Overview

Service Lifecycle Management (SLM) is super important for equipment manufacturers. Why? Because it helps optimize service delivery from the moment a product is created all the way to its retirement. This not only boosts client satisfaction but also enhances operational efficiency.

Think about it: effective SLM practices, like predictive maintenance and structured management phases, can really make a difference. For example, they lead to reduced downtime and improved customer relationships. And who doesn’t want that? Ultimately, these benefits drive profitability and success, especially in a competitive landscape.

So, if you’re in the game of equipment manufacturing, it’s time to think about how SLM can transform your operations. Let’s dive into how these practices can work for you!

Introduction

Service lifecycle management (SLM) isn’t just a buzzword; it’s a game changer for equipment manufacturers. Imagine having a structured approach that covers every step of service—from design to retirement. Sounds great, right? SLM opens the door to better efficiency and happier customers.

But here’s the kicker: implementing these practices can be tricky, especially in a world where operational transparency and resource allocation can make or break your business.

So, how can manufacturers tap into the power of SLM to not just meet, but truly exceed their clients' expectations?

Define Service Lifecycle Management (SLM)

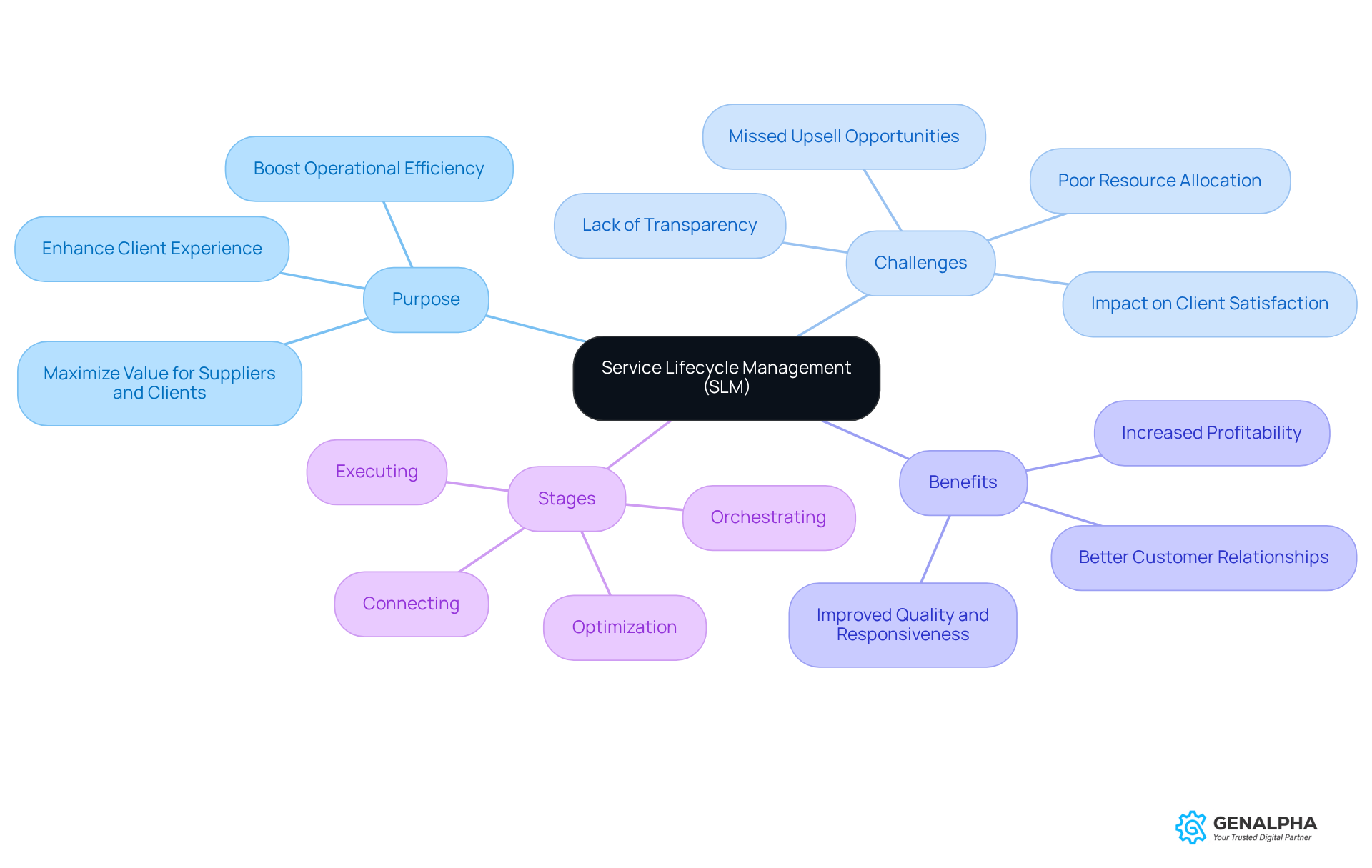

Service lifecycle management serves as a roadmap that guides us through the entire journey of a service, from its inception to its eventual retirement. This comprehensive approach is all about maximizing value for both suppliers and clients. Think of it as a toolkit that includes design, planning, execution, and continuous improvement—all aimed at enhancing the client experience and boosting operational efficiency.

Now, imagine what happens without a solid SLM solution: companies might struggle with a lack of transparency in their operations, poor resource allocation, and missed upsell opportunities. These issues can seriously affect client satisfaction and overall business performance. But when processes are managed effectively with service lifecycle management, equipment manufacturers can not only meet but exceed client expectations, building loyalty and driving success.

Practical applications of service lifecycle management highlight its importance, particularly in achieving smooth transitions that minimize downtime and ensure timely delivery. This, in turn, has a . Organizations that embrace strong service lifecycle management practices often report improved quality and responsiveness, which leads to better customer relationships and increased profitability.

Let’s break it down further: the four stages of service lifecycle management—Connecting, Orchestrating, Executing, and Optimization—illustrate the organized approach essential for effectively managing services. So, how can your organization start implementing these practices? It might just be the key to unlocking greater success!

