Overview

Have you ever thought about how crucial the bill of materials (BOM) management process is for manufacturing success? It’s all about ensuring accurate production planning, cost control, and quality assurance. When done right, effective BOM management can really boost operational efficiency. Think about it: by embracing best practices like standardization, keeping things updated regularly, and leveraging technology, we can enhance collaboration and cut down on errors in the manufacturing process.

For example, imagine a factory where everyone is on the same page thanks to a well-managed BOM. This not only simplifies the workflow but also makes it easier to spot potential issues before they escalate. So, why not take a moment to reflect on your current BOM practices? Are there areas where you could improve?

In conclusion, mastering BOM management isn’t just a technical requirement; it’s a game-changer for your manufacturing operations. Let’s aim for that efficiency and accuracy together! What steps will you take today to enhance your BOM management?

Introduction

Mastering the bill of materials (BOM) management process is not just crucial; it's often an overlooked gem in the world of manufacturing success. Think of it as the backbone of production, laying out every single component needed to create a finished product. Yet, despite its significance, many manufacturers find themselves grappling with inefficiencies and inaccuracies in their BOM practices.

So, what if we could turn this daunting task into a streamlined process? What key strategies and technologies could we explore to enhance operational efficiency?

Let's dive into this together!

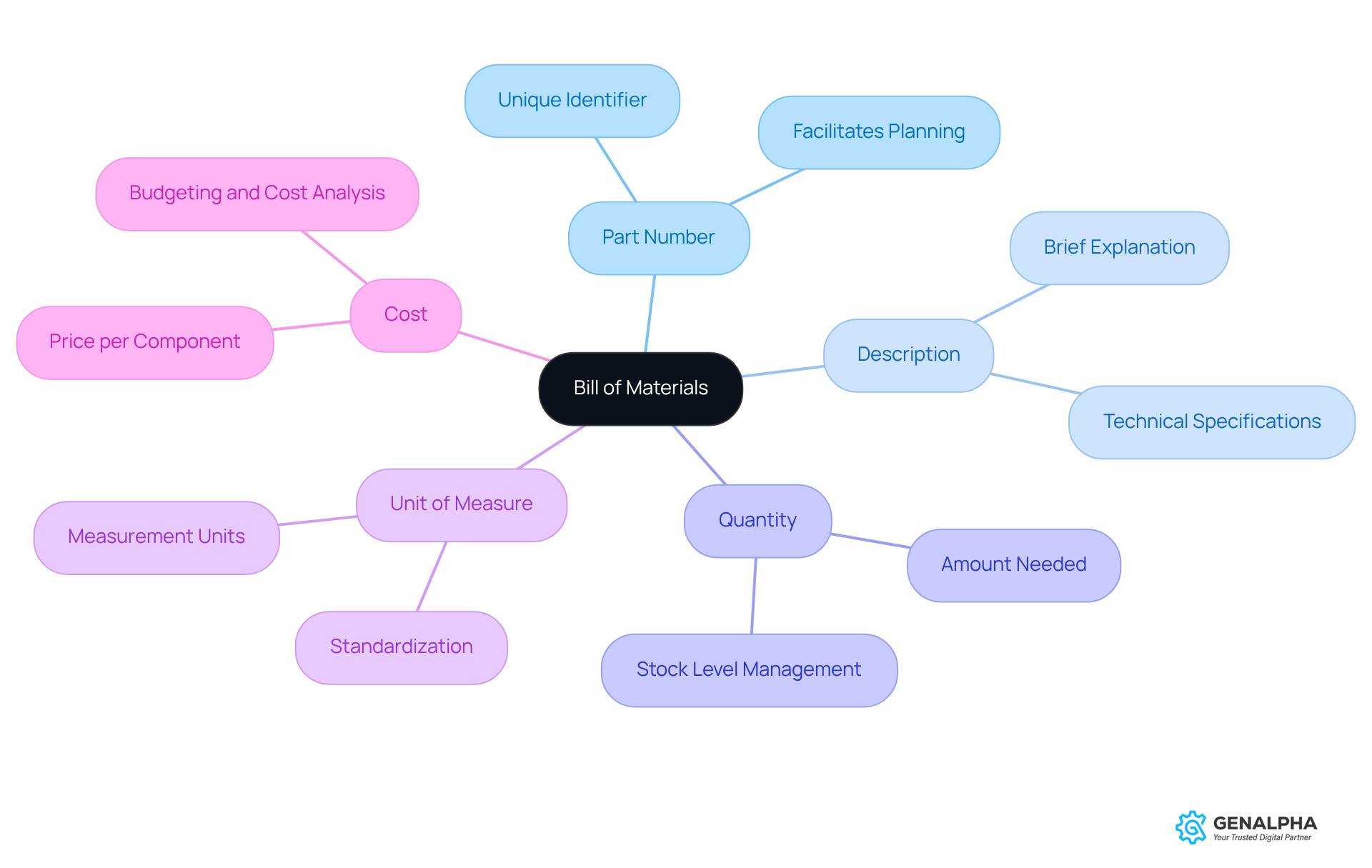

Define the Bill of Materials: Core Components and Structure

Have you ever wondered what goes into making a product? The bill of materials management process serves as a recipe for production, providing a detailed list of all the raw materials, parts, sub-assemblies, and assemblies needed to create that finished product we all love. Let’s break down the core components of a BOM, shall we?

- Part Number: This is the unique identifier for each component, kind of like a name tag.

- Description: Here, you’ll find a brief explanation of what the part or material is all about.

- Quantity: This tells you how many of each element you need to get the job done.

- Unit of Measure: It specifies the measurement unit for each element—think pieces or kilograms.

- Cost: This is the price associated with each element, which is super helpful for [budgeting and cost analysis](https://blog.genalpha.com/4-strategies-for-personalized-ecommerce-in-equipment-manufacturing).

Now, if we structure the bill of materials management process hierarchically—putting the finished product at the top and sub-assemblies branching below—it really enhances clarity and organization. This way, teams can and make the most out of it. So, next time you think about production, remember how a well-structured BOM can make all the difference!

