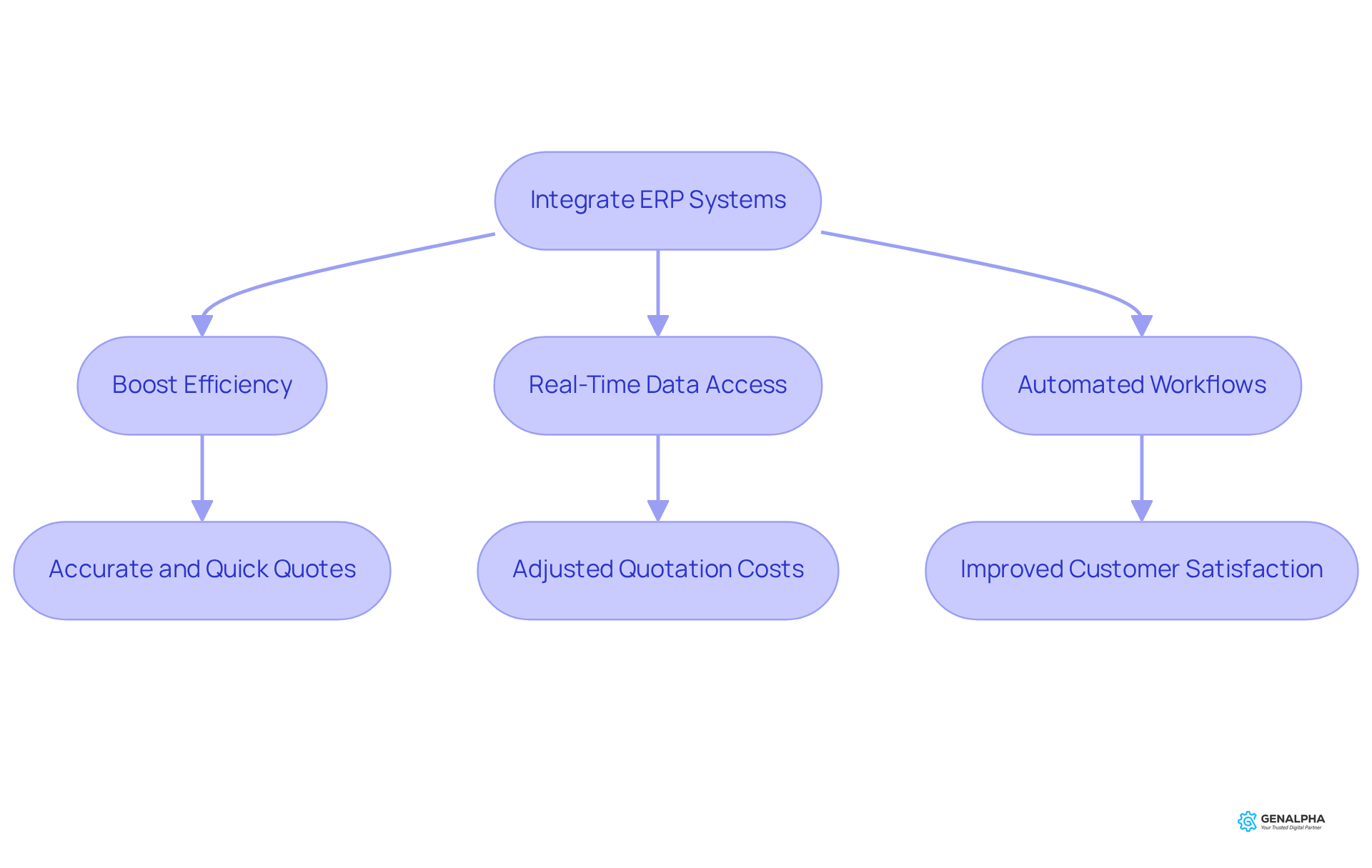

ERP Integration: Optimizing Quotation Processes for Cost Reduction

Have you ever thought about how integrating ERP systems into the quoting process can really change the game for producers? It’s all about boosting efficiency and cutting costs. By bringing together data on inventory, pricing, and customer info, producers can whip up quotes that are not only accurate and quick but also take into account the quotation cost.

