Overview

Have you ever thought about how an Order Management System (OMS) can transform the way manufacturers operate? It’s not just a fancy tool; it’s essential for automating and streamlining the entire order lifecycle. This means greater efficiency, accuracy, and, yes, happier customers!

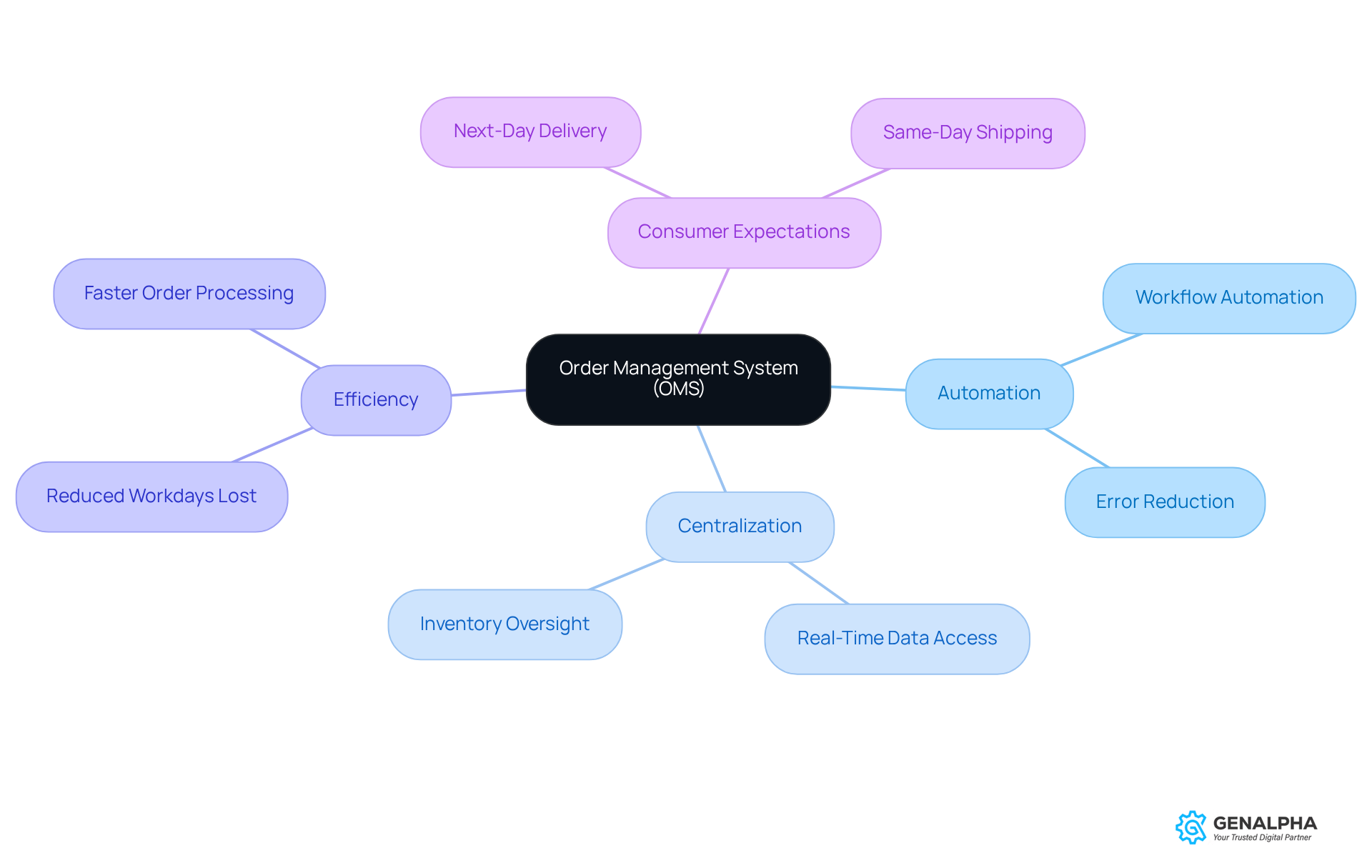

Imagine centralizing your inventory management, processing orders seamlessly, and having real-time data at your fingertips. With an OMS, manufacturers can reduce errors, cut down on lead times, and keep up with those ever-growing consumer expectations. Ultimately, this leads to better profitability and operational excellence.