Recognize the Importance of BOM Management in Manufacturing Efficiency

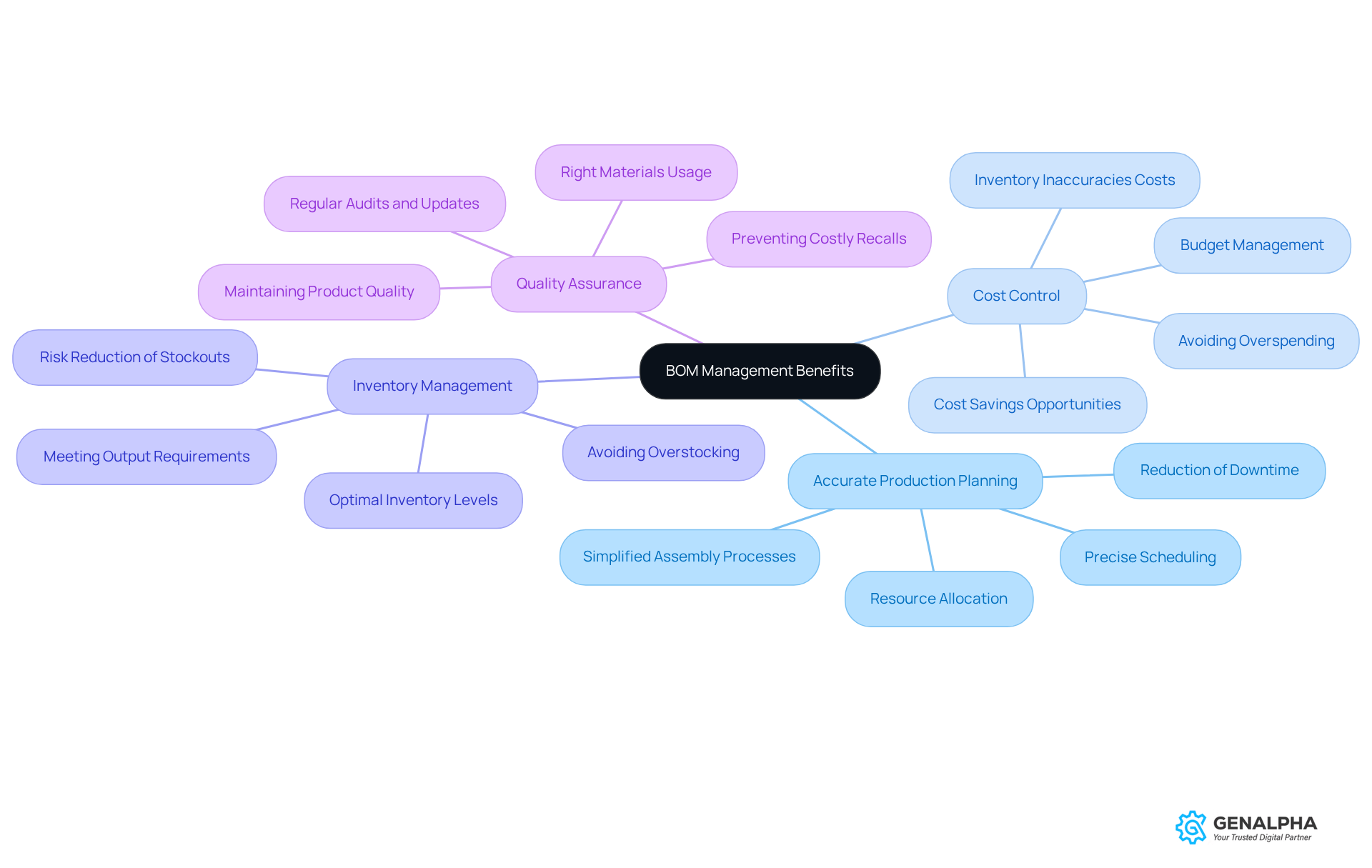

Oversight of the bill of materials management process is essential for boosting manufacturing efficiency. It ensures that all parts are accurately recorded and readily available when needed. So, what are the key benefits of effective BOM management?

- Accurate Production Planning: Imagine having a well-maintained BOM that allows for precise scheduling and resource allocation. This can significantly reduce downtime and production delays. For example, manufacturers using multi-level BOMs (MLBOMs) can simplify complex assembly processes, making sure all necessary parts are on hand when they're needed.

- Cost Control: By keeping a close eye on component costs, manufacturers can manage their budgets more effectively and spot chances for cost savings. This proactive strategy helps avoid overspending on materials, which could range from $10 to $250 per mistake due to .

Effective inventory management relies heavily on the bill of materials management process to maintain optimal inventory levels. This helps reduce the risk of stockouts or overstocking, ensuring that output requirements are met without tying up capital in excess inventory.

- Quality Assurance: A detailed BOM ensures that the right materials are used, which is crucial for maintaining product quality and meeting industry standards. Regular audits and updates to the BOM can help catch discrepancies early, preventing costly recalls and production hiccups.

Recognizing the importance of BOM oversight empowers manufacturers to enhance operational efficiency and consistently deliver high-quality products. How can you implement these insights in your own operations?