Imagine having real-time updates on material costs and availability at your fingertips! This means producers can on the fly based on what’s happening in the market. Plus, with automated workflows taking care of the tedious data entry, there’s less chance for mistakes and a faster quoting process overall.

As a result, manufacturers can jump on inquiries much quicker, which is a win for customer satisfaction and could even lead to increased sales. And let’s not forget: having access to real-time data means that the quotation cost is always reflecting the most accurate pricing and availability. This leads to smarter decision-making and a smoother operation. So, why not consider how ERP could streamline your quoting process?

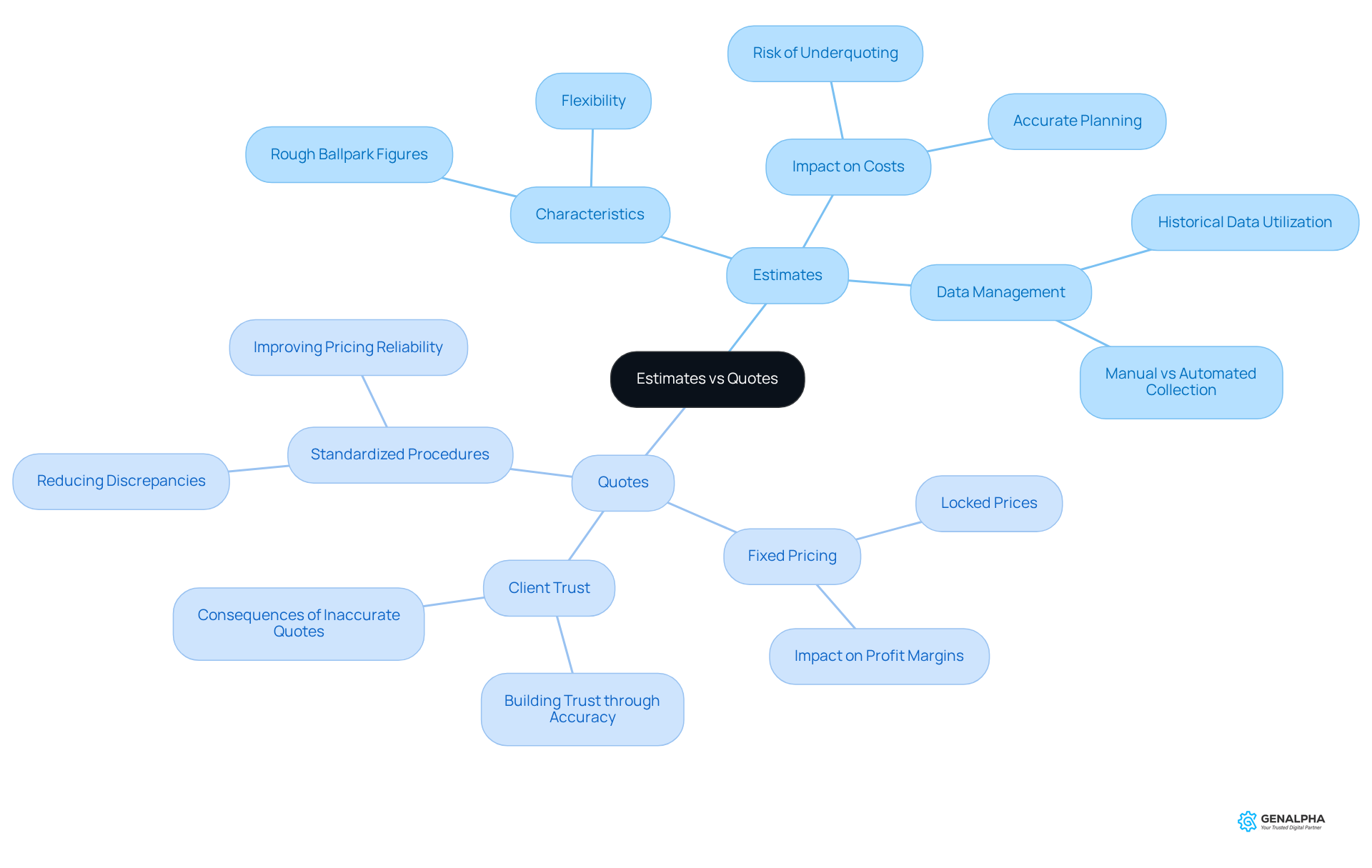

Estimates vs. Quotes: Understanding Their Impact on Quotation Costs

Understanding the difference between estimates and quotes is crucial for effectively. Think of estimates as rough ballpark figures that can change, while the quotation cost represents the fixed prices that become locked in once you say yes. It's all about clear communication—making sure everyone knows what to expect. By tapping into historical data and market trends for accurate estimates, producers can really cut down the chances of underquoting. This means that the quotation cost will accurately represent the actual costs of delivering products or services, which is a win-win for client satisfaction and profitability.

