Overview

Have you ever wondered how retailers keep track of all their products? That’s where Stock Keeping Units, or SKUs, come into play! These unique alphanumeric codes help retailers identify and manage their inventory effectively. Imagine walking into a store where everything is organized just right—SKUs make that possible!

SKUs are crucial for improving stock accuracy. They not only help in keeping track of what’s on the shelves but also facilitate better demand forecasting. This means retailers can predict what customers want and when they want it. Think about it: a well-structured SKU system can lead to increased sales and operational efficiency!

So, why should you care about SKUs? Because they enhance overall inventory management practices. If you’re in retail, implementing a robust SKU system could be your secret weapon for success. Ready to dive deeper into inventory management? Let’s explore how you can optimize your SKU strategy together!

Introduction

Have you ever thought about how retailers keep track of all their products? It’s quite a task, isn’t it? This is where Stock Keeping Units, or SKUs, come into play. These unique alphanumeric codes are more than just numbers; they help streamline inventory tracking and boost sales strategies. As businesses aim for better accuracy and responsiveness in their supply chains, it begs the question: how can effectively using SKUs change the game for inventory management and lead to greater business success? Let's dive into this together!

Define SKU: The Basics of Stock Keeping Units

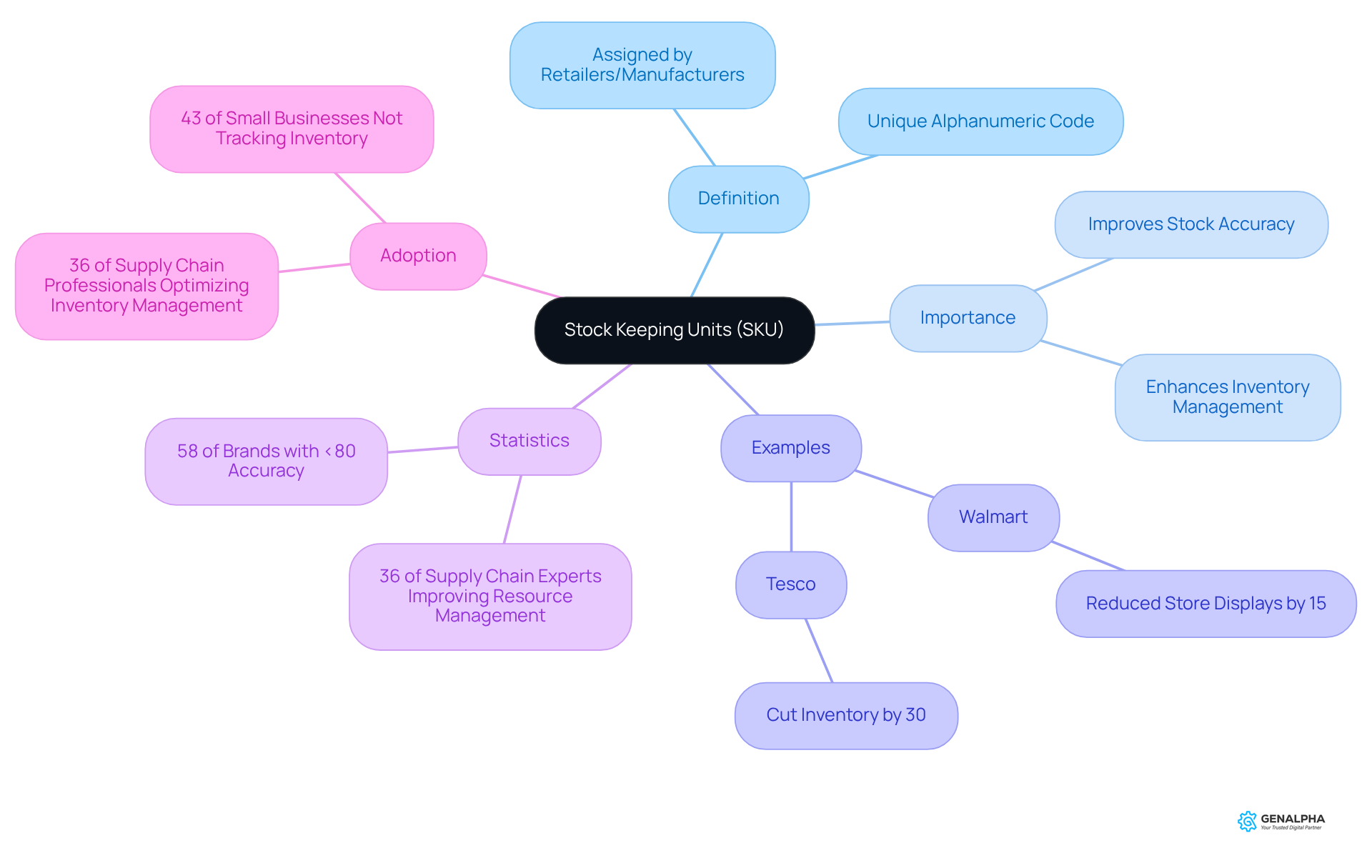

Have you ever wondered how retailers keep track of all their products? Enter the SKU definition, which is commonly referred to as Stock Keeping Unit. The SKU definition is a unique alphanumeric code assigned to specific items by retailers or manufacturers, helping them keep an eye on their stock. Each company has its own SKU definition, which allows for precise classification based on features like size, color, and style. For instance, a red t-shirt in medium might have a SKU like 'TSHIRT-RED-M'. This handy identifier, the SKU definition, makes it easier for companies to manage their inventory, ensuring they can quickly locate and track products throughout the supply chain.

Industry experts emphasize just how crucial the SKU definition is for improving stock accuracy. Nathan Kurszewski points out that by assigning a unique SKU definition to each item, businesses can monitor and manage their inventory in a detailed and organized way. This is especially important when you consider that 58% of retail brands and D2C manufacturers report having less than 80% inventory accuracy. It really highlights how effective the SKU definition can make a difference in keeping inventory in check.