So, why not consider how an OMS could work for you? It’s time to elevate your operations and meet the demands of today’s market!

Introduction

Have you ever thought about how order management can really change the game for manufacturing operations? An Order Management System (OMS) is more than just a tool; it’s a game changer for manufacturers. It automates everything from creating orders to fulfilling them, all while keeping track of inventory and sales in one central spot. But here’s the kicker: as consumers demand faster deliveries and smoother service, the big question is—how can manufacturers make the most of an OMS? How can they not only streamline their operations but also boost customer satisfaction and drive growth? Let’s dive in!

Define Order Management System (OMS)

Have you ever thought about how much time and effort goes into managing orders? What is an (OMS)? It serves as your best friend in this scenario, designed to automate and streamline everything from creation to fulfillment. Imagine having all those essential functions—inventory oversight, sales monitoring, and client data management—wrapped up in one easy-to-use platform. This means manufacturers can effortlessly handle requests across different sales channels. Pretty neat, right?

Centralizing all this information ensures that everything you need is accessible in real-time, which significantly cuts down the chances of errors that come with manual processes. In today’s fast-paced market, where nearly two-thirds of warehouses lose a staggering 52 workdays each year to small, untracked delays, knowing what is an order management system reveals the truly invaluable efficiency it brings. It helps tackle those pesky delays by automating workflows and boosting order accuracy.

And let’s not forget about consumer expectations! More than 25% of online shoppers are all about that next-day delivery. So, manufacturers equipped with a solid understanding of what is an order management system (OMS) can really enhance their operational efficiency and responsiveness. This not only drives growth but also keeps customers happy. So, why not consider how an OMS could transform your order management process?

