Overview

Have you ever wondered how electronic parts catalogs can really change the game in manufacturing? Well, the article "10 Ways Electronic Parts Catalogs Transform Manufacturing Efficiency" dives into just that! It highlights how these digital solutions boost manufacturing efficiency in a big way.

From improved inventory management to real-time updates, these catalogs offer self-service access and seamless ERP integration. Imagine reducing errors and streamlining processes—sounds great, right? All of this contributes to greater operational efficiency and, ultimately, happier customers.

So, if you're looking to enhance your manufacturing operations, this article is definitely worth a read. It’s packed with insights that can help you make informed decisions and take action toward a more efficient future!

Introduction

In the fast-paced world of manufacturing, efficiency reigns supreme, and electronic parts catalogs are shaking things up in a big way. Imagine being able to streamline operations, boost customer satisfaction, and ultimately drive sales—all thanks to digital solutions! But as businesses dive into these innovative tools, a crucial question pops up: how can they truly harness electronic catalogs to transform their manufacturing processes while minimizing errors and maximizing profitability? This article explores ten impactful ways that electronic parts catalogs can revolutionize manufacturing efficiency, offering insights that could redefine what success looks like in the industry. So, let’s dive in and discover how we can make the most of these game-changing tools together!

GenAlpha Technologies: Streamline Parts Management with Digital Solutions

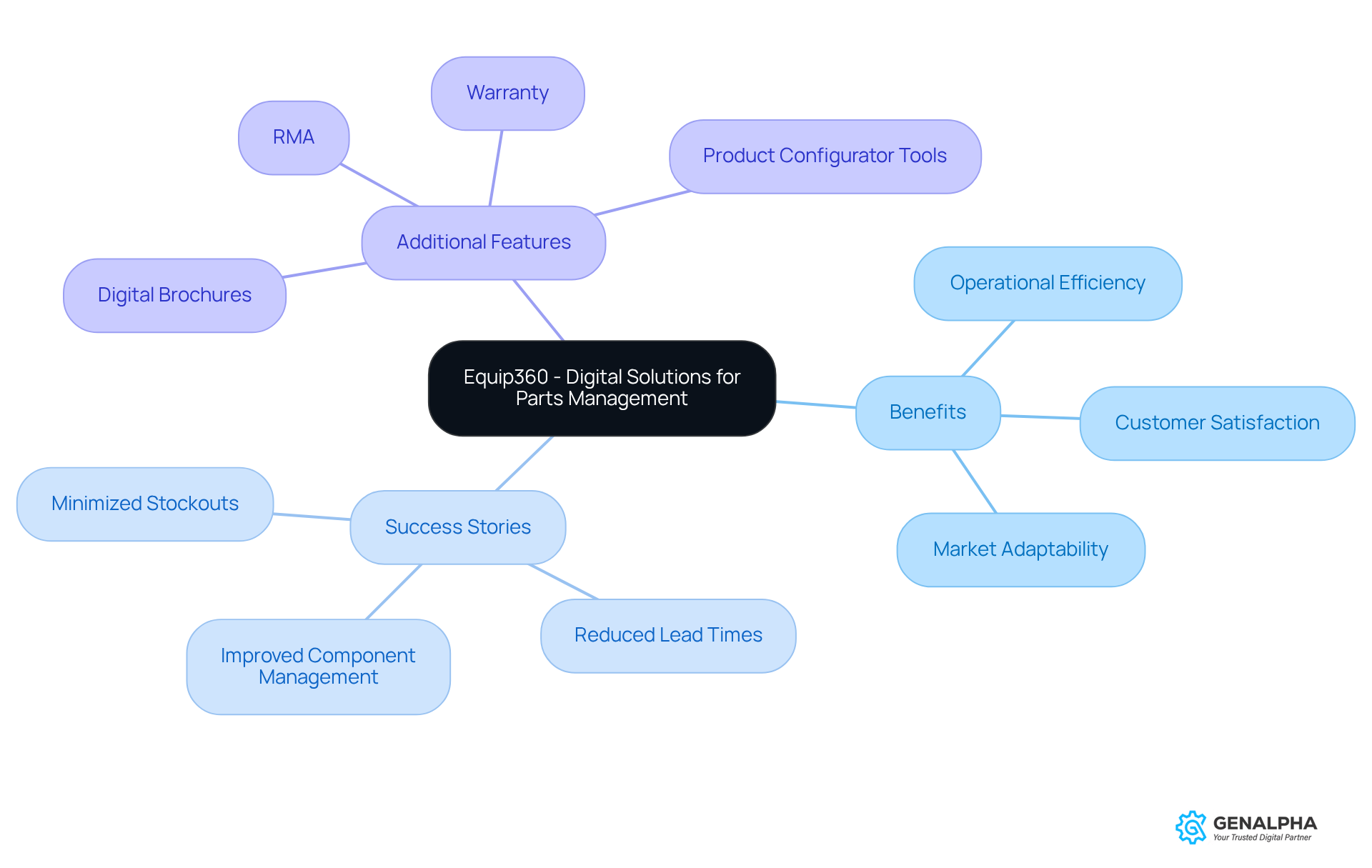

At GenAlpha Technologies, we’re all about crafting digital solutions tailored for manufacturers and distributors in the equipment and aftermarket components sectors. Our standout product, Equip360, is designed to make component management a breeze by blending eCommerce features with smart digital cataloging. This means businesses can manage their inventory more effectively, ensuring that parts are always available and easy for customers to access. The result? Enhanced operational efficiency and happier customers.

In today’s competitive landscape, it’s clear that standing out goes beyond just pricing. Equip360 empowers producers to create unique value propositions, helping them carve out their niche in the market. As Jeff Bezos wisely points out, a customer-centric strategy is key to leading in innovative solutions. That’s exactly what Equip360 offers—essential tools for producers to adapt quickly to market demands and elevate their operations.

There are plenty of success stories from manufacturers who have embraced Equip360 for their inventory management needs. These companies report impressive improvements in managing components, slashing lead times, and minimizing stockouts. By leveraging digital solutions, they not only boost their operational capabilities but also build stronger relationships with their clients, driving growth in a fast-paced marketplace.

Let’s not underestimate the impact of electronic parts catalogs as digital solutions on parts management. With Equip360, producers can harness from electronic parts catalogs to make smarter decisions, streamline their supply chains, and respond proactively to client needs. This agility is crucial for thriving in today’s manufacturing world, where efficiency and customer satisfaction reign supreme.

