Overview

Have you ever felt overwhelmed by the complexities of managing a manufacturing operation? Equip Software is here to help! This specialized digital solution is designed specifically for manufacturers, aiming to boost operational efficiency through features like:

- Inventory management

- Order processing

- Client relationship management

Imagine streamlining your processes and cutting down on those pesky operational costs. That’s exactly what Equip Software does! By showcasing how these functionalities work together, it not only simplifies your daily tasks but also enhances customer satisfaction and sales performance.

In today’s competitive manufacturing landscape, having the right tools is vital. Equip Software isn’t just a tool; it’s your partner in success. So why wait? Dive in and see how it can transform your operations!

Introduction

Have you ever wondered how technology can change the game in manufacturing? Equip Software is doing just that! They're bringing tailored digital solutions to the table that not only boost operational efficiency but also enhance customer engagement. Imagine having tools for inventory management, order processing, and client relationship management all in one place. This software empowers manufacturers to streamline their processes and adapt quickly to market demands.

But here's the kicker: as the industry evolves at lightning speed, it raises an important question. How can businesses fully leverage these advanced tools to not just survive but truly thrive in a competitive landscape? Let's dive into this together and explore the possibilities!

Define Equip Software: An Overview

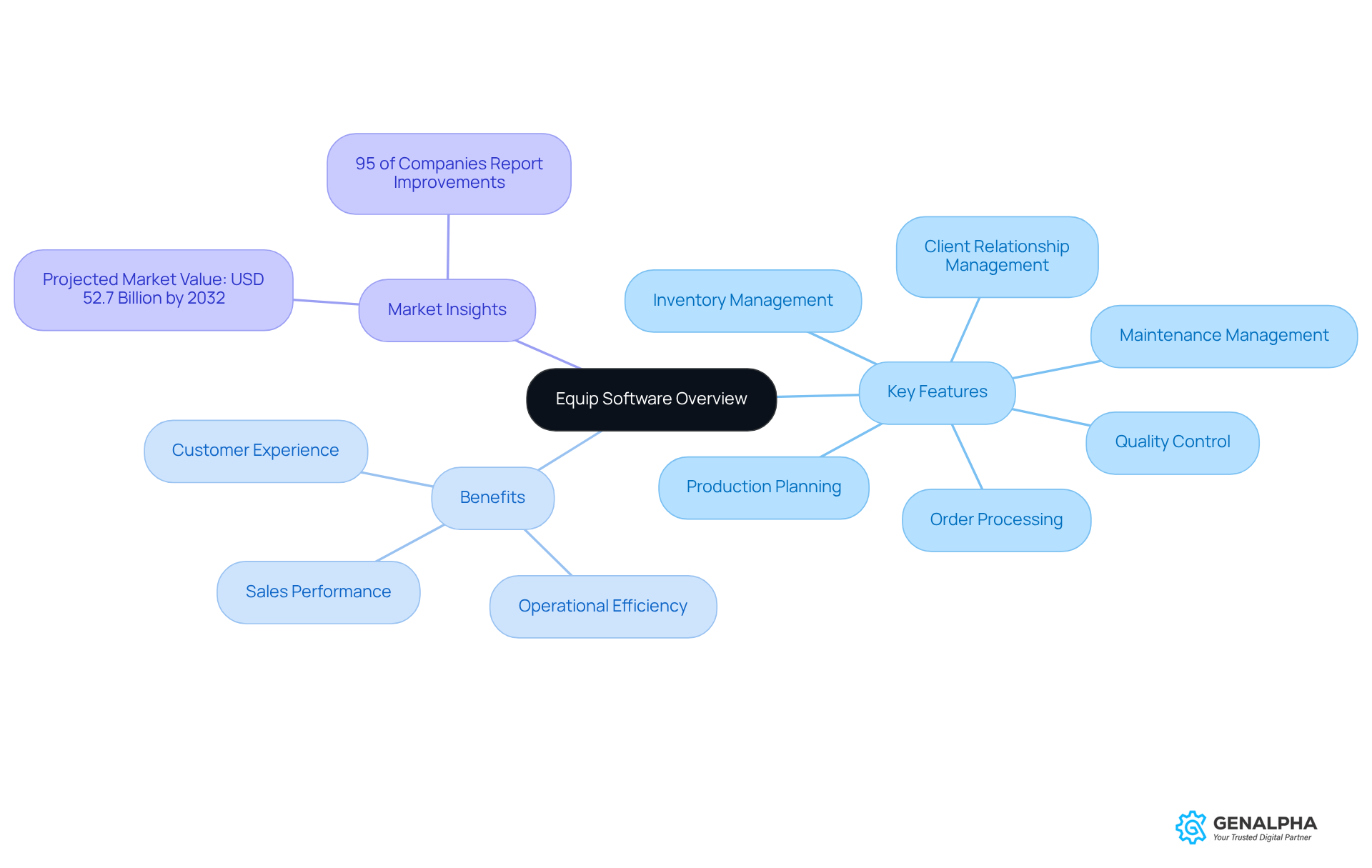