Many companies are tapping into the power of SKUs, guided by the SKU definition, to boost their inventory monitoring. Take Walmart and Tesco, for example. They’ve successfully reduced the number of distinct SKUs for similar products, which has led to increased sales by simplifying choices for customers. This strategy shows that the SKU definition plays a crucial role in smart management, driving better decision-making and enhancing sales performance. Similarly, Proctor & Gamble's decision to cut shampoo options by 50% resulted in a 10% sales boost, further proving how optimizing SKUs can positively impact sales outcomes.

When it comes to adoption, a significant number of retailers are using SKUs for stock monitoring. In fact, 36% of supply chain experts are actively working to improve their resource management processes. By implementing SKUs and understanding the SKU definition, businesses can not only refine their stock management but also enhance demand forecasting, streamline order fulfillment, and ultimately improve sales efficiency. Interestingly, 43% of small businesses don’t track their inventory, highlighting the challenges faced by smaller producers and the potential benefits of adopting SKU systems. With the Warehouse Management System (WMS) market projected to reach USD 10.5 billion by 2030, the importance of SKU management in the evolving landscape of stock management solutions is more significant than ever.

Explain the Importance of SKUs in Inventory Management

The SKU definition illustrates the vital role that Stock Keeping Units (SKUs) play in keeping track of inventory, don't they? They provide a structured way to identify and monitor items, which helps businesses maintain accurate stock levels and streamline order fulfillment by utilizing the SKU definition. This means less risk of running out of stock or having too much on hand. By using SKUs, companies can analyze sales data more effectively, which helps in establishing a clear SKU definition that leads to better demand forecasting and stock management.

For instance, imagine a seller quickly spotting which items are flying off the shelves and adjusting their inventory accordingly. This proactive approach can lead to increased sales and happier customers. Plus, SKUs enhance communication across departments, ensuring everyone in the supply chain knows what's available.

And here's a neat trick: incorporating barcodes into SKU analysis can really boost stock management. Barcodes uniquely identify each item, cutting down on manual errors. Additionally, analyzing SKUs can help optimize warehouse layouts based on how quickly items turn over, making operations even more efficient.

But it doesn't stop there! The SKU definition also supports accurate demand forecasting and helps tweak procurement strategies, empowering businesses to make informed decisions. Ever heard of Pareto Analysis? It’s a fantastic way to prioritize products based on their contribution to total sales and margins, sticking to that 80/20 rule.

