Overview

Have you ever found yourself lost in the maze of electronics components? An electronics parts catalog (EPC) is here to change that! This digital resource makes life easier for manufacturers by offering detailed information about components, which in turn boosts operational efficiency and accuracy.

Imagine streamlining your inventory management and ordering process—all thanks to advanced search features and real-time updates. Sounds great, right? Not only do EPCs help reduce costs, but they also improve customer satisfaction, especially in today's competitive market.

So, why not take a closer look at how an EPC can transform your procurement process? You might just discover that it’s the tool you didn’t know you needed!

Introduction

In the ever-evolving world of manufacturing, finding ways to boost efficiency and accuracy is crucial. Have you ever thought about how an electronics parts catalog could change the game? This handy tool transforms how manufacturers like you identify, locate, and procure essential components. With a streamlined, user-friendly interface that features real-time updates and advanced search functionalities, these catalogs can save you time and help avoid those pesky costly errors.

But as the industry continues to evolve, how can you fully tap into the potential of these catalogs to enhance your operations and keep your customers smiling?

Define Electronic Parts Catalog

Have you ever tried to find a specific part for your machine or vehicle and felt overwhelmed by the options? That’s where an electronics parts catalog comes in handy! Think of it as a sophisticated digital library packed with all the information you need about machinery components. With an electronics parts catalog, you can quickly identify, locate, and request essential parts, which makes the whole a breeze.

