Overview

Have you ever thought about how digital transformation is shaking up the manufacturing industry? It’s all about integrating cool digital technologies like AI, IoT, and data analytics to boost operational efficiency and keep up with what the market demands. Imagine a factory that runs smoother and faster, adapting on the fly to customer needs. Sounds great, right?

This transformation is driven by key factors such as rapid technological advancements and rising customer expectations. For example, manufacturers are now expected to deliver high quality and efficiency, which can be a tall order. But the good news? Embracing these digital tools can lead to significant improvements in both efficiency and product quality.

Of course, it’s not all sunshine and rainbows. Manufacturers face challenges when trying to implement these changes. It’s a journey, and understanding these hurdles is crucial.

So, what do you think? Are you ready to embrace the digital shift in manufacturing? Let’s dive into this exciting world together!

Introduction

Have you noticed how digital transformation is shaking up the manufacturing world? It’s pretty exciting! With advanced technologies like AI, IoT, and automation being woven into every part of production, things are changing fast. This shift isn’t just about keeping up; it’s about boosting efficiency and improving product quality while tackling the tough demands of a competitive market.

But let’s be real—jumping into this digital age isn’t all smooth sailing. Manufacturers are running into some serious hurdles, from people resisting change to the tricky task of integrating new systems. So, what can we do to tackle these challenges head-on and make the most of digital transformation? Let’s explore some strategies together!

Define Digital Transformation in Manufacturing

Digital transformation in the manufacturing industry is all about weaving digital tools into every part of the manufacturing process. We're talking about cutting-edge innovations like (AI), the Internet of Things (IoT), automation, and data analytics—all designed to boost operational efficiency, enhance product quality, and streamline supply chain management. The goal? To create a manufacturing environment that’s agile, responsive, and efficient, ready to adapt to the ever-changing market demands and customer expectations. By embracing these innovations, producers can refine their processes, significantly cut costs, and thrive in an increasingly competitive landscape.

So why is this shift happening? Recent trends show that for manufacturers aiming for success, embracing digital transformation in the manufacturing industry isn’t just a passing trend; it’s a must. For instance, companies that sync their tech strategies with their technology investments see a 14% bump in market value. Plus, the market for digital transformation in the manufacturing industry is set to soar from USD 0.44 trillion in 2025 to USD 1.07 trillion by 2030, boasting a compound annual growth rate (CAGR) of 19.4%.

There are plenty of success stories out there. Take a food producer that slashed production costs by 20% thanks to AI scheduling tools that optimized job shop scheduling. Or consider a sterile pharmaceutical producer that saw a 30% drop in unplanned downtime by adopting electronic tracking solutions, which improved visibility and enabled real-time decision-making.

Industry leaders are emphasizing the crucial role of digital transformation in the manufacturing industry. As one expert noted, "Online channels will be utilized for 80% of supplier-to-buyer interactions in business by 2025," highlighting the shift towards electronic engagement. Moreover, companies implementing online sales strategies have reported a 20% increase in customer satisfaction and a 15% rise in sales conversion rates, illustrating how these innovations are driving digital transformation in the manufacturing industry.

And here’s something to think about: technological change can boost On-Time In-Full (OTIF) scores by about 10 percentage points on average, which can greatly impact profitability. Looking ahead to 2025, the digital transformation in the manufacturing industry through the integration of electronic systems will continue to reshape manufacturing, driving efficiency and innovation while addressing the challenges of a rapidly changing market. Additionally, these tech initiatives can help reduce CO2 emissions and water usage by around 15% on average, underscoring the broader benefits of these innovations for sustainability.