To truly maximize the benefits of Equip360, manufacturers might want to consider adding features like:

- Digital brochures

- RMA

- Warranty

- Product configurator tools

This way, they can ensure a comprehensive approach to inventory management.

Real-Time Updates: Enhance Accuracy and Efficiency in Parts Catalogs

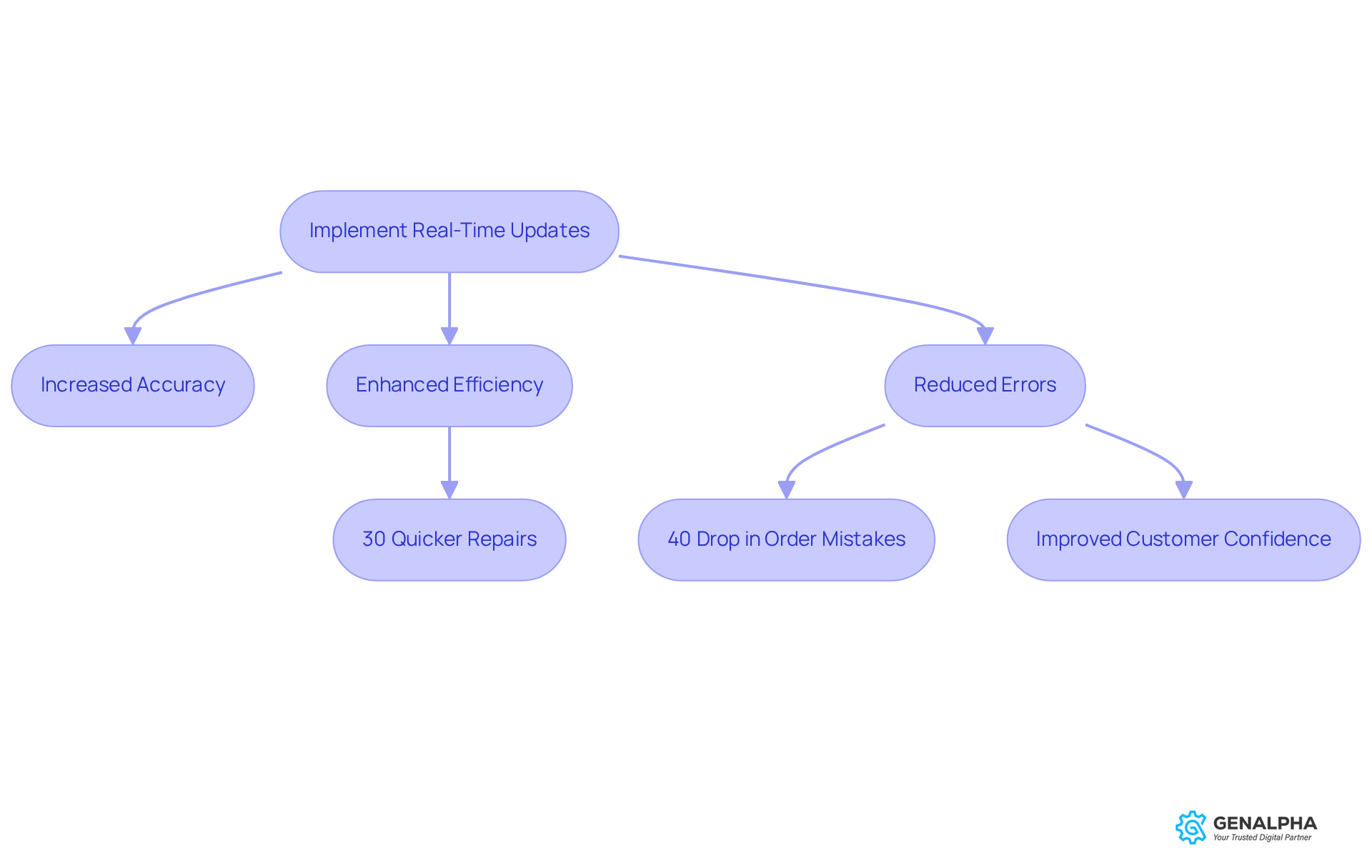

Have you ever felt frustrated when trying to find the latest information on electronic components? Implementing real-time updates in electronic parts catalogs is crucial for ensuring that you have access to the most current details about availability, pricing, and specifications. This feature drastically cuts down the chances of errors that come from outdated data, leading to smoother order processing and building trust.

For example, when the price of an item changes, real-time updates let customers see the new price right away. This not only prevents disputes but also enhances the overall purchasing experience. Did you know that repairs during busy seasons, like sowing, became 30% quicker thanks to real-time data? It really shows how operational efficiency can soar with timely updates in component listings.

Moreover, producers who utilize real-time updates have reported a 40% drop in order mistakes, backed by case studies that showcase the effectiveness of these systems. By integrating electronic parts catalogs with ERP systems, companies can further enhance the self-service experience for clients, ensuring they have instant access to the accurate information in the electronic parts catalogs.

To truly reap the benefits of real-time updates, manufacturers should prioritize implementing these systems and consider regular training for their staff. This way, everyone is well-equipped to . By minimizing discrepancies and ensuring that all stakeholders have access to current data, companies can build stronger relationships with their clients and streamline their operations. What steps are you taking to stay updated in this fast-paced environment?

