Overview

Have you ever thought about how smart parts—those advanced components with sensors and data analytics—are changing the game in production and distribution? They're not just fancy tech; they're essential for boosting efficiency and functionality.

Imagine getting real-time feedback, predicting when maintenance is needed, and making better decisions on the fly. Sounds great, right? These capabilities lead to significant increases in productivity and operational agility, especially in today's competitive markets.

So, what do you think? Are you ready to explore how these innovations could transform your operations?

Introduction

Smart manufacturing is shaking things up in the production world, and at the center of this exciting change are smart components—often called "smarty parts." These high-tech elements tap into the power of technology to boost efficiency and improve decision-making, helping manufacturers stay ahead in a fast-paced market. But as industries dive into this new era, some questions pop up:

- What exactly are these smart components?

- How can we seamlessly integrate them into our existing systems?

By exploring what smarty parts are all about, their significance, and their key features, we can uncover not just how they can simplify processes but also the hurdles organizations might face when adopting this cutting-edge technology. So, let’s dive in and find out more!

Define Smarty Parts: A Comprehensive Overview

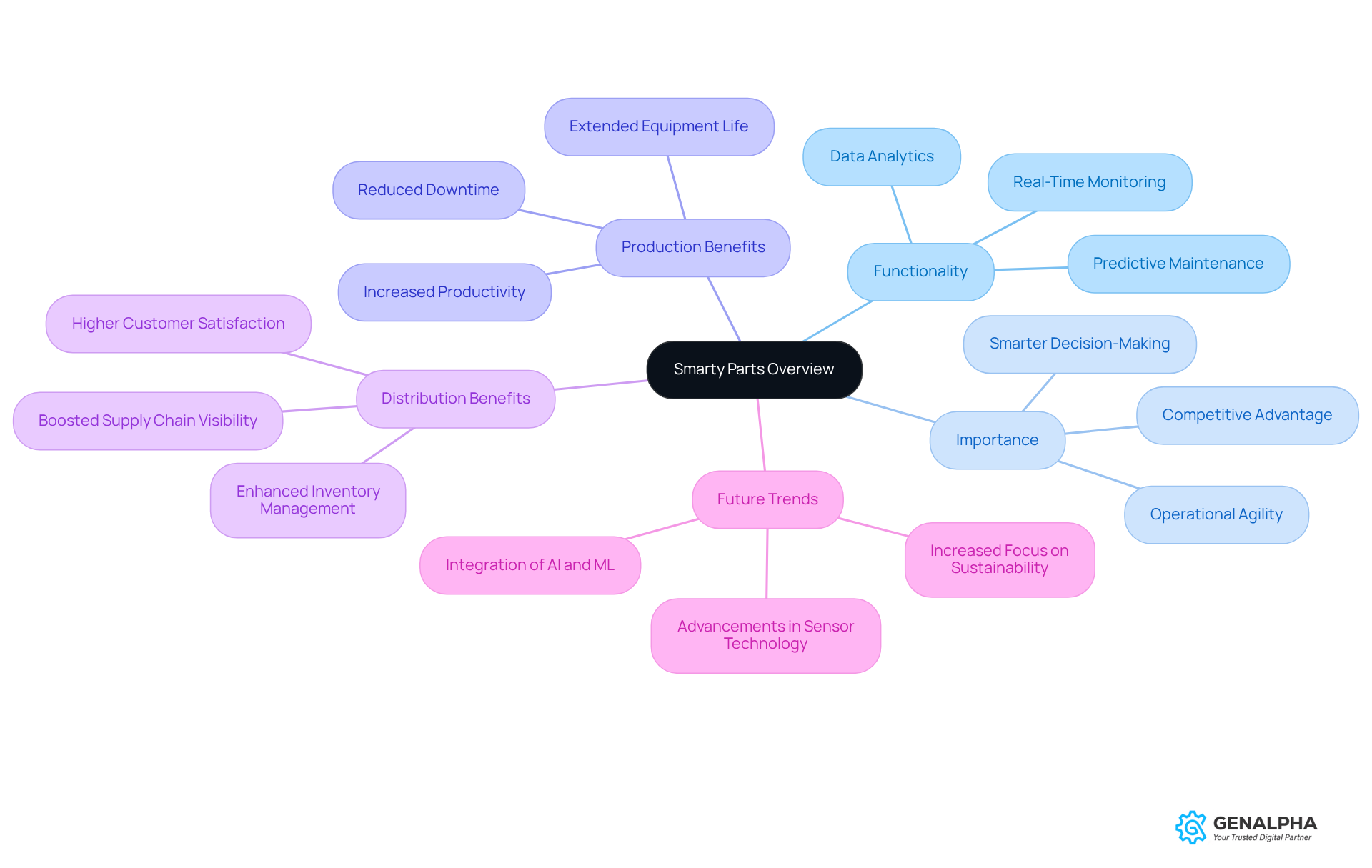

Smart elements are like the brainy buddies of production and distribution operations, designed to boost functionality and efficiency. These advanced parts tap into cutting-edge tech—think sensors and data analytics—to provide real-time feedback that supercharges operational performance. Unlike the old-school components, these innovative units can adapt and react to changing situations, making them a must-have in today’s production environments where are key.