Identify Key Drivers of Digital Transformation

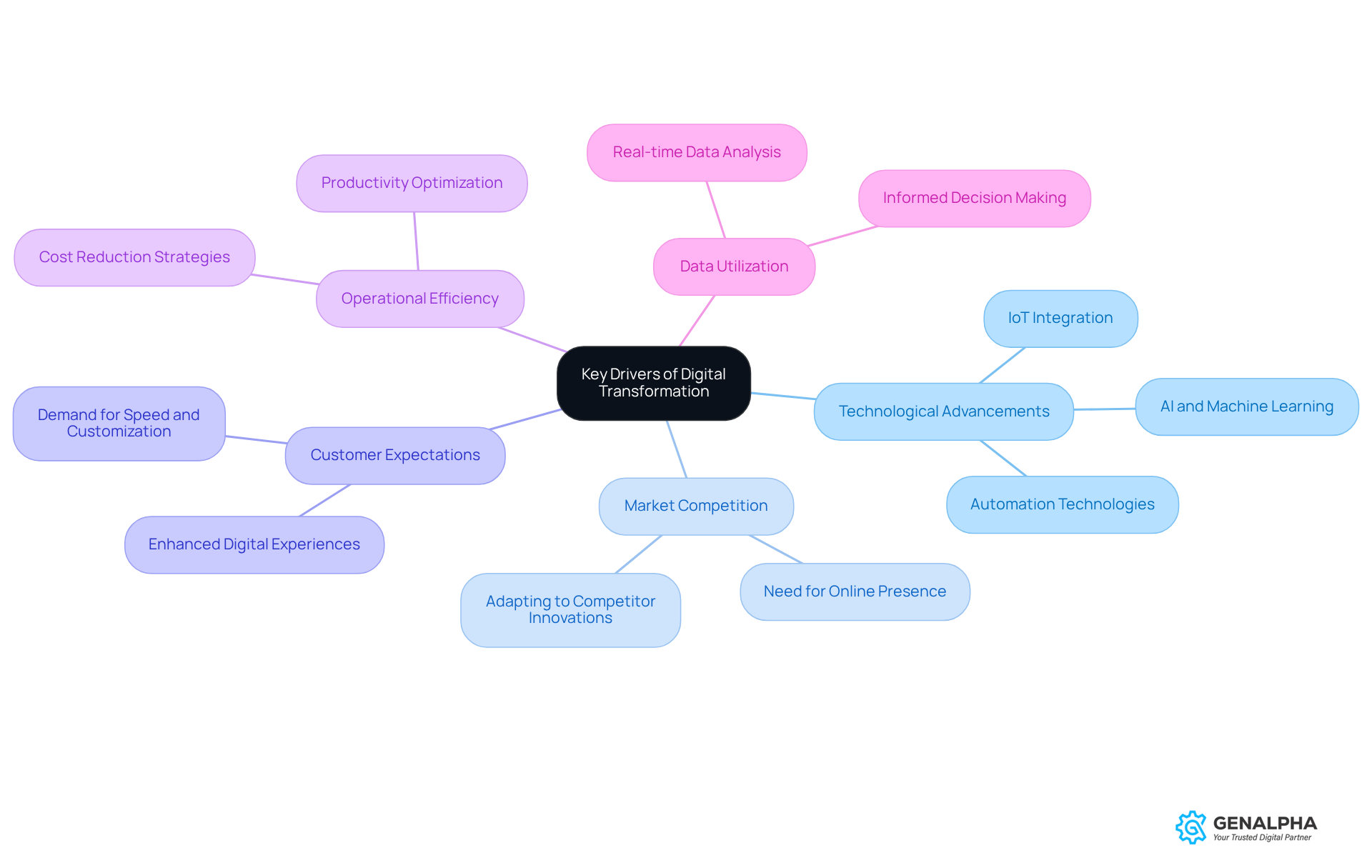

Digital transformation in the manufacturing sector is being driven by several key factors that are hard to ignore:

- Technological Advancements: With innovations like AI, IoT, and machine learning, producers are not just automating processes; they’re gaining real-time insights into their operations. How cool is that?

- Market Competition: As competitors jump on the online bandwagon, it’s crucial for producers to keep up to stay relevant and competitive. Are you ready to join the race?

- Customer Expectations: Today’s buyers want things faster and more tailored to their needs. This is pushing producers to step up their tech game. How can you meet these rising expectations?