Self-Service Access: Empower Users with Instant Information Retrieval

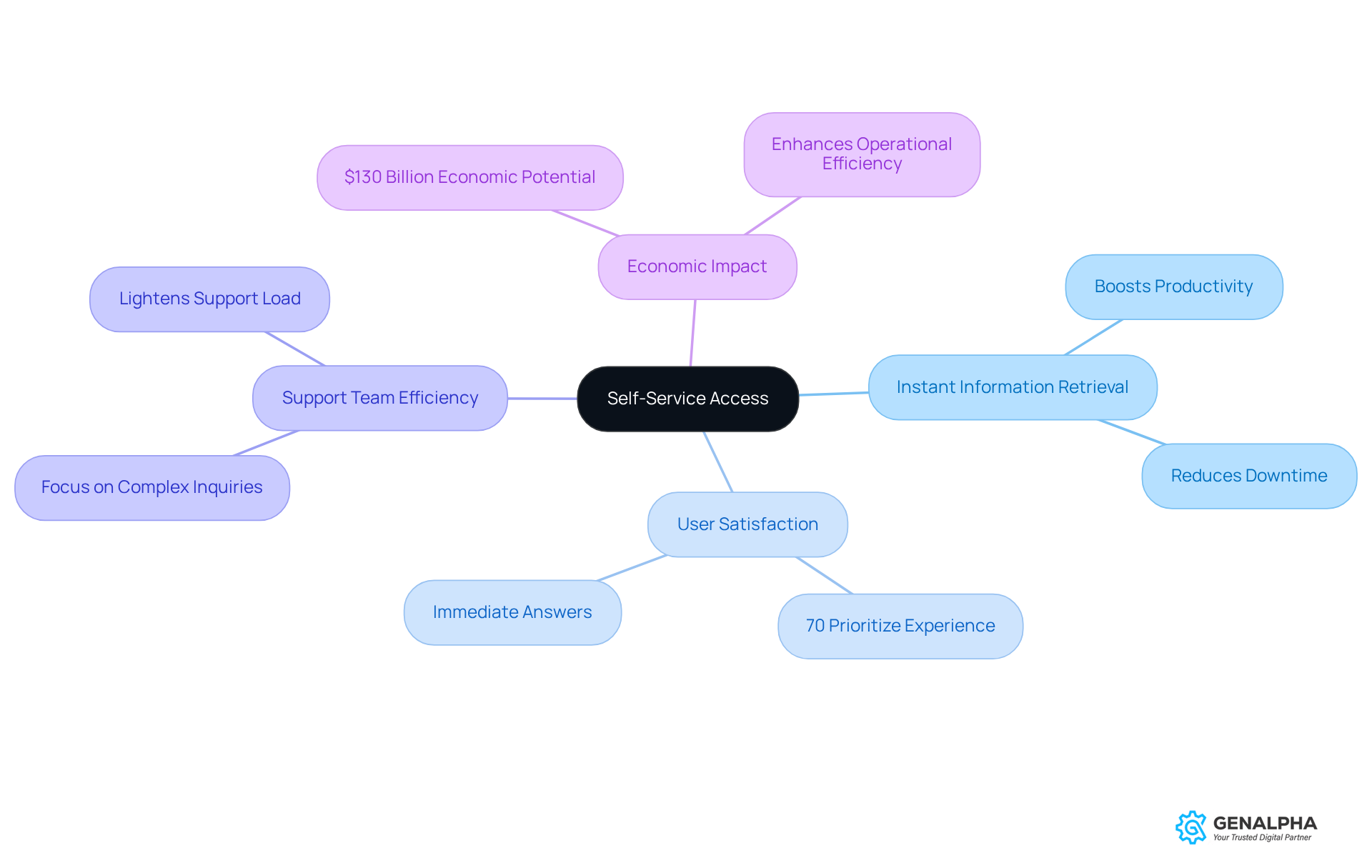

Imagine having instant access to electronic parts catalogs right at your fingertips! With , you can find the information you need without having to reach out to customer support. This not only boosts your satisfaction by providing immediate answers but also lightens the load for support teams.

Think about it: you can easily search for components in electronic parts catalogs, check their specifications, and see availability whenever you want. This streamlines the purchasing process, making life a whole lot easier. For instance, a technician can quickly find the right part for a repair without waiting for help, which means less downtime and more productivity.

Studies show that companies that embrace self-service solutions see a noticeable increase in client satisfaction. In fact, a report reveals that 70% of consumers prioritize experience over product quality. This really highlights how crucial user-friendly access to information is.

Plus, manufacturers that give users the power to retrieve information instantly report better operational efficiency. Support teams can then focus on tackling more complex inquiries instead of getting bogged down with routine requests. This shift not only enhances the overall client experience but also ramps up productivity within the organization.

And here’s a thought: the U.S. economy could potentially be about $130 billion larger each year if self-service technology were more widely used. This really underscores the significant impact these solutions can have on customer satisfaction and operational efficiency. So, why not take advantage of these tools and streamline your processes today?