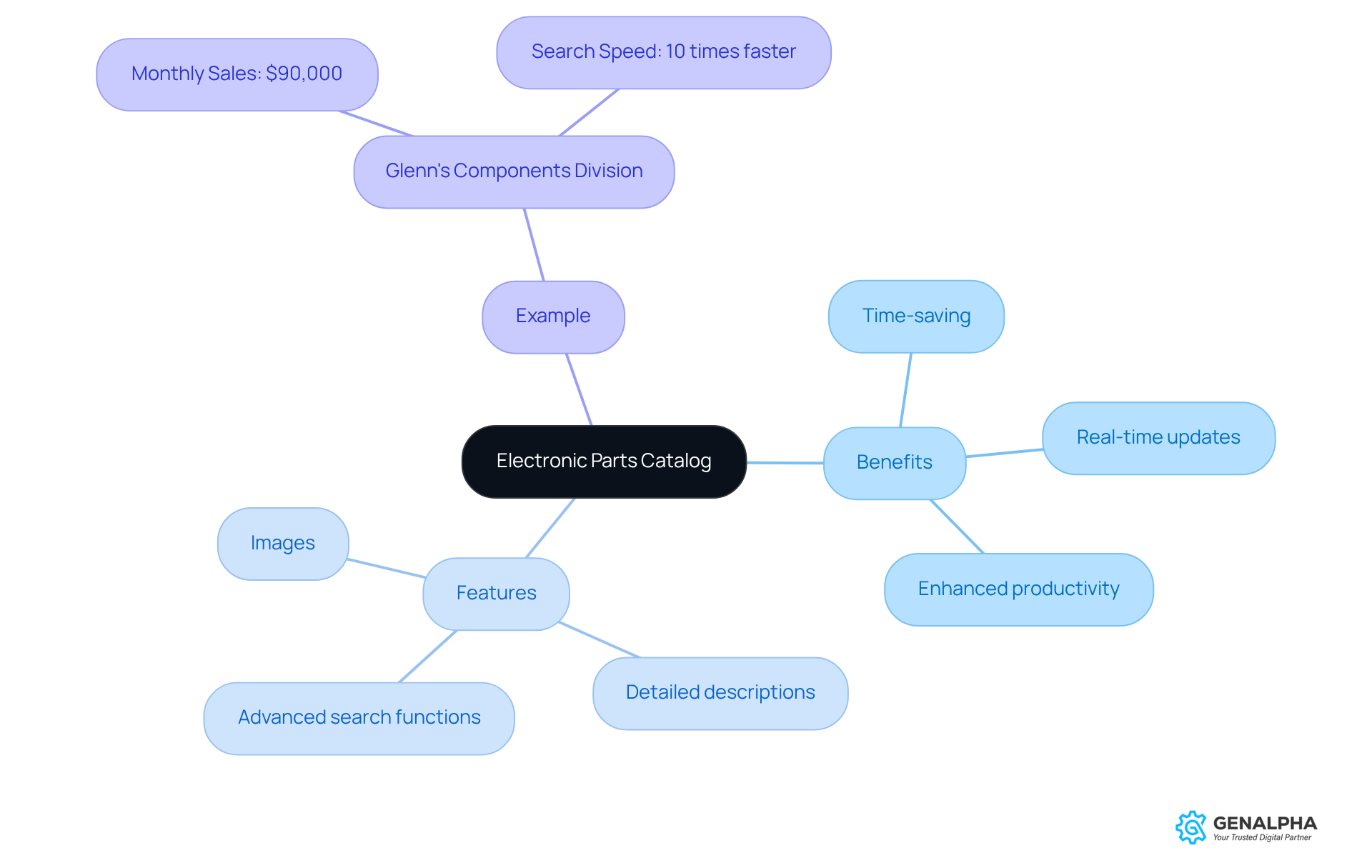

These catalogs are like a treasure trove, filled with detailed descriptions, component numbers, images, and specifications that help you make informed buying decisions. Unlike those bulky paper catalogs that can feel like a chore to navigate, EPCs are designed with advanced search functions that allow you to find what you need ten times faster. Imagine how much time you could save!

Plus, the interactive features of EPCs streamline your ordering process. You’ll get real-time updates that keep you in the loop with the latest OEM changes. This is crucial because poor spare parts management costs the automotive sector billions every year. For instance, producers can easily update item numbers and specifications from anywhere with internet access, eliminating delays that used to take 24 hours or more.

Take a look at Glenn's components division, which has successfully implemented an electronic product catalog and generates nearly $90,000 in monthly wholesale sales. This shows just how effective EPCs can be in boosting operational productivity and keeping customers happy. As the manufacturing landscape evolves, EPCs are becoming indispensable tools for manufacturers. If you’re in the machine-related business, adopting an electronics parts catalog could significantly enhance your components management and procurement processes. Why not explore how an EPC can work for you?

