Overview

Have you ever thought about how smart supplies are changing the game in equipment manufacturing? We're talking about the cool integration of advanced technologies like IoT, AI, and cloud computing. These innovations are not just fancy buzzwords; they actually help streamline processes, cut down on waste, and improve inventory management.

Imagine a world where your operations run smoothly, costs drop significantly, and your customers are happier than ever. That’s the magic of smart supplies! By embracing these technologies, manufacturers can truly transform their operations.

So, what are you waiting for? It’s time to explore how these advancements can lead to impressive cost savings and a boost in customer satisfaction. Let’s dive into the transformative potential of smart supplies in the manufacturing sector together!

Introduction

In today's fast-paced manufacturing world, smart supplies are changing the game for companies everywhere. Imagine being able to boost efficiency, cut costs, and keep your customers smiling—all thanks to technologies like IoT and AI. Sounds great, right? But let’s be real: diving into these innovations isn’t always a walk in the park. From figuring out how to integrate new systems to training your team, there are plenty of bumps along the way. So, how can manufacturers tap into the power of smart supplies to not just keep up but truly excel in this ever-evolving landscape?

Define Smart Supplies in Equipment Manufacturing

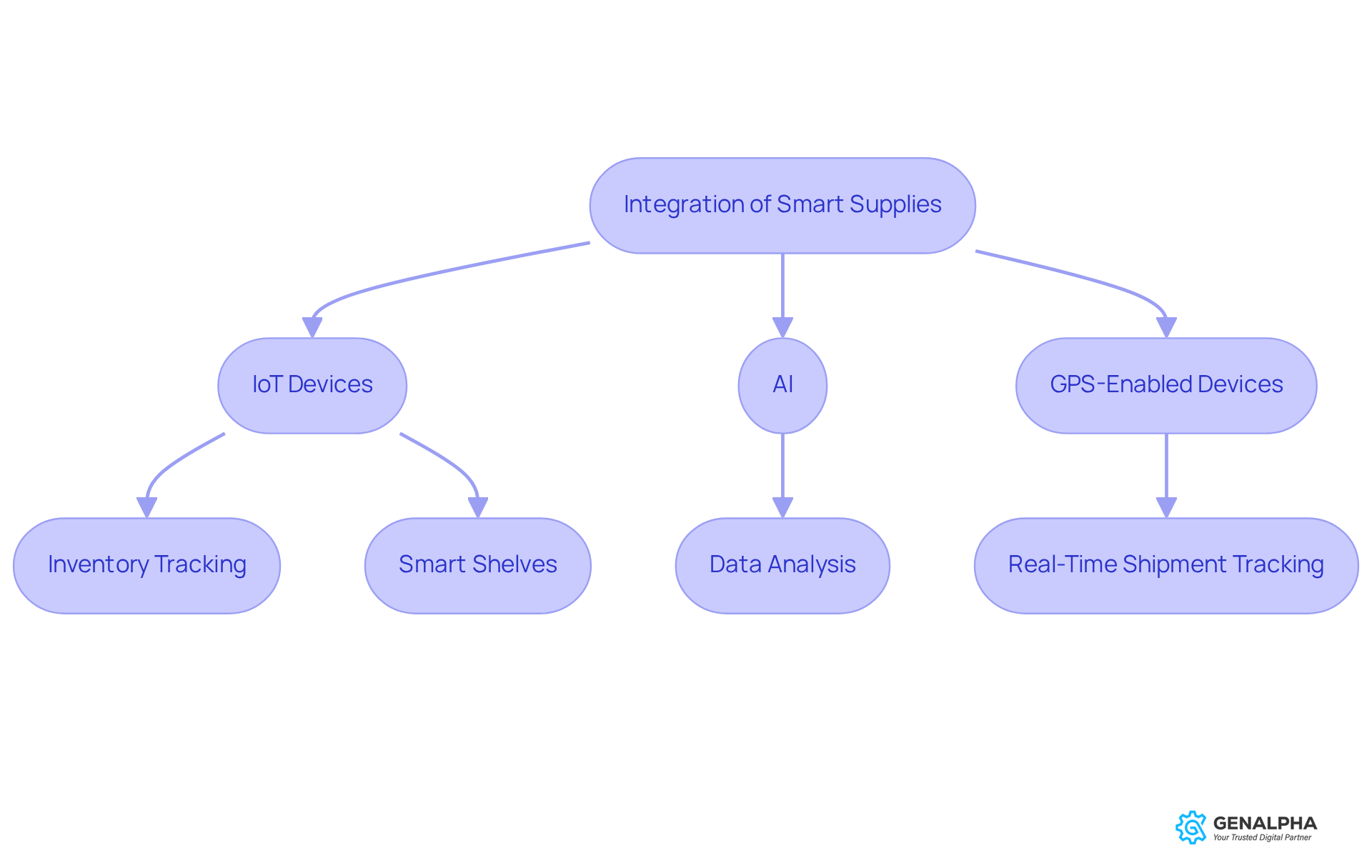

Have you ever thought about how smart supplies and technology are changing the game in equipment manufacturing? Smart supplies, such as IoT devices and AI, are being woven into logistics and inventory management, making operations smoother and smarter. These innovations help us analyze data in real-time, giving us better visibility and responsiveness.

For instance, imagine a manufacturer using IoT-enabled systems to keep tabs on inventory as it moves in and out. This means they can , cutting down on waste and avoiding those frustrating stockouts. Retailers are also getting in on the action with IoT-enabled smart shelves that help prevent out-of-stock situations. This is crucial for keeping production schedules on track and meeting customer expectations, which ultimately boosts satisfaction and loyalty.

Additionally, GPS-enabled IoT devices allow businesses to track shipments in real-time, reducing delays and improving delivery accuracy. As we look ahead to 2025, the impact of IoT on logistics management is set to be huge. Companies will be able to adapt quickly to market needs, enhancing their overall effectiveness. Practical applications, such as smart supplies like smart shelves in retail and temperature-sensitive drug transport in pharmaceuticals, demonstrate how these innovations are reshaping logistics dynamics, ensuring top-notch performance and reliability.