Contextualize SLM in Equipment Manufacturing

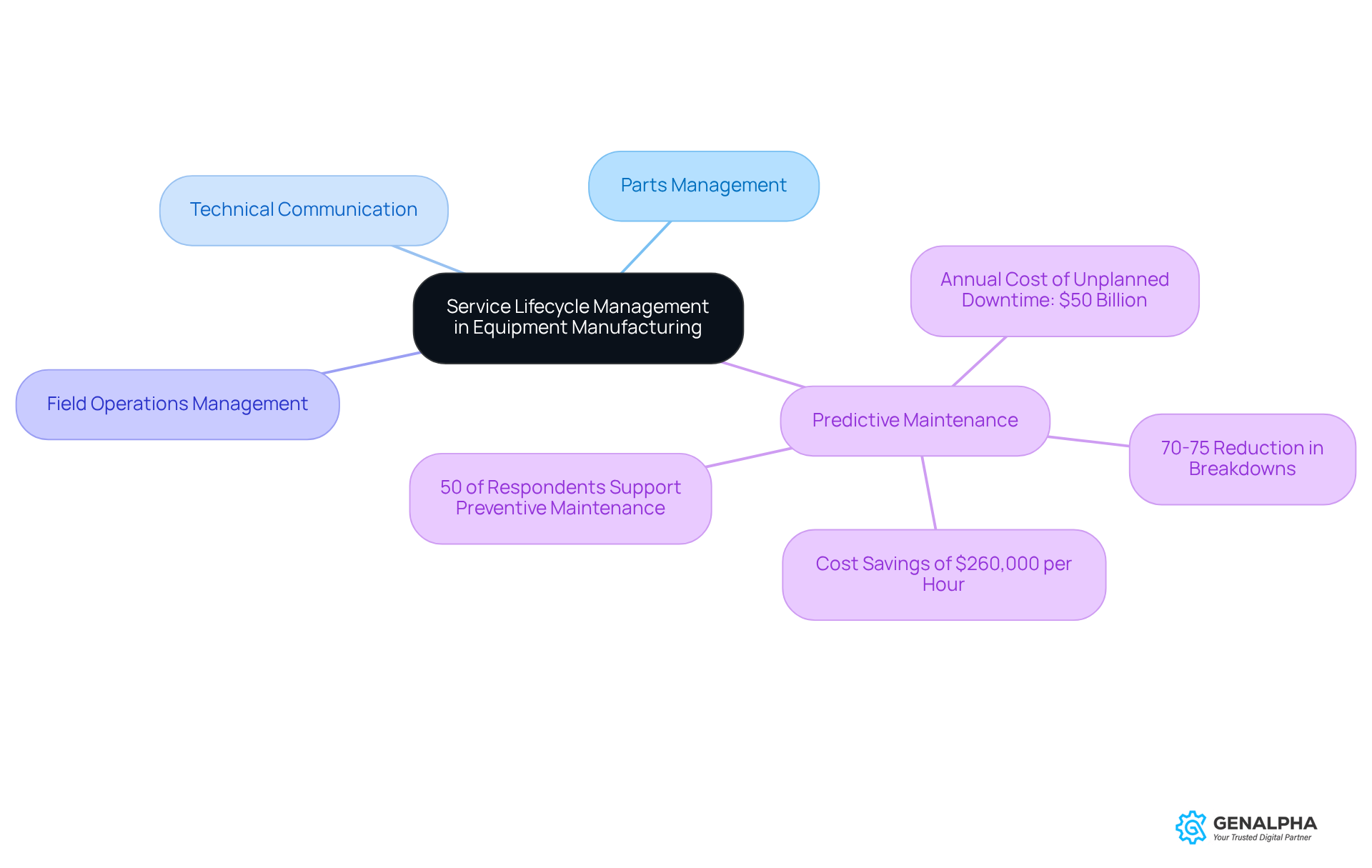

In the world of equipment manufacturing, have you ever considered how service lifecycle management plays a vital role in keeping everything running smoothly? Manufacturers deal with complex machinery that needs constant care and support. By embracing service lifecycle management, companies can seamlessly blend parts management, technical communication, and field operations management. This not only boosts operational efficiency but also makes a real difference in how things function day-to-day.

For example, consider predictive maintenance strategies, which are a game changer in service lifecycle management (SLM). They can cut down equipment breakdowns by a staggering 70% to 75%, almost wiping out catastrophic failures altogether! This proactive approach helps minimize those pesky that can cost manufacturers an eye-watering $260,000 per hour, contributing to an annual cost of up to $50 billion. Just imagine the impact on responsiveness to client needs and the consistency in service.

As a result, manufacturers can really ramp up client satisfaction, which is crucial in a competitive landscape. Did you know that 50% of survey respondents believe that a preventive maintenance strategy can significantly reduce downtime caused by aging equipment? It’s clear that service lifecycle management empowers equipment manufacturers to deliver high-quality offerings that meet and even exceed customer expectations, while also enhancing their reputation for reliability and excellence. So, why not consider how SLM can transform your operations today?

