Overview

Have you ever wondered how businesses keep track of all the materials they need for manufacturing? Well, a Master Bill of Materials (BOM) is the secret sauce! It’s not just a list; it’s a comprehensive guide that outlines every necessary material and component.

Think about it: a well-structured BOM can really boost operational efficiency. It helps reduce costs and minimize errors throughout the production process. Imagine streamlining your inventory management practices—sounds great, right?

So, if you want to enhance your inventory management, consider diving into the world of BOMs. They’re essential for keeping everything organized and running smoothly. Why not take a closer look at how you can implement one in your own operations? You might just find it’s the game-changer you’ve been looking for!

Introduction

Think of the Bill of Materials (BOM) as the backbone of manufacturing—it's like a detailed recipe that lists every component and material needed to whip up a product. But it’s not just about keeping things organized; a well-structured BOM can really boost your operational efficiency, cut costs, and make inventory management a breeze. Yet, there’s a catch: keeping it accurate and adapting to the fast-changing manufacturing world can be quite the challenge. So, how can manufacturers tap into the power of BOMs to not only tackle their current needs but also stay ahead of future demands?

Define the Bill of Materials (BOM) and Its Importance

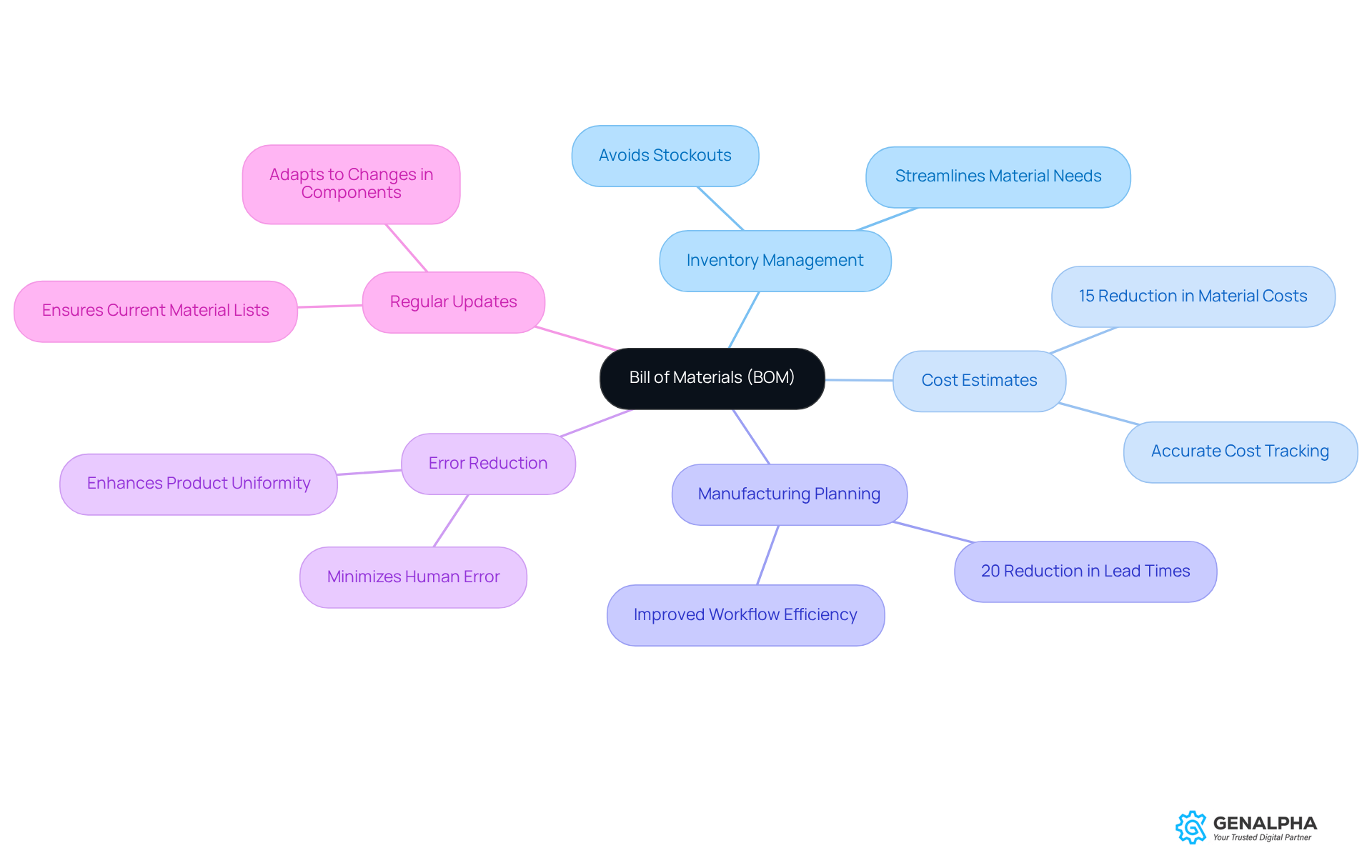