Implement Best Practices for Creating and Maintaining an Effective BOM

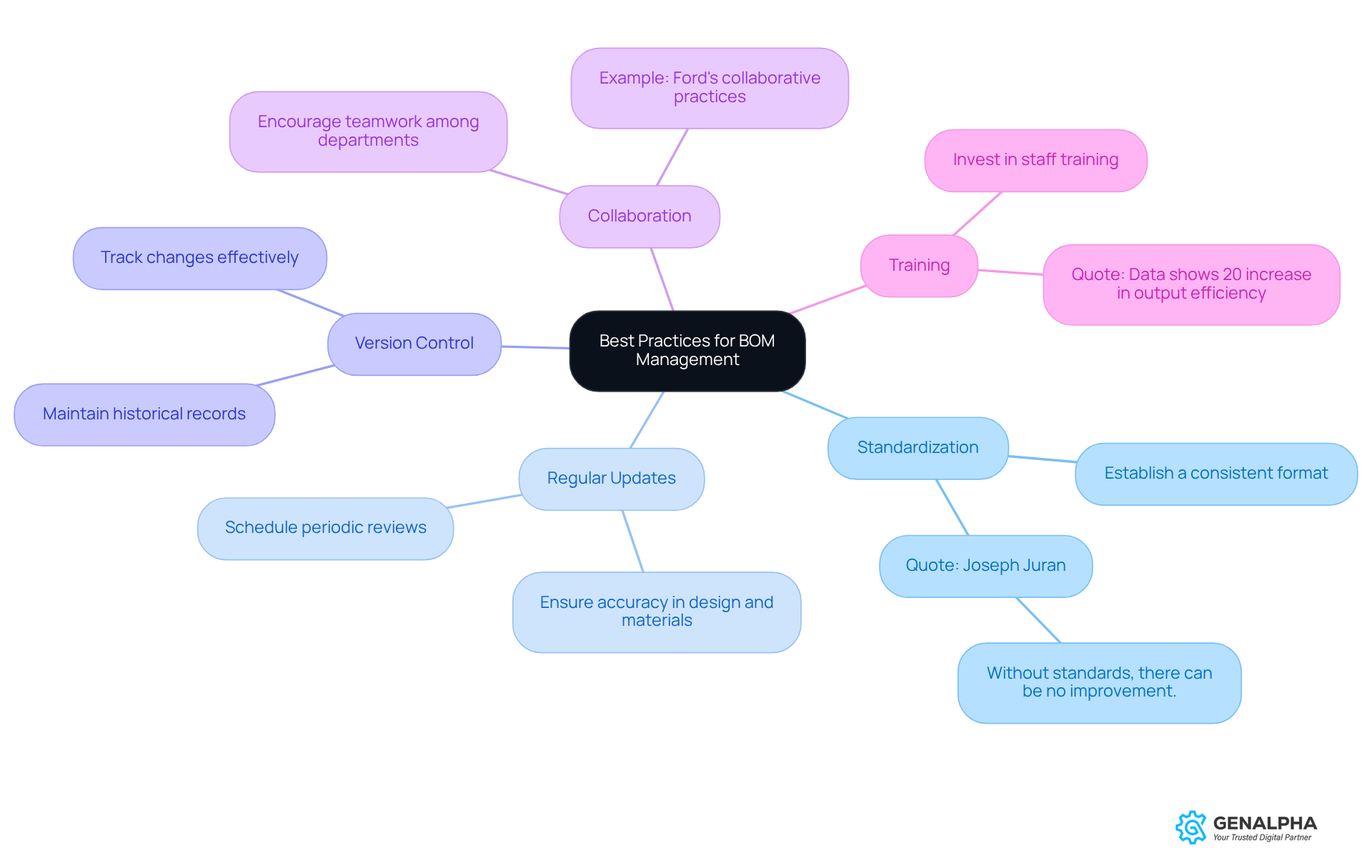

Creating and maintaining an effective bill of materials management process can seem daunting, but it doesn't have to be! Here are some friendly best practices that can help manufacturers like you get it right:

- Standardization: First things first, establish a consistent format for BOMs across all your products. This simple step makes updates easier and boosts communication among teams. As W. Edwards Deming wisely said, "Without standards, there can be no improvement." And Joseph Juran echoed this sentiment, reinforcing just how crucial standardization is for achieving operational excellence.

- Regular Updates: Next up, make it a habit to schedule periodic reviews of your BOM. This ensures it accurately reflects any changes in design, materials, or processes. Keeping your bill of materials management process up-to-date is essential for maintaining its integrity and ensuring that everyone is on the same page.

- Version Control: Have you ever found yourself confused about which version of a document is the latest? Implementing a version control system can help you avoid that headache in the bill of materials management process! It allows you to track changes and maintain historical records of BOMs, so teams can easily reference previous iterations when needed.