- Operational Efficiency: The pressure to cut costs and boost productivity is real. Producers are seeking out tech solutions that can really optimize their processes. What steps are you taking to improve efficiency?

- Data Utilization: The ability to collect and analyze data is a game changer. It empowers producers to make informed decisions and refine their processes. Are you leveraging data to its fullest potential?

These drivers are not just trends; they are that can redefine how we operate in the digital transformation in the manufacturing industry. Let’s embrace this change together!

Examine Benefits of Digital Transformation

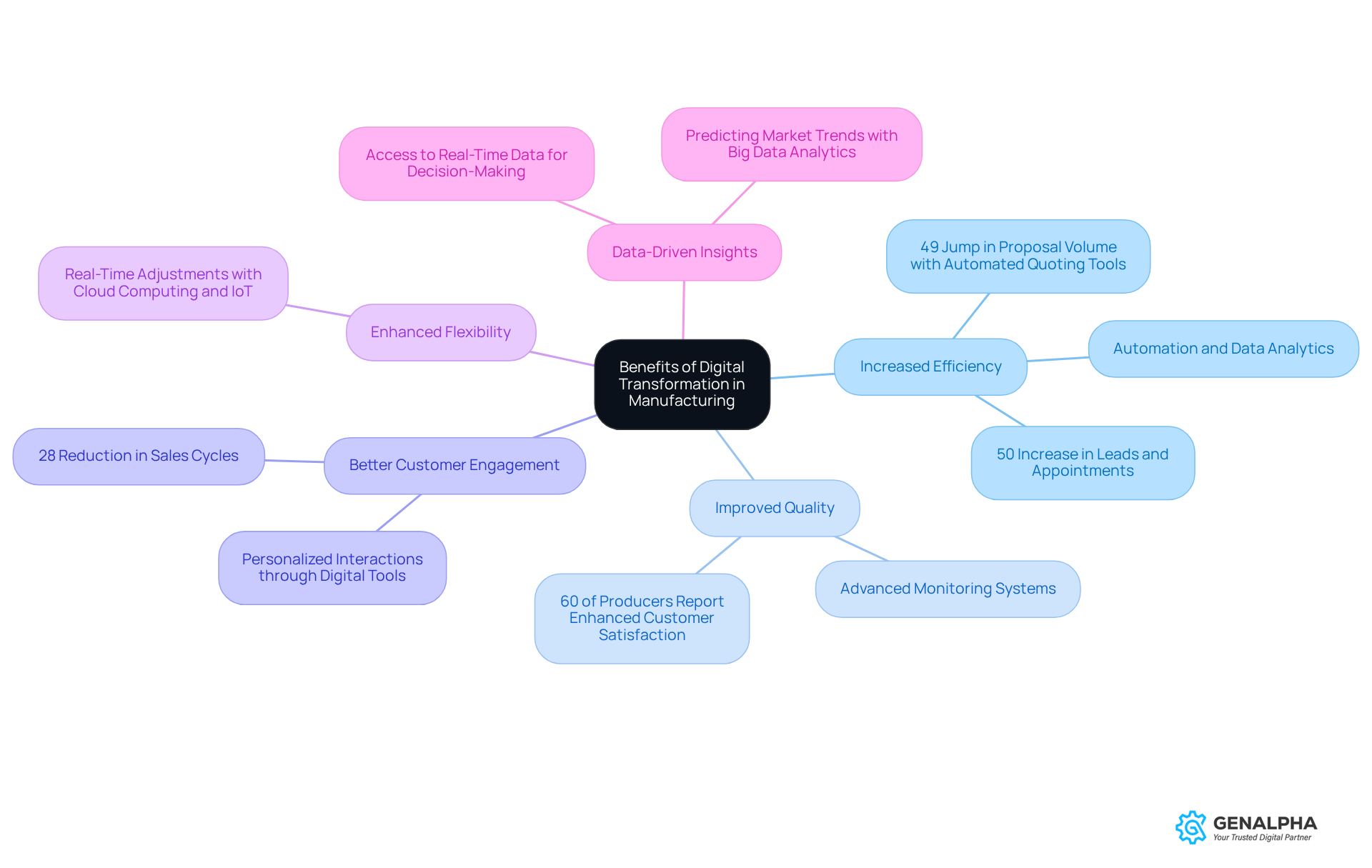

The benefits of digital transformation in the manufacturing industry are not just extensive; they're downright transformative!