Have you ever thought about how crucial a Bill of Materials (BOM) is when it comes to manufacturing? It's like the ultimate recipe that lays out all the raw materials, components, and instructions you need to create a product. Imagine having a comprehensive blueprint that ensures every part is on hand—this is what a BOM does, and it can really boost operational efficiency.

The impact of a BOM is significant! It makes bill of materials inventory management a breeze, helps you nail down accurate cost estimates, and enhances your manufacturing planning. By providing a clear structure, a BOM can help avoid those pesky stockouts and overstock scenarios that can lead to costly delays. For instance, did you know that having a well-defined BOM can cut lead times by up to 20%? That's according to industry studies! Plus, it enhances the accuracy of material requirements planning (MRP) processes.

But wait, there's more! A BOM also reduces the likelihood of human error during procurement, assembly, and production, which means a smoother workflow overall. As Katlego Thulare puts it, "A bill of materials is like your recipe and shopping list to manufacture your final product." This analogy really drives home the point that a BOM and ensures you have all the necessary resources, including alternatives for flexibility.

It's also super important to keep your BOM updated as materials and components change over time. For example, one leading manufacturer saw a 15% reduction in material costs and improved customer satisfaction just by implementing a detailed BOM. So, if you want to drive operational success, effective bill of materials inventory management is the way to go! What are you waiting for? Let's get started on streamlining your processes!

