Overview

Have you ever thought about how order management software can transform a manufacturer's day-to-day operations? Well, this article dives into some essential software solutions that can really boost efficiency. It highlights the need to integrate these tools with your current systems. Why? Because they can streamline key processes like:

- Inventory management

- Order fulfillment

- Customer engagement

This ultimately leads to better productivity and happier customers.

Imagine a world where everything runs smoothly. When you have the right software in place, those tedious tasks become a breeze. You’ll not only save time but also enhance the overall experience for your customers. So, how do you get started? It’s all about finding the right fit for your business needs.

In conclusion, integrating effective order management solutions is a game changer. It’s time to take action and explore what’s out there. Your operational efficiency—and your customers—will thank you!

Introduction

In today’s fast-paced manufacturing world, managing orders efficiently is crucial for success. Order management software solutions are more than just tools; they’re a strategic advantage that can boost operational efficiency and keep customers happy. With the mounting pressure on manufacturers to streamline processes and adapt to shifting market demands, you might wonder: which software solutions really stand out in delivering these benefits?

This article dives into seven essential order management software solutions that can transform your manufacturing operations. We’ll explore their unique features and the value they bring to the table. So, let’s get started and find out how these solutions can make a difference for you!

GenAlpha Technologies: Streamline Operations with Advanced Order Management Software

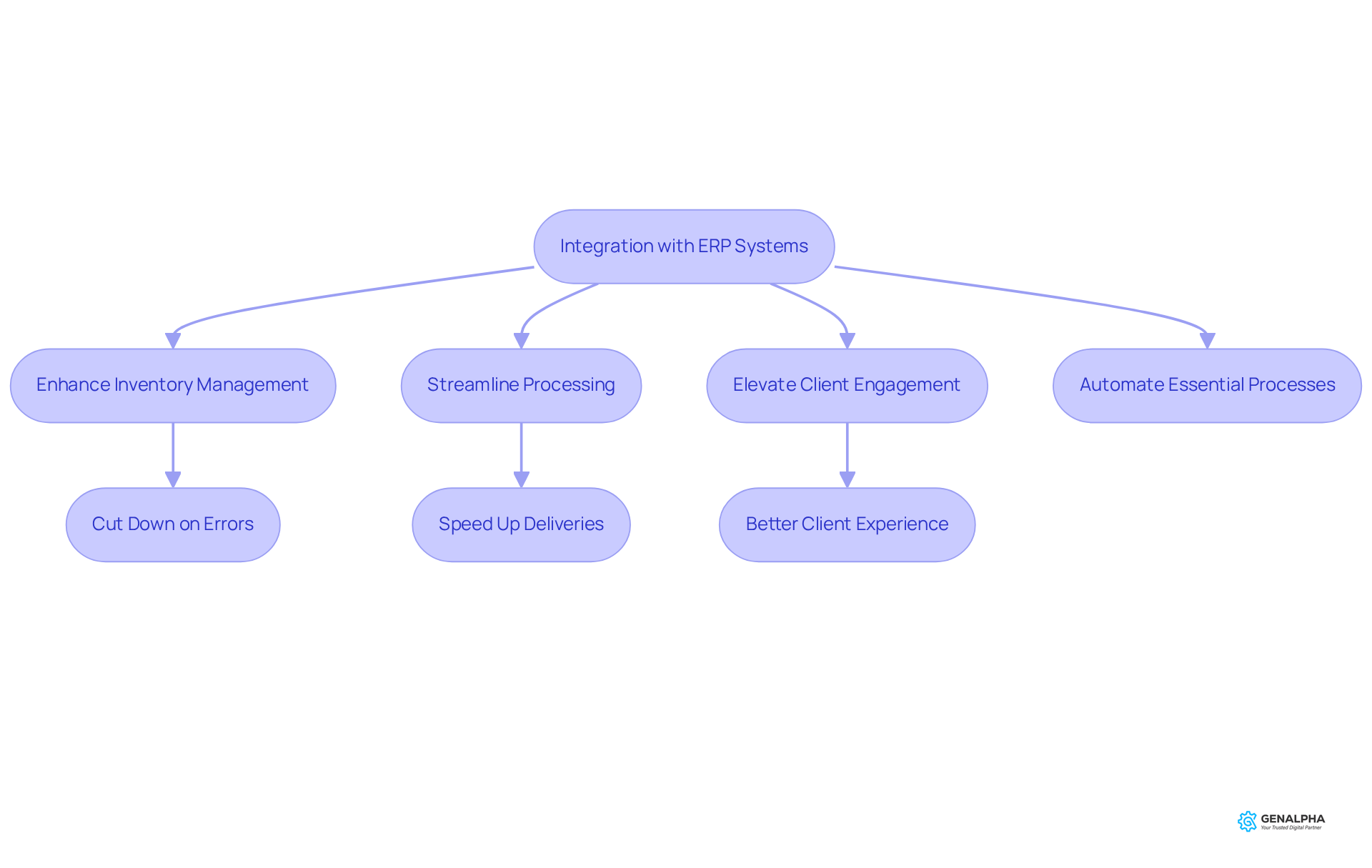

Have you ever wondered how manufacturers can streamline their operations? GenAlpha Technologies has the answer with its sophisticated software that seamlessly integrates with existing ERP systems. This innovative solution significantly boosts operational efficiency for manufacturers. It's designed to enhance inventory management, streamline processing, and elevate client engagement. By automating essential processes, producers can cut down on errors, speed up deliveries, and ultimately create a better experience for their clients.

Take the Equip360 platform, for example. It empowers businesses to manage their online sales effectively while ensuring that client needs are met promptly and accurately. As the demand for efficient procurement solutions grows, merging such software with ERP systems becomes increasingly crucial. This integration helps manufacturers and evolving client expectations.

