Overview

Have you ever wondered how to choose the right CPQ (Configure Price Quote) solution for your equipment manufacturing business? This article dives into the world of CPQ companies, comparing their key features that are tailored just for you. We’ll explore essential elements like:

- Dynamic pricing

- 3D visualization

- Integration capabilities

But that’s not all—we’ll also evaluate various CPQ providers, weighing their pros and cons. This way, you can find the most suitable solution that meets your unique operational needs. Ready to discover which CPQ could be your perfect match?

Introduction

Navigating the twists and turns of product configuration and pricing can feel overwhelming for equipment manufacturers, can’t it? That’s where CPQ (Configure Price Quote) software steps in as a trusty sidekick, making processes smoother, reducing errors, and boosting customer satisfaction.

But with so many CPQ providers out there, how do manufacturers figure out which one truly fits their unique needs?

Let’s dive into the key features and advantages of top CPQ companies. By doing so, we’ll uncover the essential elements that can revolutionize sales operations and spark growth in the equipment manufacturing world.

Ready to explore?

Understanding CPQ Software: A Foundation for Comparison

Have you ever felt overwhelmed by the complexity of configuring a product and pricing it just right? Well, that's where comes into play! This handy tool automates the whole process of configuring intricate products, pricing them accurately, and generating quotes. It's a game-changer, especially for equipment producers who often juggle complex specifications and pricing structures.

By streamlining these tasks, CPQ software not only reduces errors but also shortens sales cycles and boosts customer satisfaction. Imagine how much easier your life could be with fewer mistakes and happier customers! Understanding the essential features of CPQ companies' software is key to finding the right option tailored to your needs as a producer or distributor in the equipment industry.

So, why not take a closer look at how CPQ software can simplify your workflow? Let's explore the possibilities together!

Key Features of CPQ Solutions for Equipment Manufacturers

When it comes to CPQ solutions for equipment manufacturers, there are some standout features that really make a difference:

- Dynamic Pricing: Imagine being able to adjust prices in real-time based on market conditions. This ensures that you always have competitive pricing at your fingertips.

- 3D Visualization: Ever wish you could see exactly what you’re configuring? With 3D visualization, customers can get a clear of their choices, which boosts understanding and satisfaction.

- Integration Capabilities: No one likes data entry errors, right? These solutions seamlessly connect with existing ERP and CRM systems, making data flow smooth and reducing those pesky manual entry mistakes.

- Guided Selling: It’s like having a helpful friend by your side. Guided selling offers your team prompts and suggestions to help configure products just the way your customers need them.

- Automated Quote Generation: Say goodbye to tedious manual calculations! This feature quickly produces accurate quotes, saving time and hassle.

Together, these features transform the transaction process, making it not just efficient but also more customer-friendly. So, how can these solutions help you streamline your operations today?