Have you ever wondered how specialized digital solutions can really make a difference for manufacturers and distributors in the equipment and aftermarket parts sectors? These tools are designed to boost operational efficiency and often come packed with features like inventory management, order processing, and client relationship management, all tailored to meet the unique needs of the manufacturing world. The goal is simple: streamline processes, enhance sales performance, and elevate customer experiences. For businesses aiming to stand out in a competitive marketplace, equipping software becomes an essential ally.

Now, let’s dive a bit deeper. Within the broader category of manufacturing management applications, this system also includes crucial features such as , quality control, and maintenance management. Why are these functionalities so important? They help optimize operations and ensure compliance with industry standards. And here’s a striking fact: the Manufacturing Operations Management Solutions Market is projected to reach a whopping USD 52.7 Billion by 2032! This really highlights just how vital these solutions are becoming in the industry.

But don’t just take my word for it. Statistics show that a staggering 95% of companies reported improvements in their processes after implementing ERP systems. That’s pretty impressive, right? One particularly interesting case study reveals that a manufacturer who adopted this system saw a significant drop in order processing time and improved inventory accuracy. The result? Happier customers and increased sales.

In summary, this program isn’t just about making workflows smoother; it plays a pivotal role in how we equip software within the entire landscape of manufacturing management applications. It drives growth and fosters long-term success. So, are you ready to explore how these solutions can transform your business?

