Overview

Have you ever wondered how to make quoting in manufacturing a breeze? Well, that’s where CPQ (Configure, Price, Quote) software comes into play! This article dives into the world of CPQ software, comparing its features and benefits to show just how much it can boost quoting efficiency and accuracy.

Imagine being able to quote faster and more accurately—sounds great, right? With CPQ software, that’s not just a dream. It significantly enhances the quoting process, leading to happier customers and smoother operations. Data backs this up, showing reduced turnaround times and increased precision in quoting.

So, if you’re looking to improve your quoting process, CPQ software might just be the solution you need. It’s all about making your life easier and your customers happier. Why not explore how it can transform your operations today?

Introduction

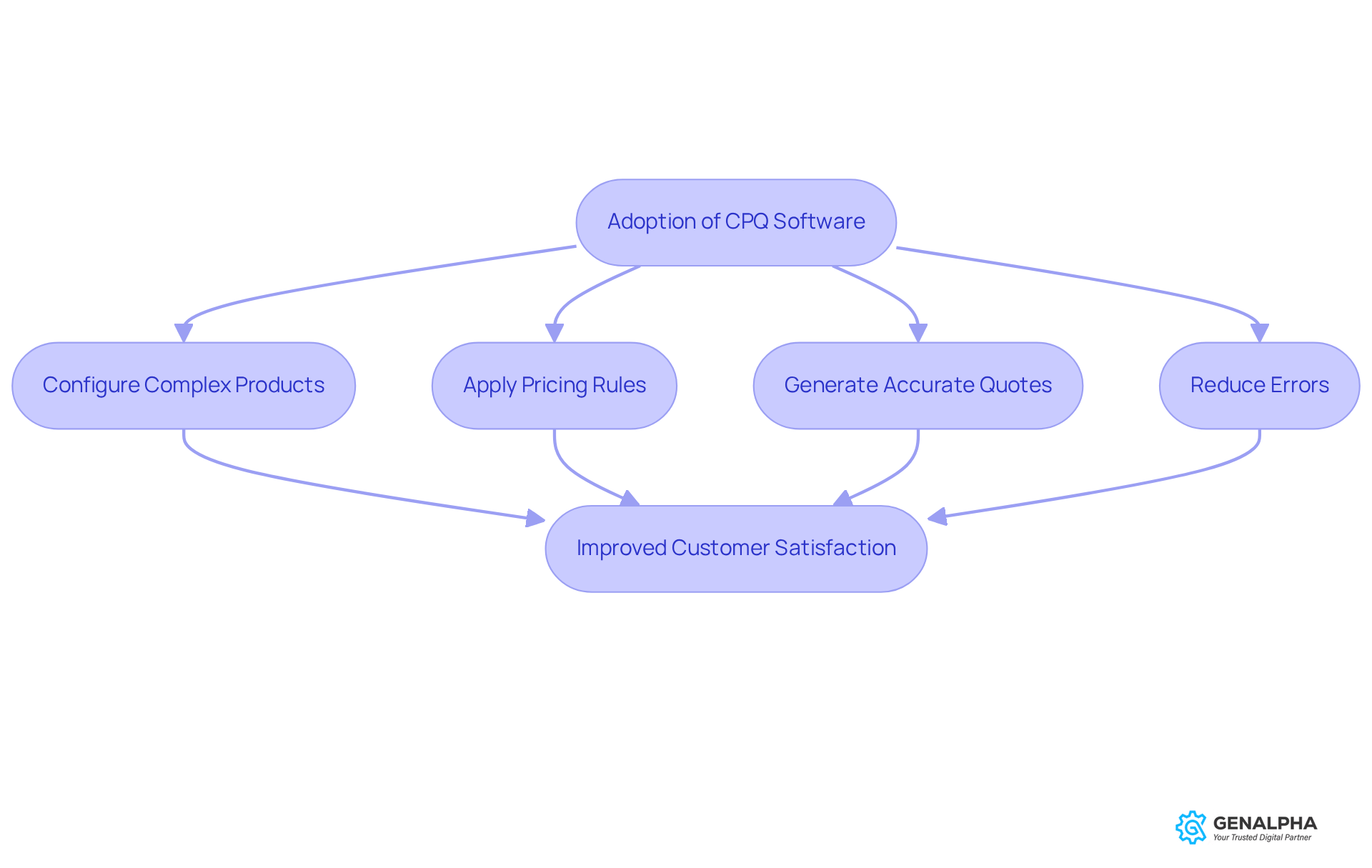

Manufacturers are always on the lookout for ways to improve their quoting processes, right? Enter CPQ software—a real game-changer in this space! These Configure, Price, Quote systems not only make complex product configurations a breeze but also cut down on errors, speed up quote generation, and boost customer satisfaction.