Did you know that the market for order management software is projected to reach USD 6.1 billion by 2030, growing at a CAGR of 13.2%? That's a clear indication of how vital order management software is becoming. Plus, GenAlpha's strategic partnership with Optessa showcases its commitment to enhancing operational efficiency, addressing challenges like stock management and customer service.

As Kris Harrington, CEO of GenAlpha Technologies, puts it, 'We do this with an exceptional customer-facing solution and combine it with our years of manufacturing experience.' So, if you're looking to optimize your manufacturing processes, why not explore how these solutions can work for you?

NetSuite Order Management: Optimize Multichannel Sales and Fulfillment

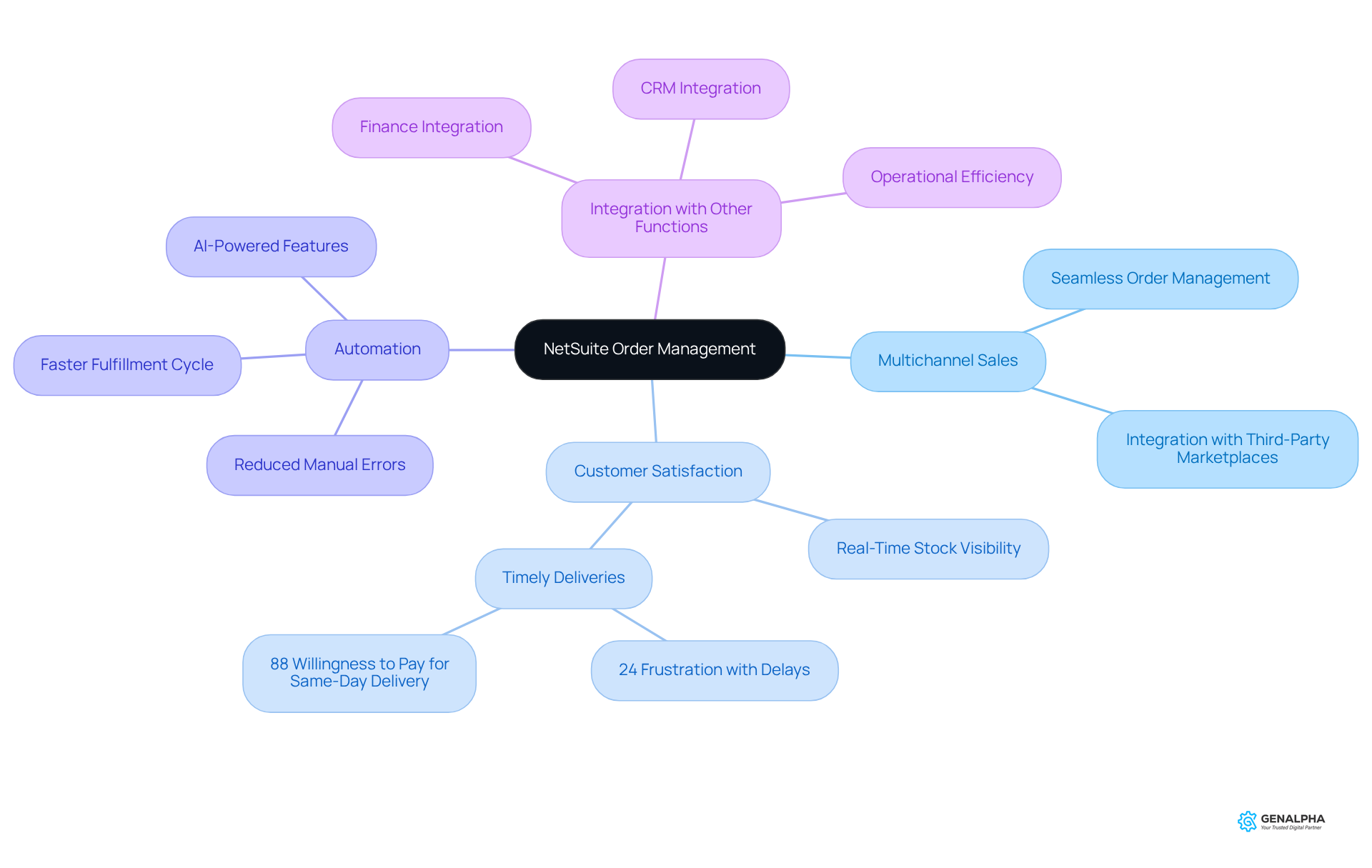

NetSuite order management software is a game-changer for manufacturers looking to simplify their multichannel sales and fulfillment processes. Imagine being able to manage orders seamlessly across online platforms, physical stores, and third-party marketplaces—sounds great, right? With real-time stock visibility, businesses can quickly respond to customer demands, ensuring that deliveries are prompt and customer satisfaction remains high. Did you know that 24% of consumers get frustrated with out-of-stock products and delays? This really highlights how crucial efficient inventory control is!

But it doesn’t stop there. Using order management software to not only cuts down on manual errors but also speeds up the fulfillment cycle, which is essential in today’s fast-paced market. Plus, when NetSuite integrates smoothly with other business functions like finance and CRM, it boosts overall operational efficiency. This means manufacturers can optimize their resources and enhance service delivery.

As Evan Goldberg, the founder and executive vice president of Oracle NetSuite, puts it, "With new AI-powered advisor and assistant features and a broad range of other updates, we continue to enable our customers." This commitment to innovation positions NetSuite as a leader in the fulfillment oversight sector, especially with the global market for fulfillment systems projected to grow to USD 3.17 billion by 2025. So, why not consider how NetSuite can help your business thrive?