- Increased Efficiency: Imagine this: automation and data analytics swooping in to streamline operations, cutting down production times and costs. Manufacturers who have embraced AI and machine learning are seeing some serious gains, with reports of efficiency boosts—some even up to a whopping 50% increase in leads and appointments thanks to smoother processes. And let’s not forget those companies using automated quoting tools, which have enjoyed a 49% jump in proposal volume. Talk about a trend in efficiency improvements!

- Improved Quality: Now, let’s talk about quality. Advanced monitoring and control systems are stepping up product quality and reducing defects like never before. Did you know that around 60% of producers have noted enhanced customer satisfaction due to the digital transformation in the manufacturing industry efforts? That’s a clear link between quality improvements and a better customer experience!

- Better Customer Engagement: Who doesn’t love personalized interactions? Digital tools make this possible, and they’re crucial for boosting customer satisfaction and loyalty. Businesses that utilize CRM systems and automated quoting tools have seen a 28% reduction in sales cycles. That’s the power of innovation in engaging customers!

- Enhanced Flexibility: Flexibility is key in today’s market, right? Manufacturers can now quickly adapt to market changes and customer demands, keeping them competitive. With , they can make real-time adjustments in production, reacting swiftly to shifts in demand.

- Data-Driven Insights: Let’s not overlook the magic of data! Access to real-time data empowers informed decision-making and strategic planning, driving growth and innovation. By leveraging big data analytics, producers can predict market trends and customer needs, giving them a competitive edge in a fast-paced environment.

While these advantages are considerable, it’s important to acknowledge that producers face challenges during this technological shift, like outdated systems and skill gaps. Setting quantifiable KPIs for strategic objectives is crucial in crafting a roadmap for technological change, guiding the process effectively. As Volker Albrecht pointed out, almost all producers, regardless of their size or position, are impacted by these changes, which underscores the importance of digital transformation in the manufacturing industry to adapt to the technological landscape.

So, are you ready to dive into the digital transformation journey? Let’s embrace the change together!