However, it’s important for producers to stay aware of potential hurdles, like integrating these new systems with existing ones and the need for employee training. As industry experts suggest, embracing these innovations is key to staying competitive in our fast-evolving market. So, what do you think? Are you ready to dive into the world of intelligent resources and see how they can transform your operations?

Explore Technologies Driving Smart Supply Implementation

Several pivotal technologies are driving the adoption of smart supplies in manufacturing, with each one boosting operational efficiency and responsiveness.

Have you ever thought about how the Internet of Things (IoT) is changing the game? IoT devices allow for real-time monitoring of inventory and equipment, giving producers crucial insights into stock levels and equipment performance. This means they can manage resources proactively, helping to avoid those frustrating stockouts and overstocking situations.

Then there's Artificial Intelligence (AI). AI algorithms are key players in analyzing data to forecast demand, optimize inventory levels, and automate decision-making. By tapping into predictive analytics, manufacturers can enhance their operational efficiency, achieving up to 38% higher profit margins through better inventory management. Plus, AI-driven predictive maintenance can cut downtime by as much as 50%, taking operational performance to the next level.

Cloud computing is another big player here. Cloud-based platforms make it easy to share data and collaborate across the network, boosting visibility and coordination among everyone involved. This connectedness means companies can respond more quickly to market changes and customer needs.

Let’s not forget about blockchain. This technology brings transparency and traceability to the distribution network, ensuring that everyone has access to accurate and up-to-date information. By building trust among stakeholders, blockchain can streamline processes and cut down on disputes.

And we can’t overlook advanced analytics. Using empowers producers to spot trends, optimize processes, and make informed decisions based on real-time data. This analytical capability is essential for refining inventory strategies and enhancing overall logistics performance.

By embracing these technologies, manufacturers can create a more agile and responsive logistics system, leading to greater efficiency and happier customers. As Christine Hansen, a manufacturing specialist, noted, "A digital logistics solution that harnesses the capabilities of AI and IoT can provide considerable advantages for companies, including speed, automation, and improved collaboration and decision-making." And let’s not forget the exciting potential of drones to speed up last-mile delivery times—just one more way IoT advancements can boost supply chain efficiency.

So, what do you think? Are you ready to explore how these technologies can transform your operations?

Highlight Benefits of Smart Supplies for Manufacturers

Have you ever considered how smart supplies could transform the manufacturing process? They provide a host of significant benefits that can really make a difference for manufacturers by utilizing smart supplies.