Now, let’s talk about why smart elements are so important in production. They empower smarter decision-making and operational agility, which are crucial for staying competitive in a fast-paced market. For example, when manufacturers integrate smart sensors, they can keep an eye on equipment status all the time, which cuts down on unplanned downtime and maintenance costs. In fact, smart factories that harness machine learning and AI have seen massive boosts in productivity and efficiency—some companies even report up to a 60% reduction in downtime thanks to predictive maintenance strategies, as industry experts point out.

In the world of equipment manufacturing, the importance of smarty parts cannot be overlooked. These elements not only amp up machinery performance but also help extend equipment life by providing actionable insights that guide maintenance schedules. Take a well-known automotive producer, for instance—they integrated smart parts into their assembly lines, leading to better quality control and a noticeable increase in production output.

Let’s not forget about distribution processes, which also benefit from Smarty Parts. Smart elements simplify logistics by enhancing inventory management and boosting supply chain visibility. This is vital for meeting customer demands quickly and efficiently. Companies that have jumped on this tech bandwagon report higher customer satisfaction rates and improved operational efficiencies.

Experts are buzzing about the game-changing potential of intelligent components in production. Industry leaders stress that the future hinges on our ability to weave advanced technologies into our operational processes. As Marc Dupaquier puts it, "Smart means being able to exercise real-time monitoring and control of machinery, allowing for precise and responsive adjustments based on data from the sensors." This evolution is crucial for organizations aiming to thrive in a competitive landscape. So, are you ready to embrace the smart revolution?

Contextualize Smarty Parts: Importance in Equipment Manufacturing

In the equipment production industry, these components are crucial for boosting operations and enhancing customer experiences. As producers face the challenges of rising production costs and fierce competition, incorporating smarty parts can really make a difference. Think about effective inventory control, predictive maintenance, and improved product quality—these are game changers! By leveraging data-driven insights, companies can optimize resource allocation and significantly increase customer satisfaction.