Analyze Challenges in Digital Transformation

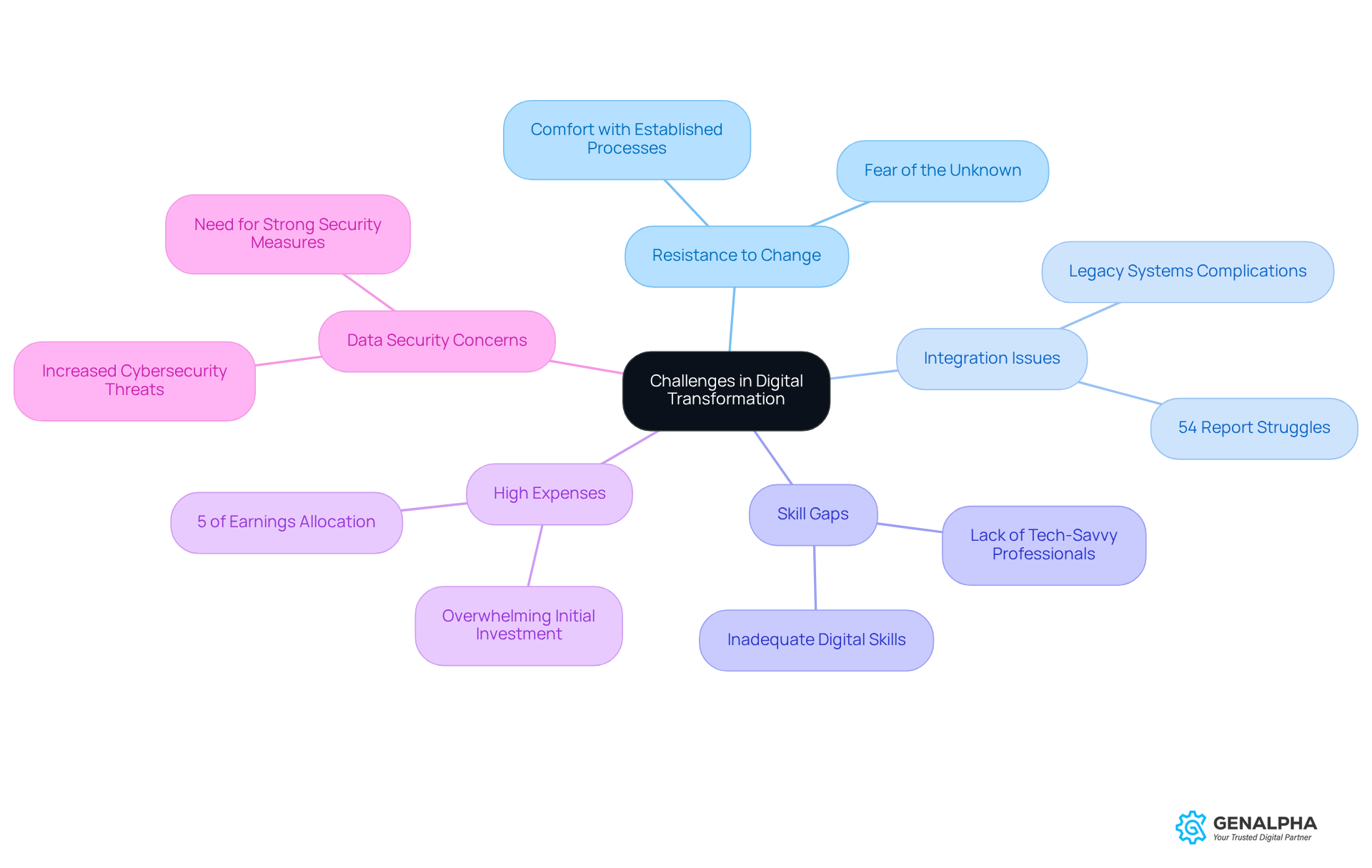

Manufacturers encounter several significant hurdles on their journey of digital transformation in the manufacturing industry, don’t they? Let’s break it down:

- Resistance to Change: Many employees feel hesitant about adopting new tools, which can really slow things down. This reluctance often comes from a comfort with established processes and a . Have you ever felt that way?

- Integration Issues: Legacy systems can really complicate the integration of new tech solutions, leading to data silos that hinder operational efficiency. In fact, about 54% of organizations report struggles with merging old and new systems, which can stall progress. And here’s a staggering fact: 87.5% of online transformation efforts fail. That really highlights how crucial these challenges are, doesn’t it?

- Skill Gaps: The lack of tech-savvy professionals is a big obstacle. Many workers simply don’t have the online skills needed to use new innovations effectively. This gap can seriously hinder the successful adoption of electronic tools.

- High Expenses: The initial investment required for digital innovations can feel overwhelming. Producers are expected to allocate about 5% of their earnings to these technologies, according to Deloitte. This can be a tough pill to swallow, especially for smaller companies looking to dive into tech initiatives.

- Data Security Concerns: As manufacturers digitize their operations, the risk of cybersecurity threats increases. Protecting sensitive information becomes a top priority, and strong security measures are essential to mitigate risks associated with technological changes.

Addressing these challenges is crucial for manufacturers aiming to leverage technology effectively and stay competitive in the landscape of digital transformation in the manufacturing industry. As Iva Krasteva wisely points out, "Companies that don't embrace this change are risking obsolescence." So, what steps can we take to overcome these hurdles together?