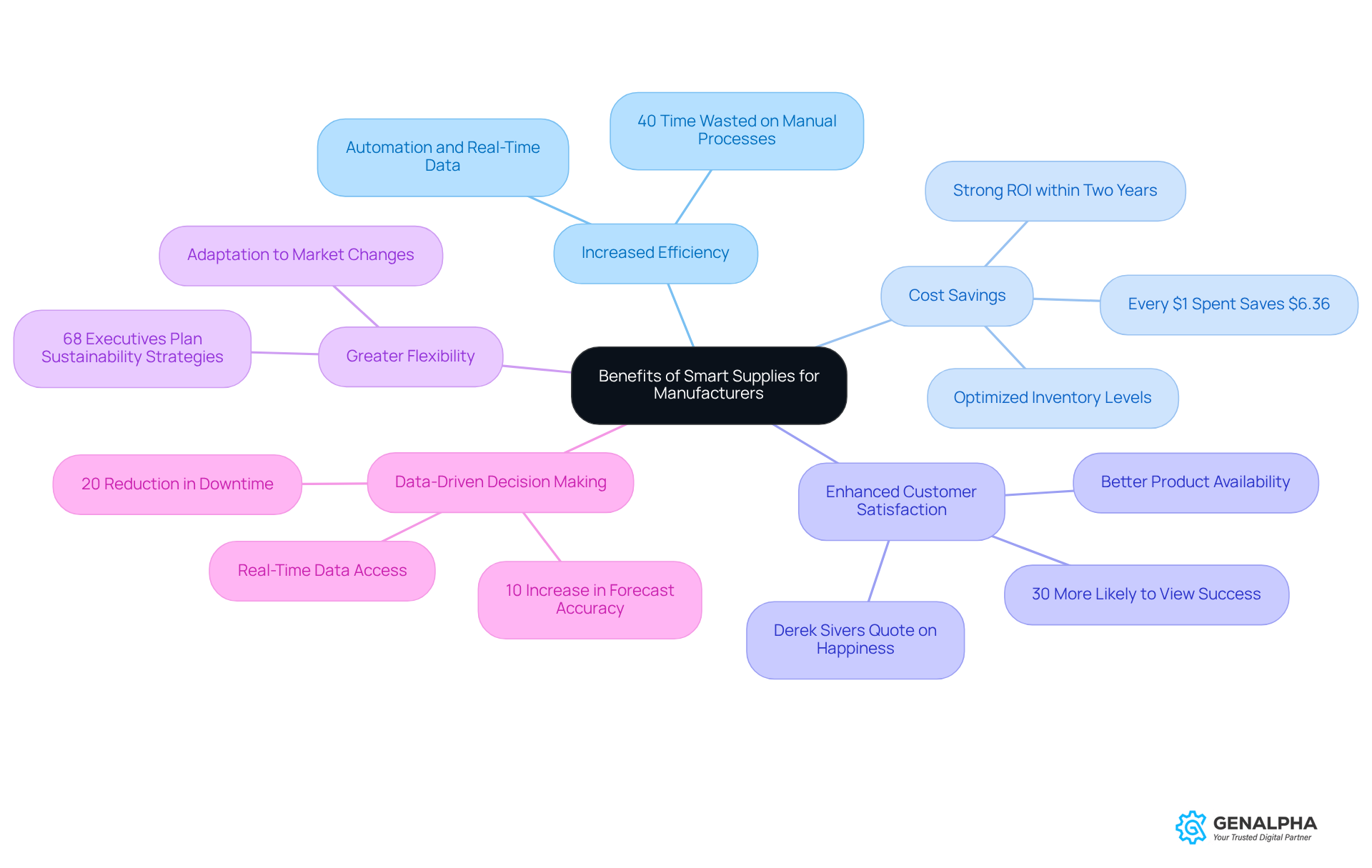

First up, let’s talk about Increased Efficiency. With automation and , operations can be streamlined, cutting down on manual tasks and minimizing errors. Did you know that manufacturers waste over 40% of their time on manual processes? This really highlights the need for smart supplies to provide smarter solutions.

Next, consider Cost Savings. By optimizing inventory levels and reducing waste, manufacturers can see substantial reductions in operational costs. Research shows that implementing chain optimization technologies can yield impressive returns on investment within just two years. In fact, for every $1 spent on management, companies can save about $6.36 in costs!

Now, let’s not forget about Enhanced Customer Satisfaction. Better inventory management means better product availability, which helps producers meet customer demands quickly. Companies that focus on customer feedback are 30% more likely to view themselves as successful. As Derek Sivers, founder of CD Baby, wisely said, "The single most important thing is to make people happy. If you are making people happy, as a side effect, they will be happy to open up their wallets and pay you."

Another key benefit of smart supplies is greater flexibility. Smart resources allow producers to adapt quickly to changing market conditions and customer preferences, giving them a competitive edge. For instance, 68% of manufacturing executives plan to adopt extensive sustainability strategies, showing a move toward more adaptable operations.