For instance, producers who use standardized quoting methods have noticed fewer discrepancies and improved pricing reliability. This builds trust and strengthens client relationships. Plus, as April Guenet, a Product Marketing Manager, points out, 'Consistently inaccurate quotation costs can erode customer trust and result in lost business.' So, accurate planning and resource allocation from precise estimates can help avoid operational hiccups and boost project execution.

And here's a thought: with 70% of producers still collecting data manually, the risk of inaccuracies could lead to revenue losses of up to 12%. This really highlights the need for better data management practices. To up the ante on quoting accuracy, manufacturers should think about putting standardized quoting procedures in place. What do you think? Wouldn't that make a difference?

Pricing Strategies: Navigating Complexity to Control Quotation Costs

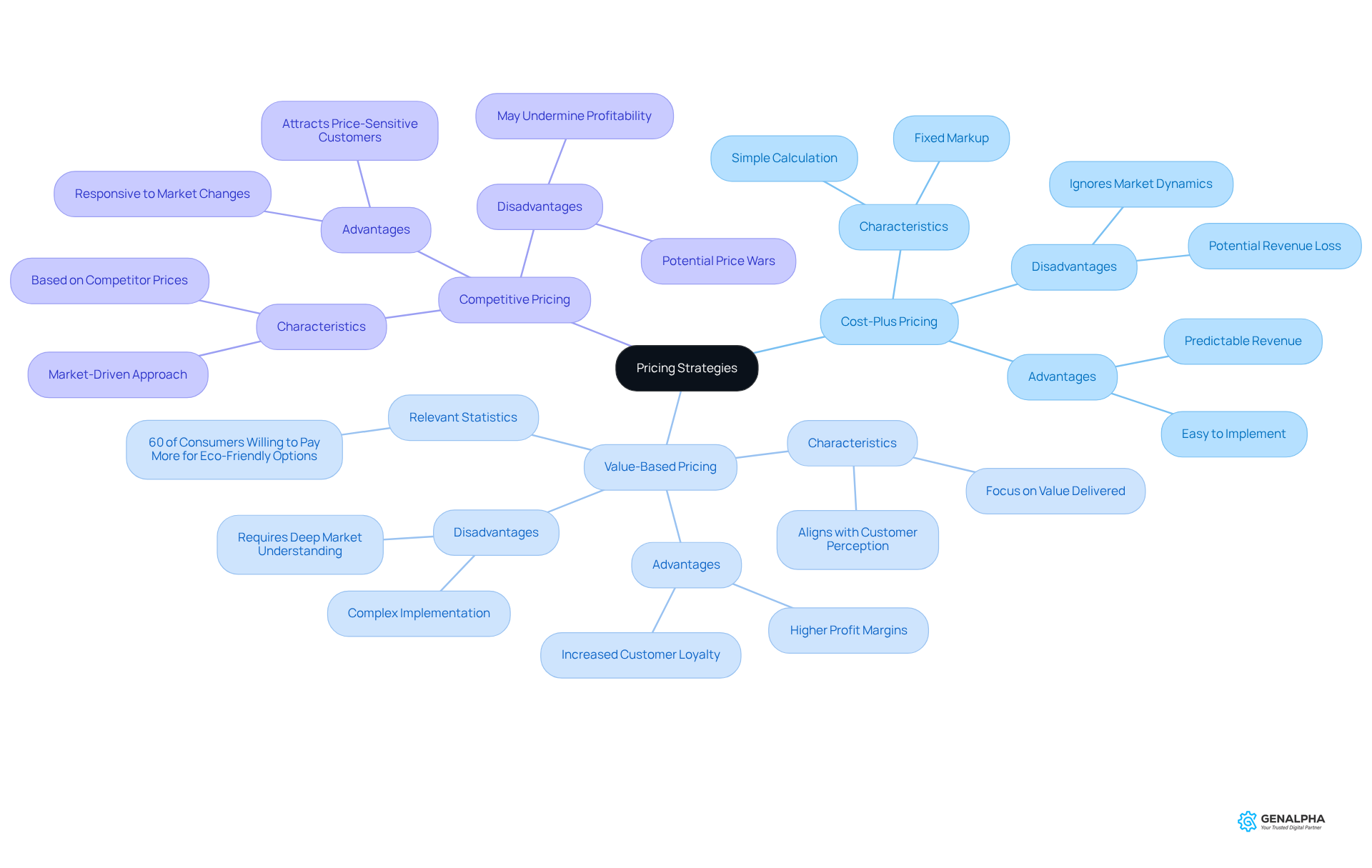

Navigating cost complexities is essential for managing quotation costs effectively in manufacturing. Have you ever thought about how a mix of cost structures might help? Manufacturers should really consider blending strategies like cost-plus, value-based, and competitive methods to find what works best for their products.

Now, the cost-plus strategy is pretty straightforward, but it often overlooks market dynamics and what buyers are willing to pay, which could lead to lost revenue. On the flip side, value-oriented strategies align costs with what clients perceive as valuable, and that can significantly boost profitability. For instance, producers using value-oriented cost strategies have reported better margins, and AI-driven methods can even increase profitability by up to 10% by analyzing data to fine-tune costs based on demand and customer history.

To stay competitive, producers need to keep an eye on market trends and consumer preferences. This means using data analytics to understand demand fluctuations and adjusting costs accordingly. Regularly assessing cost frameworks, guided by client feedback, can really enhance strategies and improve client satisfaction.