Explore Different Types of BOMs and Their Applications

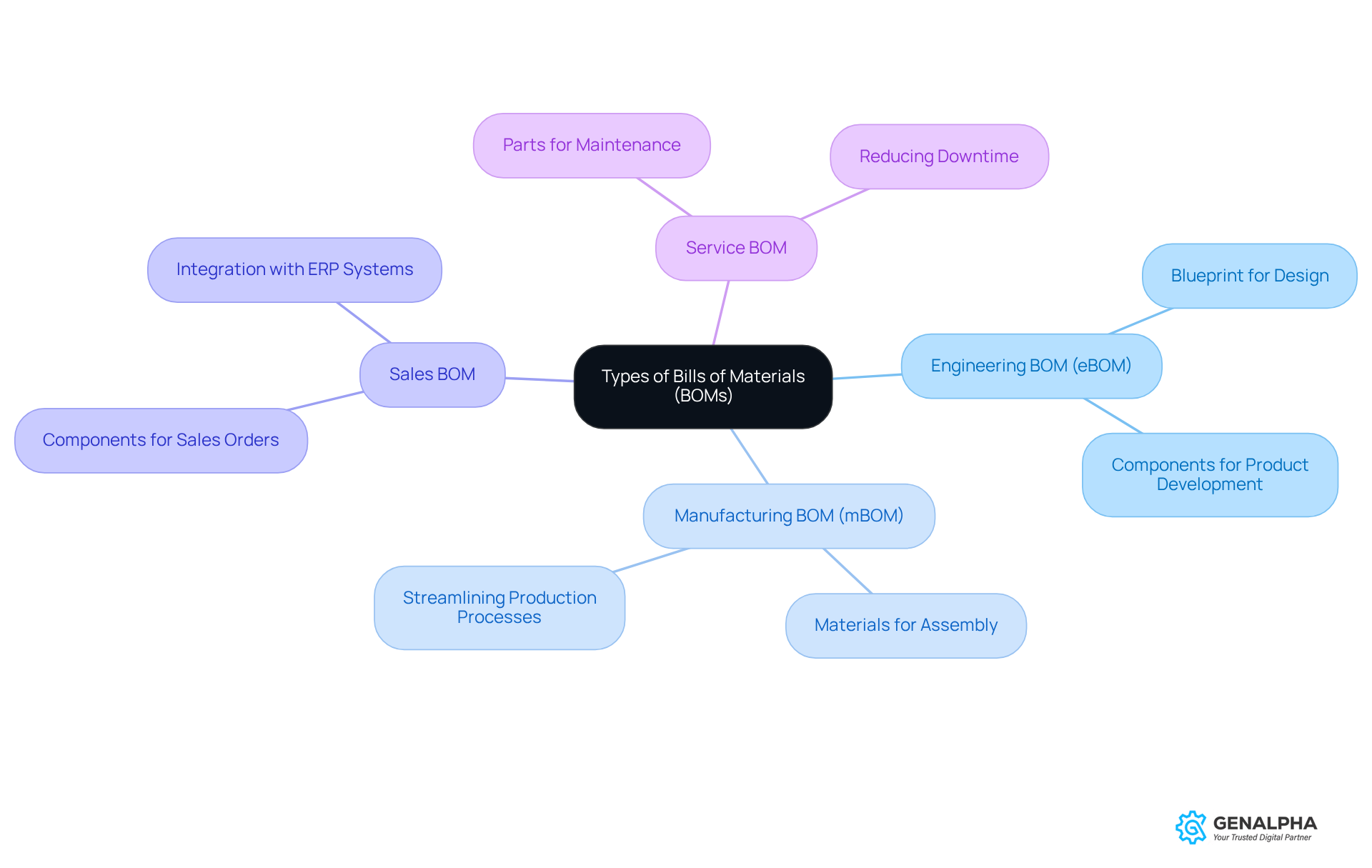

Let’s talk about the different types of Bills of Materials (BOMs) and how they play a vital role in the manufacturing process. Each type has its own unique function, helping to boost efficiency and maintain effective bill of materials inventory management.

- Engineering BOM (eBOM): Think of this as your blueprint during the design phase. It outlines all the components needed for product development, ensuring that everything aligns with design specifications. This can really speed up product development! As they say, "Accurate BOMs are critical for manufacturing success because they provide a solid foundation for the entire manufacturing cycle."

- Manufacturing BOM (mBOM): Now, this one is all about the manufacturing process itself. The mBOM lists the materials needed for assembly, making sure that all essential components are on hand. This helps to streamline processes and cut down on delays. After all, no one wants production hiccups or costly mistakes, right?

- Sales BOM: This BOM is crafted for sales teams. It details the components required for specific customer orders, allowing for accurate quotes and fulfilling requests seamlessly. Plus, when BOMs integrate with ERP systems, sales teams can access real-time information—how cool is that?

- Service BOM: Last but not least, we have the service BOM. This one includes all the , ensuring that service teams are always prepared. A proactive approach here can really reduce downtime and boost service efficiency. And remember, training personnel involved in BOM oversight is key to keeping everything accurate and effective.

By getting to know these different BOM types, manufacturers can fine-tune their processes to enhance efficiency, minimize errors, and improve their bill of materials inventory management strategies. Excitingly, the global BOM software market is projected to grow from USD 8.20 Billion in 2023 to USD 25.69 Billion by 2033, at a CAGR of 12.10%. This growth underscores the increasing importance of precise bills of materials in aligning manufacturing with customer needs and ensuring everyone has access to the latest information. So, how are you planning to leverage BOMs in your operations?