Explain the Importance of OMS for Manufacturers

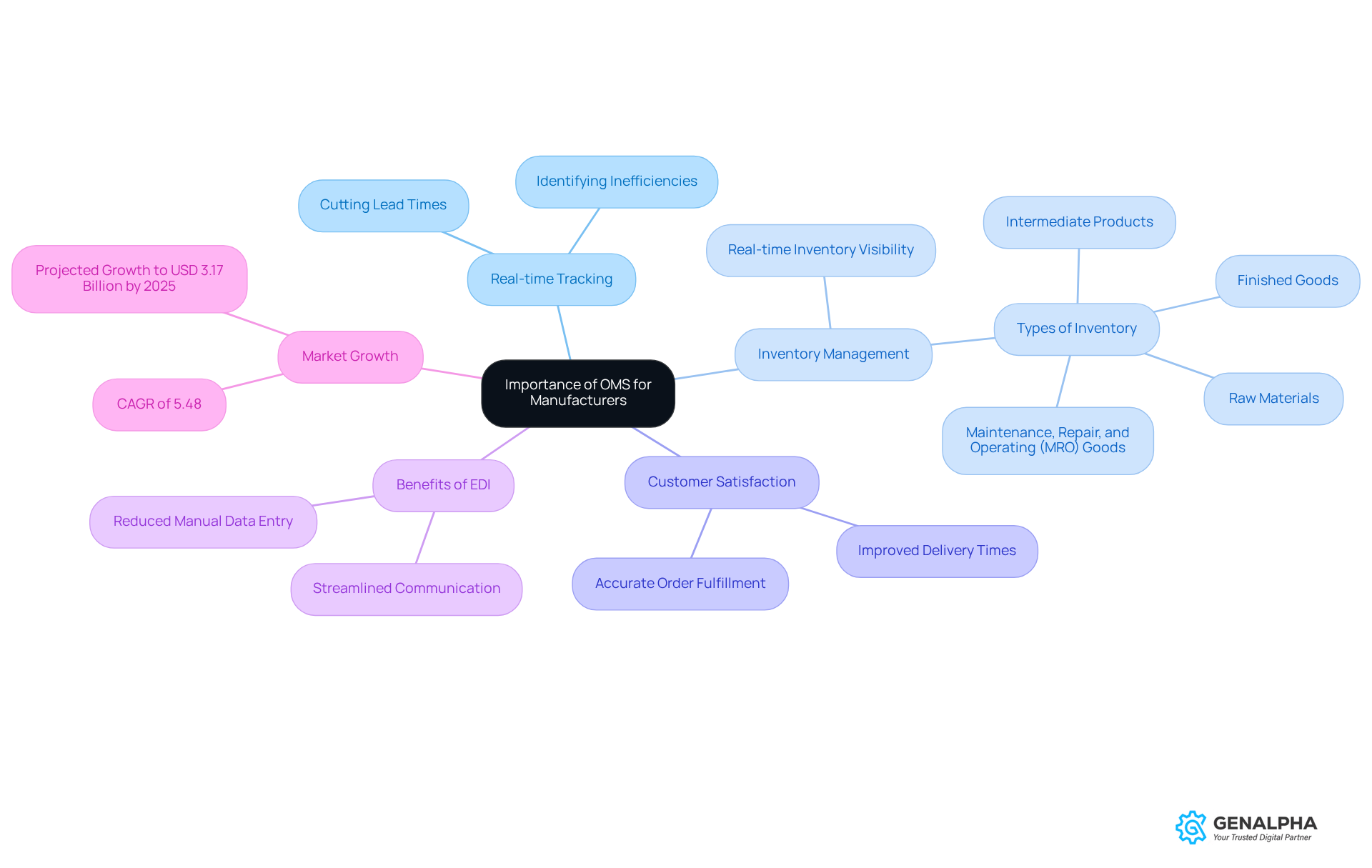

Have you ever thought about what is an order management system and how crucial it is for producers? In today’s fast-paced world, where precision and efficiency matter more than ever, what is an order management system truly becomes the backbone of processing requests. It allows for real-time tracking of transactions and effective inventory management. By automating these processes, producers can cut down lead times and minimize errors, which directly boosts client satisfaction and illustrates what is an order management system.

For instance, businesses that have adopted solutions that answer what is an order management system (OMS) often report better accuracy in their requests and faster fulfillment rates, leading to increased customer loyalty. Isn’t that what we all want? Plus, understanding what is an order management system (OMS) provides essential data analytics that help producers make informed decisions, improve their supply chains, and ultimately drive profitability. Did you know that the global market for order management systems is expected to hit USD 3.17 billion by 2025, growing at a CAGR of 5.48%? This really highlights what is an order management system and how .

Producers also juggle four different types of inventory—finished goods, raw materials, intermediate products, and maintenance, repair, and operating (MRO) goods. This highlights that the comprehensive capabilities of what is an order management system are not just useful, but essential. And let’s not forget about Electronic Data Interchange (EDI); integrating it within an OMS streamlines communication and cuts down on manual data entry, which boosts operational efficiency even further.

In a competitive landscape where margins are often razor-thin, knowing what is an order management system is key to staying ahead and achieving operational excellence. As producers face challenges like inaccurate inventory information and communication gaps, knowing what is an order management system and adopting it isn’t just a smart move—it’s essential for ongoing growth and efficiency. So, what’s holding you back from exploring the benefits of an OMS?

Outline Key Features and Functionalities of OMS

Let’s dive into the key features and functionalities of an Order Management System (OMS) that can really make a difference:

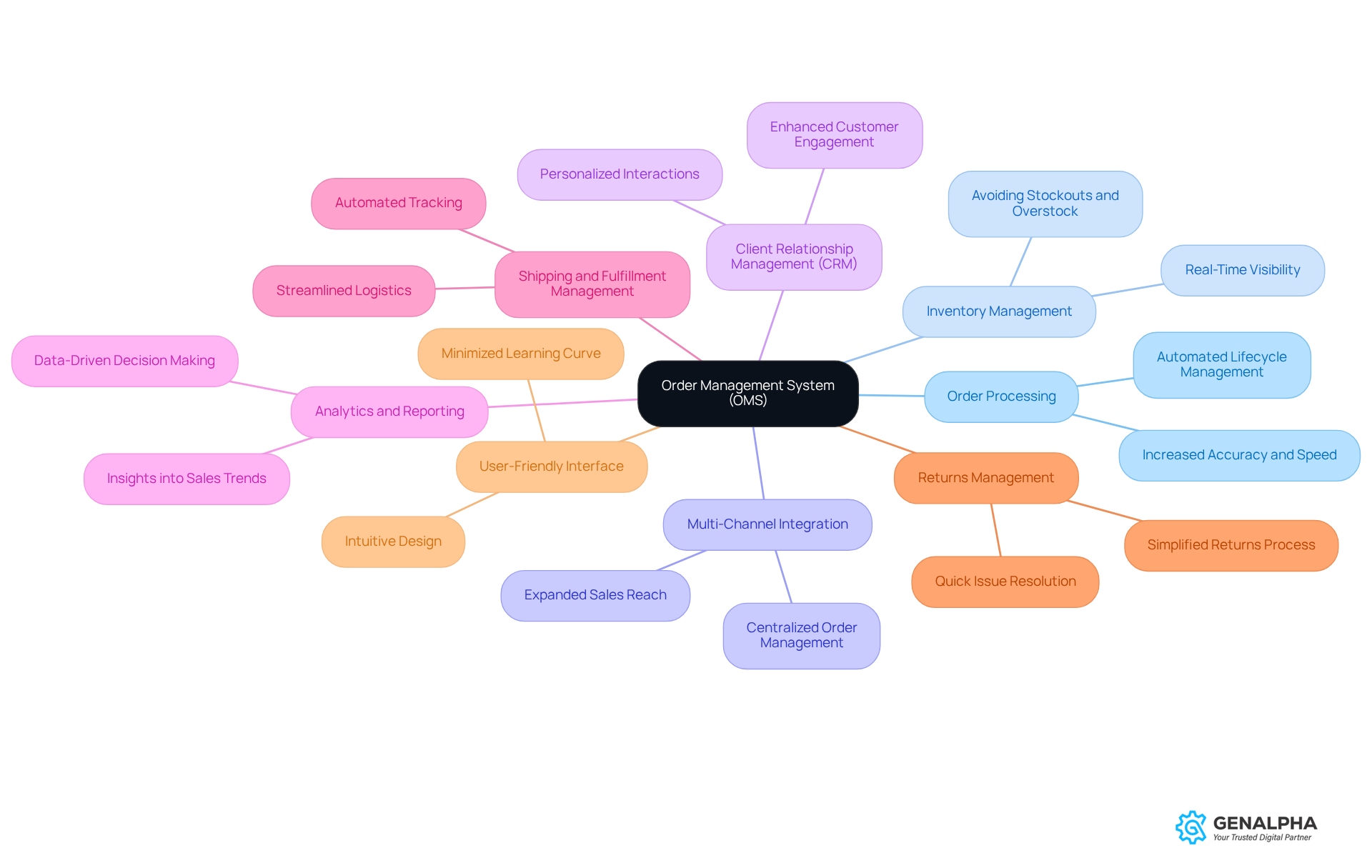

- Order Processing: Imagine automating the entire order lifecycle—from entry to fulfillment. This means accuracy and speed go hand in hand, drastically reducing processing times. It’s a game changer for producers looking to manage larger quantities effectively.

- Inventory Management: Picture having real-time visibility into stock levels. This helps manufacturers avoid those dreaded stockouts and overstock situations. Efficient inventory management is crucial because it cuts down on delays and mistakes, ultimately boosting customer satisfaction.

- Multi-Channel Integration: Ever thought about managing purchases across various sales channels, like eCommerce platforms and physical stores? This integration is vital for producers wanting to expand their reach and optimize operations. It allows for centralized management of orders from different sources.

- Client Relationship Management (CRM): Integrating client data can enhance service and support, leading to personalized interactions. By tapping into consumer insights, producers can foster better connections and cultivate loyalty.

- Analytics and Reporting: How about gaining insights into sales trends, inventory turnover, and customer behavior? Comprehensive analytics empower manufacturers to pinpoint areas for improvement and fine-tune their operations.

- Shipping and Fulfillment Management: Streamlining logistics by automating shipping processes and tracking deliveries can really speed things up. This not only accelerates order fulfillment but also enhances visibility throughout the order lifecycle.

- Returns Management: An effective OMS simplifies the returns process, which is a win for client satisfaction and operational efficiency. Automating return approvals and tracking means producers can tackle issues quickly and maintain solid client relationships.

- User-Friendly Interface: A well-designed OMS features an intuitive interface that makes it easy for new employees to get up to speed, enhancing both operational efficiency and client satisfaction.

