Overview

Have you ever wondered how manufacturers can really boost their efficiency? Well, Parts Smart Solutions has some exciting ways to do just that! By integrating advanced technologies and analytics, they help streamline operations, improve stock management, and enhance customer interactions.

Imagine reducing waste and lowering costs while also increasing customer satisfaction—sounds great, right? These solutions bring significant benefits that many businesses are already enjoying. For example, successful implementations have shown how effective strategies can make a real difference.

So, if you’re looking to elevate your manufacturing game, why not explore how Parts Smart Solutions can work for you? It’s all about making those smart choices that lead to better outcomes for everyone involved!

Introduction

In the fast-paced world of manufacturing, efficiency is the name of the game. Have you ever wondered how some companies seem to have it all figured out? Well, Parts Smart Solutions are shaking things up by revolutionizing the way components are managed and distributed. These innovative frameworks tap into advanced analytics and automation, making operations smoother, cutting down lead times, and boosting customer satisfaction.

But let’s be real: as manufacturers dive into these solutions, they often encounter hurdles with integration and adaptability. It raises a big question—how can they navigate these complexities to fully harness the potential of Parts Smart Solutions? Staying competitive in an ever-evolving market is no small feat.

So, what’s the game plan? Let’s explore how to tackle these challenges together and unlock the full benefits of these smart solutions.