Brightly: Enhance Maintenance Efficiency with Work Order Management Solutions

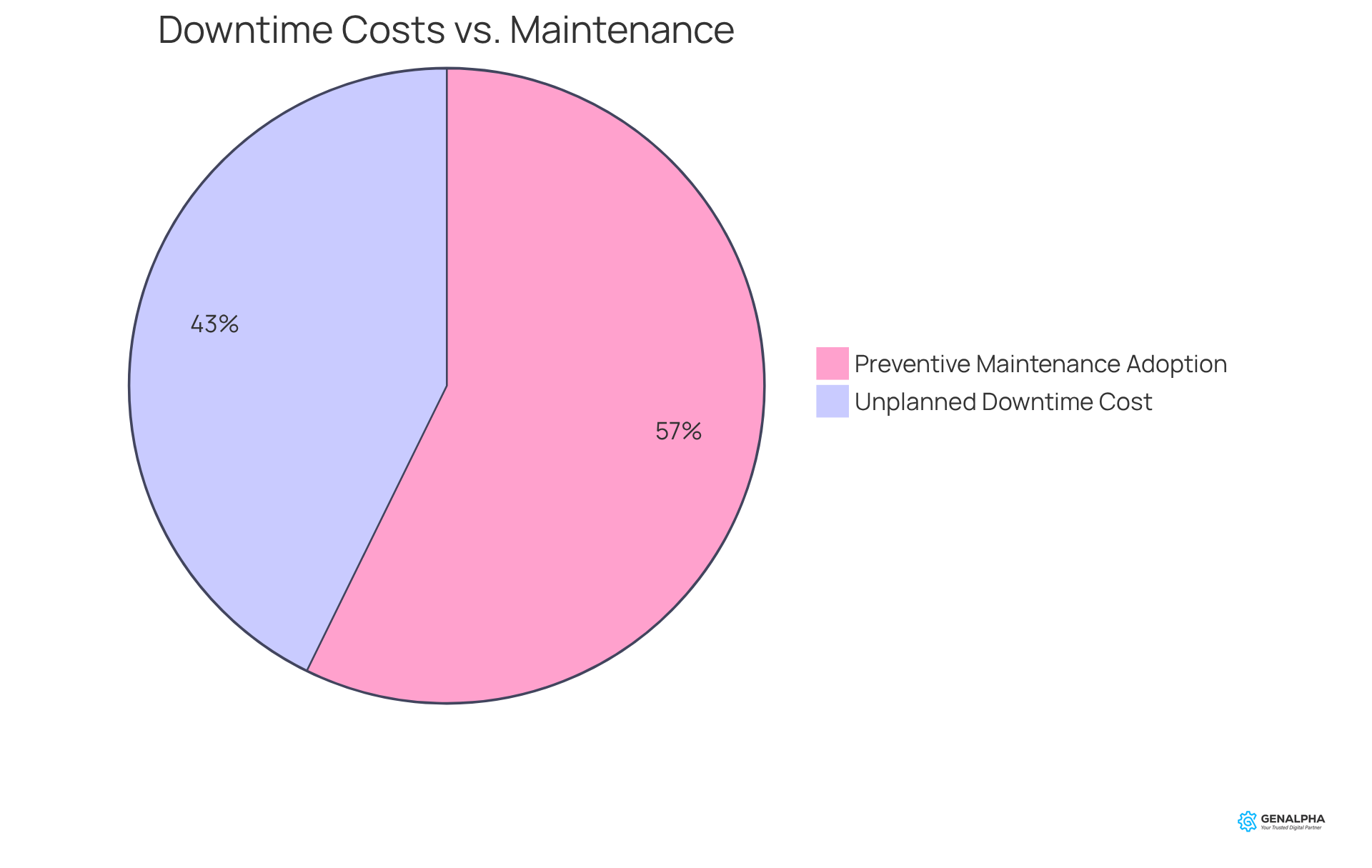

Have you ever thought about how much downtime can cost a manufacturer? Brightly offers work task coordination solutions that can really make a difference in maintenance efficiency. By streamlining how work requests are created, monitored, and fulfilled, this platform helps reduce equipment downtime and improve service delivery. In the manufacturing world, where delays can lead to significant financial losses, that’s crucial. Did you know that unplanned downtimes can cost industrial manufacturers around $50 billion each year? That’s between 5% and 20% of their productive capacity! In fact, the automotive industry alone faces costs averaging $22,000 per minute.

But here’s where Brightly shines. Its analytics capabilities empower organizations to spot trends and optimize maintenance schedules. This proactive approach can cut machine downtime by an impressive 30-50%! It’s no wonder that 67% of manufacturing firms are turning to preventive maintenance as their go-to strategy for avoiding downtime in 2024. This highlights just how important work request oversight is in today’s landscape.

This data-driven strategy not only boosts operational efficiency but also helps with compliance to safety regulations. Ultimately, it drives across manufacturing operations. As Deloitte points out, effective work request oversight can elevate overall equipment effectiveness (OEE) to over 90%. That’s a game-changer in modern manufacturing!

So, how can manufacturers get on board with these efficient work request handling techniques? It starts with assessing existing systems and considering the addition of more proactive maintenance methods. Are you ready to take your maintenance strategy to the next level?