Evaluating CPQ Companies: Addressing Equipment Manufacturers' Unique Needs

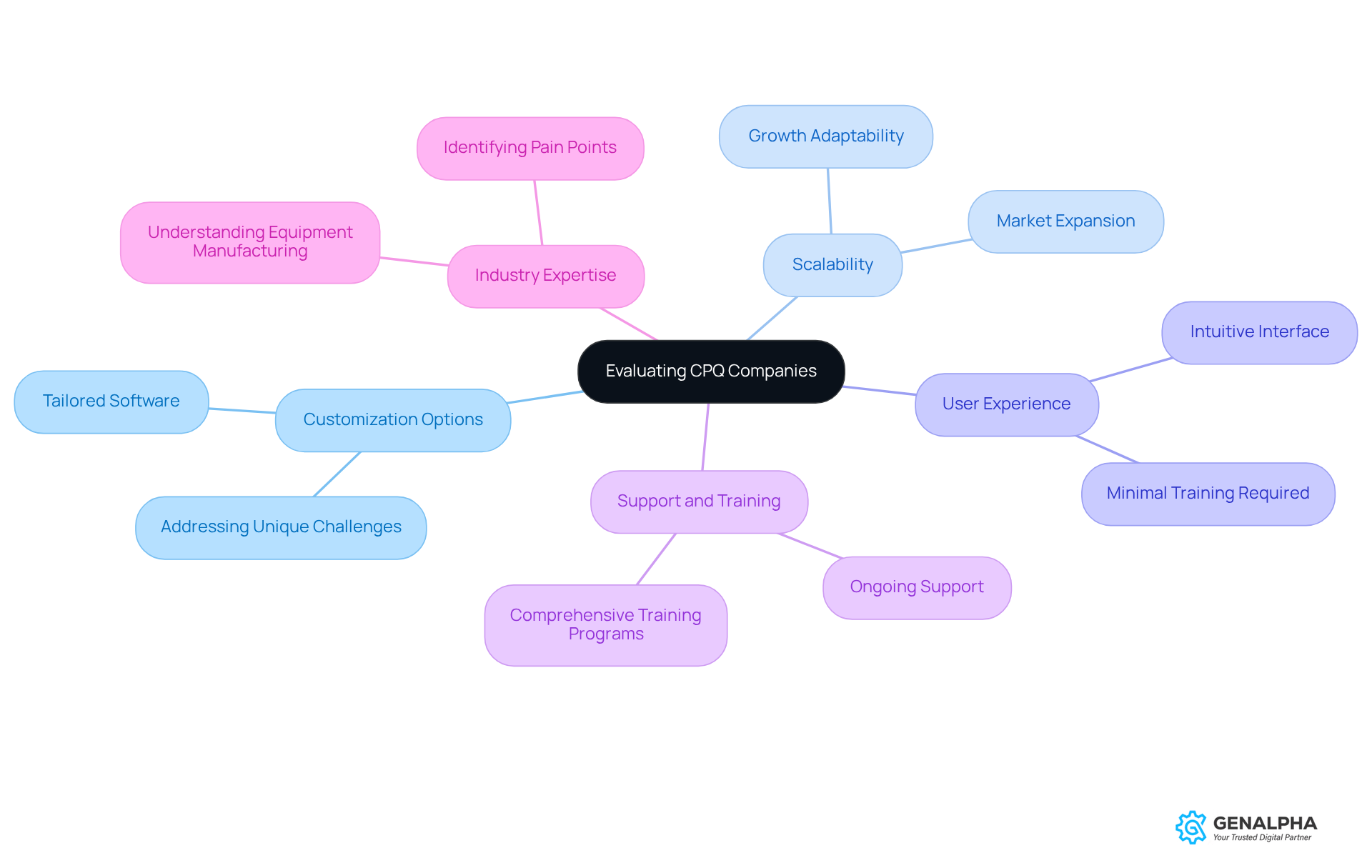

When evaluating CPQ companies, equipment manufacturers should really think about a few key factors that can make a big difference:

- Customization Options: It’s super important to have the ability to tailor the software to fit your specific product lines and sales processes. Remember what Joanne said? "Fear not, leaders, for Configure Price Quote (CPQ) technology is here to save the day!" This really highlights how CPQ can tackle unique challenges and streamline quoting processes efficiently.

- Scalability: As your business grows, your CPQ system needs to grow with you. Did you know that the CPQ companies are projected to increase the software market from $2.2 billion to $7.3 billion by 2030? This shows just how crucial it is to pick solutions that can adapt. For example, DealHub CPQ is a great option that helps businesses manage increased complexity without missing a beat.

- User Experience: An intuitive interface can significantly impact how quickly your sales teams adopt the system. A user-friendly CPQ that’s easy to navigate, fast to load, and requires minimal training can really encourage widespread usage. As Joanne points out, this is vital in a fast-paced market where quick responses can give you that competitive edge.

- Support and Training: Ongoing support and solid training resources are key for getting the most out of your software. Manufacturers should look for providers that offer comprehensive training programs to help users become efficient and ensure smooth transitions.

- Industry Expertise: The provider’s understanding of the equipment manufacturing sector can really influence how effective the offering is. It’s smart for producers to identify pain points in their current quoting processes before jumping into CPQ. Firms with deep industry knowledge can provide tailored insights and features that align perfectly with what producers need.