But here’s the thing: as the market for CPQ solutions keeps expanding, how can manufacturers effectively assess and implement these tools? It’s all about maximizing benefits while navigating potential challenges. Let’s dive into this together!

Understanding CPQ Software in Manufacturing

Have you ever wondered how manufacturers streamline their quoting process? Enter cpq software for manufacturing, also known as Configure, Price, Quote systems—an essential tool that automates and refines this very process. With CPQ, sales teams can easily configure complex products, apply pricing rules, and quickly generate accurate quotes. In industries where product customization is key, CPQ solutions can drastically reduce errors and speed up the sales cycle, cutting quote completion times by over 50%. By embracing cpq software for manufacturing, manufacturers not only enhance their operational efficiency but also improve customer satisfaction through faster and more precise quoting.

Recent trends show that CPQ solutions are getting even smarter, incorporating advanced features like predictive analytics and AI-driven insights. This evolution makes quoting even more efficient and supports better decision-making. Imagine being able to generate quotes in just minutes instead of hours—this responsiveness can truly transform your sales approach! Experts predict that the market for cpq software for manufacturing applications will grow from $2.2 billion to $7.3 billion by 2030, underscoring their rising importance in the industry.

Real-world examples highlight how cpq software for manufacturing can significantly impact operations. Companies that have adopted CPQ solutions report notable decreases in quoting errors and enhanced customer experiences. In fact, studies reveal that up to 86% of customers might switch brands after just two negative experiences. Industry leaders emphasize that modern CPQ systems are a must-have, not just for improving quoting accuracy but also for fostering better collaboration between sales and engineering teams. As Nicole Epstein puts it, 'CPQ applications are essential in the sales toolkit.'

With cpq software for manufacturing poised for substantial growth, manufacturers are encouraged to to stay competitive and meet the evolving needs of their clients. So, why not explore how CPQ can transform your quoting process today?