Investopedia: Improve Inventory Control for Better Order Management

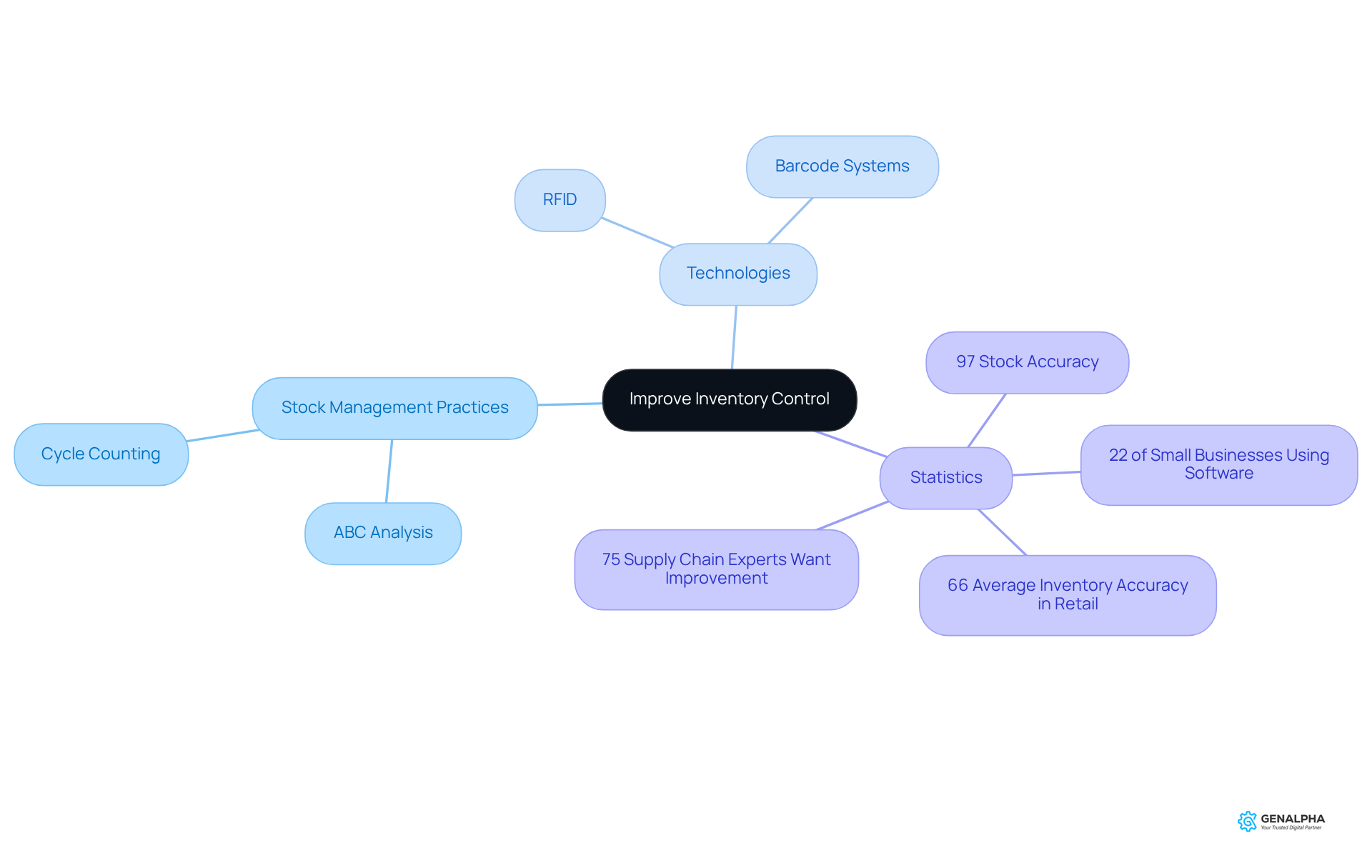

Efficient stock oversight is crucial for producers who want to streamline their order management software processes. By embracing solid stock management practices, businesses can ensure that products are readily available, which significantly cuts down on stockouts and helps avoid surplus goods that can put a strain on cash flow.

Have you heard about methods like ABC analysis? It classifies stock based on importance, while cycle counting involves regular checks of stock levels. These strategies are key to maintaining optimal stock quantities. Not only do they improve order fulfillment with order management software, but they also enhance customer satisfaction.

Additionally, incorporating advanced technologies like RFID and barcode systems can boost stock accuracy to an impressive 97%. This means fewer human errors—something that plagues nearly 43% of warehouses. As producers increasingly recognize the value of effective stock control, investing in order management software becomes essential for achieving operational excellence and maintaining a competitive edge in the market.

Colleen, a marketing specialist at Meteor Space, puts it perfectly: "With our expert team on your side, you’ll never worry about stockouts or late deliveries." Isn’t that reassuring? It’s also worth noting that 75% of supply chain experts express a desire to improve their stock control practices, highlighting the ongoing need for efficient solutions. Yet, despite this demand, only 22% of small businesses currently use , which points to significant hurdles in adopting these vital tools.

What about your business? Are you ready to take the next step in stock management?