Define Parts Smart Solutions in Manufacturing

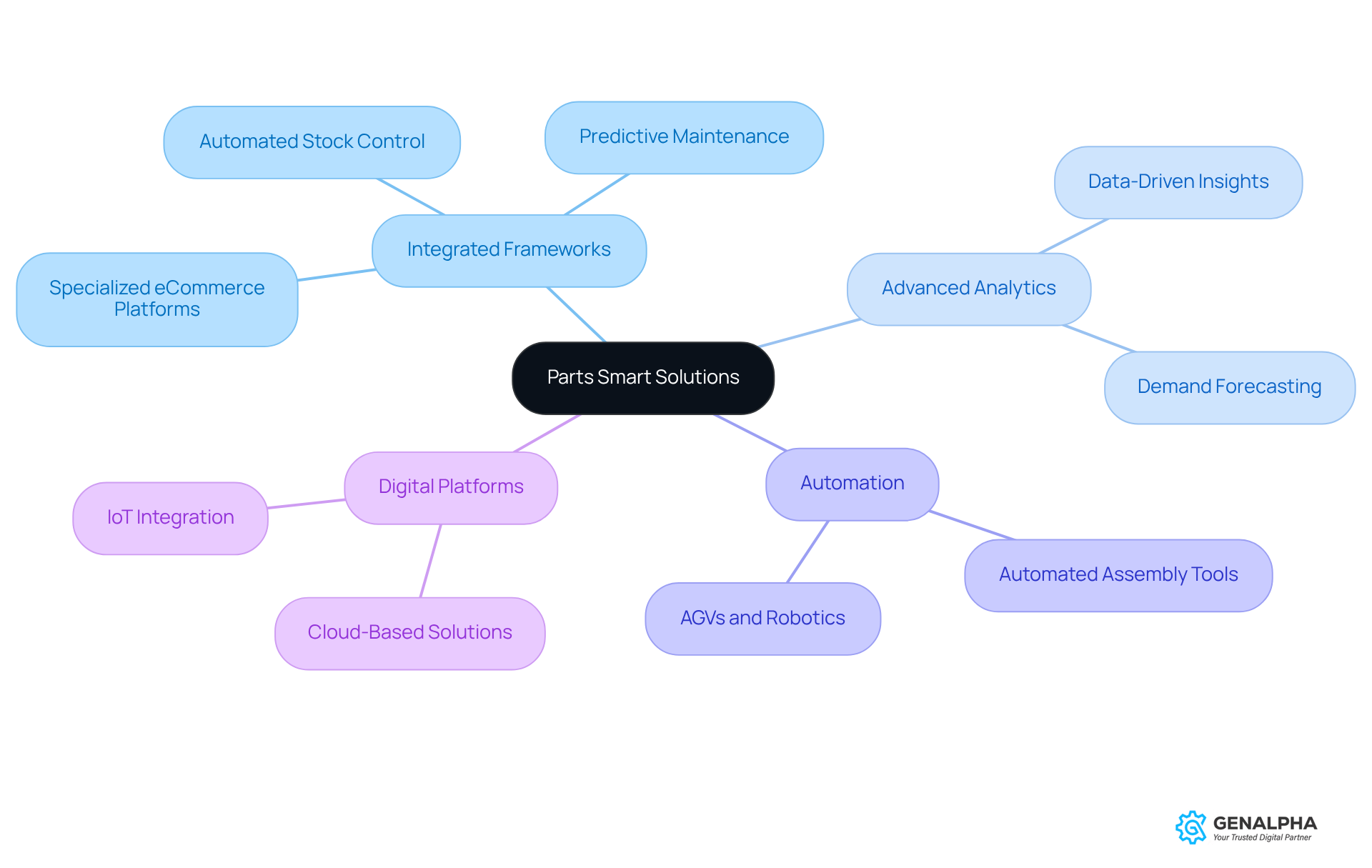

Have you ever wondered how manufacturers keep everything running smoothly? Well, Parts Smart is here to provide smart solutions! These integrated frameworks and technologies are specifically designed to improve how components are overseen, distributed, and sold in the manufacturing sector. By employing , automation, and digital platforms, these solutions optimize operations, enhance stock handling, and elevate customer interactions.

Imagine being able to forecast demand accurately and minimize lead times. With , manufacturers can ensure that essential parts are available right when they’re needed. This proactive approach not only boosts but also significantly enhances .

For example, think about:

- Predictive maintenance tools

These are just a few significant instances showcasing Parts Smart in action! The latest trends show that manufacturers are increasingly relying on these integrated systems, recognizing their potential to drive productivity and competitiveness in a rapidly evolving market.

So, why not explore how these solutions can make a difference for you? Let's explore the realm of together!