Key Features of Leading CPQ Solutions

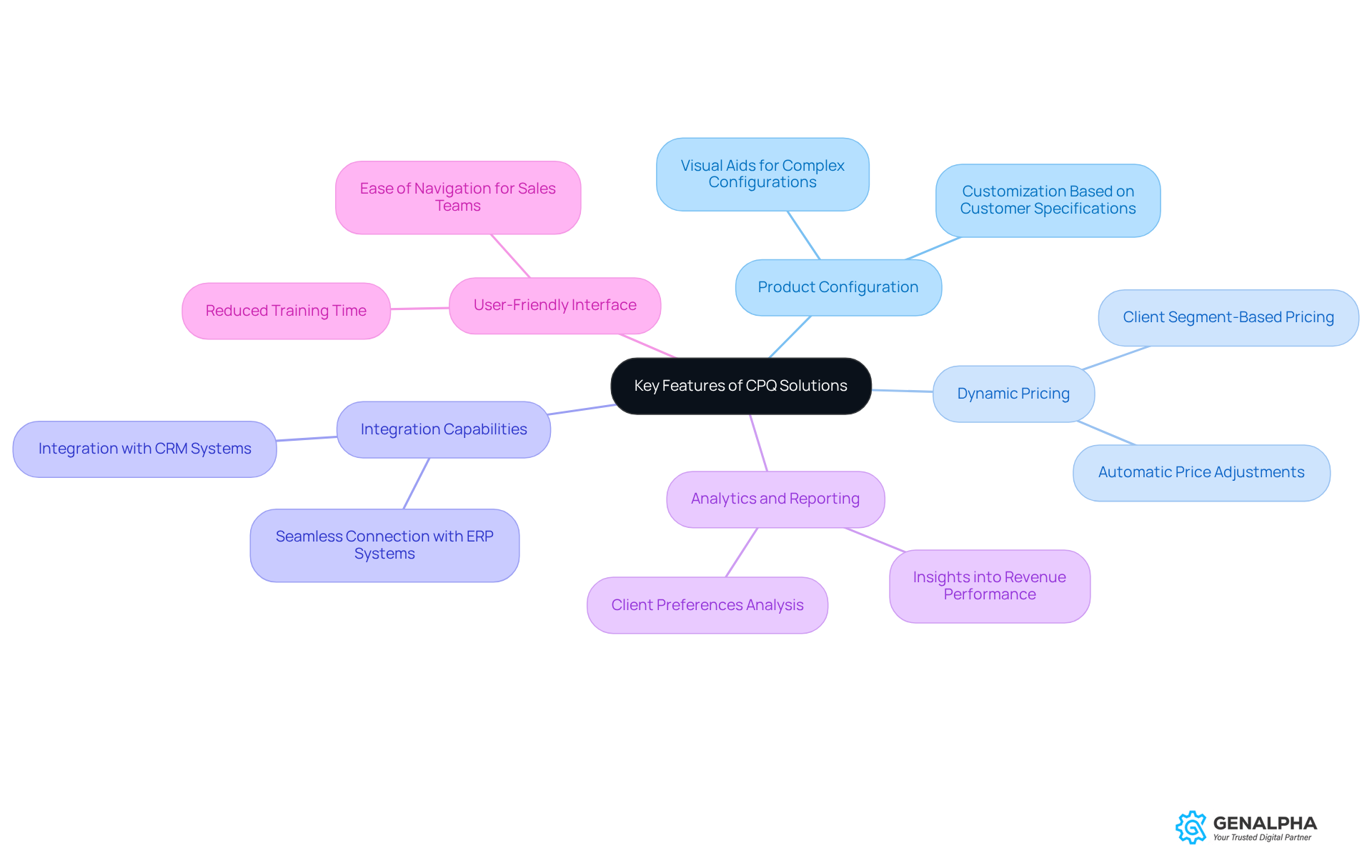

When it comes to , leading CPQ solutions really shine with a variety of features designed just for that. Have you ever struggled with getting the right product configuration? Well, with product configuration tools, you can customize products based on customer specifications, ensuring everything is spot on.

Then there's dynamic pricing. Imagine prices that automatically adjust based on discounts, promotions, and client segments—how convenient is that? And let’s not forget about integration capabilities! These solutions seamlessly connect with your existing ERP and CRM systems, keeping your data consistent and your workflows smooth.

Analytics and reporting are also game-changers. They provide insights into revenue performance and client preferences, helping you make informed, data-driven decisions. Plus, a user-friendly interface means your sales team can navigate the system with ease, cutting down on training time and boosting overall efficiency.

All these features work together to make the quoting process faster and more accurate. In today's competitive manufacturing sector, CPQ software for manufacturing is not just a nice-to-have; it's essential. So, are you ready to enhance your quoting process and stay ahead of the game?

Benefits and Challenges of CPQ Implementation

Implementing cpq software for manufacturing offers a host of advantages for manufacturers. Let’s dive into a few of them!