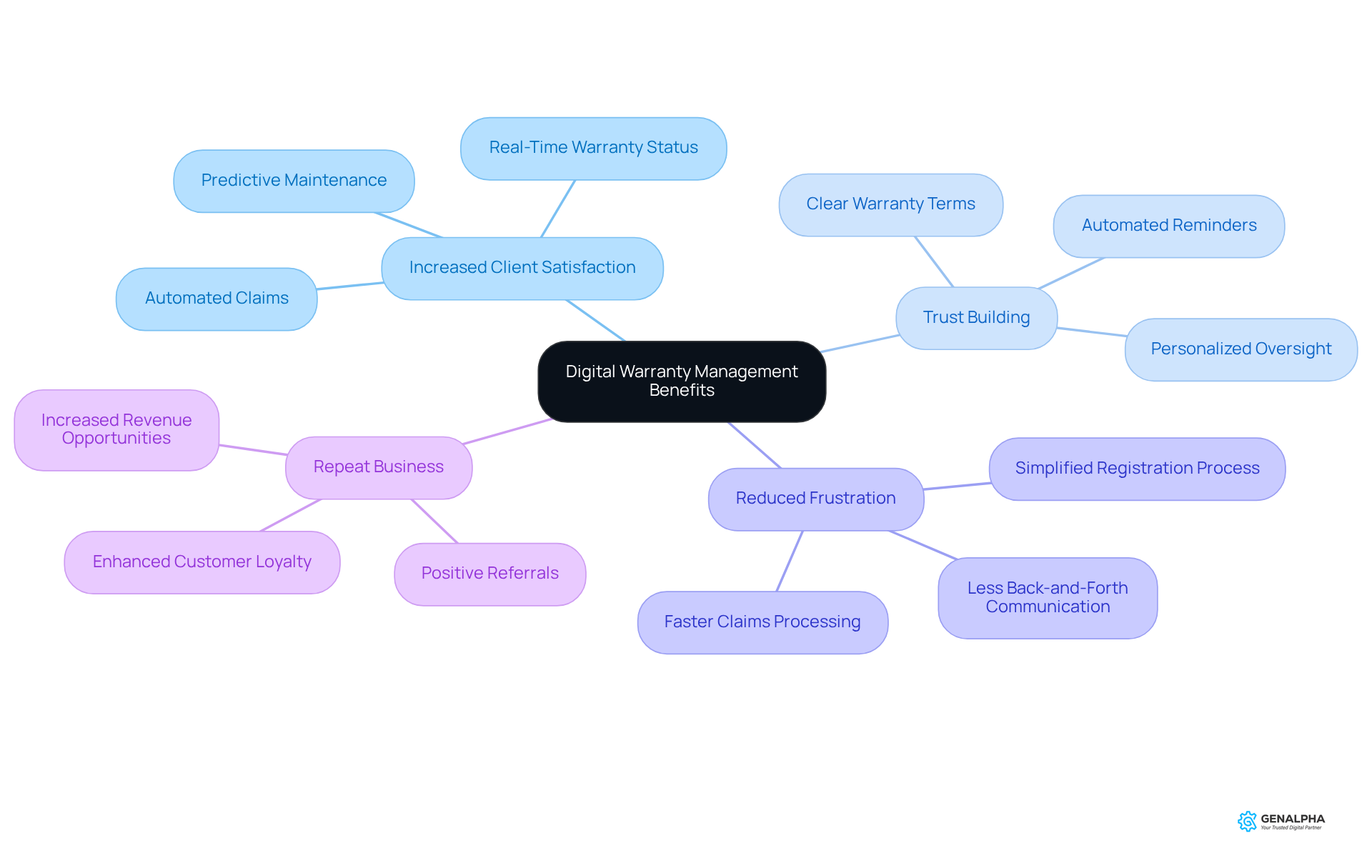

GenAlpha Technologies: Elevate Customer Satisfaction with Digital Warranty Management

At GenAlpha Technologies, we’re all about making digital warranty management a breeze! Imagine a world where warranty claims are automated and consumers can easily access their warranty info. Sounds great, right? This not only lightens the load for your staff but also builds that all-important trust with your clients. After all, a well-organized warranty tracking system can really cut down on frustration and boost client confidence.

Did you know that efficient warranty tracking can enhance client satisfaction by 5-10%? In today’s competitive market, having a smooth warranty process can really set your brand apart. As Vicente González-Prida puts it, 'Personalized warranty oversight enhances client satisfaction by offering a proactive, customized service experience.' So, what does this mean for your business? Well, it likely translates to more repeat business and positive referrals.

If you haven’t already, it’s time to think about implementing automated warranty oversight systems. Trust us, the benefits are worth it, and your will thank you!