Explore Key Components and Phases of SLM

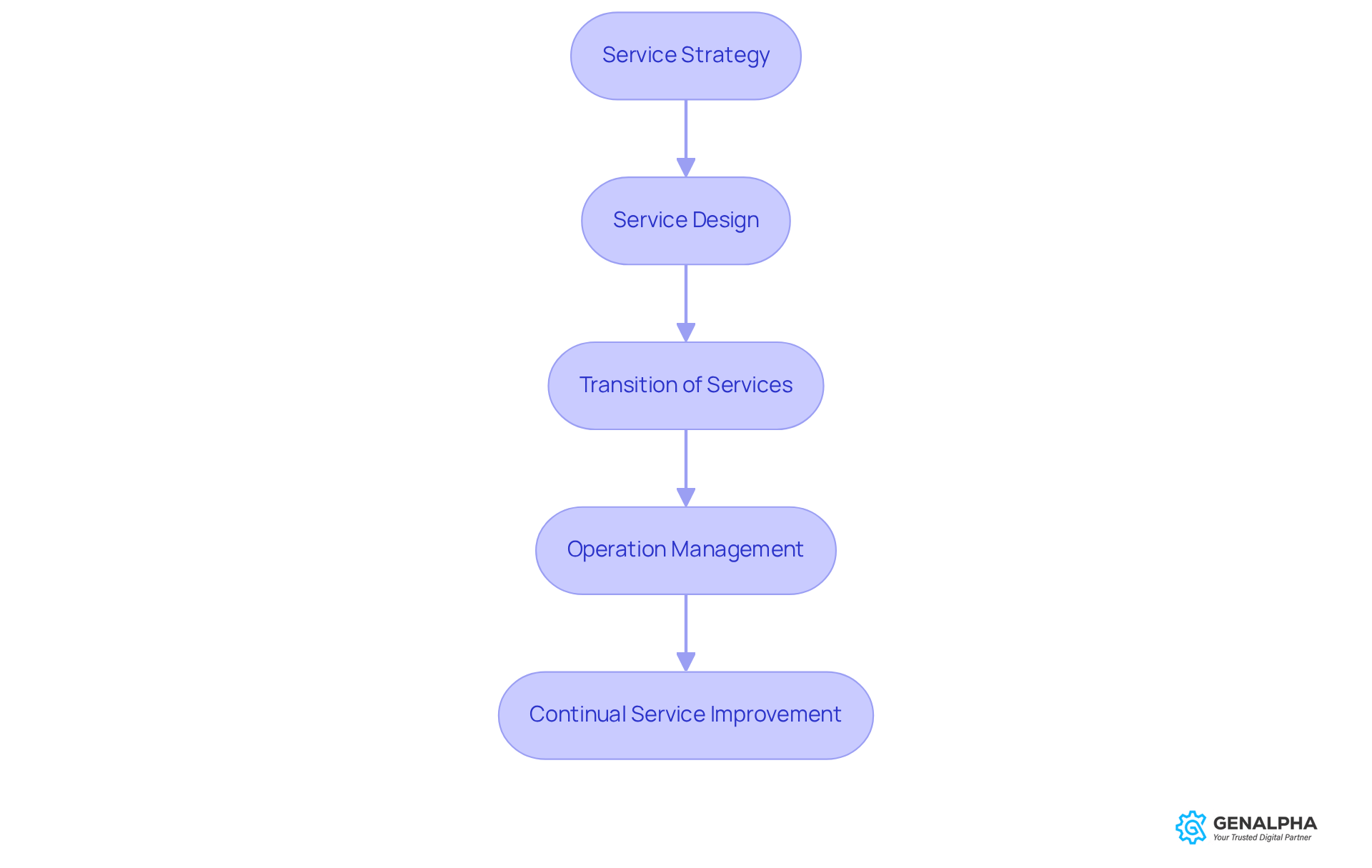

Service lifecycle management (SLM) focuses on five key phases: strategy, design, transition, operation, and continual improvement. Each of these phases plays a vital role in service lifecycle management, ensuring that services are delivered efficiently and effectively.

- Service Strategy: Think of this as the foundation. Here, we define what services we’re offering and make sure they align with our broader business goals. This sets the stage for everything that follows, ensuring our offerings meet market demands and client expectations.

- Service Design: Next up, we focus on crafting offerings that not only satisfy customer needs but are also practical and cost-effective. This includes creating detailed specifications, process diagrams, and establishing (SLAs) to ensure we hit our quality and performance targets.

- Transition of Services: This phase is all about careful planning and managing changes. We want to make sure that any new or modified offerings are rolled out smoothly. A well-executed transition minimizes disruptions and boosts the reliability of our service delivery.

- Operation Management: Here, we handle the day-to-day management of our offerings, ensuring they’re delivered as promised and meet our quality standards. Effective operation is crucial for keeping our clients happy and maintaining operational efficiency. For instance, real-time synchronization is key, ensuring that data is updated across all systems promptly, which helps us maintain quality.

- Continual Service Improvement: This phase is ongoing and focuses on spotting opportunities to enhance our delivery and boost client satisfaction. By leveraging feedback and performance metrics, we can implement improvements that enhance both operational efficiency and quality.

Let’s take a moment to consider real-world examples. In manufacturing, for instance, an effective support strategy and design can lead to optimized maintenance schedules and improved equipment reliability, which ultimately enhances customer satisfaction. Plus, applying service lifecycle management principles has been shown to improve delivery consistency by 25-40%. That’s a clear win for a structured approach to management! And don’t forget, the tangible outputs—like blueprints, level agreements, and quality metrics—become the technical DNA that gets configured in CPQ systems and later translated into field workflows for FSM platforms.

So, how can you start implementing these phases in your own organization? Let’s dive into it together!