Lastly, companies might consider outsourcing some aspects of SKU management to third-party logistics (3PL) firms. These experts can provide valuable support in managing stock efficiently. So, why not take a closer look at how SKUs can streamline your inventory management and enhance your business operations?

![]()

Differentiate SKUs from UPCs and Other Inventory Codes

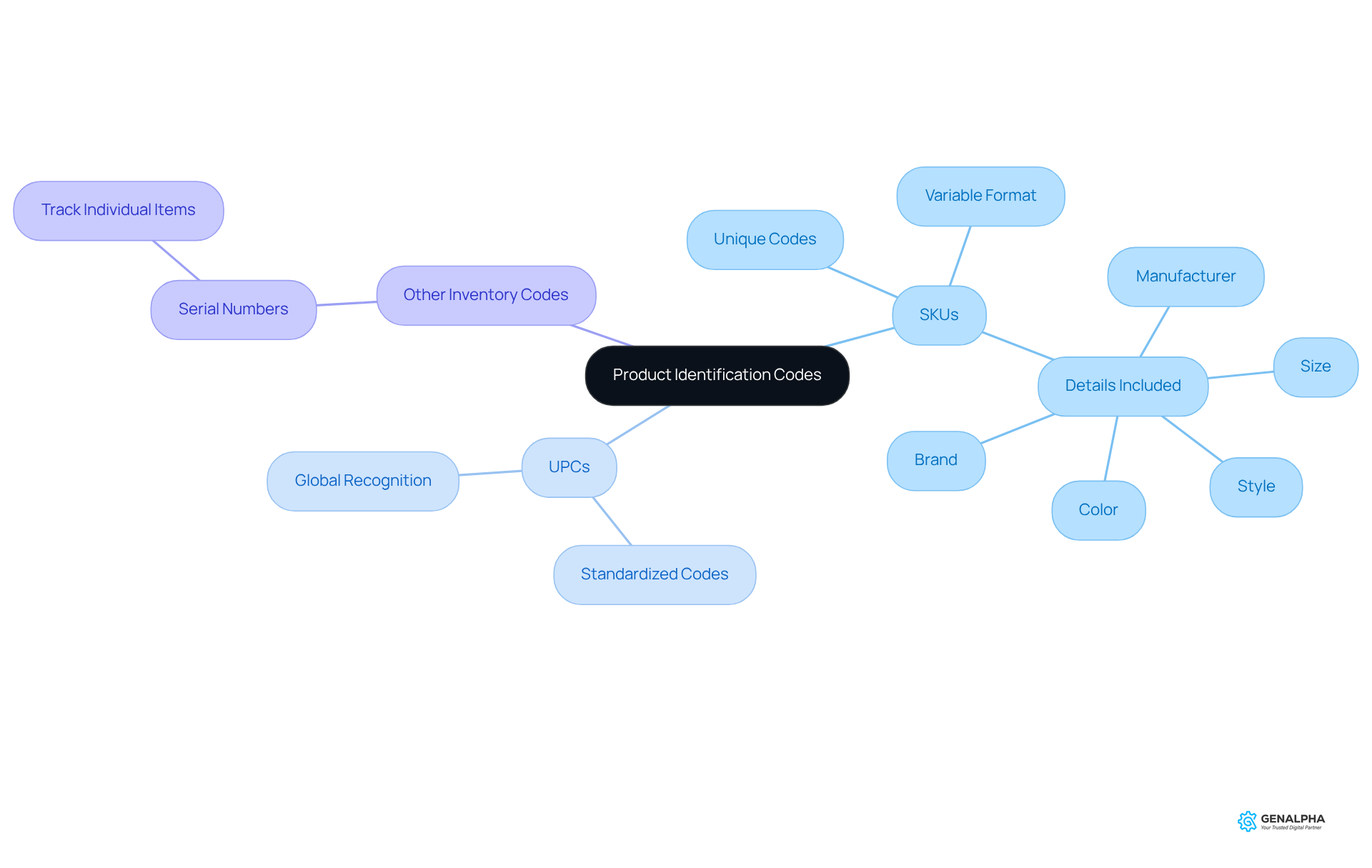

Have you ever wondered how products are identified in stores? While both Stock Keeping Units (SKUs) and Universal Product Codes (UPCs) serve as product identifiers, the sku definition highlights their different roles in the retail world. The sku definition explains that SKUs are unique codes created by businesses to help manage their inventory, while UPCs are standardized codes used globally at the point of sale.