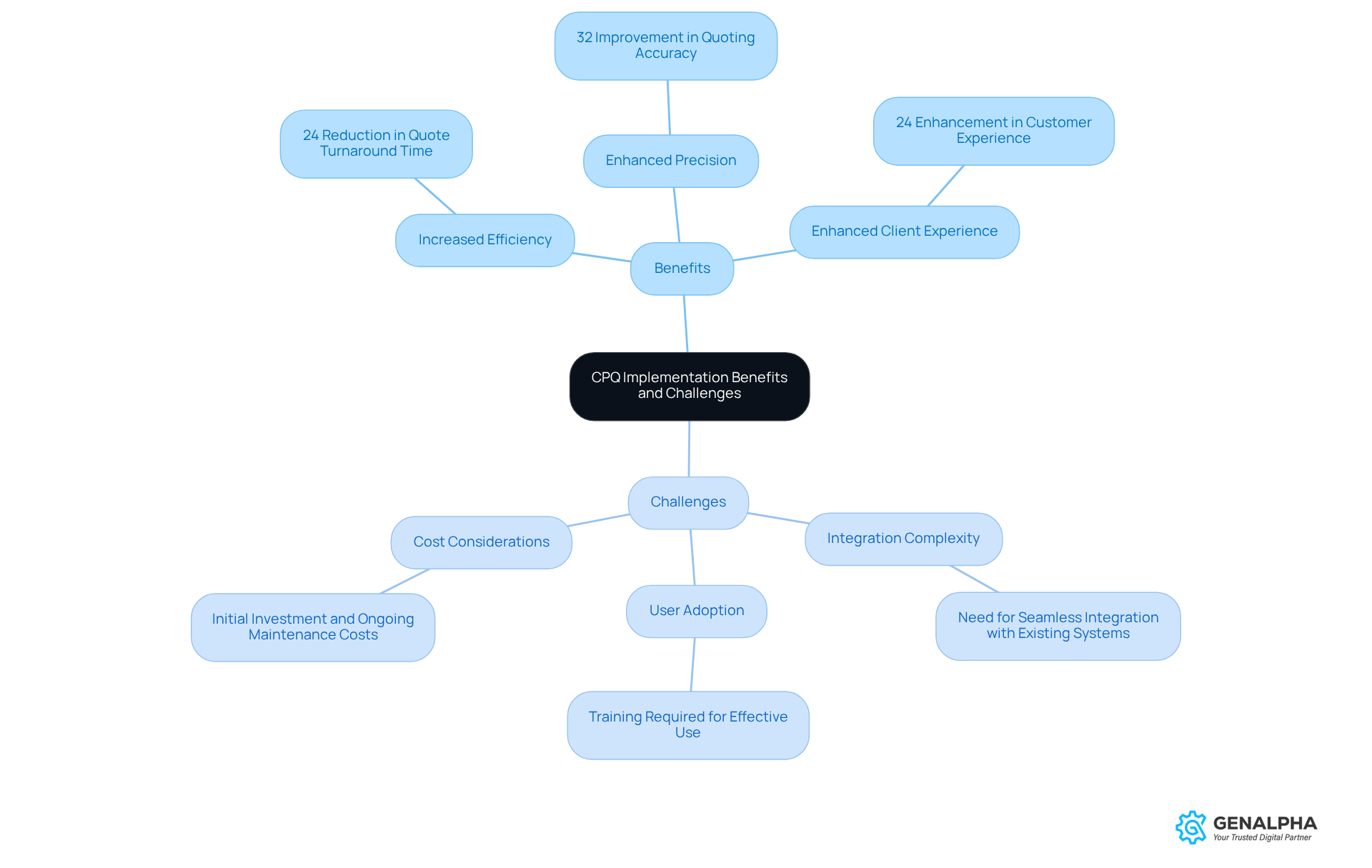

- Increased Efficiency: Imagine automating the quoting process—sounds great, right? CPQ software for manufacturing can drastically reduce the time required to generate quotes, enabling sales teams to respond to customer requests almost instantly. This efficiency can lead to a whopping , helping manufacturers meet modern client expectations for speedy responses by utilizing cpq software for manufacturing.

- Enhanced Precision: Nobody likes mistakes, especially when it comes to pricing and product setups. CPQ software for manufacturing helps to minimize errors, ensuring that quotes are accurate and aligned with client needs. This accuracy is crucial; companies using CPQ applications report a 32% improvement in quoting precision, which directly boosts client satisfaction and trust.

- Enhanced Client Experience: Who doesn’t appreciate quick responses and accurate quotes? These factors significantly improve interactions with customers. Manufacturers that have adopted cpq software for manufacturing have observed a 24% enhancement in customer experience, fostering brand loyalty and increasing the chances of repeat business.

But, of course, it’s not all smooth sailing. Manufacturers may face a few challenges during implementation:

- Integration Complexity: One major hurdle is ensuring that CPQ software integrates seamlessly with existing systems like ERP and CRM platforms. Strategic integration is key to improving data flow and business intelligence. If this isn’t managed well, it can lead to delays and increased costs.

- User Adoption: Training staff to effectively use the new system can be quite the task. Sales teams might encounter a learning curve that temporarily impacts productivity. However, companies that invest in thorough training often see a quicker onboarding process, allowing sales representatives to hit the ground running from day one, reducing that learning curve and boosting productivity.