When you put all these features together, they significantly , cut costs, and improve customer satisfaction. In fact, producers using an OMS, which answers what is an order management system, have reported a 35% increase in request accuracy and a 50% boost in fulfillment speed—talk about concrete advantages! Plus, the flexibility of an OMS supports sustained growth and quick responses to changing market demands. For instance, Snarky Tea saved a whopping 360 hours annually through automation. Doesn’t that sound like a smart move?

Discuss Benefits of Implementing an OMS

What is an order management system (OMS) and how can implementing it really change the game for manufacturers by offering a host of significant benefits? Let's dive into some of these perks!

- Increased Efficiency: Imagine automating your order processing and inventory management—sounds great, right? This automation cuts down on manual tasks, leading to faster order fulfillment. And with the multichannel management market expected to grow from USD 2.07 billion to USD 4 billion by 2025, it's clear that streamlined operations are more important than ever.

- Enhanced Precision: Nobody likes mistakes, especially when it comes to orders. An OMS helps reduce human errors in product input and inventory tracking, ensuring your clients get the right items on time. Accurate inventory info is crucial; it helps avoid stockouts and overselling, which can frustrate customers and lead to lost sales. In our connected world, customers have little patience for incorrect stock details and will quickly look elsewhere if you can’t deliver as promised.

- Improved Client Satisfaction: With features like and efficient fulfillment processes, your clients will enjoy a smoother buying experience. This can lead to higher retention rates. Companies that refine their management processes often see a boost in customer loyalty and repeat business.

- Cost Savings: Who doesn’t want to save money? Streamlining operations through an OMS can significantly cut overhead costs tied to order processing and inventory management. By automating those labor-intensive tasks, manufacturers can see substantial savings, which can enhance profit margins. Plus, reducing manual errors and optimizing resources means better resource allocation.

- Improved Decision-Making: Having access to detailed analytics means you can make smart choices about inventory levels, production schedules, and client engagement strategies. Most OMS software comes with robust inventory reporting and predictive insights, helping leaders forecast demand and optimize stock levels. An OMS gathers all this information into easy-to-understand summaries of order trends and customer behavior, allowing leaders to refine operations effectively.

In conclusion, understanding what is an order management system not only boosts operational capabilities but also sets manufacturers up for long-term success in a competitive landscape. It ensures that you can meet evolving customer expectations and market demands. So, are you ready to take the plunge into the world of OMS?

Conclusion

An order management system (OMS) isn't just a tool; it's a game-changer for manufacturers looking to handle orders, inventory, and customer interactions more effectively. By bringing everything together and automating workflows, an OMS can boost operational efficiency, cut down on errors, and ultimately lead to happier customers. If you're a manufacturer aiming to stand out in today's fast-paced market, understanding the role of an OMS is key—precision and speed are everything!

Throughout this article, we've explored some essential insights, like the must-have features of an OMS, including:

- Order processing

- Inventory management

- Multi-channel integration

The perks of implementing an OMS are huge! We're talking about increased efficiency, improved accuracy, better client satisfaction, and even cost savings. With the global market for OMS set to grow significantly, the importance of jumping on board with these systems is clearer than ever.

So, to wrap things up, embracing an order management system is crucial for manufacturers who want to optimize their operations and stay ahead of the curve. An OMS not only streamlines processes but also empowers you to make informed decisions that can drive profitability and growth. Why wait? Now is the perfect time to dive into how an OMS can revolutionize your order management and lay the groundwork for long-term success!

Frequently Asked Questions

What is an Order Management System (OMS)?

An Order Management System (OMS) is a platform designed to automate and streamline the entire order process, from creation to fulfillment, including functions like inventory oversight, sales monitoring, and client data management.

How does an OMS improve efficiency in order management?

An OMS centralizes information, ensuring real-time accessibility, which reduces errors associated with manual processes. It automates workflows and boosts order accuracy, helping to tackle delays in the order management process.

What impact do delays have on warehouses?

Delays can significantly affect warehouse operations, with nearly two-thirds of warehouses losing an average of 52 workdays each year due to small, untracked delays.

How does an OMS help meet consumer expectations?

An OMS enables manufacturers to enhance their operational efficiency and responsiveness, which is crucial as more than 25% of online shoppers expect next-day delivery.

Why should manufacturers consider implementing an OMS?

Implementing an OMS can transform the order management process, drive growth, and improve customer satisfaction by ensuring timely and accurate order fulfillment.