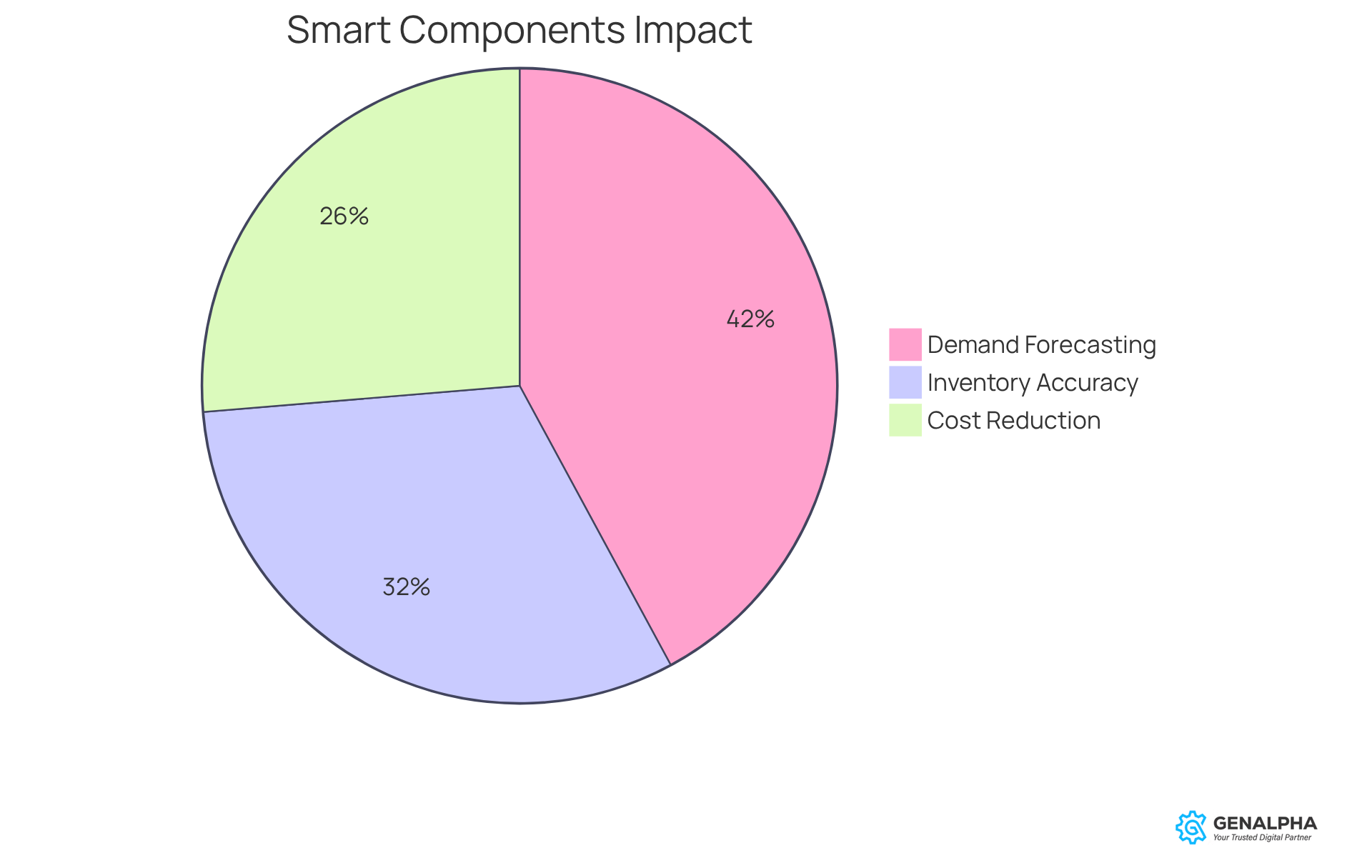

For example, studies show that businesses using IoT-enabled inventory management systems have seen a 25-35% improvement in inventory accuracy and a 20-30% reduction in carrying costs. Isn’t that impressive? In a world where customer expectations are constantly changing, it's essential to keep up. In fact, 58% of retail brands recognize the need for better inventory accuracy to meet consumer demands.

Additionally, real-time monitoring capabilities have led to a whopping 40% increase in demand forecasting accuracy. This allows manufacturers to and enhance overall customer experiences. The impact of smarty parts extends beyond just operational metrics; they play a vital role in creating a responsive and customer-focused production environment. So, how are you planning to incorporate these smart components into your operations?