Contextualize the Importance of Equip Software in Manufacturing

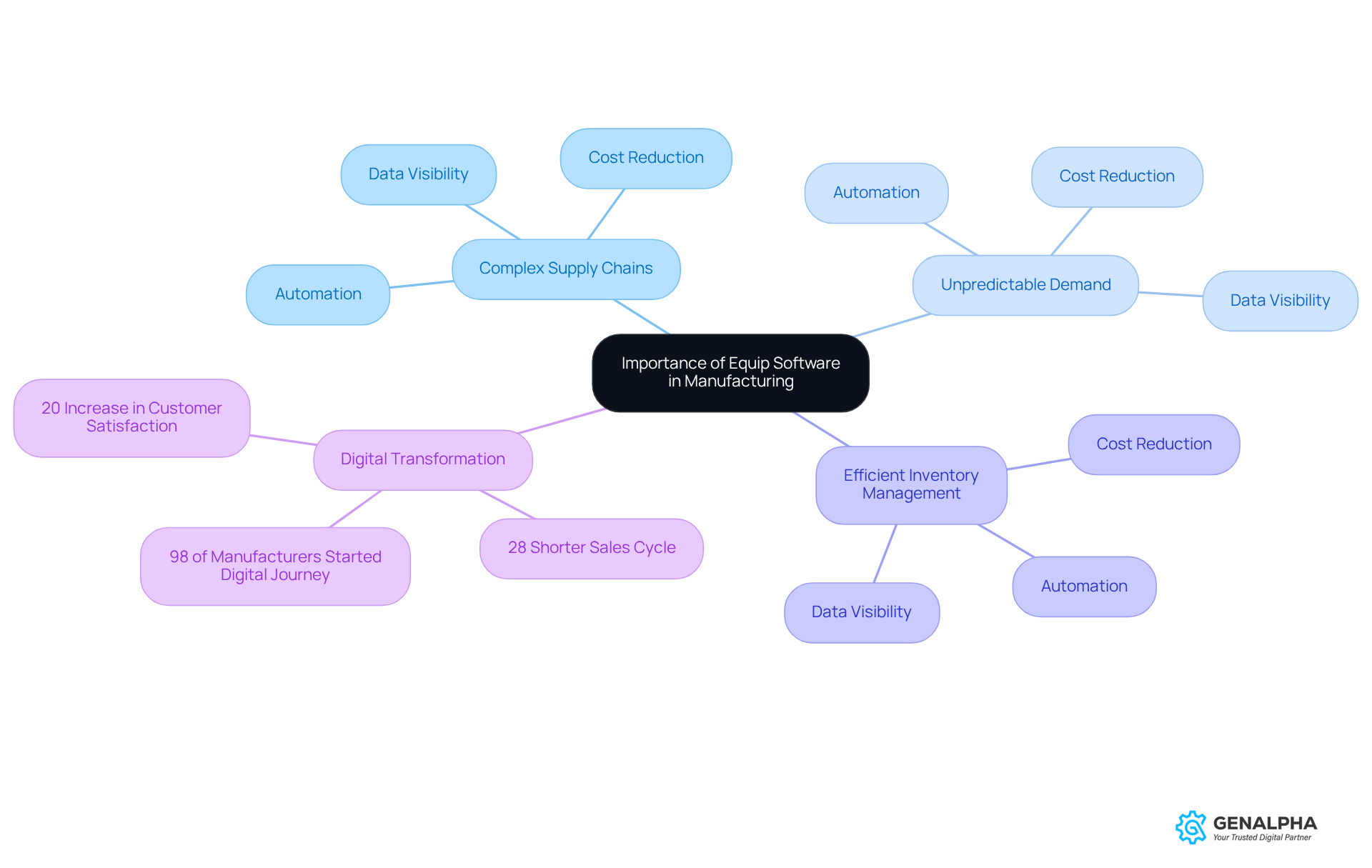

Manufacturers today face a bunch of challenges, right? Think about it: complex supply chains, unpredictable demand, and the constant need for efficient inventory management. This is where Equip Software comes into play, providing producers with advanced tools to streamline their operations. By automating processes and boosting data visibility, Equip Software enables manufacturers to quickly adapt to market changes, cutting down on operational costs and enhancing customer engagement.

And here’s the kicker: the push for digital transformation in manufacturing is picking up speed. By 2023, a whopping 98% of manufacturers had already started their digital journey. Companies that have embraced digital sales strategies are seeing a 20% jump in customer satisfaction, while those using automated quoting tools enjoy a 28% shorter sales cycle. As more businesses lean into technology, the projected $642.35 billion digital transformation market in manufacturing by 2025 underscores just how crucial these solutions are. They not only but also give companies a competitive edge in a fast-paced environment. So, are you ready to join the digital revolution?