Then there’s Data-Driven Decision Making. Having access to real-time data enables producers to make informed choices that enhance strategic planning and execution. One producer that integrated IoT sensors to monitor equipment performance reported a 20% reduction in downtime, which significantly boosted both production capacity and customer satisfaction. Plus, Mahindra and Mahindra’s use of AI and predictive analytics led to a 10% increase in forecast accuracy and a 20% reduction in inventory investment.

These benefits clearly show how smart supplies not only enhance operational efficiency but also help create a more responsive and customer-focused manufacturing environment. However, it’s crucial for manufacturers to watch out for common pitfalls, like underestimating integration complexity and failing to align investments with strategic goals, to ensure successful adoption. So, what steps will you take to embrace these smart solutions?

Implement Strategies for Effective Smart Supply Integration

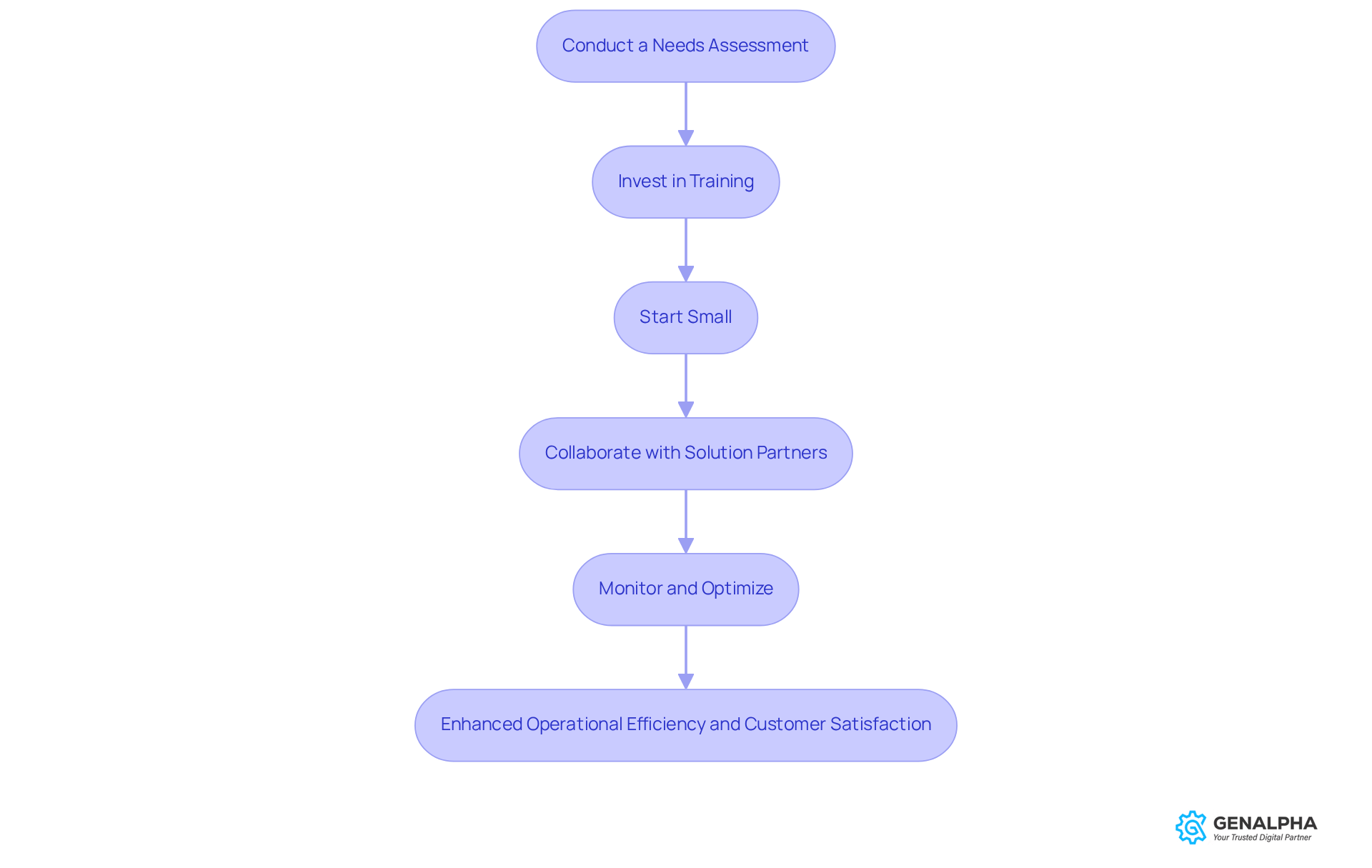

Are you ready to incorporate smart supplies into your manufacturing operations? Let’s explore some strategies that can really make a difference!