Implement a Digital Transformation Strategy

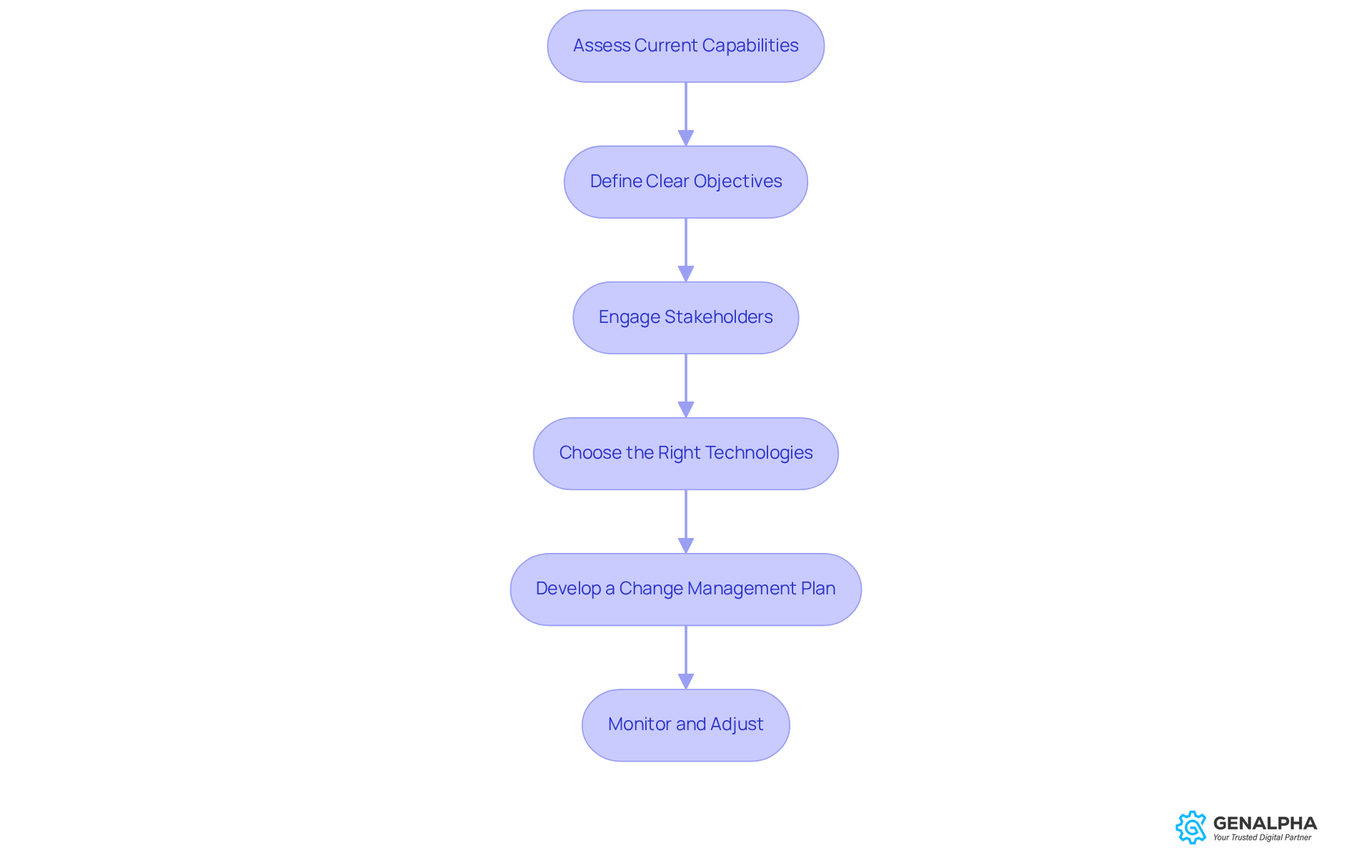

Ready to dive into digital transformation? Here’s a friendly roadmap for manufacturers looking to make a change:

- Assess Current Capabilities: Start by taking a good look at your existing processes, technologies, and workforce skills. What gaps do you see? Where are the opportunities?

- Define Clear Objectives: What do you want to achieve with this online change initiative? Maybe it’s about boosting efficiency or enhancing the customer experience—get specific!