Highlight Benefits of Implementing SLM

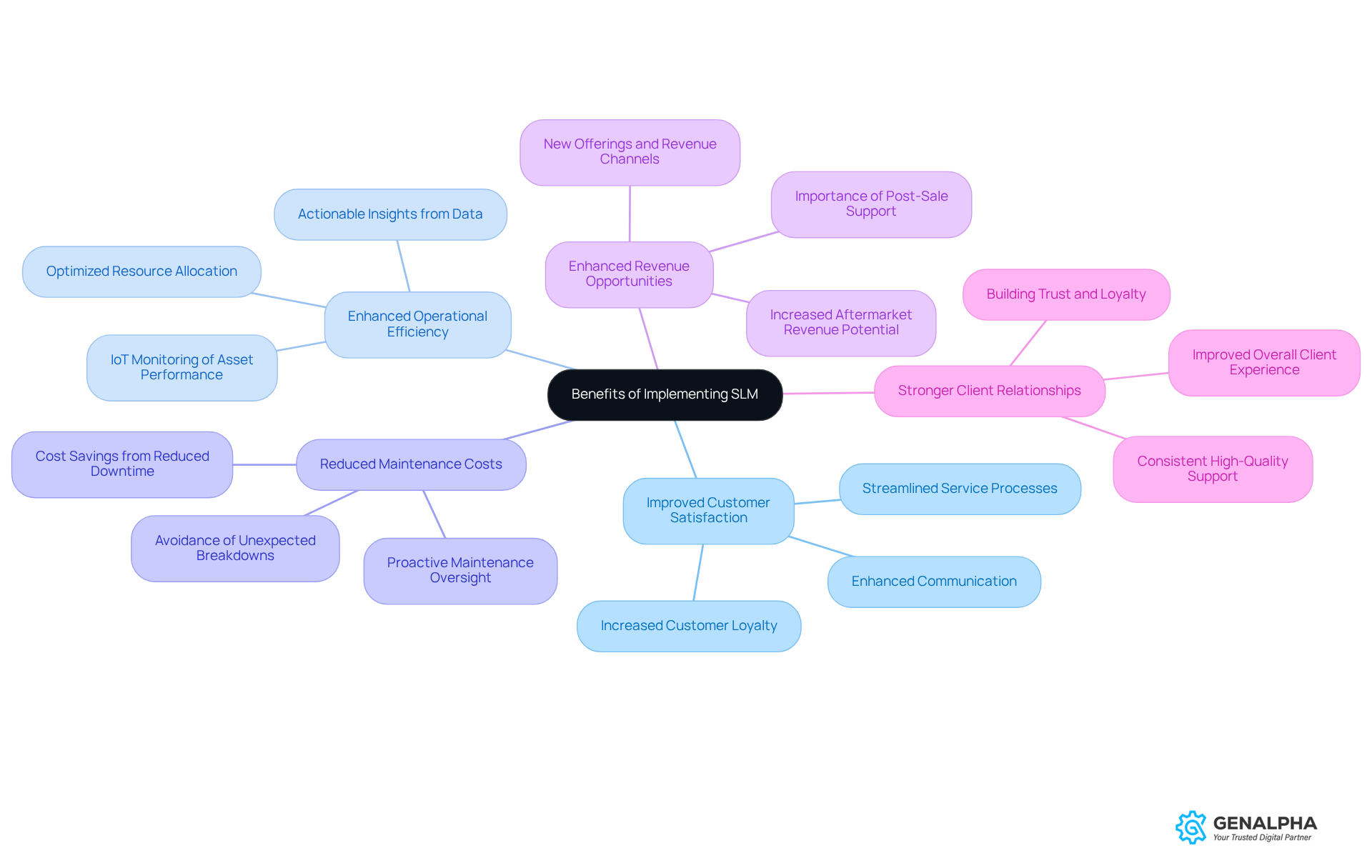

Implementing service lifecycle management brings a host of significant benefits for equipment manufacturers. Let’s dive into some of them!

- Improved Customer Satisfaction: Imagine being able to streamline your service processes and enhance communication so effectively that you can respond to customer needs almost instantly! That’s the role of service lifecycle management. Organizations using it have reported a noticeable uptick in service delivery, which directly boosts customer loyalty and retention. Who wouldn’t want that?