Contextualize Its Importance for Manufacturers

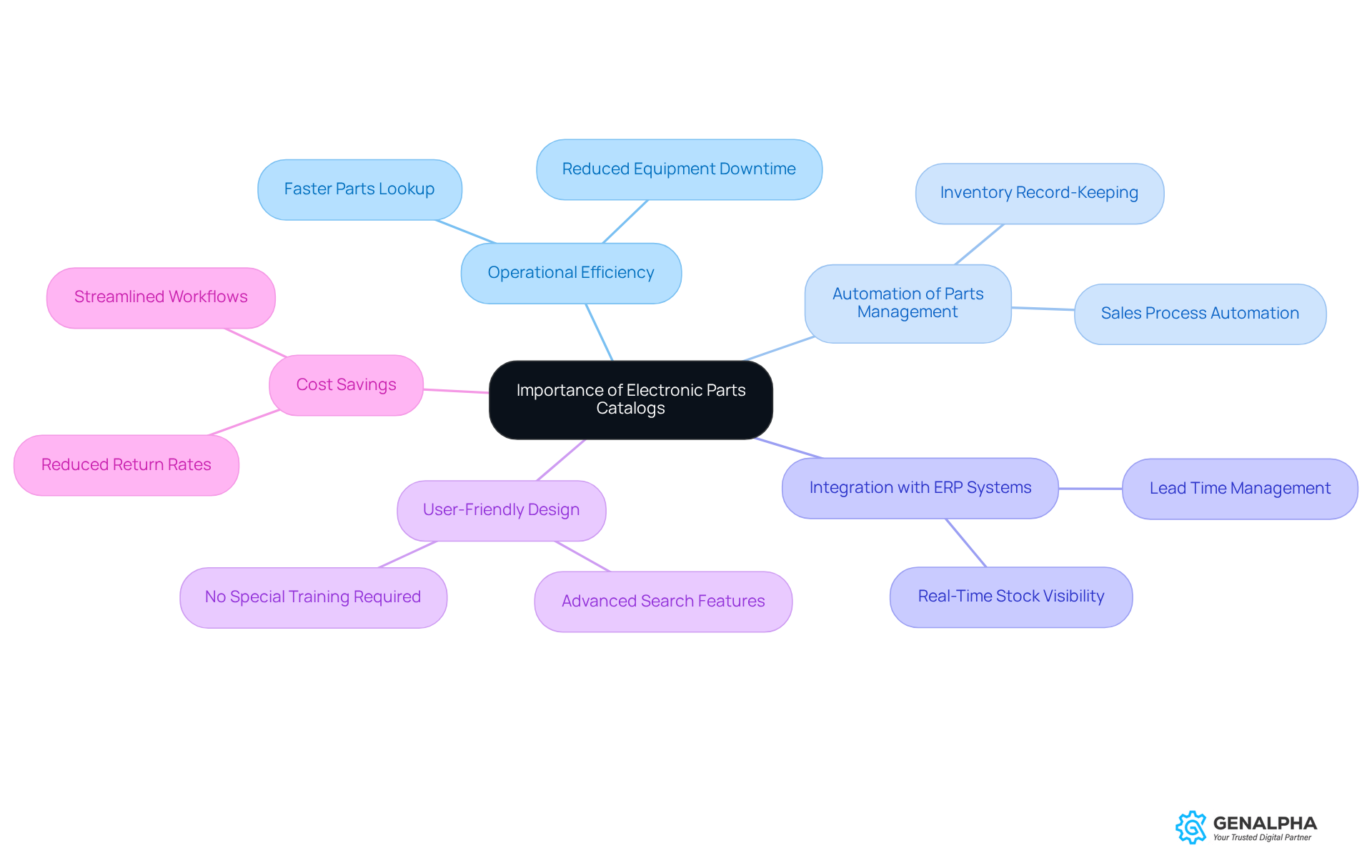

In today’s fast-paced manufacturing world, who doesn’t want operational efficiency and accuracy? Traditional methods for identifying and ordering components often lead to delays, mistakes, and higher costs. That’s where electronics parts catalogs come into play—they're game changers for manufacturers. By giving quick access to accurate component information, these catalogs help cut down on downtime and improve inventory management, which ultimately boosts customer satisfaction. As more manufacturers jump on the digital bandwagon, it’s clear that engineering and construction firms play a vital role in keeping things running smoothly.

Think about it: electronic parts controllers automate many parts management tasks, from keeping inventory records to handling sales processes—tasks that used to be done manually. This automation not only makes operations more efficient but also cuts down on the chances of making incorrect orders, which means fewer returns and lower costs. Plus, when you combine engineering procurement contracts with up-to-date ERP and inventory systems, you get real-time insights into stock levels, lead times, and delivery schedules. This means producers can meet customer expectations without a hitch.

And let’s not forget about the user-friendly design of electronics parts catalogs. They make it super easy for staff to find components quickly with advanced search features. Users can refine and sort items effortlessly, speeding up the retrieval process to be ten times faster than before. This efficiency translates into , as manufacturers can streamline workflows and allocate resources more effectively. As the demand for efficient component management grows, adopting EPCs isn’t just a trend—it’s a strategic must for those looking to thrive in a competitive market.