Trace the Evolution of Equip Software: Origins and Development

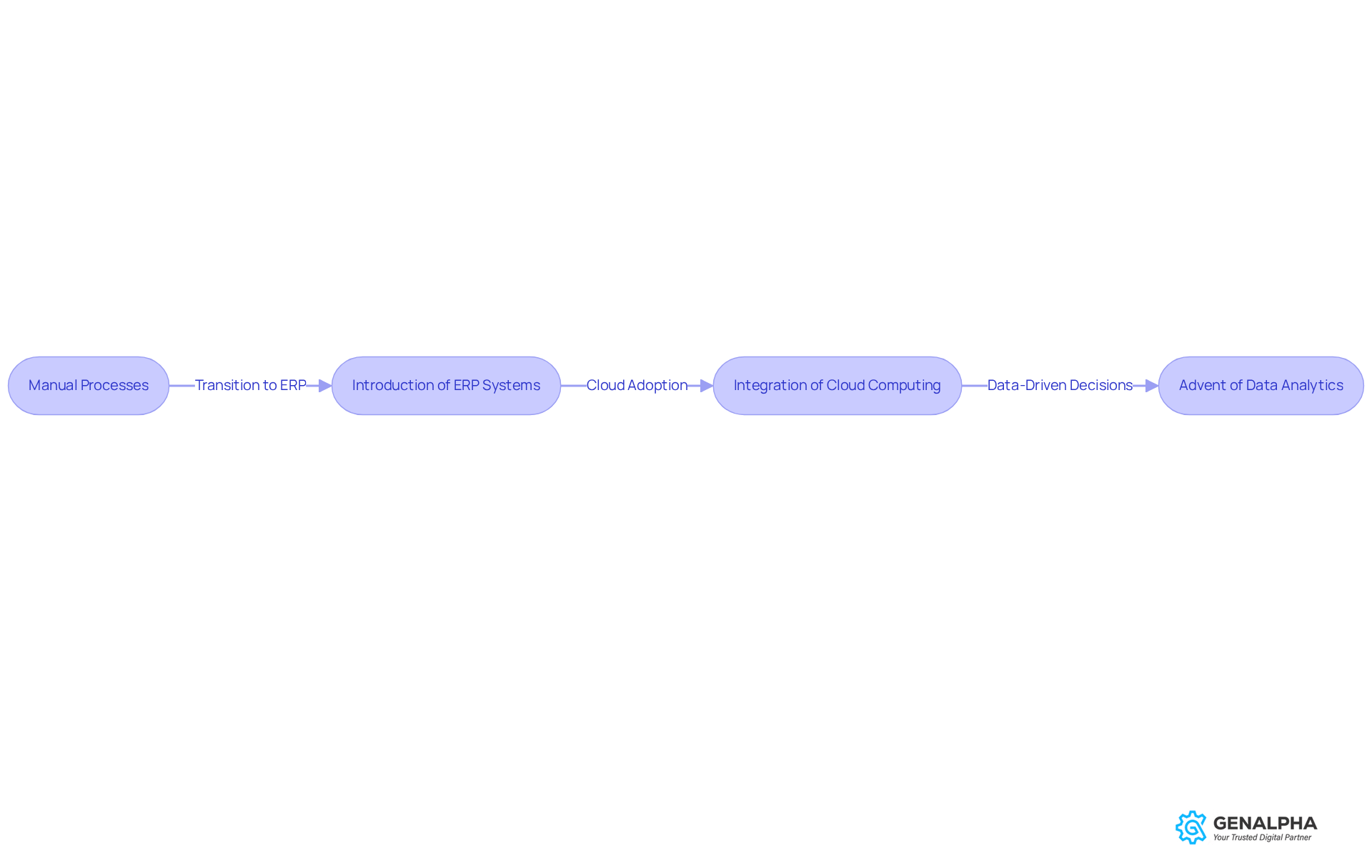

Have you ever thought about how far we've come in manufacturing? It all started back in the day when companies were heavily reliant on manual processes and stacks of paper. But as technology began to take center stage, the demand to equip software with smarter solutions grew. Remember when ERP (Enterprise Resource Planning) systems made their debut in the late 20th century? That was a game changer! Suddenly, producers could bring together various functions into one cohesive platform.

Fast forward to today, and this platform has transformed dramatically. We now see advanced features like , mobile access, and data analytics, which empower producers to make decisions based on real-time information. For example, Learning Resources shared, "Once we went live with Dynamics 365, we saw massive improvements throughout," showcasing just how impactful modern ERP solutions can be.

Additionally, cloud computing has played a crucial role to equip software in this evolution. Did you know that the global cloud computing market is expected to hit $1.614 trillion by 2030? This highlights how cloud-based solutions equip software to enhance flexibility and scalability in manufacturing processes. As this application continues to evolve, it remains a vital tool for producers, helping them adapt to the ever-changing demands of the industry. So, how can you leverage these advancements to thrive in a competitive landscape?