Implement Best Practices for Effective BOM Management

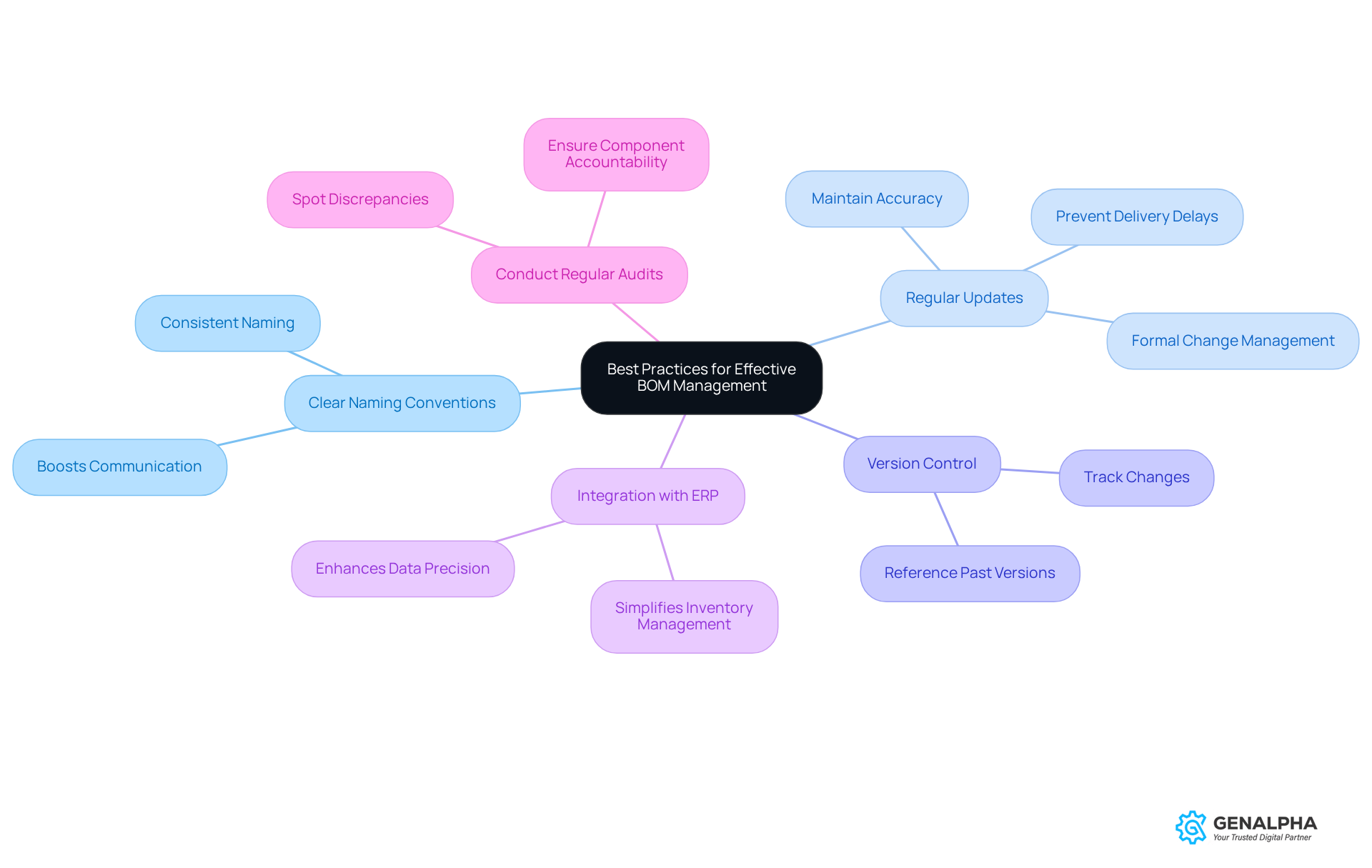

Managing Bills of Materials (BOMs) can feel overwhelming, but it doesn't have to be! Here are some best practices that can really make a difference:

- Establish Clear Naming Conventions: Think about how confusing it can be when names don’t match up. By using consistent naming conventions, everyone on the team can easily identify components. This not only boosts communication but also cuts down on mistakes in manufacturing.

- Regularly Update Bills of Materials: Have you ever experienced a mix-up because the BOM wasn’t up to date? Setting up a formal change management process is key to keeping your BOM aligned with design and manufacturing changes. Regular updates help maintain accuracy and prevent those costly miscommunications. Did you know that research shows one in three orders faces significant delivery delays? That’s a clear sign of the need for precise BOMs!

- Utilize : Ever wish you could track changes easily? Keeping a history of changes through version control is essential for tracking revisions and ensuring production accuracy. It allows your team to reference past versions and see how the BOM has evolved over time.

- [Integrate with ERP Systems](https://weje.io/blog/bill-of-materials): Imagine how much easier it would be if your BOM was linked with your ERP systems! This connection greatly enhances data precision and simplifies inventory management. A systematic approach to ERP maintenance can directly affect future costs, making this integration essential for effective bill of materials inventory management.