Explore Key Features and Functionalities

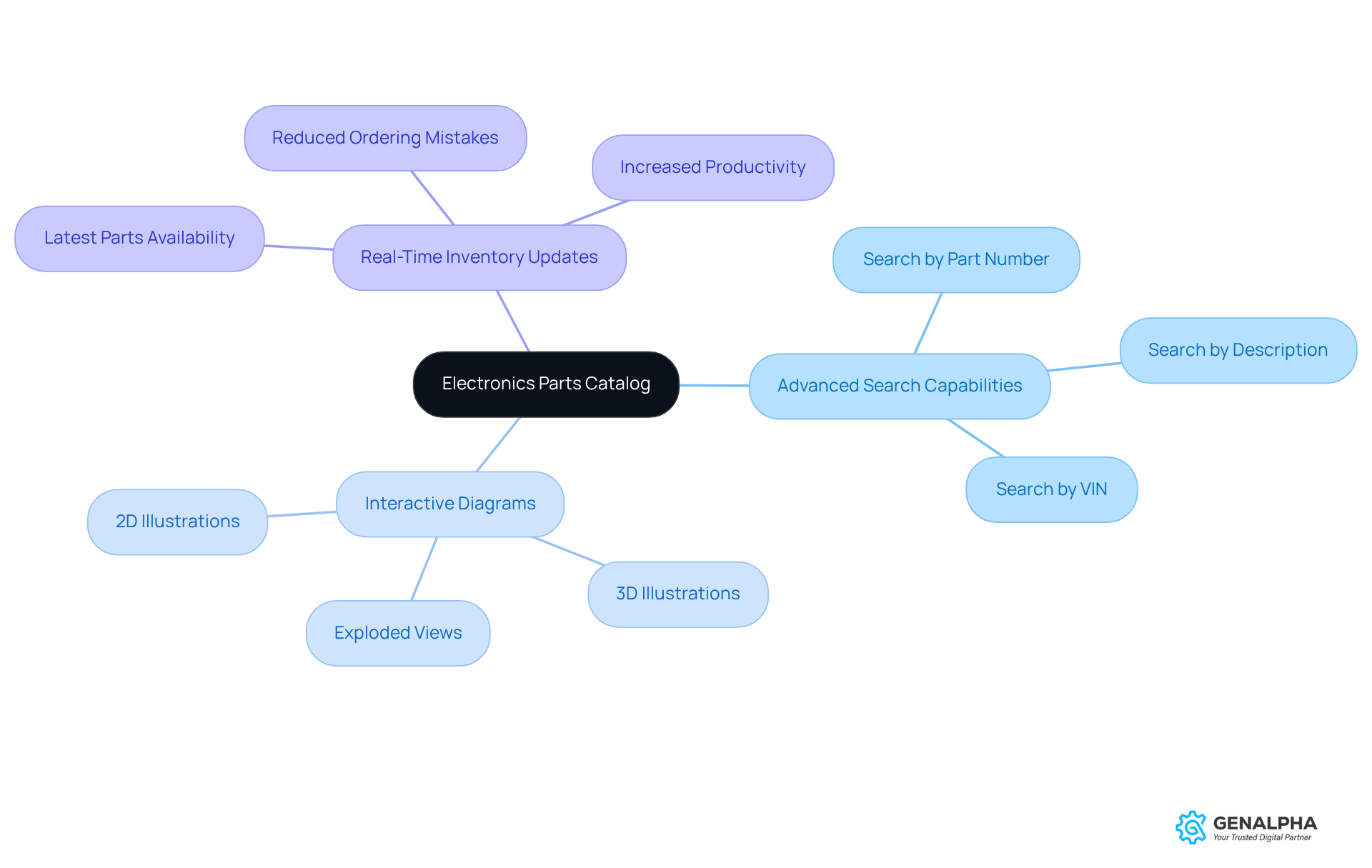

Have you ever found yourself searching for that one elusive part for your vehicle? Well, electronics parts catalogs are here to simplify your life significantly! With , you can hunt down components using various criteria—be it part numbers, descriptions, or even your vehicle identification number (VIN).

But that’s not all! The interactive diagrams let you visualize how everything fits together, making it a breeze to identify the right components. Imagine being able to see the assembly of elements right in front of you; it’s like having a roadmap for your parts!