- Cost Considerations: Let’s talk money. The initial investment and ongoing maintenance costs of cpq software for manufacturing can add up. Manufacturers need to craft a clear ROI strategy to justify these expenses, especially in the early stages of implementation. This strategy is vital for understanding the financial implications of adopting CPQ.

In the end, manufacturers need to weigh these benefits against the challenges to figure out if CPQ implementation is the right move for their operations.

Integration with Existing Systems: A Critical Comparison

When it comes to evaluating cpq software for manufacturing, are a big deal. Why? Because they can really make or break your operational efficiency and client satisfaction. Let’s take a look at some leading solutions and how well they connect with existing ERP, CRM, and other business systems:

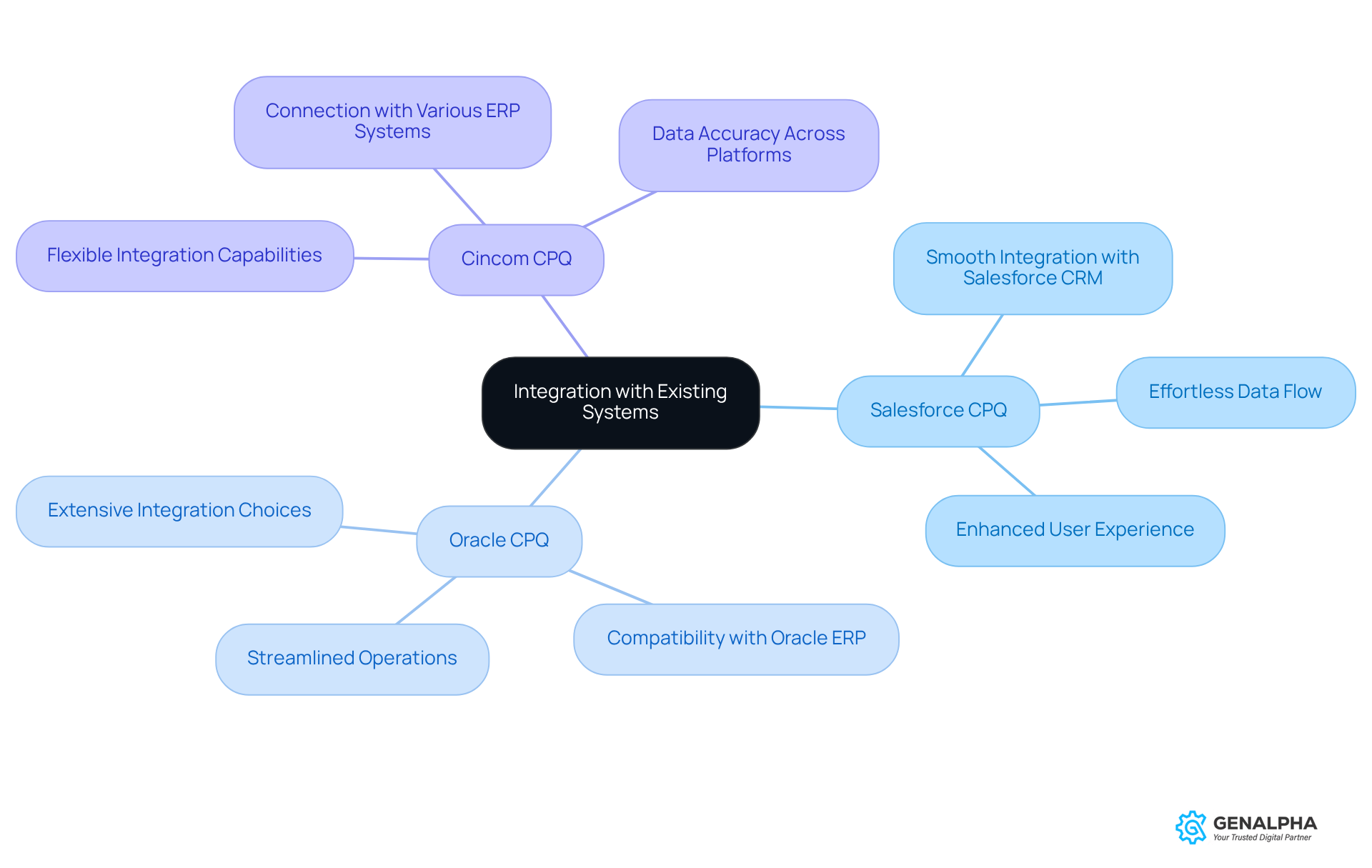

- Salesforce CPQ: This one’s famous for its smooth integration with Salesforce CRM. It makes data flow effortlessly between sales and customer management, which can significantly enhance the user experience.