First up, Conduct a Needs Assessment. Take a good look at your current supply chain processes. What areas could use a little intelligent boost? This kind of evaluation helps ensure that your meet your specific operational needs.

Next, Invest in Training. It’s crucial to educate your staff on the latest innovations and processes. Did you know that organizations focusing on training see a 20% rise in adoption rates? That’s a big deal! Plus, with 74% of logistics chain executives planning to ramp up investments in automation and IoT to tackle talent shortages by 2025, training is more important than ever.

Now, let’s Start Small. Consider launching pilot projects to test how smart supplies perform before going all in. This approach allows you to make adjustments based on real-world outcomes, minimizing any risks along the way.

Don’t forget to Collaborate with Solution Partners. Teaming up with service providers ensures that your chosen solutions align with your business goals and fit seamlessly with your existing systems. This partnership can significantly enhance the overall effectiveness of your implementation.

Lastly, Monitor and Optimize. Keep an eye on performance metrics and gather feedback to refine your processes and technologies. Businesses that actively oversee their logistics performance report a 15% decrease in operational expenses! However, it’s worth noting that only 6% of companies claim to have comprehensive visibility in their logistics—a pitfall you’ll want to avoid.

By embracing these strategies, manufacturers can make a successful shift to smart supplies, enhancing operational efficiency and customer satisfaction. As Nesrin Chabbah puts it, "To succeed in logistics management, prioritize tech utilization, ensure accurate and timely data, and remain flexible in adapting to shifts." And let’s not forget those case studies—like the implementation of RFID tags that can increase inventory accuracy to around 95%. That’s the kind of practical benefit that smart supplies can bring to the table!

Conclusion

Embracing smart supplies marks a big change in equipment manufacturing. With innovative technologies like IoT, AI, and cloud computing stepping in, we're seeing a real revolution in how efficiently and responsively operations can run. By weaving these advancements into their processes, manufacturers can boost logistics, streamline inventory management, and ultimately, enhance customer satisfaction.

Throughout this discussion, we've highlighted some key points that really showcase why adopting smart supplies is so important. The benefits are impressive—think increased efficiency, cost savings, improved flexibility, and data-driven decision-making. By implementing solid strategies—like conducting thorough needs assessments, investing in training, and teaming up with solution partners—manufacturers can tackle the complexities of integrating these technologies into their operations.

The importance of smart supplies truly cannot be overstated. As the manufacturing landscape keeps evolving, the ability to adapt and leverage these tools will be vital for staying competitive. So, let’s encourage manufacturers to take proactive steps toward implementation. By doing so, they’ll be well-prepared to meet market demands and build customer loyalty in this fast-paced environment. The future of manufacturing is smart, and those who embrace these changes will surely enjoy the rewards.

Frequently Asked Questions

What are smart supplies in equipment manufacturing?

Smart supplies refer to innovations such as IoT devices and AI that are integrated into logistics and inventory management to enhance operations, providing real-time data analysis for better visibility and responsiveness.

How do smart supplies improve inventory management?

Smart supplies allow manufacturers to monitor inventory in real-time, enabling just-in-time restocking, which reduces waste and prevents stockouts, thus maintaining production schedules and meeting customer expectations.

What role do IoT-enabled smart shelves play in retail?

IoT-enabled smart shelves help retailers prevent out-of-stock situations, which is essential for keeping production schedules on track and enhancing customer satisfaction and loyalty.

How does GPS-enabled IoT technology benefit logistics?

GPS-enabled IoT devices enable businesses to track shipments in real-time, which reduces delays and improves delivery accuracy.

What is the anticipated impact of IoT on logistics management by 2025?

By 2025, the impact of IoT on logistics management is expected to be significant, allowing companies to quickly adapt to market needs and enhance their overall effectiveness.

What are some practical applications of smart supplies?

Practical applications include smart shelves in retail and temperature-sensitive drug transport in pharmaceuticals, demonstrating how these innovations are reshaping logistics dynamics.

What challenges do producers face when adopting smart supplies?

Producers may face challenges such as integrating new systems with existing ones and the need for employee training to effectively use these innovations.

Why is it important for companies to embrace smart supplies?

Embracing smart supplies is crucial for companies to remain competitive in a rapidly evolving market and to enhance their operational efficiency.