Highlight Benefits of Parts Smart Solutions

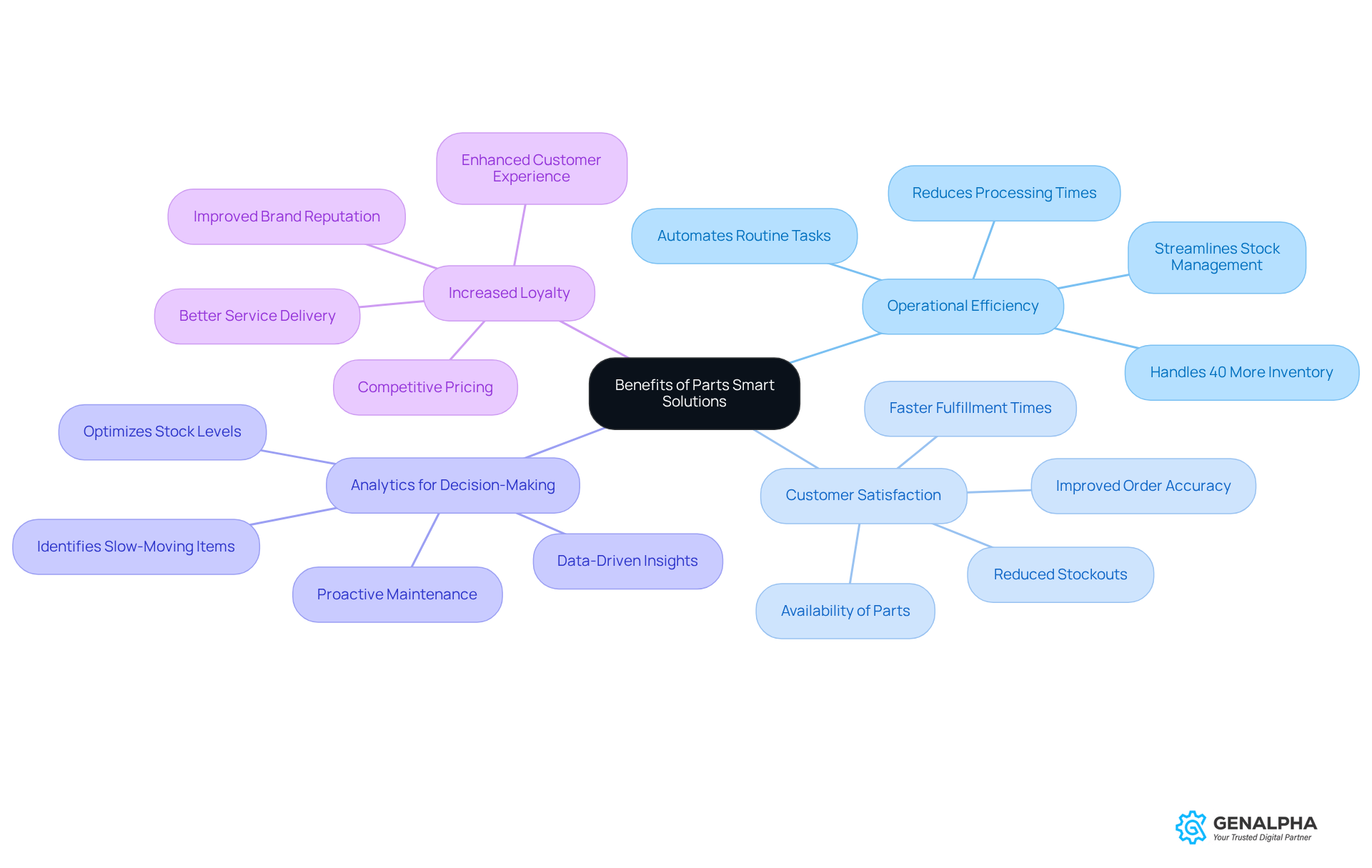

Have you ever thought about how much easier life could be with the right solutions? Well, implementing can really make a difference! For starters, they boost by and . This means and lower expenses—who wouldn’t want that?

But wait, there’s more! These solutions also ramp up by ensuring that parts are available when needed, making purchasing a breeze. Imagine a world where you don’t have to wait around for parts to arrive!

Plus, manufacturers can leverage . This leads to and . For example, many businesses have successfully by using automated stock management solutions, which in turn has led to happier customers and increased loyalty.

So, why not explore how Parts Smart can provide solutions that work for you? It’s time to take action and see the benefits for yourself!