And let’s talk about real-time inventory updates. You’ll always have the latest info on parts availability, which means fewer ordering mistakes and a boost in productivity. It’s a win-win! These features truly make the electronics parts catalog an invaluable resource for both producers and suppliers. So, why not dive in and explore what these catalogs can do for you?

Highlight Benefits of Implementing an Electronic Parts Catalog

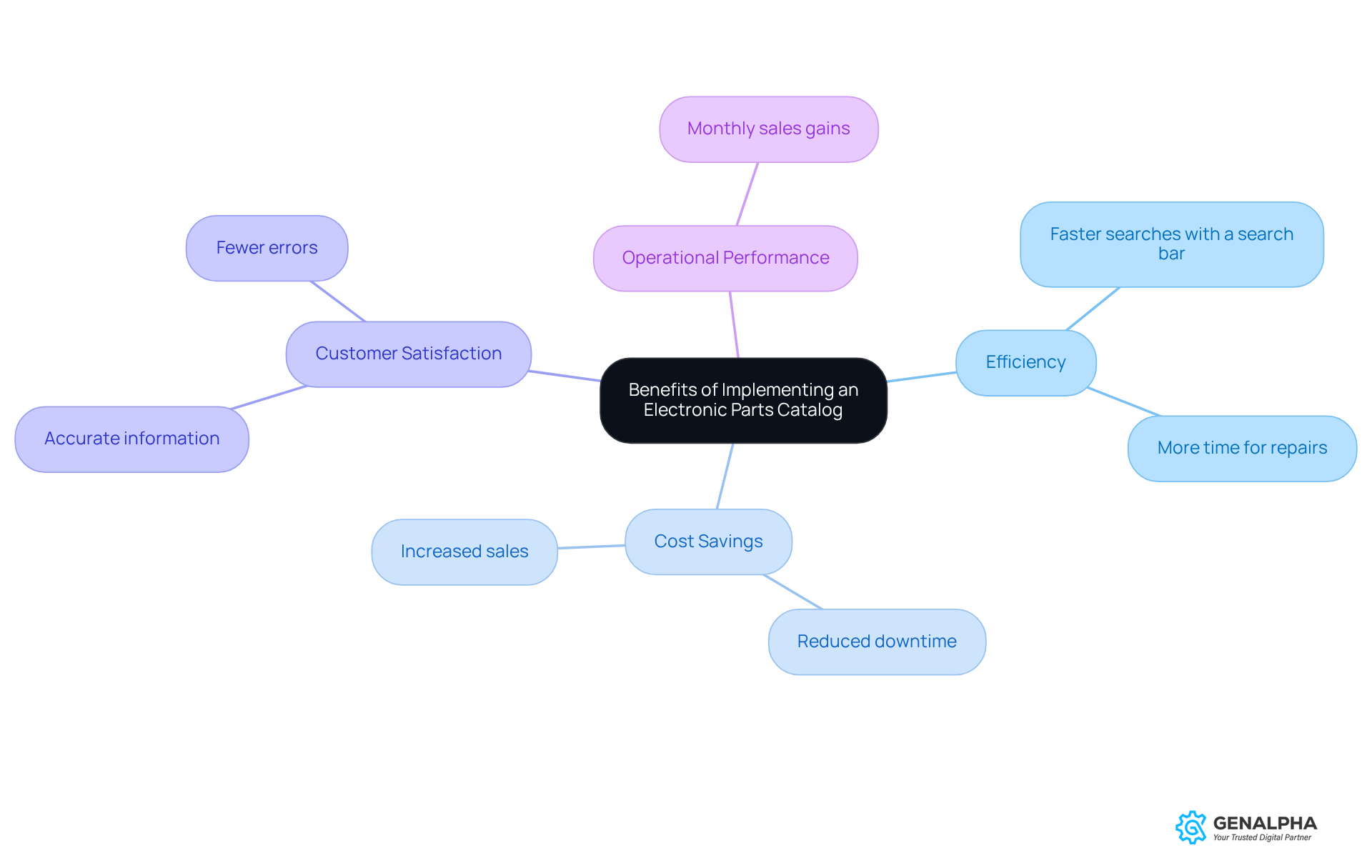

Implementing an electronics parts catalog brings a host of benefits for manufacturers, making things more efficient, cutting costs, and boosting customer satisfaction. Imagine how much easier it is for engineering project contractors when identifying and ordering components. By streamlining this process, technicians can spend less time searching for items and more time on repairs and maintenance. For instance, adding a search bar in the electronics parts catalog can make finding components ten times faster than traditional methods, leading to impressive productivity gains.

This newfound efficiency not only reduces downtime but also translates into . Producers using engineering procurement contracts have seen their operational performance soar, with some components departments raking in nearly $90,000 in monthly wholesale sales. That’s a clear win for anyone looking to enhance their bottom line through real-time component information updates.

But there’s more! Engineering procurement companies also ramp up customer satisfaction by providing accurate and timely information, ensuring clients get the right components when they need them. This capability is essential for keeping customers loyal; after all, fewer errors and shorter wait times create a much more pleasant purchasing experience. Plus, the help desk feature tied to the electronics parts catalog alleviates the stress of searching for parts, further enhancing customer interactions. So, manufacturers that jump on the EPC bandwagon can expect to see significant improvements in both their operational efficiency and customer relationships, ultimately driving growth in a competitive marketplace. Are you ready to embrace the change?

Conclusion

You know, the importance of an electronics parts catalog (EPC) for manufacturers is something we can't overlook. These digital tools act like a treasure chest of information, simplifying the procurement process and making it a breeze for businesses to find, locate, and order those essential components. With advanced search capabilities and real-time updates at their fingertips, manufacturers can boost their operational efficiency and cut down on those pesky delays, which ultimately leads to happier customers.