Trace the Evolution of Smarty Parts: Historical Development

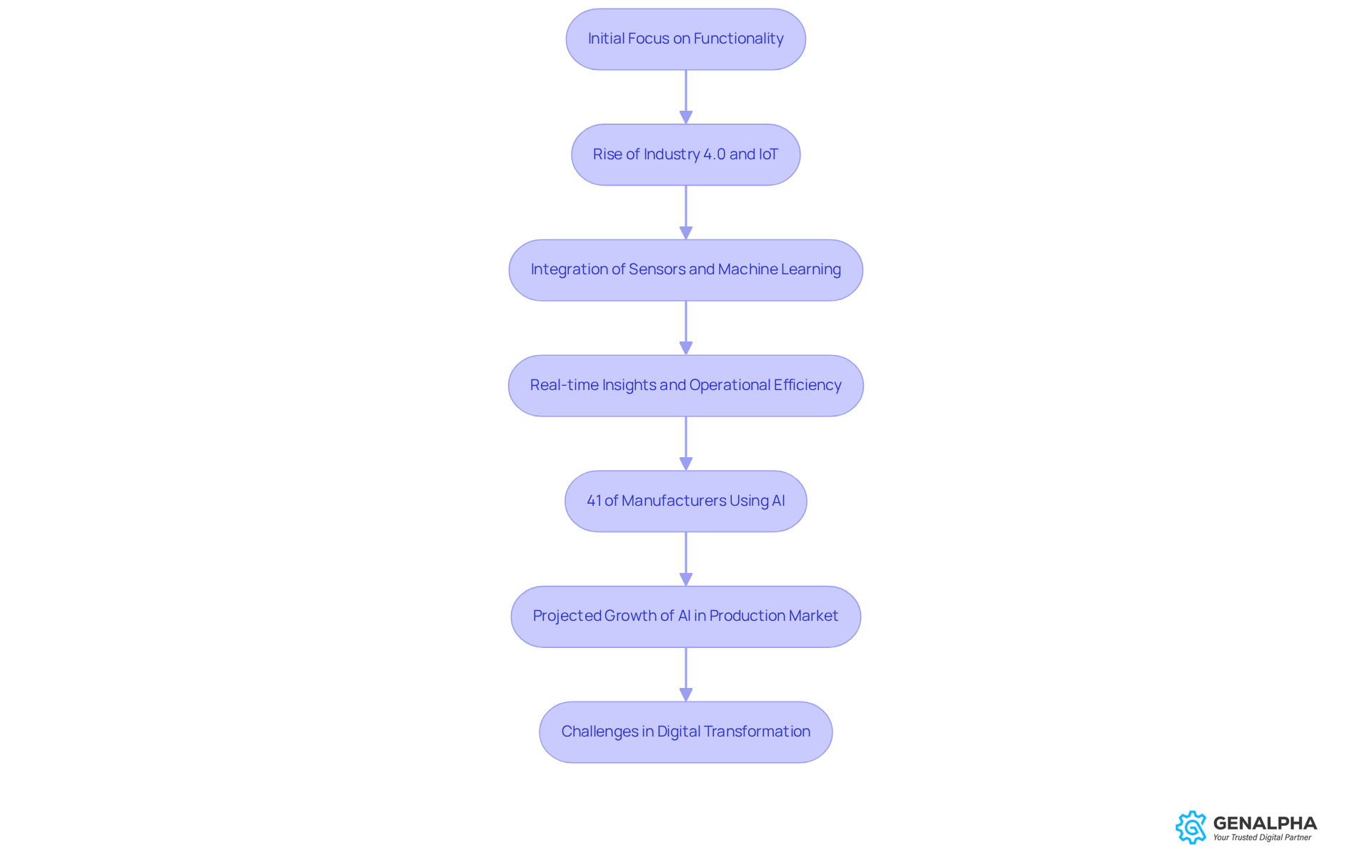

Have you ever thought about how much technology has changed manufacturing over the years? The evolution of smarty parts really highlights this shift, showcasing significant advancements and a growing need for efficiency. Initially, the focus was mainly on functionality. But with the rise of Industry 4.0 and the Internet of Things (IoT), we’re seeing a big change. Now, it’s all about creating smarty parts that can communicate and adapt.

This is fascinating! It’s driven by the use of sensors, machine learning algorithms, and data analytics that allow systems to provide real-time insights and boost operational efficiency. As more producers jump on the digital transformation bandwagon, the role of Smart Components is only going to grow, paving the way for innovations that could redefine industry standards.

For instance, did you know that nearly 41% of manufacturers are using AI to improve supply chain management? This shows just how reliant we’re becoming on smarty parts to streamline operations. There are specific case studies out there that illustrate how AI applications help manufacturers gather and analyze data effectively, enhancing logistics planning and supplier coordination.