Cost Efficiency: Reduce Operational Expenses with Digital Catalogs

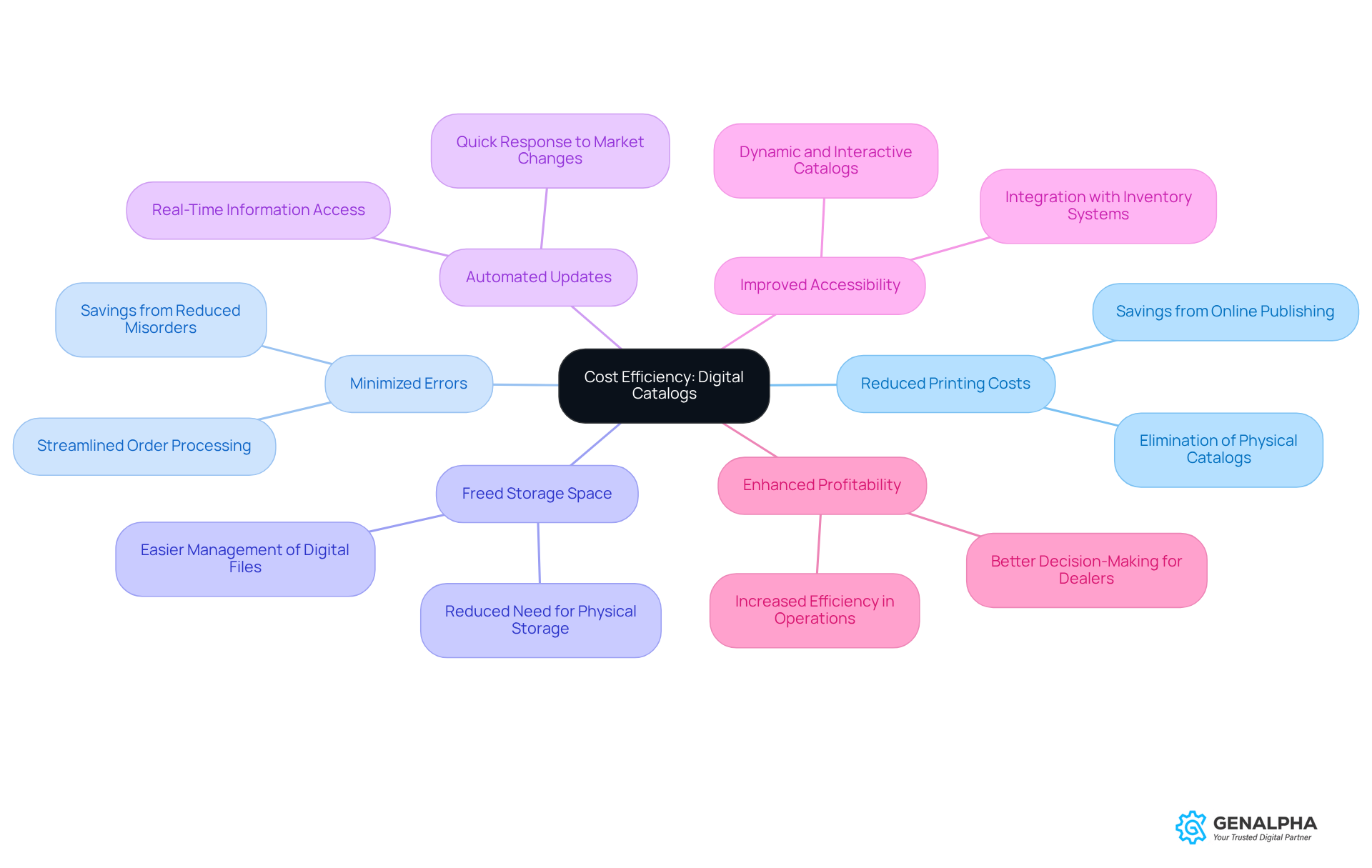

Digital component listings are a game changer when it comes to cutting operational costs. By ditching printed materials, businesses can not only save on printing expenses but also minimize errors in order processing. Just think about it: going digital means you can free up storage space and reduce the hassle of managing physical collections. For instance, companies that use e-catalogs often report significant savings. Some producers have even shared stories of cutting down on misorders and returns, which can save them thousands of dollars each year. It’s clear that traditional spare parts management was not only ineffective but also pricey, leading to longer lead times and lower productivity.

Additionally, automating updates and order processing streamlines operations and lessens the chances of costly mistakes. With , updates are immediate, and accessibility is a breeze. This allows manufacturers to quickly respond to market changes and ensure that dealers have the latest information at their fingertips. Plus, including 2D/3D illustrations in e-catalogs makes the ordering process easier for dealers, boosting their decision-making and overall efficiency. This proactive approach can really enhance profitability for companies that embrace digital solutions. As industry experts put it, "The ability to envision and drive change is just as important as the ability to work with technology. If you don’t have both, you can’t succeed in this world.

Improved Customer Satisfaction: Elevate Service Quality with Digital Tools

Imagine you're trying to find the right electronic component for your project. Frustrating, right? Well, the implementation of can really change the game. They make it super easy for clients to find accurate information quickly. You can locate the parts you need, check out detailed specifications, and get timely updates on your orders—all at your fingertips.

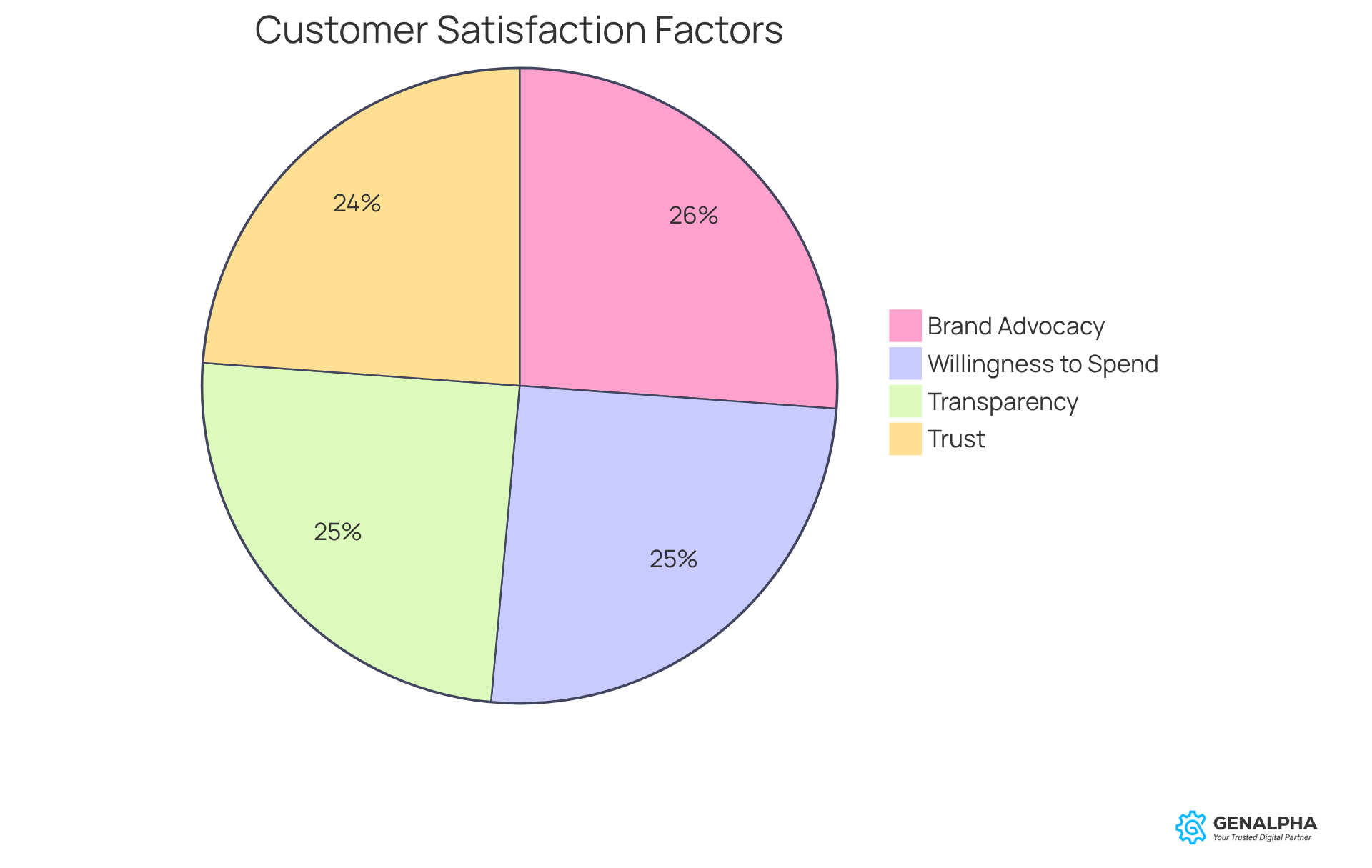

This kind of transparency not only boosts efficiency but also builds trust and loyalty. When clients feel empowered in their purchasing choices, it creates a better experience. For instance, think about how real-time order tracking can enhance your experience. Studies show that a whopping 86% of American clients prioritize transparency from companies. Plus, brands that focus on reliability are three times more likely to earn consumer trust. It's no wonder that 83% of people won’t engage with brands they don’t trust.