Think about it: businesses that effectively communicate the value of their products, especially when it comes to sustainability, can justify higher prices. In fact, 60% of consumers are willing to pay more for eco-friendly options! Being clear about costs is crucial for building trust with customers, which is key for fostering long-term relationships.

Additionally, integrating market analysis into cost decisions is vital. Understanding directly impacts manufacturing profitability by influencing sales volumes and cost strategies. Producers who tackle cost challenges head-on can not only manage expenses but also position themselves strategically in a competitive landscape, paving the way for long-term success. Plus, using CPQ (configure-price-quote) tools can enhance cost strategies by enabling sales teams to quickly adjust value variables for customized solutions.

Automated Quoting Tools: Enhancing Efficiency and Reducing Costs

Have you ever thought about how automated pricing tools can really change the game for businesses? These tools are essential for boosting efficiency and cutting quotation costs in the pricing process. They quickly generate estimates that reflect the quotation cost by pulling data from multiple sources, ensuring that costs and product configurations are spot on.

Imagine being able to handle millions of quote transactions without losing accuracy or flexibility. That’s the beauty of automated systems! They significantly cut down on manual input, which means fewer errors and a faster estimation process. This allows sales teams to respond to customer inquiries in a flash, ultimately enhancing customer satisfaction.

Additionally, real-time pricing and inventory checks help minimize errors that could lead to disputes or rework. And let’s not forget the valuable insights these systems provide about pricing performance. Producers can easily spot areas for improvement and fine-tune their pricing strategies.

For example, companies that have embraced automated quoting solutions often see a dramatic drop in quote generation time—some reducing it from days to just minutes! This boost in efficiency not only speeds up response times but also ramps up win rates, since the first accurate quotation cost is often the one that seals the deal. It’s a great way to gain a competitive edge.

So, by leveraging these advanced tools, producers can streamline operations, cut costs, and stay ahead in the market. Why not consider how these tools could today?