As we dive deeper, it’s clear that EPCs automate a bunch of tasks that used to be done manually, like inventory management and order processing. This shift not only cuts down on errors but also speeds up workflows, letting manufacturers use their resources more wisely. Take Glenn's components division, for instance—they’ve seen impressive monthly sales thanks to the benefits of using an electronic parts catalog in a competitive market.

So, here’s the deal: embracing electronics parts catalogs is a smart move that can really shake up manufacturing processes. With the demand for efficiency and accuracy on the rise, it’s high time manufacturers looked into how EPCs can elevate their operations. By hopping on board with these innovative tools, businesses can not only enhance their component management but also build stronger relationships with customers, setting the stage for sustainable growth and success in the industry. What do you think? Are you ready to explore the possibilities?

Frequently Asked Questions

What is an electronic parts catalog (EPC)?

An electronic parts catalog is a digital library that contains detailed information about machinery components, helping users identify, locate, and request essential parts efficiently.

How does an EPC differ from traditional paper catalogs?

Unlike bulky paper catalogs, EPCs feature advanced search functions that allow users to find parts much faster. They are designed for ease of use and provide interactive features for a streamlined ordering process.

What kind of information can be found in an EPC?

An EPC includes detailed descriptions, component numbers, images, and specifications of parts, which aid in making informed buying decisions.

How do EPCs improve the procurement process?

EPCs offer real-time updates on OEM changes, allowing producers to easily update item numbers and specifications from anywhere with internet access, thus eliminating delays in the procurement process.

What impact do EPCs have on the automotive sector?

Poor spare parts management costs the automotive sector billions every year. EPCs help mitigate these costs by improving parts management and streamlining the ordering process.

Can you provide an example of a successful implementation of an EPC?

Glenn's components division successfully implemented an electronic product catalog and generates nearly $90,000 in monthly wholesale sales, demonstrating the effectiveness of EPCs in boosting operational productivity.

Why are EPCs becoming essential for manufacturers?

As the manufacturing landscape evolves, EPCs are becoming indispensable tools for manufacturers, significantly enhancing components management and procurement processes.