This really highlights how crucial transparency is for building long-lasting relationships. In fact, 91% of consumers are willing to advocate for brands they feel emotionally connected to, and 88% are more likely to spend more when they have a positive emotional connection. So, integrating digital tools like electronic parts catalogs isn’t just a nice-to-have—it’s essential for manufacturers looking to boost service quality and client loyalty.

And here’s a fun fact: Intelli Catalog’s AI capabilities can cut down on mistakes in component identification by 40%. That’s a significant step towards enhancing client satisfaction. So, why not explore how these tools can make your experience smoother and more enjoyable?

Enhanced Product Discovery: Drive Sales Through Improved Catalog Navigation

Navigating through electronic parts catalogs can feel like a bit of a maze, right? But when it’s improved, it really boosts how easily you can find what you need. Think about it: with advanced search filters, intuitive categories, and helpful visuals, shopping becomes a breeze. This not only makes your experience smoother but can also lead to more sales for businesses.

For example, imagine an inventory where you can filter by component type, application, or compatibility. Not only does this enhance your shopping experience, but it also encourages you to explore more options, which can bump up those conversion rates. Recent stats show that manufacturers who have upgraded their product features are seeing sales increases of up to 30%! That’s a clear sign that investing in user-friendly navigation pays off.

Take, for instance, an automobile OEM that adopted electronic parts catalogs such as Intelli Catalog. They’ve successfully ramped up their sales growth by enhancing their electronic parts catalogs. This really underscores how crucial is in today’s competitive landscape. Plus, let’s not forget the role of electronic parts catalogs in cutting down inventory costs and boosting accuracy. It all points to how essential better listing navigation is for driving operational efficiencies and sales performance. So, what are you waiting for? Let’s make shopping for electronic components easier and more enjoyable!

Seamless ERP Integration: Optimize Workflow with Connected Systems

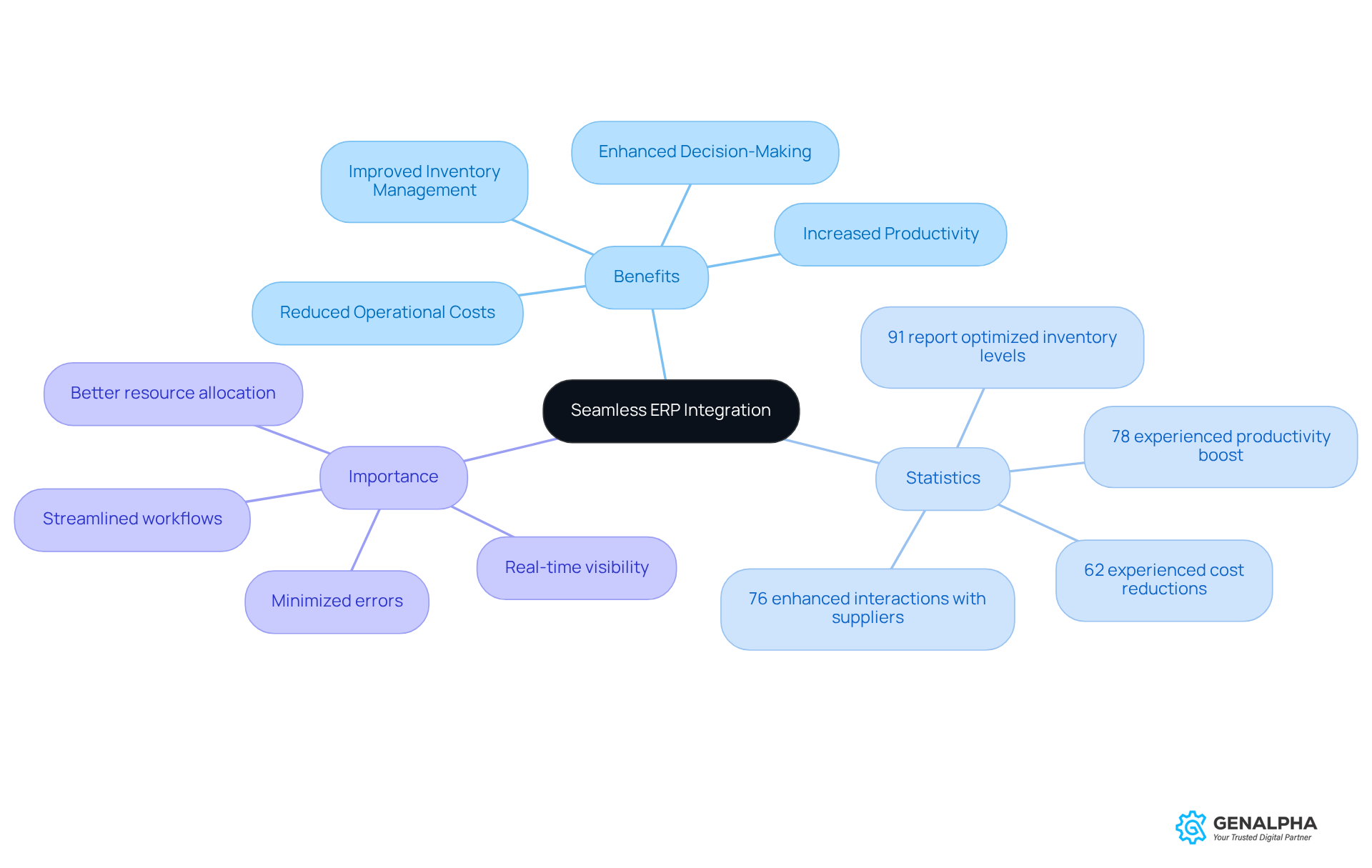

Integrating electronic parts catalogs with existing ERP systems is a game changer for data flow and workflow efficiency. Imagine having your inventory levels, pricing, and order statuses always in sync—sounds great, right? This integration helps minimize errors and boosts your . For example, when an item gets sold, the ERP system automatically updates the inventory, which means no more overselling and keeping your stock levels precise. This streamlined approach not only saves you valuable time but also enhances overall operational efficiency by utilizing electronic parts catalogs.