Implement Effective Strategies for Parts Smart Solutions

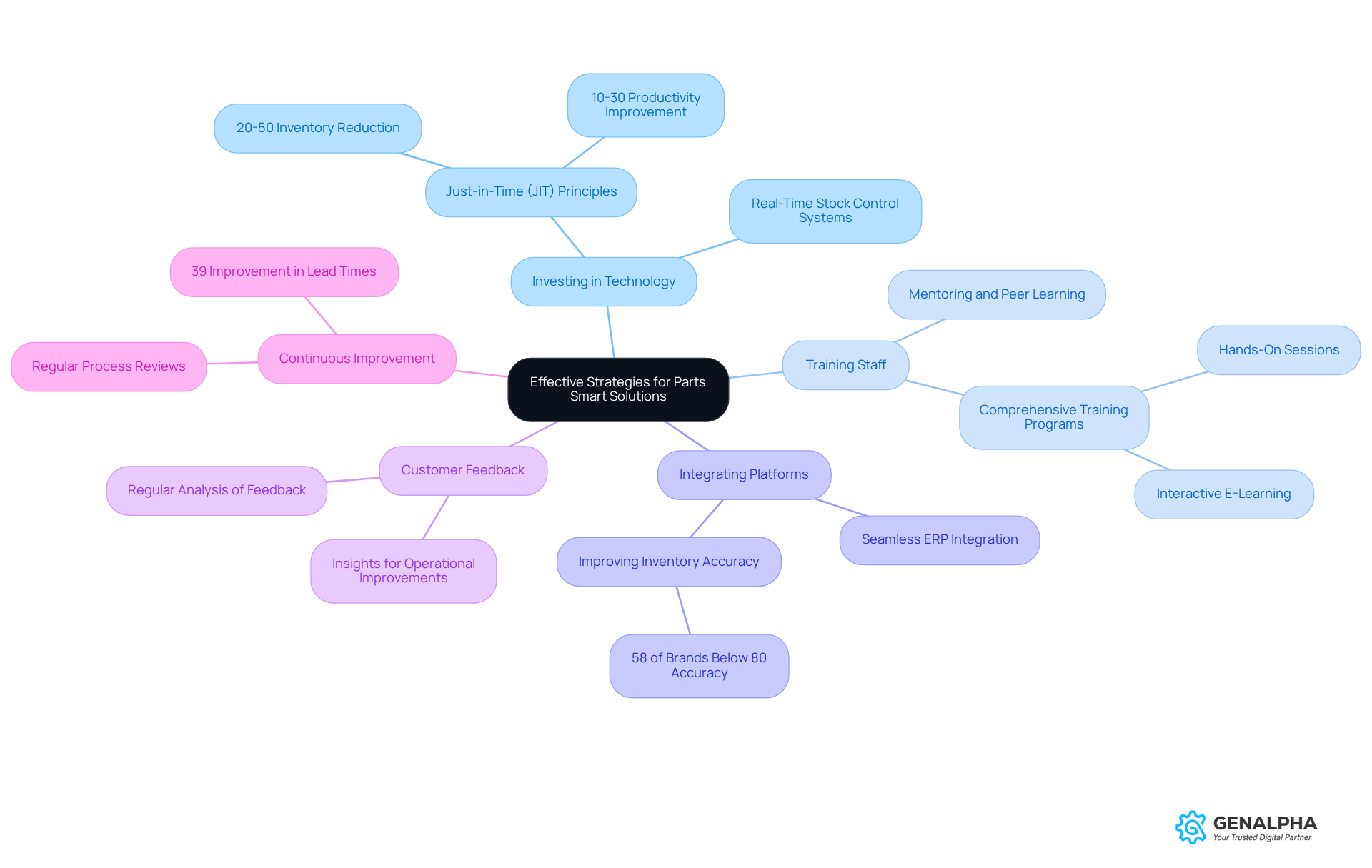

To kick off the journey with Parts Smart, manufacturers should start by taking a good look at their current processes. This helps identify areas that could use a little boost. Here are some key strategies to consider:

- : Why not embrace some sophisticated stock control systems? These systems use real-time information to keep tabs on stock levels and predict demand. For instance, businesses that adopt have seen stock reductions of 20-50% while by 10-30%, according to a McKinsey study.

- Training Staff: It’s crucial to prioritize on new technologies. Let’s highlight the importance of precision in stock management! Research shows that —think hands-on sessions, step-by-step demonstrations, and interactive e-learning—can significantly enhance employee competence and confidence.

- Integrating Platforms: Ensure that you seamlessly . This can really enhance data flow and . Did you know that studies reveal 58% of retail brands and D2C manufacturers struggle with ?

- : Don’t forget to regularly gather and analyze customer feedback. This can refine processes and elevate service delivery. Engaging with customers often leads to insights that drive operational improvements and boost satisfaction.

- : Let’s foster a culture of continuous improvement! Regularly review and optimize processes based on performance metrics. Companies that embrace this approach often see impressive gains in efficiency and effectiveness. For example, some organizations have achieved up to a 39% improvement in lead times through systematic evaluations.