- Conduct Regular Audits: Have you checked your BOM lately? Regular audits are necessary to spot discrepancies and ensure all components are accounted for. These reviews help maintain the integrity of your BOM and support efficient production planning, ultimately leading to better operational efficiency.

By embracing these practices, you can significantly reduce errors, enhance operational efficiency, and improve overall inventory control. So, why not start implementing them today?

Leverage Technology for Streamlined BOM Management

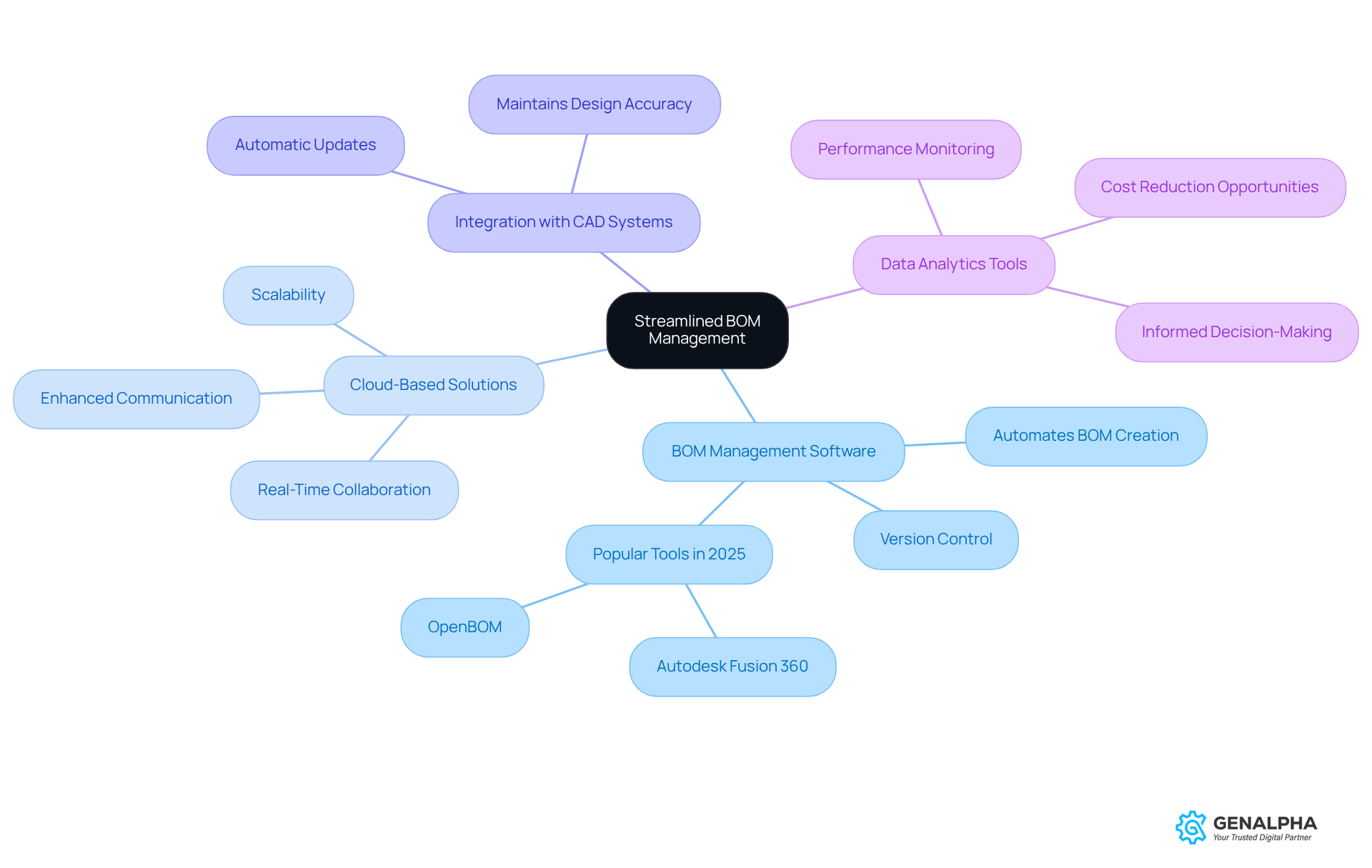

Harnessing technology can really boost our bill of materials inventory management processes. Let’s dive into some key strategies to consider:

- BOM Management Software: Think about implementing specialized software that automates the creation, updating, and version control of BOMs. This can seriously cut down on manual errors and improve accuracy. Popular BOM software tools in 2025, like Autodesk Fusion 360 and OpenBOM, are specifically designed to meet the needs of manufacturers.