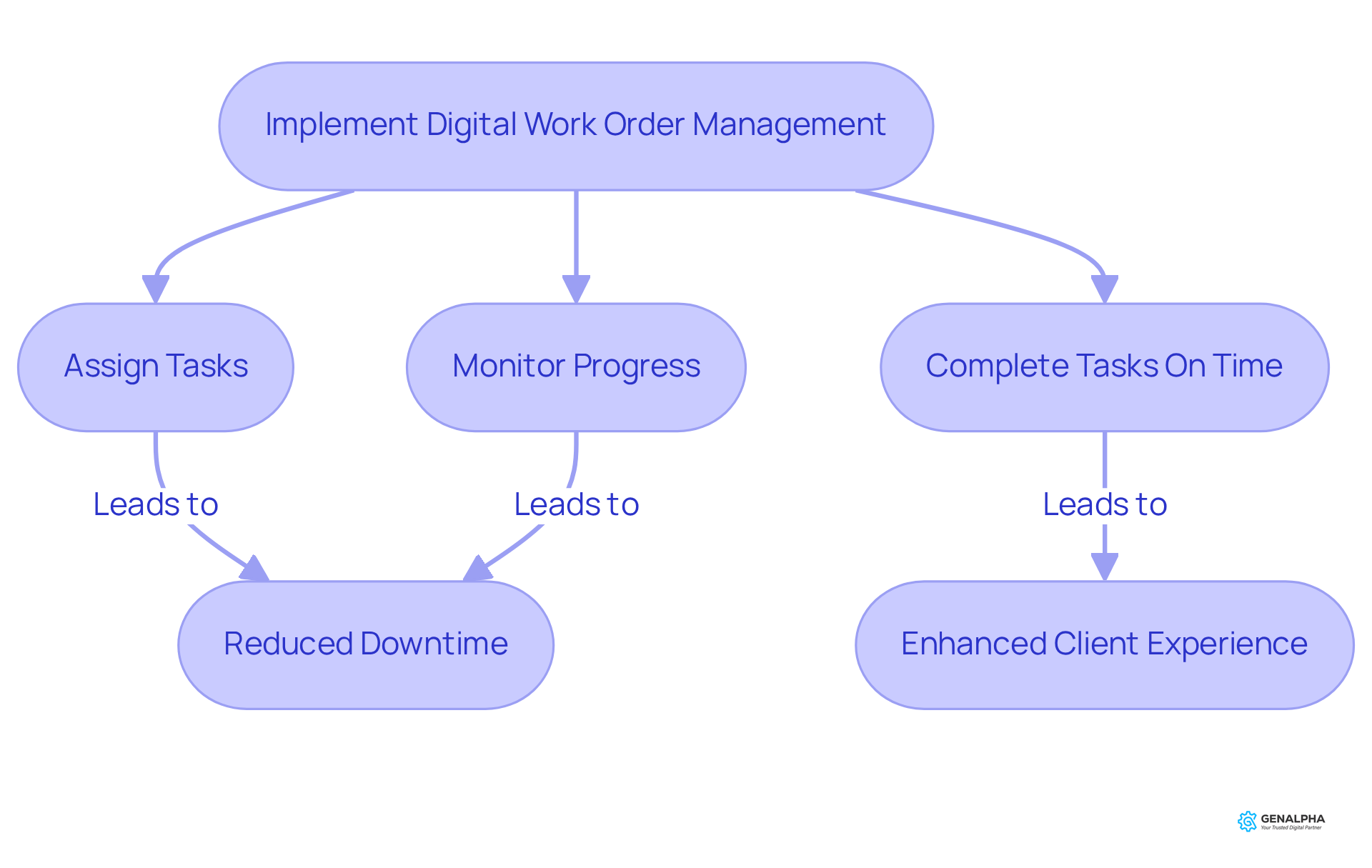

Digital Work Order Management: Minimize Downtime and Enhance Service Delivery

Have you ever thought about how digital work management systems can really shake things up for manufacturers? They can drastically cut down on downtime and boost service delivery. By implementing order management software for a digitized work order process, organizations can quickly assign tasks, monitor progress, and ensure everything is completed on time. This streamlined method not only ramps up but also enhances the client experience, ensuring that products and services arrive right when they’re expected.

Plus, these systems often come packed with performance tracking features. Think about auto-generating service tickets and organizing tasks right in the app! This means there’s always room for improvement. For instance, companies in the oil and gas sector that have embraced predictive maintenance strategies have seen a whopping 20% average drop in downtime, which translates to better productivity and happier clients.

C.D. Jackson once said, 'Great ideas need landing gear as well as wings,' and he couldn’t be more right. Efficient task organization using order management software is key to cutting delays and boosting service delivery times. In the end, this creates a more responsive and agile manufacturing environment where teamwork and collaboration are vital for success. So, how can your organization leverage these tools to enhance efficiency and client satisfaction?