These criteria can help producers choose a CPQ system offered by CPQ companies that meets their current needs while also ensuring the software can handle future growth. With the CPQ software market expected to , it’s essential to select solutions that not only boost operational efficiency but also enhance revenue growth. So, what are you waiting for? Let’s get started on finding the right CPQ solution for your business!

Comparative Analysis of Leading CPQ Providers: Pros and Cons

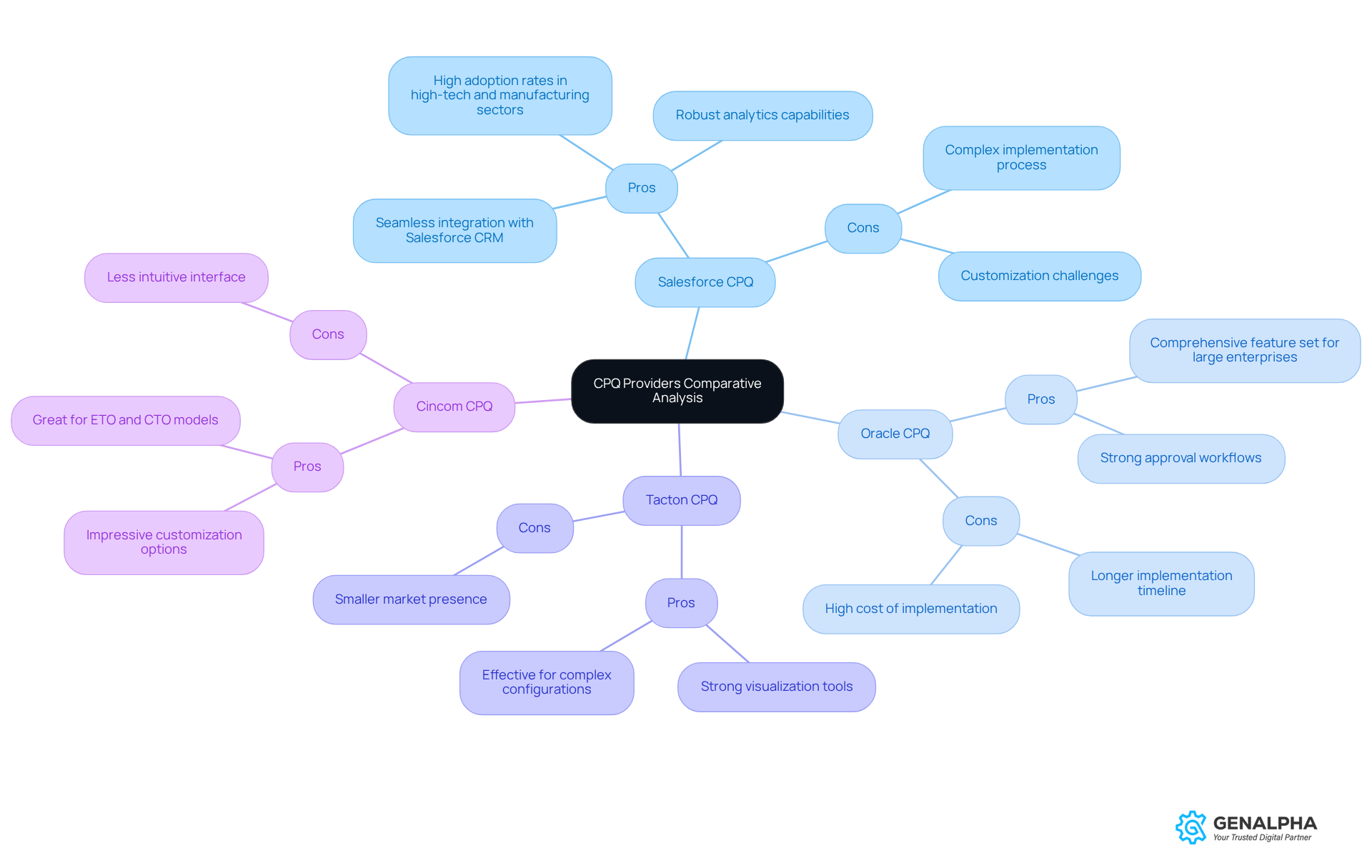

When we take a closer look at the leading CPQ companies, it’s clear that each has its own set of pros and cons that can really shape how equipment manufacturers operate. Let’s dive in!