- Oracle CPQ: If you’re using Oracle ERP systems, this option has got your back with extensive integration choices that ensure compatibility and streamlined operations.

- Cincom CPQ software for manufacturing: This solution offers flexible integration capabilities, enabling manufacturers to connect with various ERP systems. This flexibility is crucial for keeping data accurate across different platforms.

So, when you’re on the hunt for cpq software for manufacturing, it’s important to examine your current technology stack and consider any potential integration hurdles. A well-integrated cpq software for manufacturing not only boosts operational efficiency but also provides your teams with real-time data and insights. Imagine connecting your transactions directly to production data by combining CPQ and ERP!

And here’s something to think about: studies show that organizations using cpq software for manufacturing experience a 28% reduction in sales cycle length and a 49% increase in proposal volume per representative. That really underscores how crucial effective integration of cpq software for manufacturing is for thriving in the competitive manufacturing world. Plus, Heather Hasz points out that "CPQ and ERP systems provide an essential foundation for meeting the expectations of customers that have become increasingly comfortable with e-commerce." Doesn’t that just highlight the critical role of integration even more?

Conclusion

Embracing CPQ software for manufacturing is a game-changer! It can really enhance the quoting process, streamline operations, and boost customer satisfaction. Imagine automating those complex configurations and pricing—manufacturers can achieve greater accuracy and efficiency, cutting down on quote turnaround times and minimizing errors. This tech not only helps sales teams deliver timely and precise quotes but also encourages better collaboration between departments, which is crucial in today’s fast-paced market.

Let’s dive into the key features and benefits of leading CPQ solutions. They can truly revolutionize the quoting process. With perks like increased efficiency, enhanced precision, and improved customer experiences, it’s clear that integrating CPQ software isn’t just a nice-to-have; it’s essential for manufacturers who want to stay competitive. Of course, it’s not all smooth sailing—there are challenges like integration complexity and user adoption that need to be tackled to fully enjoy these benefits.

As the manufacturing landscape keeps evolving, the role of CPQ software is becoming even more critical. Manufacturers should really consider exploring these solutions—not just to meet client expectations but to drive operational excellence. Investing in CPQ software today can set the stage for a more agile and responsive business model, leading to sustained growth and success in the industry. So, why not take that step and see how CPQ can transform your operations?

Frequently Asked Questions

What is CPQ software in manufacturing?

CPQ software, or Configure, Price, Quote systems, is a tool that automates and refines the quoting process for manufacturers, allowing sales teams to configure complex products, apply pricing rules, and quickly generate accurate quotes.

How does CPQ software benefit manufacturers?

CPQ software helps manufacturers enhance operational efficiency, reduce quoting errors, speed up the sales cycle, and improve customer satisfaction by providing faster and more precise quotes.

What impact does CPQ software have on quote completion times?

CPQ solutions can cut quote completion times by over 50%, allowing for quicker responses to customer inquiries.

What advanced features are being incorporated into CPQ solutions?

Recent trends show that CPQ solutions are incorporating advanced features like predictive analytics and AI-driven insights, making the quoting process more efficient and supporting better decision-making.

What is the expected market growth for CPQ software in manufacturing?

The market for CPQ software for manufacturing applications is predicted to grow from $2.2 billion to $7.3 billion by 2030, highlighting its increasing importance in the industry.

How do companies benefit from adopting CPQ software?

Companies that adopt CPQ solutions report notable decreases in quoting errors and enhanced customer experiences, which is crucial as studies indicate that up to 86% of customers may switch brands after two negative experiences.

Why are modern CPQ systems considered essential?

Modern CPQ systems are considered essential not only for improving quoting accuracy but also for fostering better collaboration between sales and engineering teams.

How can manufacturers leverage CPQ software to stay competitive?

Manufacturers are encouraged to leverage CPQ tools to meet the evolving needs of their clients and maintain competitiveness in the market.