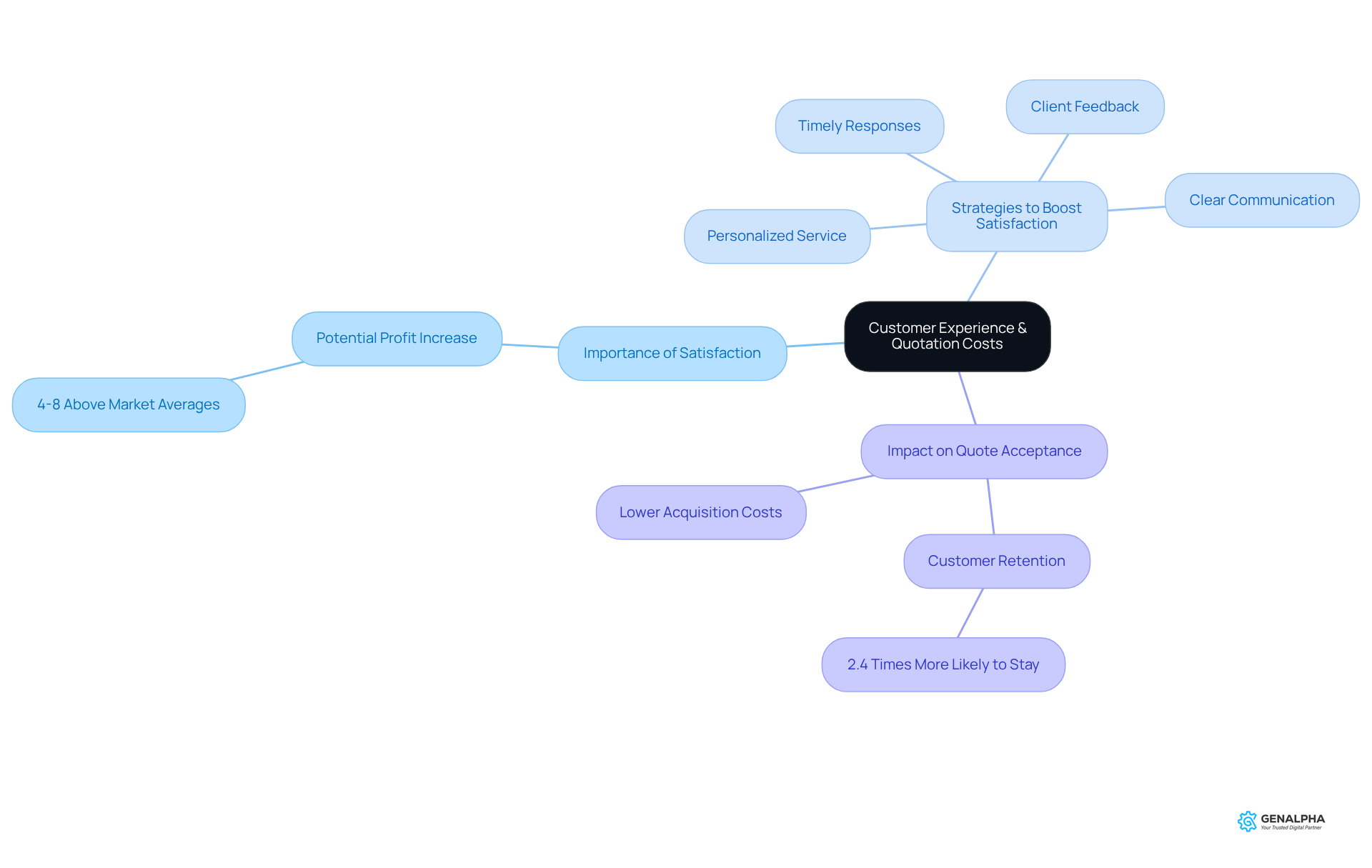

Customer Experience: Influencing Quotation Costs Through Satisfaction

Did you know that customer experience can significantly impact quotation cost? It’s true! Research indicates that satisfied clients are much more likely to accept quotes and come back for repeat transactions, potentially increasing profitability by 4-8% above market averages.

So, how can producers boost client satisfaction? One effective way is by actively seeking and incorporating client feedback into quoting processes. This means ensuring clear communication, providing timely responses, and offering personalized service that caters to individual needs. By fostering strong connections with clients, manufacturers can cultivate loyalty—clients are 2.4 times more likely to stick with a brand that quickly resolves their issues.

This approach not only but also lowers the quotation cost related to acquiring new clients. By applying these strategies, you can streamline your pricing process, ultimately lowering costs and paving the way for greater business success. Ready to take your customer experience to the next level?