- Salesforce CPQ:

Pros: One of the standout features of Salesforce CPQ is its seamless integration with Salesforce CRM. This makes data alignment and user experience a breeze! Plus, its robust analytics capabilities empower manufacturers to make informed decisions, boosting revenue efficiency and customer satisfaction. With a and over 3,044 customers, it’s a popular choice, especially in the high-tech and manufacturing sectors—some places see adoption rates soar to 80%!

Cons: But, it’s not all smooth sailing. The implementation process can be quite complex, often requiring extensive training and support. Users might struggle with customization, especially if they have unique pricing structures, which can lead to higher costs and longer setup times. - Oracle CPQ:

Pros: Designed with large enterprises in mind, Oracle CPQ offers a comprehensive feature set that meets the needs of complex manufacturing. Its strong approval workflows and integration with Oracle ERP help manage intricate sales processes efficiently. This is particularly beneficial for organizations that need advanced pricing models and scalability.

Cons: However, the high cost associated with Oracle CPQ can be a barrier for some manufacturers, and the implementation timeline is often longer than with other options, requiring careful planning and resource allocation. Plus, the user interface can be a bit challenging for some users. - Tacton CPQ:

Pros: Tailored specifically for manufacturing, Tacton CPQ shines with its strong visualization tools that improve the customer experience. Its ability to manage complex configurations makes it a valuable tool for manufacturers with intricate product offerings.

Cons: On the downside, Tacton CPQ has a smaller market presence compared to its larger competitors, which might limit the availability of support and resources. - Cincom CPQ:

Pros: Focusing on the manufacturing sector, Cincom CPQ offers impressive customization options that allow businesses to tailor the solution to their unique needs. It’s great for handling Engineer-to-Order (ETO) and Configure-to-Order (CTO) models, ensuring accurate quoting and smooth integration with engineering workflows.

Cons: However, some users find the interface less intuitive than other CPQ solutions, which can slow down user adoption and efficiency.

This analysis is designed to help equipment manufacturers pinpoint which CPQ companies provide solutions that best fit their operational needs and customer engagement strategies. Ultimately, the right choice can significantly enhance their sales processes and customer satisfaction. So, which one do you think fits your needs best?

Conclusion

Exploring CPQ software for equipment manufacturers really showcases how it can transform the way we handle complex pricing and configuration processes. By automating these tasks, CPQ solutions not only boost efficiency but also enhance customer satisfaction, making them essential tools for today’s manufacturers.

Let’s talk about some key features:

- Dynamic pricing

- 3D visualization

- Integration capabilities

- Guided selling

- Automated quote generation

These are critical components to consider when selecting the right CPQ software. Plus, it’s important to evaluate customization options, scalability, user experience, support, and industry expertise. This way, manufacturers can find a solution that truly fits their unique operational needs and growth goals.

Ultimately, the choice of CPQ software can have a big impact on an equipment manufacturer’s efficiency and customer engagement. As the market for these solutions keeps growing, embracing the right CPQ technology is crucial for staying competitive and driving revenue growth. So, why not take a proactive approach? Assess your options and invest in a CPQ solution that not only meets your immediate needs but also supports your long-term success in an ever-evolving industry landscape.

Frequently Asked Questions

What is CPQ software?

CPQ software is a tool that automates the process of configuring complex products, accurately pricing them, and generating quotes.

How does CPQ software benefit equipment producers?

It helps equipment producers manage complex specifications and pricing structures, reduces errors, shortens sales cycles, and boosts customer satisfaction.

What are the main advantages of using CPQ software?

The main advantages include fewer mistakes in product configuration and pricing, quicker sales processes, and improved customer satisfaction.

Why is it important to understand the features of CPQ software?

Understanding the essential features of CPQ software is crucial for finding the right option that meets the specific needs of producers or distributors in the equipment industry.

How does CPQ software impact workflow?

CPQ software simplifies workflow by automating complex tasks, allowing users to focus on other important aspects of their business.