Did you know that recent studies show 91% of organizations reported optimized inventory levels after implementing ERP systems? And 78% of companies experienced a productivity boost post-adoption. Experts agree that optimizing workflows through these integrated systems is crucial for manufacturers wanting to thrive in today's competitive landscape. Why? Because it provides real-time visibility and better resource allocation.

Plus, over 50% of businesses confirm that ERP systems help improve inventory management, which really highlights their effectiveness in enhancing workflow efficiency. Common benefits that contribute to ROI include:

- Reduced operational costs

- Improved inventory management

- Increased productivity

- Enhanced decision-making driven by real-time data

However, it’s super important for organizations to understand their existing workflows to ensure a successful ERP implementation. So, what are you waiting for? Let's dive into optimizing your processes!

Data-Driven Insights: Leverage Analytics for Strategic Decision-Making

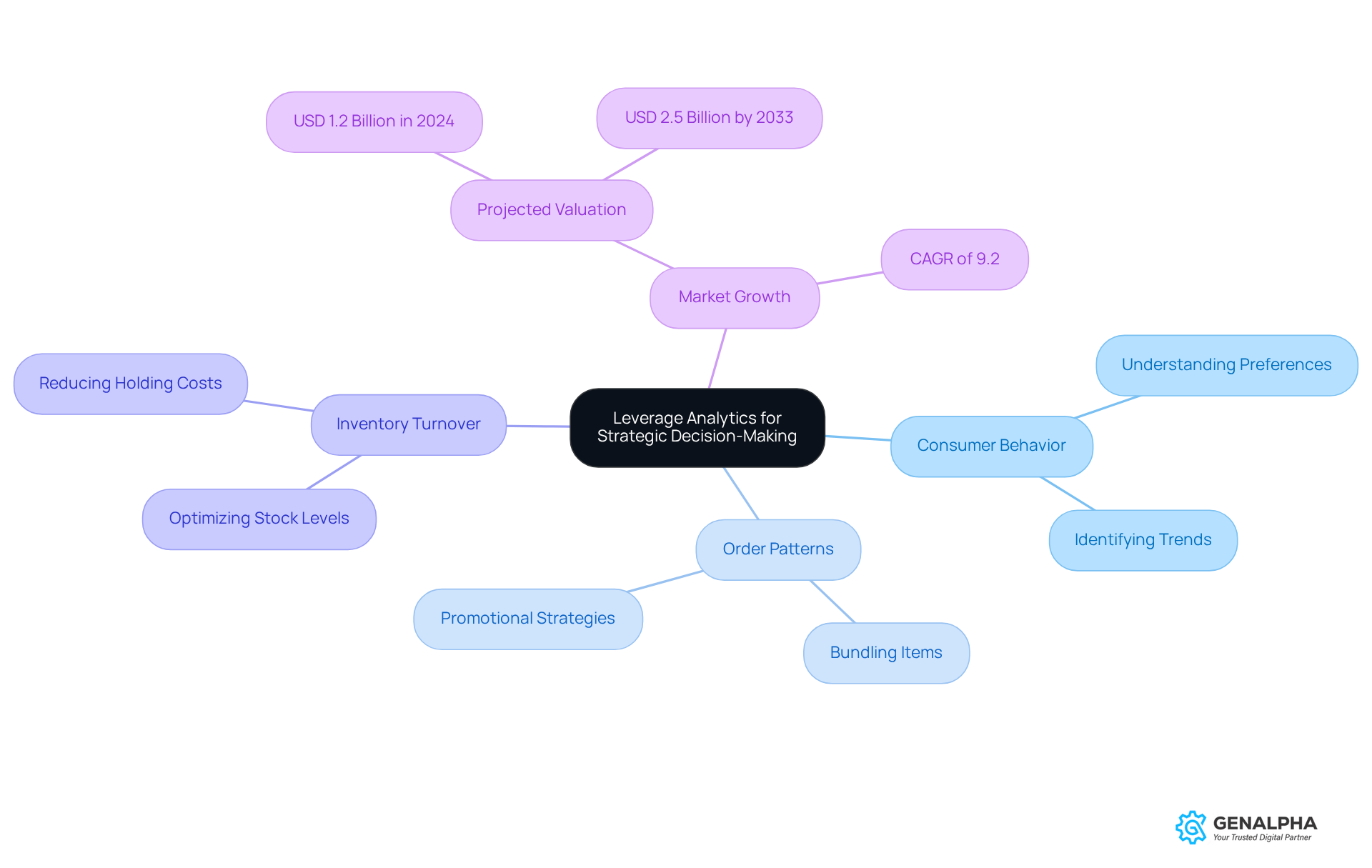

Have you ever thought about how electronic parts catalogs can be more than just lists of components? Well, they can actually be powerful tools equipped with that provide valuable data-driven insights. By looking closely at consumer behavior, order patterns, and inventory turnover, businesses can spot trends and make smart adjustments to their operations.

For example, if analytics show that certain parts are often ordered together, businesses might consider bundling these items for promotions. This not only enhances sales opportunities but also boosts customer satisfaction. Did you know the electronic parts catalogs market was valued at USD 1.2 billion in 2024? It's projected to grow significantly, reaching USD 2.5 billion by 2033, which really highlights the market's potential.

As Geoffrey Moore wisely said, 'Without big data, you are blind and deaf and in the middle of a freeway.' This really underscores how crucial it is to leverage data analytics for informed decision-making. So, where should producers start? It’s all about integrating data analysis into their operational processes. By doing this, they can uncover valuable insights that drive growth. What steps will you take to start utilizing analytics in your business?