So, are you ready to take these steps and discover how Parts Smart can transform your operations?

Integrate Parts Smart Solutions with Existing Systems

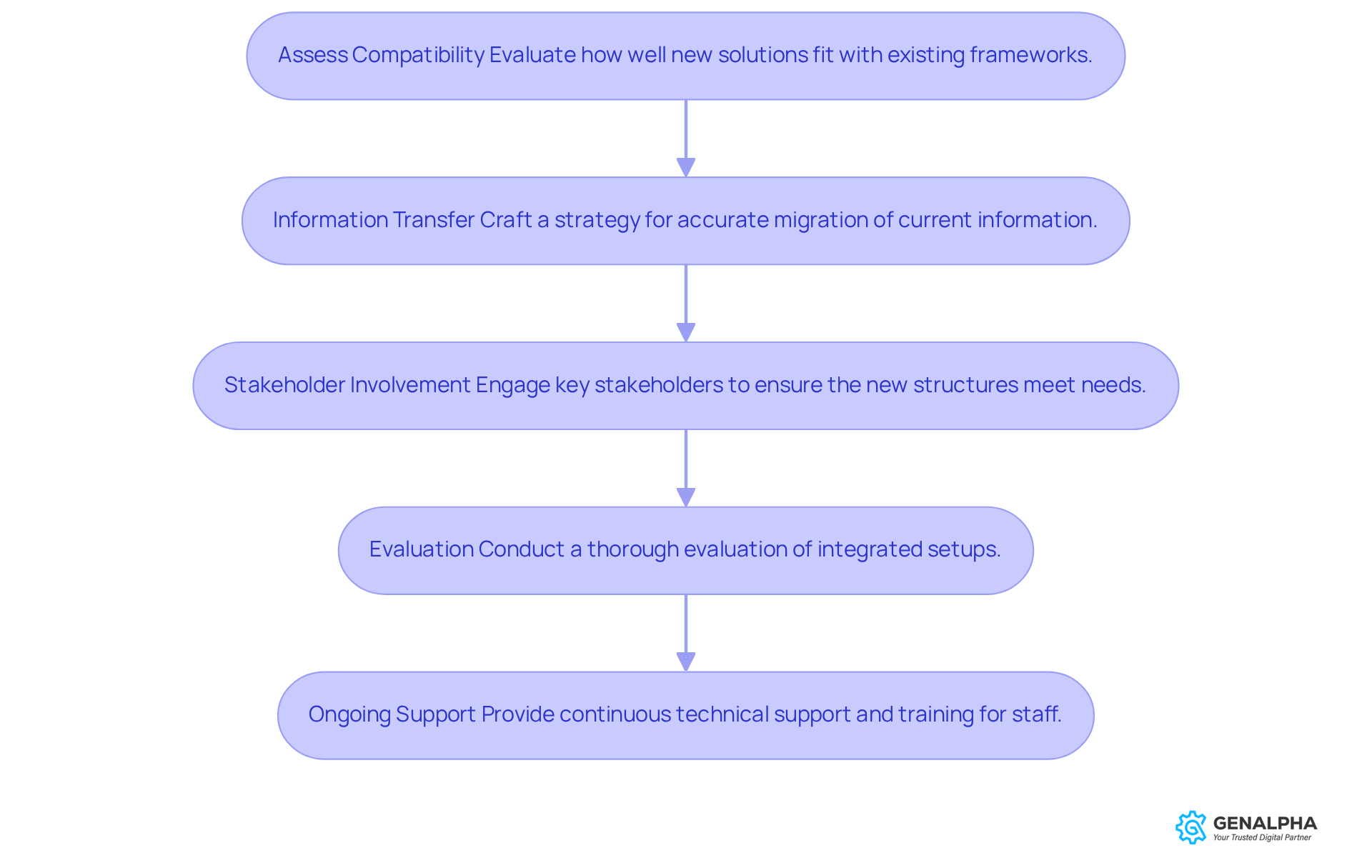

Incorporating into current frameworks is no small feat—it requires careful planning and execution. So, how do we ensure a successful integration? Let’s break it down into a few key steps:

- Assess Compatibility: First things first, assess how well the new solutions fit with your existing frameworks. This step is crucial; it helps you spot potential integration challenges early on, giving you the chance to come up with proactive solutions.