Identify Key Features and Functionalities of Equip Software

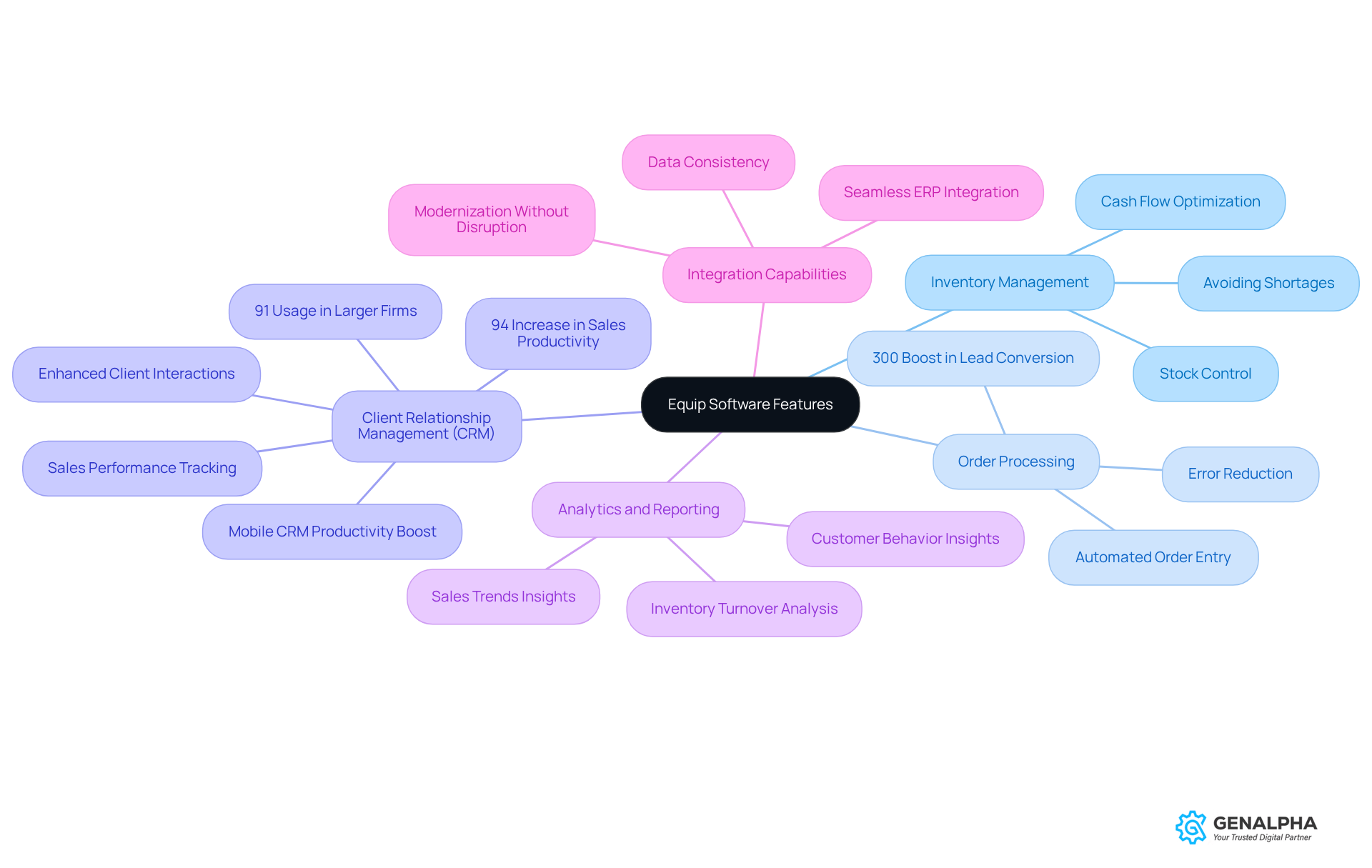

Equip Software is equipped with fantastic features that significantly enhance its functionality for manufacturers. Let’s take a closer look at a few key areas that make a difference:

- Inventory Management: Imagine having a system that keeps your stock in check, ensuring you have just the right amount to meet customer demand. Effective inventory management is a game changer—it helps you avoid tying up cash in excess stock while also minimizing shortages that could lead to lost sales.

- Order Processing: How much easier would it be if order entry and fulfillment were automated? This feature cuts down on errors and ramps up efficiency, allowing manufacturers to respond quickly to client needs. In fact, automating order processing can lead to a whopping 300% boost in lead conversion rates, making your sales process so much smoother.

- Client Relationship Management (CRM): Ever thought about how important client interactions are? This functionality not only enhances those interactions but also keeps tabs on sales performance, helping foster long-term relationships. Did you know that 91% of firms with 11 or more staff use CRM applications? Integrating CRM into your system is essential for managing client relationships effectively. Plus, 94% of businesses report an increase in sales productivity after implementing a CRM service. That’s significant! And let’s not forget about mobile CRM, which can increase productivity by up to 50%—talk about effective client engagement!