Error Reduction: Minimize Misorders with Accurate Digital Catalogs

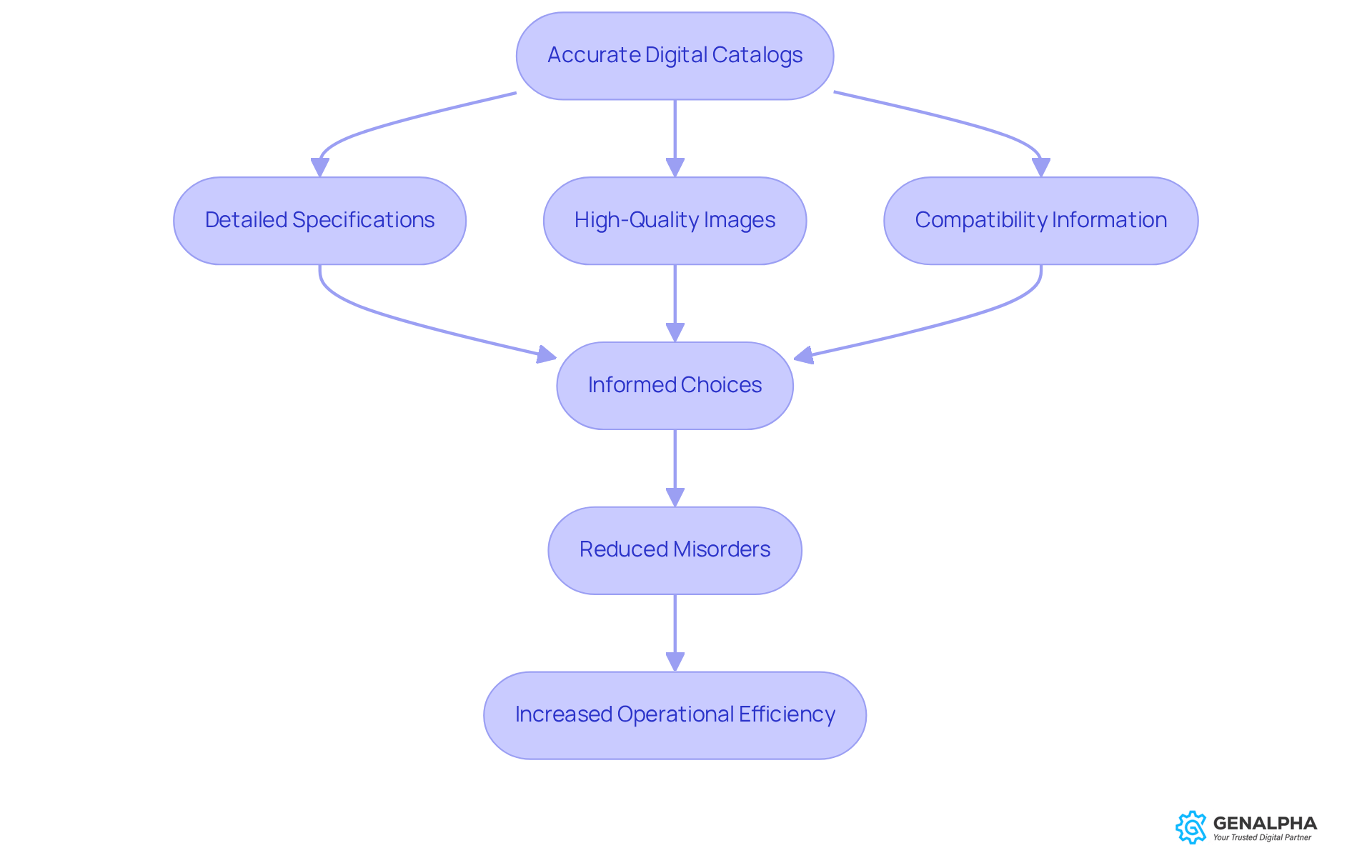

Have you ever faced the frustration of receiving the wrong part for a project? Precise digital listings can help prevent those misorders that often lead to costly mistakes for producers and suppliers. By offering detailed specifications, high-quality images, and compatibility information, electronic parts catalogs empower buyers to make informed choices. This, in turn, .

For example, imagine a technician using a digital inventory to quickly verify that a part meets the required specifications. Not only does this cut down on returns, but it also boosts overall operational efficiency. Producers who have embraced comprehensive digital listings have reported significant drops in misorder rates, leading to happier customers and lower operational costs.

Take a New Jersey PPE supplier, for instance. They saw a 30% decrease in last-minute rush orders thanks to improved order accuracy from their digital catalog. Similarly, an industrial equipment manufacturer using Intelli Catalog achieved an impressive 40% reduction in errors, proving just how effective these solutions can be.

As Chandra Shekhar, Senior Manager at Intellinet Systems, wisely pointed out, "Shipping the incorrect component is a hardship in the aftermarket that results in returns, delays, and dissatisfied clients." This transformation underscores the importance of investing in accurate and engaging electronic parts catalogs as part of digital inventory solutions. So, why not take a step toward enhancing your ordering processes today?