Typically, UPCs are 12 digits long and are recognized everywhere. On the flip side, the sku definition shows that SKUs can vary in size and format based on a company's specific needs. Isn’t it interesting that the sku definition can even include details about an item, like its size and color? UPCs, however, don’t provide that kind of information.

Additionally, there are other inventory codes, such as serial numbers, which track individual items rather than categories. This further sets them apart from SKUs. So, next time you're shopping, you might think about all the behind-the-scenes coding that helps keep everything organized. How do you think this impacts your shopping experience?

Outline Best Practices for SKU Creation and Management

Creating effective SKU definitions doesn’t have to be a chore! Let’s dive into some best practices that can really make a difference. First off, it’s super important to establish a consistent format for the SKU definition. Think about including relevant item information like the category, brand, and attributes. For instance, a SKU for a blue medium-sized jacket could look like this: JACKET-BLUE-M. Simple, right?

Next, let’s talk about special characters and spaces. You’ll want to avoid those because they can make data entry and retrieval a real headache. Trust me, keeping it straightforward pays off! And here’s a big one: ensure that the SKU definition for each item is unique. This helps prevent any mix-ups in stock management, which we all want to avoid.

Don’t forget, regular audits and updates to your SKU system are crucial! This keeps everything accurate and allows you to adapt to any changes in your product offerings. By following these best practices, you’ll not only enhance your inventory management processes but also boost your overall operational efficiency. So, what are you waiting for? Let’s get started on creating those effective SKUs!

Conclusion

Understanding what Stock Keeping Units (SKUs) are and why they matter is key to managing inventory effectively. Think of SKUs as unique identifiers for your products; they help businesses keep track of their stock in a precise and efficient way. When companies implement a solid SKU system, they can streamline operations and respond more swiftly to market demands.

Throughout this article, we’ve highlighted several key points that showcase the significance of SKUs in inventory management:

- Boosting stock accuracy

- Improving demand forecasting

- Optimizing warehouse layouts

Using SKUs effectively can lead to increased sales and operational efficiency. Just look at industry giants like Walmart and Proctor & Gamble; their success stories illustrate the real benefits of SKU optimization and the value of having a well-defined SKU strategy.

So, what’s the takeaway? SKUs do more than just identify products; they play a crucial role in driving inventory accuracy and enhancing overall business performance. By adopting best practices in SKU creation and management, you can improve your stock management processes and gain a competitive edge in the marketplace. It’s time to recognize the transformative potential of SKUs and take actionable steps toward implementing robust inventory management systems. Are you ready to make that leap?

Frequently Asked Questions

What does SKU stand for?

SKU stands for Stock Keeping Unit, which is a unique alphanumeric code assigned to specific items by retailers or manufacturers.

Why are SKUs important for retailers?

SKUs are important because they help retailers manage their inventory by allowing precise classification of products based on features like size, color, and style, making it easier to locate and track items throughout the supply chain.

How does the SKU definition improve inventory accuracy?

By assigning a unique SKU to each item, businesses can monitor and manage their inventory in a detailed and organized way, which is crucial for maintaining stock accuracy.

What percentage of retail brands report having less than 80% inventory accuracy?

58% of retail brands and D2C manufacturers report having less than 80% inventory accuracy.

Can you provide examples of companies that have successfully used SKUs?

Yes, companies like Walmart and Tesco have reduced the number of distinct SKUs for similar products, leading to increased sales by simplifying choices for customers. Similarly, Proctor & Gamble cut shampoo options by 50%, resulting in a 10% sales boost.

What percentage of supply chain experts are working to improve resource management processes using SKUs?

36% of supply chain experts are actively working to improve their resource management processes through the use of SKUs.

What challenges do small businesses face regarding inventory tracking?

43% of small businesses do not track their inventory, highlighting the challenges they face and the potential benefits of adopting SKU systems for better inventory management.

What is the projected market value of the Warehouse Management System (WMS) by 2030?

The Warehouse Management System (WMS) market is projected to reach USD 10.5 billion by 2030, emphasizing the growing importance of SKU management in stock management solutions.