- Analytics and Reporting: Equip Software doesn’t just stop at managing; it also provides valuable insights into sales trends, inventory turnover, and customer behavior. This data is crucial for making informed strategic decisions. The ability to analyze data helps producers adjust to market changes and boost operational efficiencies.

- Integration Capabilities: Worried about how this software will fit into your current setup? No need! Equip Software seamlessly connects with existing ERP systems, ensuring a smooth transition and data consistency. This integration is vital for producers looking to modernize without disrupting their workflows.

When you combine all these features, it’s clear that the software equips manufacturers to , enhance overall business performance, and improve client satisfaction. In today’s competitive landscape, that’s more important than ever. So, are you ready to take your manufacturing process to the next level?

Explore How Equip Software Can Transform Manufacturing Processes

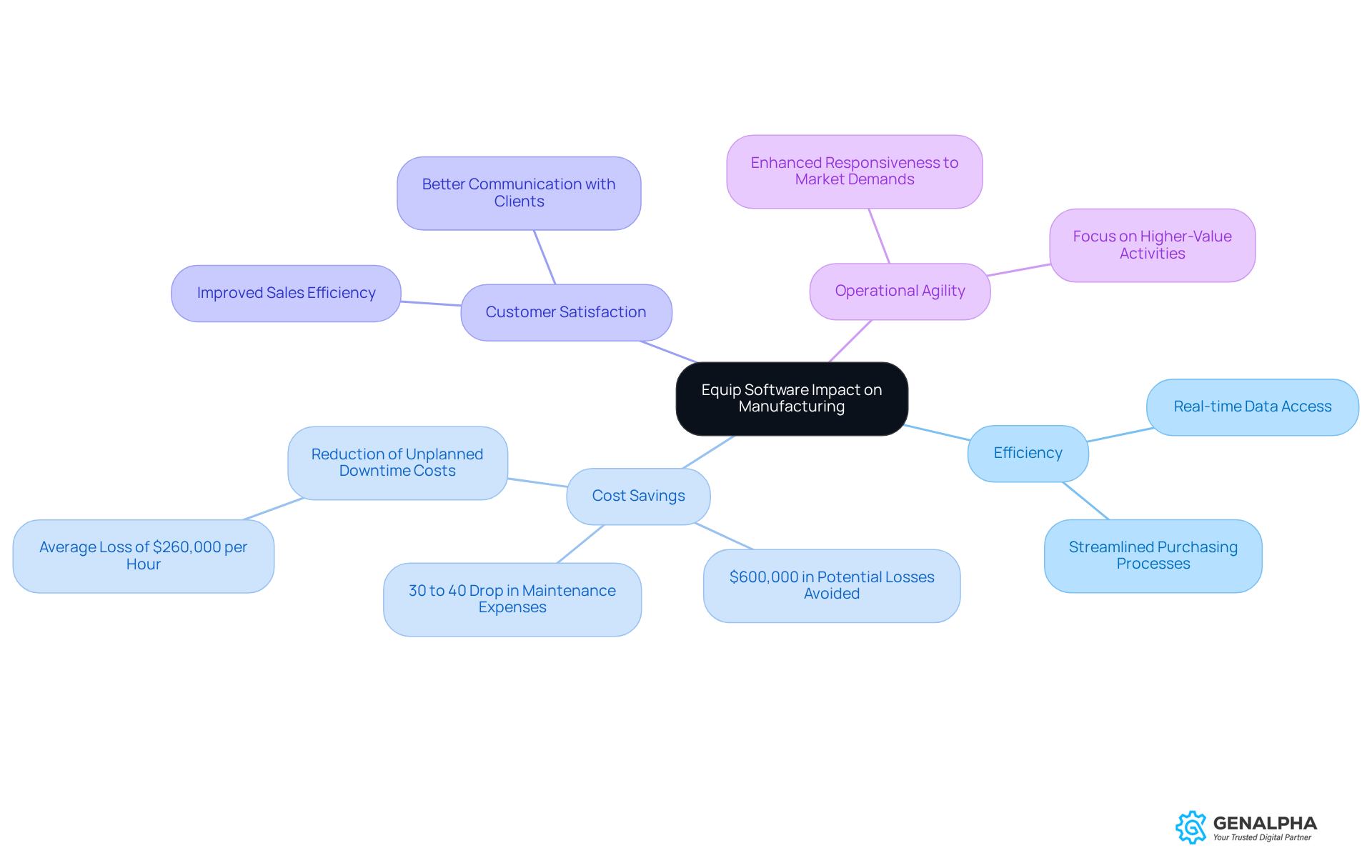

Imagine a world where manufacturing processes are transformed, where efficiency skyrockets, operational costs plummet, and customer satisfaction reaches new heights. Sounds good, right? That’s exactly what this technology brings to the table. By automating repetitive tasks, producers can free up their employees to focus on higher-value activities that spark innovation and growth. In fact, organizations that have embraced this system report a staggering 30% to 40% drop in maintenance expenses, all thanks to enhanced task automation and predictive analytics that optimize operations and minimize downtime.

But wait, there’s more! is a game changer, allowing producers to make quick, informed decisions that enhance responsiveness to market demands. Companies using this platform have experienced improved sales efficiency and better customer experiences. Why? Because it streamlines purchasing processes and fosters better communication with clients. Case studies reveal that producers leveraging this platform have achieved remarkable cost savings, with some reporting reductions in operational expenses by as much as $600,000 in potential losses avoided through predictive maintenance in just the first year.

Now, let’s talk about the impact of unexpected equipment breakdowns. Did you know that organizations can lose an average of $260,000 per hour when this happens? That really puts into perspective the financial consequences of neglecting maintenance solutions and predictive upkeep strategies. Overall, integrating equip software into manufacturing operations not only creates a more agile and competitive business model but also positions companies to thrive in our increasingly digital world. By embracing this technology, manufacturers can optimize their workflows, boost productivity, and ultimately drive sustainable growth. So, are you ready to take the leap into the future of manufacturing?

Conclusion