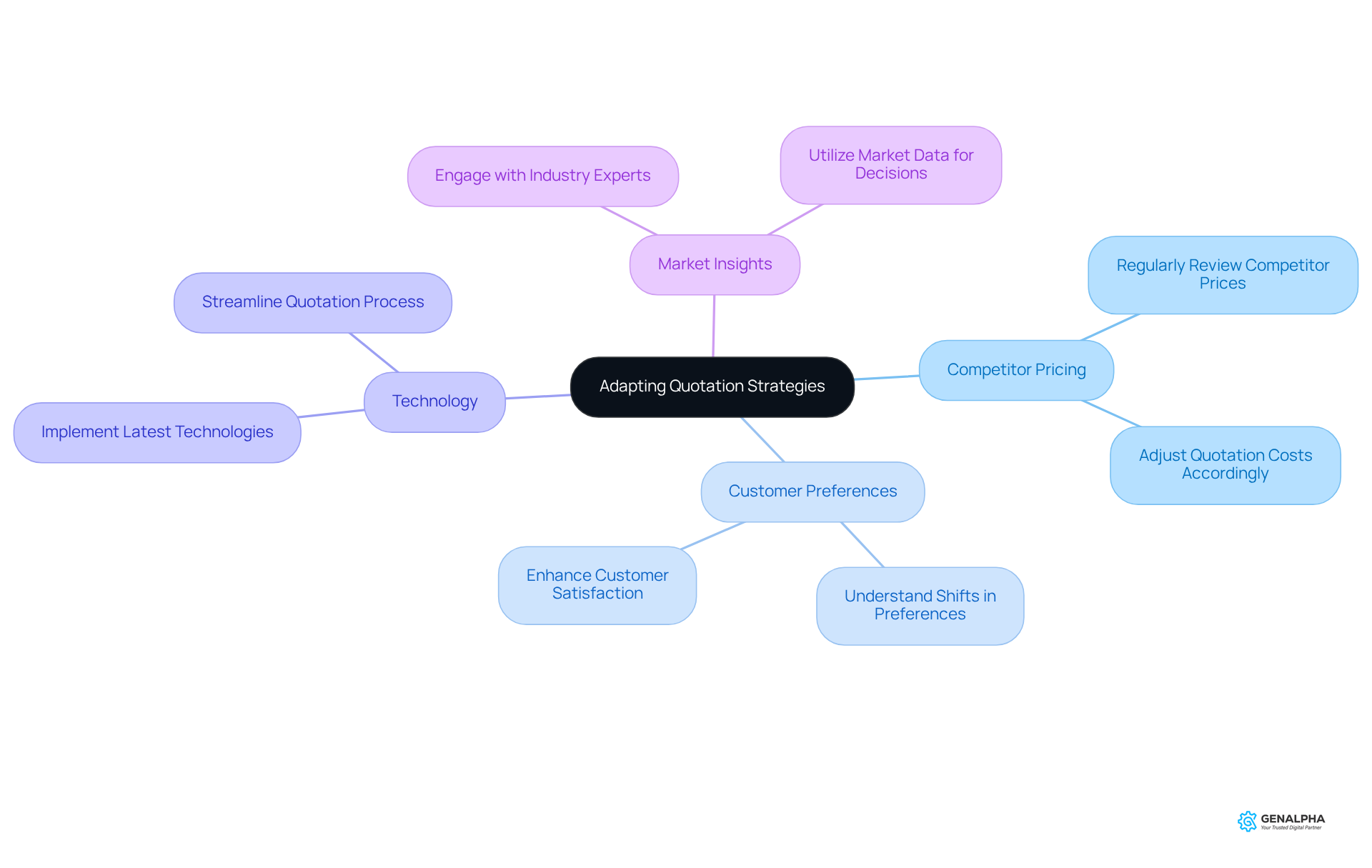

Market Trends: Adapting Quotation Strategies to Stay Competitive

To stay competitive, manufacturers must closely monitor that impact their quotation cost strategies. This means keeping a close eye on what competitors are charging, understanding shifts in customer preferences, and using the latest technologies to streamline the quotation cost process. Engaging proactively with market data and industry experts is key, as it offers valuable insights that can guide smart decisions. As Lisa Schwarz, Senior Director of Global Product Marketing, puts it, "Manufacturers cannot overcome these challenges without first understanding the ins and outs of their business."