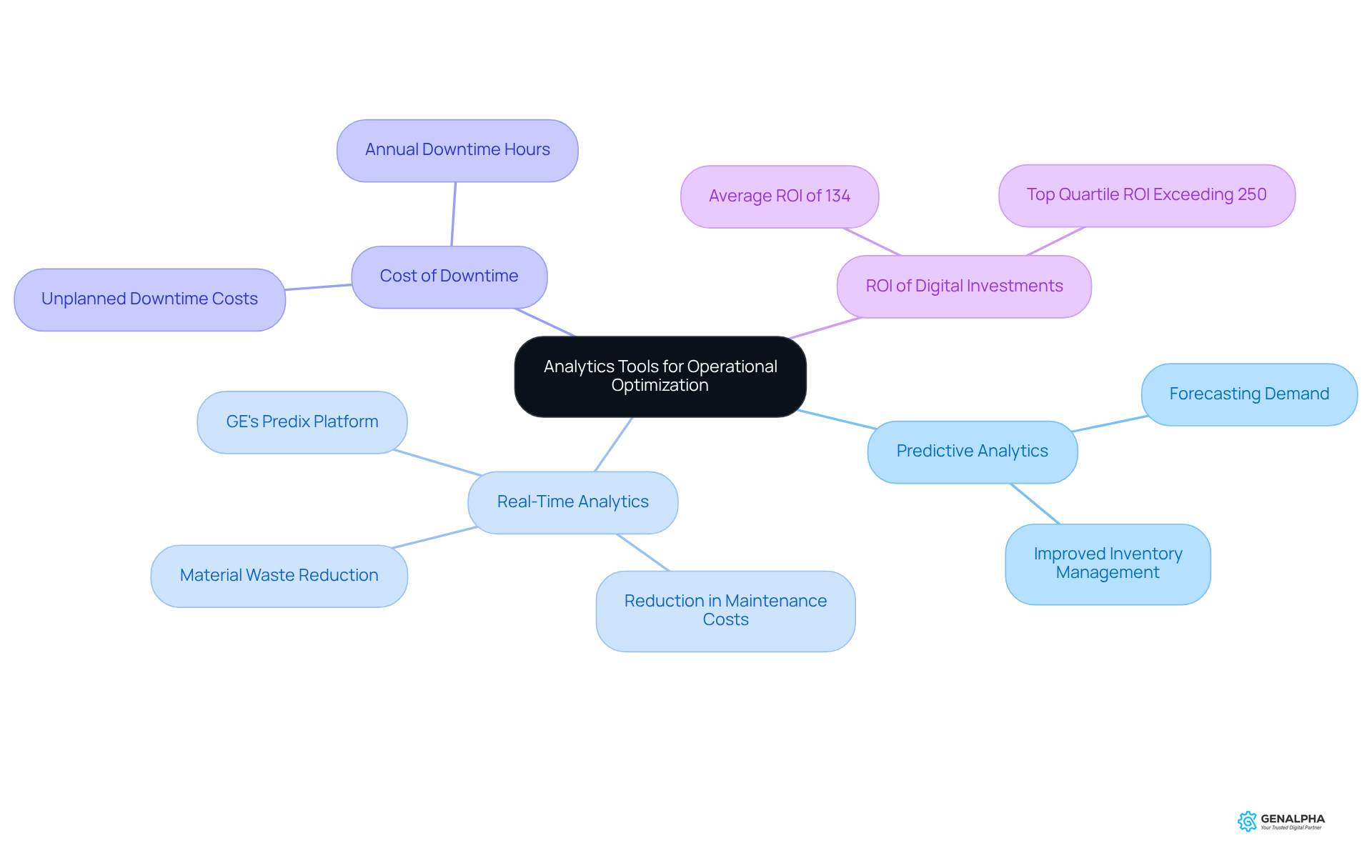

Analytics Tools: Unlock Data-Driven Insights for Operational Optimization

Analytics tools are absolutely vital for unlocking those data-driven insights that can really optimize operations in manufacturing. Have you ever thought about how examining purchase trends, stock levels, and consumer behavior can lead to practical insights that significantly improve processing procedures? For instance, predictive analytics allows businesses to forecast demand accurately. This means they can proactively adjust inventory levels and enhance service delivery.

Now, consider this: unanticipated downtime costs manufacturers around $260,000 every hour! With the average manufacturer facing about 800 hours of downtime each year, it’s clear that for handling orders is a must. Plus, organizations that tap into advanced analytics report an impressive average ROI of 134% on their digital investments. The top quartile even sees returns exceeding 250%! This just goes to show the tangible benefits of leveraging data-driven insights.

Real-time analytics don’t just streamline operations; they also empower manufacturers to respond swiftly to market changes. Take GE’s Predix platform, for example. It helps reduce maintenance costs by 10-25% and cuts down unplanned downtime by 5-20%. Ultimately, this leads to better customer satisfaction and operational efficiency. So, how are you planning to leverage analytics in your operations?

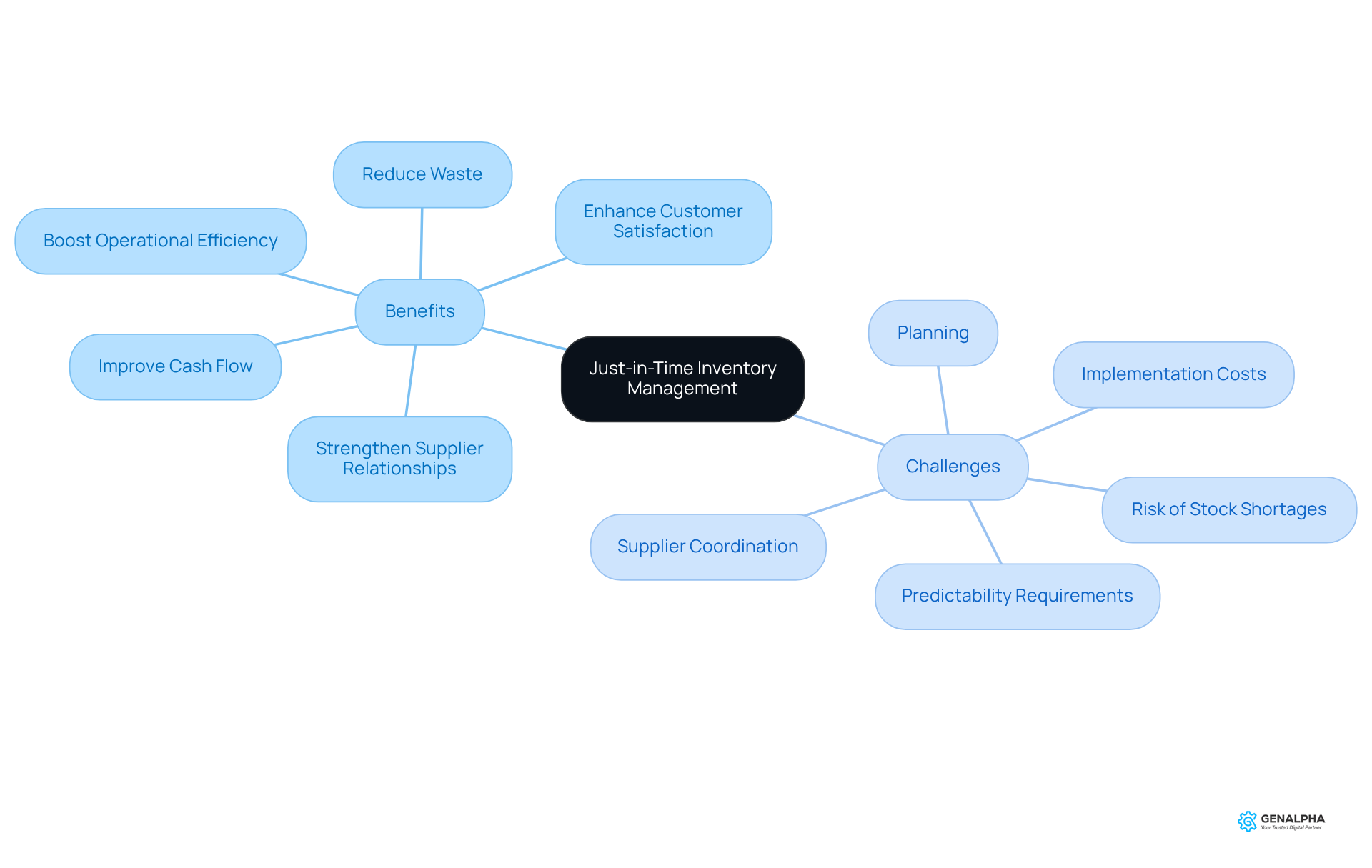

Just-in-Time Inventory Management: Reduce Waste and Improve Cash Flow

Have you ever thought about how manufacturers keep their operations running smoothly while minimizing waste? That’s where just-in-time (JIT) stock management comes into play! This smart strategy helps businesses by receiving goods only as they’re needed in the production process. Imagine cutting down on excess inventory and the costs that come with storing it—sounds great, right?