- Collaboration: Teamwork makes the dream work! Encourage collaboration among your engineering, manufacturing, and procurement teams. When everyone has access to the most accurate information from the bill of materials management process, operational efficiency soars, and the risk of errors drops. Just look at manufacturers like Ford—they’ve successfully adopted collaborative BOM practices that have significantly improved their output efficiency.

- Training: Last but not least, invest in comprehensive training for your staff on BOM oversight tools and processes. This not only boosts their understanding but also in using BOMs, leading to better outcomes. In fact, data shows that companies that allocate resources for BOM training see a 20% increase in output efficiency.

By following these best practices, you can ensure that your bill of materials management process results in reliable, accurate, and effective tools for managing production. So, why not start implementing these strategies today? Your operational success is just around the corner!

Leverage Technology for Streamlined BOM Management and Collaboration

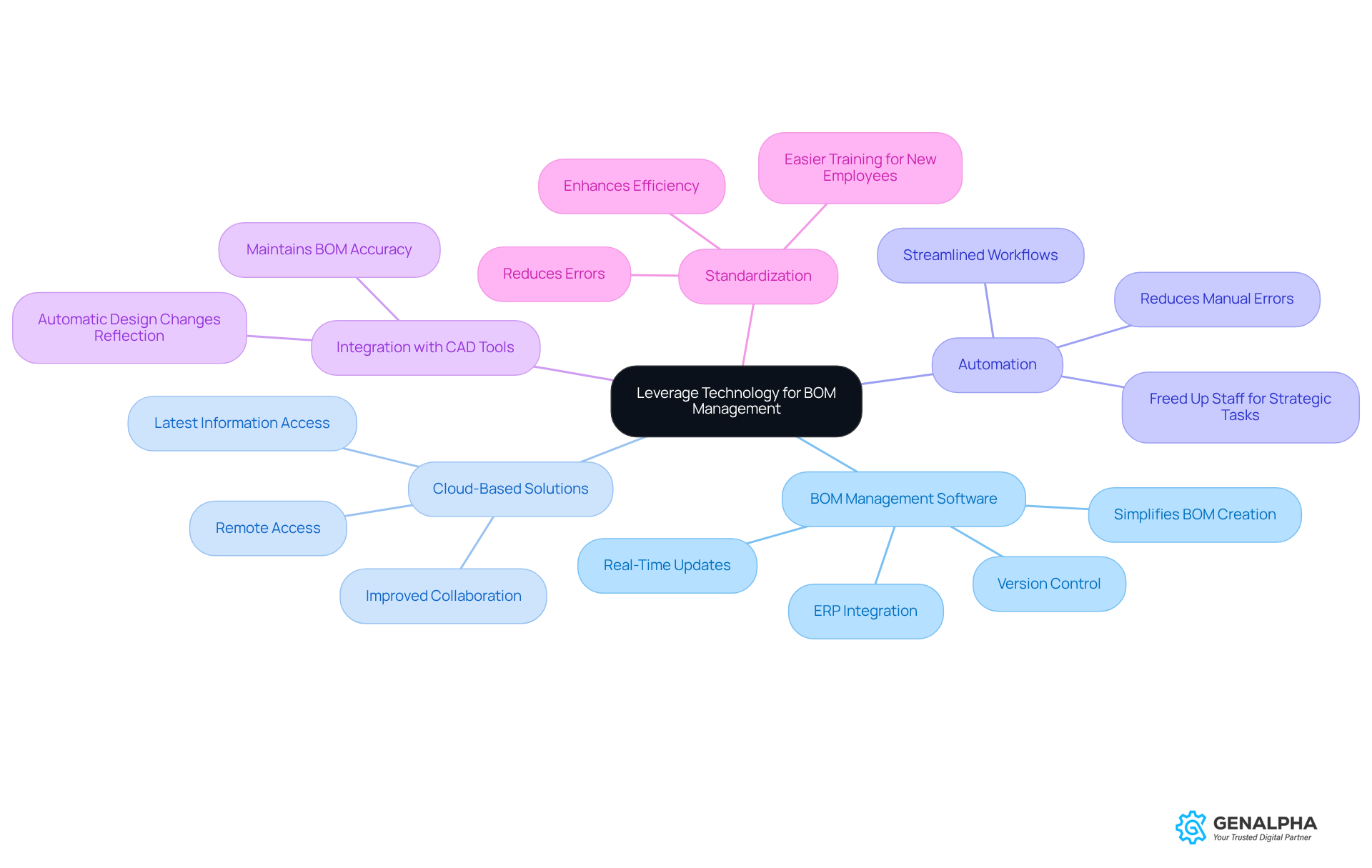

Using technology is key to and enhancing collaboration among teams. Have you ever thought about how tech can make our work easier? Here are some effective ways to leverage technology:

- BOM Management Software: Consider implementing specialized software that simplifies the creation, modification, and sharing of BOMs across departments. This type of software often features version control, real-time updates, and integration with ERP systems, which are essential for streamlining operations and enhancing decision-making.

- Cloud-Based Solutions: Why not use cloud-based platforms? They enable remote access to BOMs, allowing teams to collaborate effortlessly, no matter where they are. This accessibility improves communication and ensures that everyone is working with the latest information.

- Automation: Think about automating routine tasks like data entry and updates. This can help reduce manual errors and free up your staff for more strategic activities. Automation not only streamlines workflows but also boosts overall productivity.

- Integration with CAD Tools: Integrating BOM oversight with CAD software is another smart move. This ensures that any design changes are automatically reflected in the BOM, maintaining accuracy and consistency.

- Standardization: Establishing standard procedures for BOM creation and handling can significantly reduce errors and enhance efficiency across the organization. Standardization brings clarity and consistency, making it easier to train new employees and integrate new systems.