- Cloud-Based Solutions: How about leveraging cloud technology? It can facilitate real-time collaboration among teams, ensuring that everyone has immediate access to the most current BOM information. This not only enhances communication but also . The BOM software market is expected to grow significantly in 2025, driven by increased digital adoption and the need to manage product complexity, highlighting the advantages of cloud-based solutions.

- Integration with CAD Systems: By combining BOM oversight with Computer-Aided Design (CAD) software, organizations can ensure automatic updates whenever design changes occur. This helps maintain accuracy and reduces the risk of discrepancies, which is crucial for keeping BOMs aligned with the latest design specifications.

- Data Analytics Tools: Don’t forget about utilizing analytics to monitor BOM performance! This can help identify opportunities for cost reduction and efficiency improvements. A data-driven approach enables organizations to make informed decisions that enhance operational effectiveness. As Bill Gates points out, effectively using IT can foster growth and efficiency, making analytics a vital tool in BOM oversight.

Adopting these technologies can lead to streamlined bill of materials inventory management processes, which results in improved inventory accuracy and overall operational efficiency. In 2025, the market for cloud-based BOM solutions is projected to grow significantly, driven by the increasing demand for real-time collaboration and data accessibility across manufacturing teams. So, are you ready to take your BOM management to the next level?

Conclusion

Mastering the Bill of Materials (BOM) is crucial for effective inventory management and operational success in manufacturing. Think of a BOM as your detailed guide to all the materials and components you need. When it's well-structured, it boosts efficiency, cuts down on errors, and streamlines production processes. This foundational document not only helps with accurate cost estimation but also plays a key role in maintaining optimal inventory levels. In the end, that means happier customers and lower operational costs.

Throughout this article, we’ve highlighted the importance of various types of BOMs—like Engineering, Manufacturing, Sales, and Service BOMs. Each one serves a unique purpose that contributes to overall efficiency. We’ve also discussed best practices for BOM management, such as:

- Establishing clear naming conventions

- Keeping regular updates

- Integrating with ERP systems

These strategies are essential for minimizing errors and enhancing production planning. Plus, using technology like specialized software and cloud-based solutions can really boost BOM oversight and collaboration among teams.

So, let’s wrap this up! The significance of a well-managed BOM is huge in today’s competitive manufacturing landscape. By adopting best practices and embracing technological advancements, organizations can optimize their BOM management processes. This leads to greater operational efficiency and a quicker response to market demands. With the BOM software market on the rise, now’s the perfect time to invest in effective BOM strategies that will drive success and innovation in your manufacturing operations. Are you ready to take that step?

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a comprehensive list that outlines all the raw materials, components, and instructions needed to create a product, functioning as a detailed recipe for manufacturing.

Why is a BOM important in manufacturing?

A BOM is crucial because it enhances operational efficiency, simplifies inventory management, provides accurate cost estimates, and improves manufacturing planning by ensuring that all necessary parts are available.

How does a BOM impact lead times?

A well-defined BOM can cut lead times by up to 20%, according to industry studies, by helping to avoid stockouts and overstock scenarios that can cause delays.

What role does a BOM play in material requirements planning (MRP)?

A BOM enhances the accuracy of material requirements planning (MRP) processes by providing a clear structure for material needs.

How does a BOM reduce human error?

A BOM reduces the likelihood of human error during procurement, assembly, and production, leading to a smoother workflow overall.

Why is it important to keep a BOM updated?

It is important to keep a BOM updated as materials and components change over time to maintain efficiency and accuracy in manufacturing processes.

What benefits can a detailed BOM provide to a manufacturer?

Implementing a detailed BOM can lead to a reduction in material costs (up to 15% in some cases) and improved customer satisfaction.