- Enhanced Operational Efficiency: Think about optimizing your resource allocation and delivery to minimize waste and boost productivity. With SLM, that’s entirely possible! By integrating service-related data from design to execution, manufacturers can gain actionable insights that lead to smarter decision-making. Plus, with IoT technology monitoring asset performance trends, planning capabilities just got a whole lot better.

- Reduced Maintenance Costs: How about anticipating maintenance needs before they become a problem? Proactive oversight supported by data analytics allows manufacturers to do just that. This foresight helps avoid unexpected breakdowns and the costs that come with them, creating a more reliable production environment. Did you know that 81% of producers have faced production halts due to robot upkeep? Effective service lifecycle management can significantly reduce these risks through proactive management.

- Enhanced Revenue Opportunities: Service lifecycle management opens doors to discovering new offerings and revenue channels, such as maintenance contracts and support agreements. This strategic approach can really boost profitability, especially as companies recognize the importance of in their business models. Not to mention, it also enhances the potential for aftermarket revenue, linking directly to financial gains.

- Stronger Client Relationships: Consistent, high-quality support builds trust and loyalty among clients. By focusing on client satisfaction through efficient management, producers can create lasting connections that benefit everyone involved. Streamlined service delivery not only enhances the overall client experience but also contributes to improved satisfaction and loyalty.

In summary, the implementation of service lifecycle management doesn’t just streamline operations; it significantly enhances customer satisfaction, driving growth and profitability in the competitive world of equipment manufacturing. So, are you ready to take the plunge into SLM and see these benefits for yourself?

Conclusion

Service lifecycle management (SLM) is like a roadmap for equipment manufacturers, guiding them through the complex journey of service delivery—from the very start to retirement. By embracing a structured approach to SLM, organizations can really boost their operational efficiency and keep clients happy, which ultimately leads to better business performance. This all-encompassing methodology not only helps with smooth transitions and proactive maintenance but also equips companies to meet and even exceed customer expectations.

As we wrap up, let’s reflect on the key insights shared about the phases of SLM—strategy, design, transition, operation, and continual improvement. Each phase is vital for ensuring services are delivered efficiently, with a strong focus on customer satisfaction and operational excellence. The perks of implementing SLM are impressive: think improved customer loyalty, enhanced operational efficiency, lower maintenance costs, and more revenue opportunities. These benefits really highlight the transformative power of SLM in today’s competitive equipment manufacturing landscape.

When we think about the significance of service lifecycle management, it’s clear that adopting these practices isn’t just about keeping operations running smoothly; it’s a strategic advantage. Companies that prioritize SLM find themselves better prepared to tackle the complexities of equipment manufacturing, building stronger client relationships and driving sustainable growth. So, why not take some time to explore how SLM can shake up your operations and open up new paths for success?

Frequently Asked Questions

What is Service Lifecycle Management (SLM)?

Service Lifecycle Management (SLM) is a comprehensive approach that guides the entire journey of a service from its inception to retirement, focusing on maximizing value for both suppliers and clients.

What are the main components of SLM?

The main components of SLM include design, planning, execution, and continuous improvement, all aimed at enhancing the client experience and boosting operational efficiency.

What issues can arise without a solid SLM solution?

Without a solid SLM solution, companies may face a lack of transparency, poor resource allocation, and missed upsell opportunities, which can negatively impact client satisfaction and overall business performance.

How does effective SLM benefit equipment manufacturers?

Effective SLM allows equipment manufacturers to meet and exceed client expectations, building loyalty and driving success.

What are the practical applications of SLM?

Practical applications of SLM include achieving smooth transitions that minimize downtime and ensure timely delivery, which directly impacts client satisfaction.

What improvements do organizations report when they embrace strong SLM practices?

Organizations that embrace strong SLM practices often report improved quality and responsiveness, leading to better customer relationships and increased profitability.

What are the four stages of Service Lifecycle Management?

The four stages of Service Lifecycle Management are Connecting, Orchestrating, Executing, and Optimization, which illustrate the organized approach essential for effectively managing services.

How can an organization start implementing SLM practices?

Organizations can start implementing SLM practices by following the structured approach outlined in the four stages, which may unlock greater success in their operations.