By embracing these technological advancements, manufacturers can elevate their bill of materials management process, resulting in improved efficiency, fewer errors, and better collaboration across teams. As Andrew Schultz, Chief Technology Officer, pointed out, having a unified BOM creates a smoother interface between manufacturing and engineering, which is crucial for effective product development. So, are you ready to take your BOM management to the next level?

Conclusion

Mastering the bill of materials (BOM) management process is crucial for manufacturing success. Think of a well-structured BOM as the backbone of production—it details every little component needed to create a finished product. By getting familiar with its core elements—like part numbers, descriptions, quantities, units of measure, and costs—you can boost clarity and organization, leading to improved operational efficiency.

Throughout this article, we’ve shared some key insights on why effective BOM management is so important. The benefits are clear:

- Accurate production planning

- Cost control

- Quality assurance

All contribute to smoother manufacturing processes. By implementing best practices such as:

- Standardization

- Regular updates

- Version control

- Collaboration

- Staff training

You can really solidify the BOM’s role in driving efficiency and cutting down on errors. Plus, leveraging technology with specialized software and cloud-based solutions can streamline BOM management and enhance communication among teams.

In conclusion, the importance of mastering the BOM management process is hard to overstate. By focusing on accurate documentation, embracing best practices, and taking advantage of technological advancements, you can not only boost your efficiency but also ensure you’re delivering high-quality products. So, why not take these proactive steps? They could be your ticket to securing a competitive edge in the manufacturing landscape.

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a detailed list of all the raw materials, parts, sub-assemblies, and assemblies needed to create a finished product.

What are the core components of a BOM?

The core components of a BOM include Part Number, Description, Quantity, Unit of Measure, and Cost.

What is the purpose of the Part Number in a BOM?

The Part Number serves as a unique identifier for each component, similar to a name tag.

What information does the Description provide in a BOM?

The Description offers a brief explanation of what the part or material is.

Why is Quantity important in a BOM?

Quantity indicates how many of each element are needed for production.

What does Unit of Measure refer to in a BOM?

Unit of Measure specifies the measurement unit for each element, such as pieces or kilograms.

How does Cost factor into a BOM?

Cost reflects the price associated with each element, which is useful for budgeting and cost analysis.

How should a BOM be structured for clarity?

A BOM should be structured hierarchically, with the finished product at the top and sub-assemblies branching below, enhancing clarity and organization for teams.