- Information Transfer: Next up is crafting a solid strategy for moving your current information to the new systems. Keeping your information accurate and intact is vital. After all, improper migration can lead to significant operational hiccups. A phased approach often works best here, allowing for gradual adjustments and minimizing risks. For example, has been a game-changer for many, enhancing supply chain processes by providing real-time data on spare part stock levels.

- : Don’t forget to engage key stakeholders from various departments throughout the integration process. Their insights are invaluable—they help ensure that the new structures meet everyone’s needs, fostering a sense of ownership and collaboration.

- Evaluation: Before you go all in, conduct a thorough evaluation of the integrated setups. This step is crucial for identifying and addressing any issues, ensuring that all components work together smoothly.

- : Finally, provide continuous technical support and training for your staff. This not only makes for a smoother transition but also encourages everyone to embrace the new systems, which is key to maximizing efficiency.

As we navigate these integration challenges, it's worth noting that about 40% of businesses might struggle to survive if they don’t adapt to new technologies. Plus, 39% of facilities management teams highlight backup inventory as a strategy for ensuring critical supplies are available. This really underscores the importance of parts smart during integration. By embracing change and fostering a culture of innovation, we can significantly boost in today’s competitive manufacturing landscape. So, are you ready to take the leap?

Conclusion

Maximizing efficiency in manufacturing isn’t just a goal; it’s a must-have in today’s competitive world. Have you heard about Parts Smart Solutions? They bring a game-changing approach to managing components by leveraging advanced analytics, automation, and digital platforms. These integrated systems not only smooth out operations but also boost customer satisfaction, making sure essential parts are available when you need them and that production flows without a hitch.

So, what are the key benefits of Parts Smart Solutions? Think:

- Improved operational efficiency through automation

- Less waste

- Better decision-making powered by data insights

By taking steps like:

- Investing in technology

- Training your team

- Integrating platforms

- Embracing continuous improvement

manufacturers can really ramp up their productivity and responsiveness to market demands. Plus, merging these solutions with existing systems is crucial for a seamless transition.

Ultimately, getting on board with Parts Smart Solutions goes beyond just using new tools; it’s about creating a culture of innovation and adaptability. As we look to the future, prioritizing these smart solutions will not only enhance efficiency but also set manufacturers up for ongoing success in a fast-changing industry. Taking proactive steps today can lead to significant improvements in operational performance and customer satisfaction, paving the way for a stronger and more competitive manufacturing environment. So, why wait? Let’s embrace these changes together!

Frequently Asked Questions

What are Parts Smart Solutions in manufacturing?

Parts Smart Solutions are integrated frameworks and technologies designed to improve the oversight, distribution, and sale of components in the manufacturing sector. They utilize advanced analytics, automation, and digital platforms to optimize operations and enhance customer interactions.

How do Parts Smart Solutions benefit manufacturers?

These solutions help manufacturers forecast demand accurately, minimize lead times, improve operational efficiency, enhance stock handling, and significantly boost customer satisfaction.

Can you provide examples of Parts Smart Solutions?

Examples include automated stock control solutions, predictive maintenance tools, and specialized eCommerce platforms tailored for parts sales.

Why are manufacturers increasingly relying on Parts Smart Solutions?

Manufacturers recognize the potential of these integrated systems to drive productivity and competitiveness in a rapidly evolving market.

What is the impact of data-driven insights in Parts Smart Solutions?

Data-driven insights allow manufacturers to ensure that essential parts are available when needed, leading to improved operational efficiency and higher customer satisfaction.