Equip Software is shaking things up in the manufacturing world, giving organizations the tools they need to boost efficiency and keep customers happy. With features like inventory management, order processing, and client relationship management, this software tackles the unique challenges manufacturers face, paving the way for growth and long-term success.

Let’s talk about why Equip Software is a game changer. It streamlines processes and helps businesses adapt to market changes. Manufacturers who embrace these solutions see real benefits, like lower costs and better sales efficiency. As the manufacturing industry goes digital, the role of this software is more important than ever. It’s what will help businesses thrive in a competitive landscape.

So, what’s next? Embracing Equip Software isn't just a smart move; it’s essential for sustainable growth and innovation. As manufacturers deal with tricky supply chains and unpredictable demand, these advanced tools can unlock new levels of productivity and agility. The time to invest in Equip Software is now; it has the potential to reshape the future of manufacturing and lead businesses to incredible success.

Frequently Asked Questions

What is Equip Software?

Equip Software refers to specialized digital solutions designed for manufacturers and distributors in the equipment and aftermarket parts sectors, aimed at boosting operational efficiency through features like inventory management, order processing, and client relationship management.

What are the main benefits of using Equip Software?

The main benefits include streamlining processes, enhancing sales performance, improving customer experiences, optimizing operations, and ensuring compliance with industry standards.

What features are included in Equip Software?

Equip Software includes features such as production planning, quality control, maintenance management, inventory management, and order processing.

How significant is the market for manufacturing operations management solutions?

The Manufacturing Operations Management Solutions Market is projected to reach USD 52.7 billion by 2032, highlighting the growing importance of these solutions in the industry.

What impact do ERP systems have on companies?

Statistics show that 95% of companies reported improvements in their processes after implementing ERP systems, leading to benefits such as reduced order processing time and improved inventory accuracy.

What challenges do manufacturers face that Equip Software addresses?

Manufacturers face challenges like complex supply chains, unpredictable demand, and the need for efficient inventory management, which Equip Software helps to address by automating processes and boosting data visibility.

How has the digital transformation in manufacturing progressed?

By 2023, 98% of manufacturers had begun their digital transformation journey, with those adopting digital sales strategies experiencing a 20% increase in customer satisfaction and a 28% shorter sales cycle.

What is the projected market size for digital transformation in manufacturing by 2025?

The projected market size for digital transformation in manufacturing is expected to reach $642.35 billion by 2025, emphasizing the critical role of these solutions in providing a competitive edge.