Did you know that a recent survey found that 65% of manufacturing leaders are worried about their company's future? This highlights just how important it is to be flexible with cost strategies. By regularly reviewing competitor pricing, manufacturers can effectively adjust their quotation cost, ensuring they remain attractive to customers while safeguarding their profit margins. For instance, companies that have successfully tweaked their estimation strategies in response to competitor costs have not only bolstered their market position but also increased customer satisfaction and loyalty.

This approach is especially vital in today’s manufacturing world, where challenges like skills gaps and supply chain disruptions are all too common. So, how is your company adapting to these changes? It's time to think about how you can stay ahead!

Cost Tracking: Ensuring Accurate Quotation for Profitability

Implementing effective cost tracking is crucial for obtaining accurate quotation cost and ensuring healthy profits in manufacturing. Have you ever thought about how much a systematic approach to monitoring production costs can help? It’s not just about materials; it includes labor and overhead too. By consistently comparing quotation costs with actual expenses, producers can identify discrepancies and adjust their pricing strategies as needed.

For example, using sophisticated software solutions like job costing systems can really streamline cost tracking. These tools provide real-time insights that guide pricing decisions and improve overall financial performance. Imagine capturing accurate costs in real-time—this not only leads to better estimates but also enhances cash flow management. Plus, these systems help identify potential savings through real-time tracking and reporting.

Additionally, when you pair machine data with these tools, you can boost operational performance and pricing precision. By adopting these technologies, producers can improve quoting accuracy and manage quotation costs while remaining agile in response to market changes and client needs. This is especially important since many manufacturers still rely on , which often lead to inefficiencies and inaccuracies. So, why not take the leap and explore these solutions? Your bottom line will thank you!

![]()

Conclusion

In the competitive world of equipment manufacturing, managing quotation costs effectively is crucial for success. Have you ever thought about how a multifaceted approach could transform your quoting process? This article highlights the importance of incorporating digital tools, effective communication, and strategic pricing methods. By leveraging technology like automated quoting systems and ERP integration, manufacturers can streamline their processes, reduce errors, and boost customer satisfaction.

Key strategies we discussed include:

- The significance of clear communication among teams

- The necessity of accurate project estimates

- How customer experience impacts quotation acceptance

Additionally, understanding market trends and implementing robust cost tracking systems are essential for maintaining profitability and adapting to the ever-changing industry landscape. Each of these elements plays a vital role in ensuring that quotation costs are not only controlled but also optimized for better financial outcomes.

Ultimately, manufacturers who embrace these strategies can set themselves up for long-term success. By prioritizing efficiency, accuracy, and customer satisfaction, they can navigate the complexities of quotation costs and build stronger relationships with clients. So, why wait? Now is the time to explore these strategies and consider how they can transform your quotation processes, leading to improved operational performance and enhanced competitiveness in the market.

Frequently Asked Questions

What is Equip360 and how does it benefit equipment producers?

Equip360 is a flagship product from GenAlpha Technologies designed to integrate with existing ERP systems. It provides real-time access to critical data and automates the quoting process, reducing errors and speeding up response times, which leads to lower quotation costs compared to traditional manual methods.

How does automating the quoting process impact customer satisfaction?

By automating the quoting process, businesses can provide accurate and timely quotes, resulting in smoother operations and increased customer satisfaction.

What is the potential impact of implementing eCommerce solutions like Equip360?

Reports indicate that 80% of parts orders can shift to digital channels within a year of implementing eCommerce solutions, allowing businesses to meet the growing demand for fast, reliable service and gain a competitive edge.

What key factors should be considered for accurate software development quotes?

Key factors include clearly defining project requirements, utilizing historical data for insights, and maintaining open communication with software providers to ensure accurate cost estimations.

How can communication improve quotation accuracy in manufacturing?

Effective communication between sales, engineering, and production teams ensures all relevant information is considered when determining quotation costs, leading to more accurate estimates.

What tools can enhance communication and reduce errors in quoting?

Collaborative tools such as project management software and messaging platforms facilitate real-time updates and feedback, significantly reducing errors in the quoting process.

Why is training important for improving communication in manufacturing?

Regular training sessions focused on communication best practices help create an environment of seamless information flow, boosting quotation accuracy and overall operational efficiency.