- Engage Stakeholders: Don’t forget to involve key players from different departments. Their support is crucial for making sure everyone is on the same page during this journey.

- Choose the Right Technologies: Select the electronic tools and platforms that not only align with your objectives but also fit seamlessly with your current systems.

- Develop a Change Management Plan: Change can be tough, right? Create a plan to tackle any resistance, complete with training programs and communication strategies that support your team through the transition.

- Monitor and Adjust: Keep an eye on how things are going! Regularly evaluate the progress of your digital transformation in manufacturing industry initiative and be ready to make adjustments to stay on track toward those goals.

So, what do you think? Are you ready to take the plunge into digital transformation?

Conclusion

Digital transformation in manufacturing is a game changer, isn’t it? It’s all about weaving advanced technologies into the fabric of operations to boost efficiency and responsiveness. For manufacturers today, this isn’t just a nice-to-have; it’s a must if they want to stay competitive. By tapping into innovations like AI, IoT, and data analytics, manufacturers can streamline their processes, cut costs, and keep up with the ever-shifting market demands.

Throughout this discussion, we’ve pointed out some key drivers behind this transformation—think technological advancements, fierce market competition, and the changing expectations of customers. These factors highlight why it’s crucial for manufacturers to embrace digital strategies to stay in the game. The perks are significant:

- Greater efficiency

- Better product quality

- Improved customer engagement

- Insightful data

But let’s be real, the journey isn’t all smooth sailing. Challenges like resistance to change, integration hiccups, and skill gaps need to be tackled head-on for successful implementation.

So, why does embracing digital transformation matter so much? It’s not just about fine-tuning what’s already there; it’s a chance to innovate and adapt to what the market will demand in the future. Manufacturers should take a proactive approach—assess where they currently stand, set clear goals, and involve stakeholders in this vital journey. By doing this, they can set themselves up for lasting success in a world that’s becoming increasingly digital. The goal? Not just to survive, but to truly thrive in the manufacturing landscape of tomorrow. What steps will you take to join this exciting transformation?

Frequently Asked Questions

What is digital transformation in manufacturing?

Digital transformation in manufacturing involves integrating digital tools such as artificial intelligence (AI), the Internet of Things (IoT), automation, and data analytics into every aspect of the manufacturing process to enhance operational efficiency, product quality, and supply chain management.

Why is digital transformation important for manufacturers?

Embracing digital transformation is crucial for manufacturers as it helps them adapt to changing market demands and customer expectations. Companies that align their technology strategies with investments can see significant increases in market value and overall competitiveness.

What are the projected market trends for digital transformation in manufacturing?

The market for digital transformation in manufacturing is expected to grow from USD 0.44 trillion in 2025 to USD 1.07 trillion by 2030, with a compound annual growth rate (CAGR) of 19.4%.

Can you provide examples of successful digital transformation in manufacturing?

Yes, one example is a food producer that reduced production costs by 20% using AI scheduling tools. Another example is a pharmaceutical producer that decreased unplanned downtime by 30% through electronic tracking solutions.

How does digital transformation impact supplier-buyer interactions?

Experts predict that by 2025, online channels will account for 80% of supplier-to-buyer interactions, indicating a significant shift towards electronic engagement in business transactions.

What benefits do companies experience from implementing online sales strategies?

Companies that adopt online sales strategies report a 20% increase in customer satisfaction and a 15% rise in sales conversion rates.

How does technological change affect On-Time In-Full (OTIF) scores?

Technological advancements can improve On-Time In-Full (OTIF) scores by approximately 10 percentage points on average, positively impacting profitability.

What are some sustainability benefits of digital transformation in manufacturing?

Digital transformation initiatives can help reduce CO2 emissions and water usage by around 15% on average, contributing to sustainability efforts in the manufacturing sector.

What are the key drivers of digital transformation in manufacturing?

The key drivers include technological advancements, market competition, customer expectations, operational efficiency, and data utilization. These factors push producers to adopt new technologies and optimize their processes.