Moreover, the global AI in production market is projected to skyrocket from USD 5.94 billion in 2024 to around USD 230.95 billion by 2034, with a staggering CAGR of 44.20%. This really highlights the vital role that smarty parts play in our ever-evolving landscape.

However, it’s not all smooth sailing. Challenges like change management and hefty upfront capital investments are still significant hurdles for digital transformation. It’s clear that manufacturers face complexities in this transition. What do you think? Is your organization ready to embrace these changes?

Identify Key Characteristics of Smarty Parts: Components and Functions

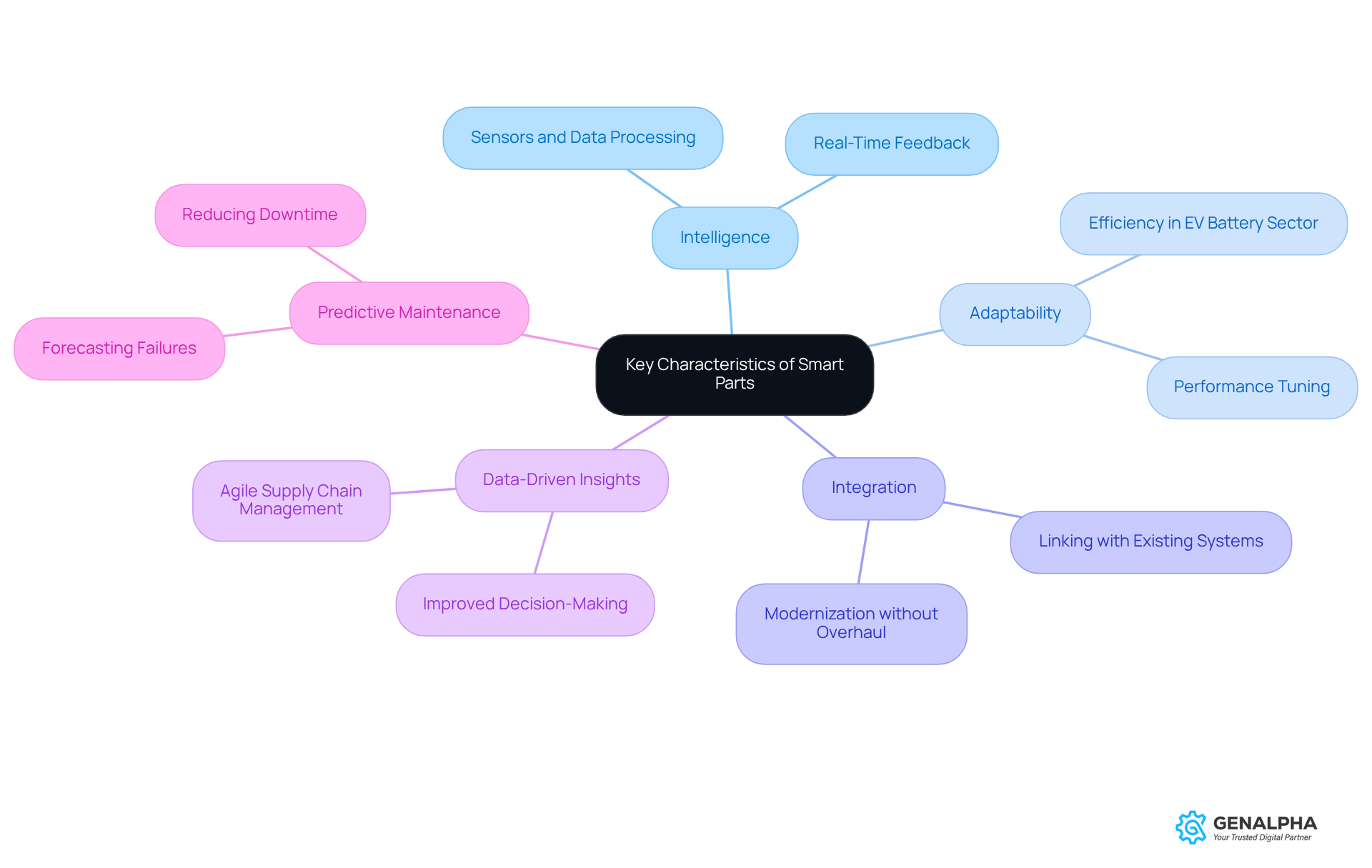

Smart elements stand out because they come with some essential features that set them apart from traditional items, making them key players in today’s manufacturing world. Let’s break down what makes them so special:

- Intelligence: These components are packed with sensors and data processing abilities, which means they can keep an eye on conditions and give real-time feedback. This smartness allows manufacturers to when things change on the floor.

- Adaptability: They can tweak their performance based on the environment, ensuring they work optimally even when conditions shift. For instance, in the electric vehicle battery sector, companies can adjust their operations to fit various charging scenarios, boosting efficiency.

- Integration: These components easily link up with existing manufacturing systems and software, which ramps up overall efficiency. This kind of integration is a game changer for manufacturers looking to modernize without completely overhauling their setup.

- Data-Driven Insights: By generating valuable information, these smart parts help improve decision-making. Manufacturers can dive into this data to fine-tune inventory management and elevate customer service, leading to a more agile supply chain.

- Predictive Maintenance: They keep tabs on performance metrics to forecast potential failures, enabling proactive maintenance. This capability cuts down on downtime significantly. For example, one manufacturer managed to hit a handling rate of 200 parts per minute (PPM) by using predictive maintenance strategies.

Adopting smart parts not only boosts operational capabilities but also helps manufacturers keep pace with the fast-changing market, driving growth and efficiency. So, are you ready to explore how these smart components can transform your operations?

Conclusion

Smarty parts are really changing the game in modern manufacturing. They combine advanced technology with operational efficiency, and these smart elements come packed with sensors and data analytics. They’re not just nice-to-haves; they’re vital for manufacturers looking to quickly adapt to market demands and fine-tune their processes.

Throughout our discussion, we've seen how crucial smarty parts are for boosting productivity, cutting down on downtime, and enhancing customer satisfaction. Think about predictive maintenance strategies that can dramatically reduce operational costs or real-time monitoring that keeps inventory accurate—these benefits are huge! Plus, as these components evolve, they reflect a bigger trend towards automation and smart manufacturing, highlighting their pivotal role in shaping the future of production.

As industries grapple with challenges like rising costs and fierce competition, embracing smart technology is a must. Organizations that are ready to weave smarty parts into their operations not only position themselves for a competitive edge but also help create a more efficient and responsive manufacturing landscape. So, what are you waiting for? The time to invest in smart components is now, setting the stage for innovation and growth in an ever-changing market.

Frequently Asked Questions

What are Smarty Parts?

Smarty Parts are advanced components in production and distribution operations designed to enhance functionality and efficiency by utilizing cutting-edge technology such as sensors and data analytics for real-time feedback.

How do Smarty Parts improve operational performance?

Smarty Parts improve operational performance by enabling smarter decision-making and operational agility, which helps reduce unplanned downtime and maintenance costs through continuous monitoring of equipment status.

What benefits have companies experienced by integrating Smarty Parts?

Companies that integrate Smarty Parts report significant boosts in productivity and efficiency, with some experiencing up to a 60% reduction in downtime due to predictive maintenance strategies.

How do Smarty Parts affect equipment life and maintenance?

Smarty Parts provide actionable insights that guide maintenance schedules, which not only enhances machinery performance but also extends equipment life.

In what ways do Smarty Parts benefit distribution processes?

Smarty Parts enhance logistics by improving inventory management and supply chain visibility, leading to quicker and more efficient responses to customer demands.

What impact do Smarty Parts have on customer satisfaction?

Companies that adopt Smarty Parts report higher customer satisfaction rates due to improved operational efficiencies and the ability to meet customer demands more effectively.

What is the future outlook for Smarty Parts in production?

The future of production hinges on incorporating advanced technologies like Smarty Parts into operational processes, as they allow for real-time monitoring and precise adjustments based on sensor data, which is crucial for organizations to remain competitive.