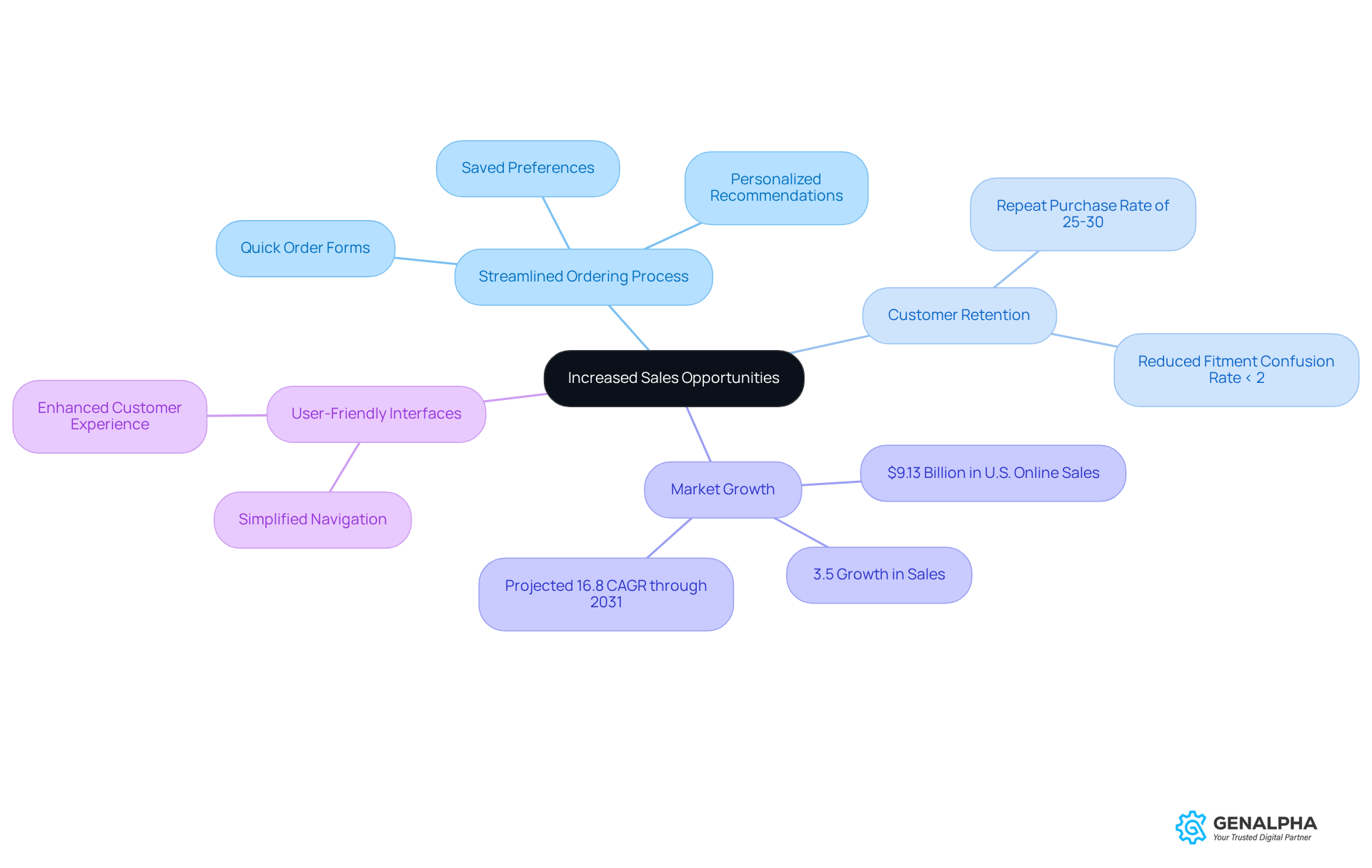

Increased Sales Opportunities: Boost Revenue with E-Catalog Orders

Have you ever considered how your sales game could be transformed by electronic parts catalogs? They really do enhance sales opportunities by streamlining the ordering process, making it a breeze for clients to find and buy parts. With features like quick order forms, saved preferences, and , the purchasing journey becomes not just simpler but also more inviting, encouraging clients to follow through with their purchases.

For example, when clients can quickly reorder their favorite products, they're much more likely to return. This not only promotes repeat transactions but also boosts overall revenue. In fact, did you know that the automotive components eCommerce market hit a whopping $9.13 billion in U.S. online sales in 2023? That’s a 3.5% growth from the previous year! It really shows how effective these streamlined processes are and how much trust consumers are placing in online shopping.

Additionally, businesses that utilize electronic parts catalogs can reduce the fitment confusion rate to below 2%. This means clarity in compatibility information, which is key to keeping customers happy. Manufacturers that embrace electronic parts catalogs are seeing impressive results, with reports of average cart value increasing by over 20% since they started using these tools.

So, what’s the takeaway here? Experts agree that focusing on user-friendly interfaces and efficient ordering systems is essential for maximizing revenue potential in today’s competitive landscape. Are you ready to take your sales to the next level?

Conclusion

The transformation of manufacturing efficiency through electronic parts catalogs is truly remarkable. Imagine being able to streamline parts management and enhance inventory accuracy all while boosting customer satisfaction—sounds great, right? With digital solutions like Equip360, manufacturers can do just that! Real-time updates, self-service access, and data-driven insights not only help cut operational costs but also allow for a more agile response to market demands.

Let’s think about some key points here. Adopting electronic parts catalogs can minimize misorders and open up new sales opportunities. Companies that jump on board with these digital tools often see improved operational efficiency, fewer errors, and a stronger connection with their clients. Plus, the focus on user-friendly navigation and seamless ERP integration highlights just how essential these solutions are in today’s competitive landscape.

So, what does this all mean? The shift toward electronic parts catalogs isn't just a passing trend; it's a strategic move for manufacturers who want to thrive. By embracing these technologies, businesses can optimize their processes and build lasting relationships with their customers. The future of manufacturing is all about adapting to digital advancements—now is the perfect time to invest in solutions that enhance efficiency and drive growth. Are you ready to take that step?

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies specializes in creating digital solutions for manufacturers and distributors in the equipment and aftermarket components sectors, with their standout product being Equip360.

What features does Equip360 offer?

Equip360 combines eCommerce features with smart digital cataloging to help businesses manage their inventory effectively, ensuring parts are always available and accessible to customers.

How does Equip360 enhance operational efficiency?

Equip360 empowers producers to create unique value propositions, adapt quickly to market demands, and improve component management, which leads to enhanced operational efficiency and increased customer satisfaction.

What are the reported benefits of using Equip360?

Manufacturers using Equip360 have reported improvements in managing components, reduced lead times, minimized stockouts, and stronger client relationships, contributing to growth in a competitive marketplace.

How do electronic parts catalogs impact parts management?

Electronic parts catalogs, when integrated with Equip360, provide data-driven insights that help producers make smarter decisions, streamline supply chains, and respond proactively to client needs.

What additional features can manufacturers consider for Equip360?

Manufacturers might consider adding features like digital brochures, RMA (Return Merchandise Authorization), warranty management, and product configurator tools to enhance their inventory management approach.

Why are real-time updates important for electronic parts catalogs?

Real-time updates ensure access to the most current information regarding availability, pricing, and specifications, significantly reducing errors from outdated data and enhancing the overall purchasing experience.

What improvements have been reported by producers using real-time updates?

Producers utilizing real-time updates have reported a 40% decrease in order mistakes and faster repair processes, demonstrating increased operational efficiency.

How can integrating electronic parts catalogs with ERP systems benefit companies?

Integrating electronic parts catalogs with ERP systems enhances the self-service experience for clients, providing them with instant access to accurate information and further streamlining operations.

What advantages do self-service options provide to users?

Self-service options allow users to access electronic parts catalogs instantly, check specifications, and see availability without needing to contact customer support, resulting in increased satisfaction and productivity.

How do self-service solutions affect operational efficiency?

Companies that implement self-service solutions experience higher client satisfaction and improved operational efficiency, as support teams can focus on more complex inquiries rather than routine requests.

What is the potential economic impact of wider self-service technology usage?

If self-service technology were more widely used, it could potentially increase the U.S. economy by about $130 billion each year, highlighting its significant impact on customer satisfaction and operational efficiency.