Not only does JIT boost operational efficiency, but it also allows producers to respond quickly to what clients want. This means happier customers and a more agile business. But here’s the catch: implementing JIT isn’t just a walk in the park. It takes careful planning and solid coordination with suppliers to make sure everything arrives right on time. So, are you ready to explore how JIT can transform your business?

Materials Requirement Planning: Align Production with Order Fulfillment

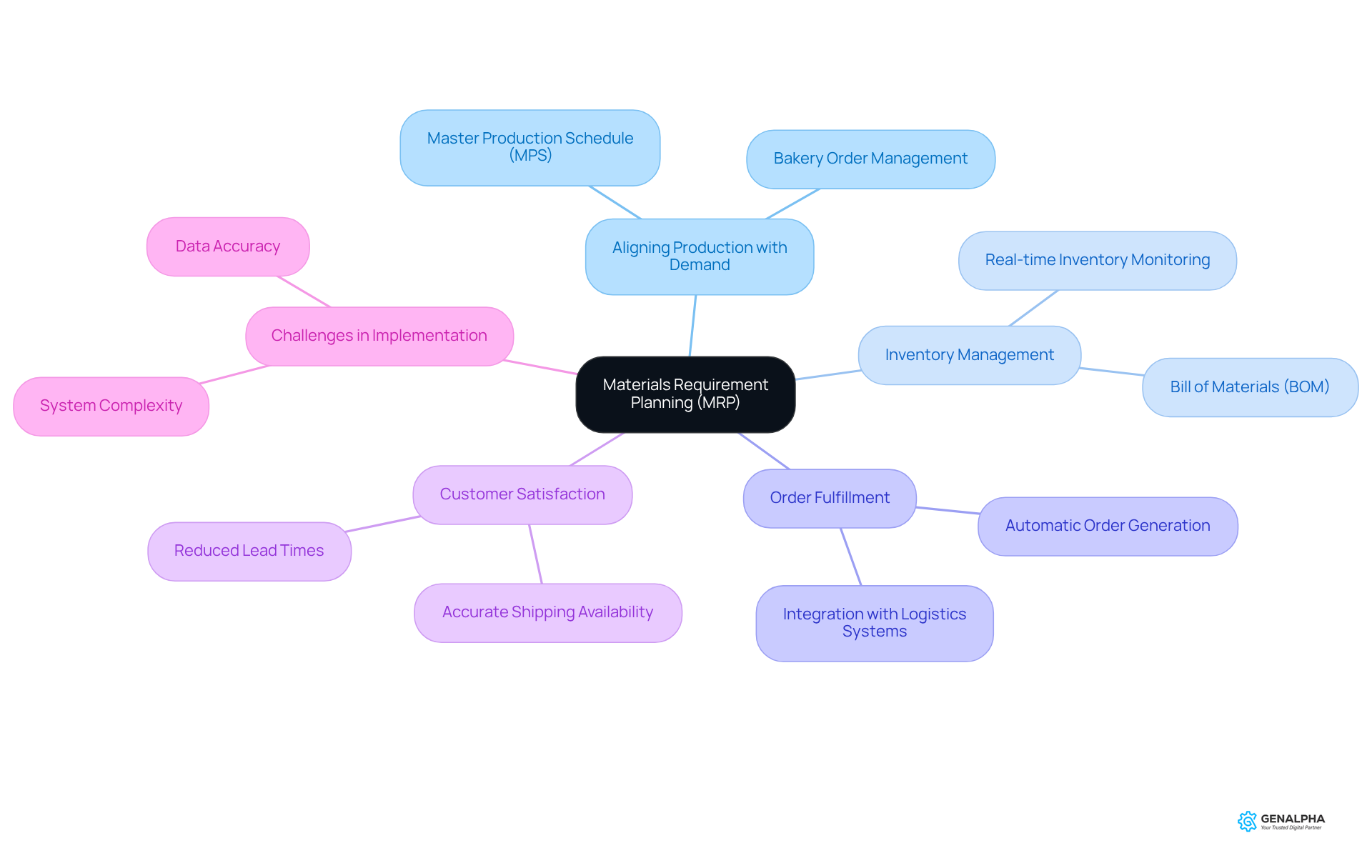

Have you ever wondered how manufacturers keep everything running smoothly? Well, that’s where materials requirement planning (MRP) comes in! It’s a crucial process that helps manufacturers align production with what customers actually want. By accurately predicting demand and planning production accordingly, businesses can ensure they have the right materials on hand to meet customer requests. This not only cuts down on lead times but also reduces the chances of running out of stock, which is a win for customer satisfaction!

MRP systems often work hand-in-hand with order management software, giving a complete view of inventory and production schedules. For example, imagine you’re running a bakery. With MRP, you can based on the orders you have, ensuring you never run out right before a big event. So, if you’re looking to enhance your production process and keep your customers happy, consider diving into MRP systems. They might just be the solution you’ve been searching for!

Economic Order Quantity: Optimize Order Sizes for Cost Efficiency

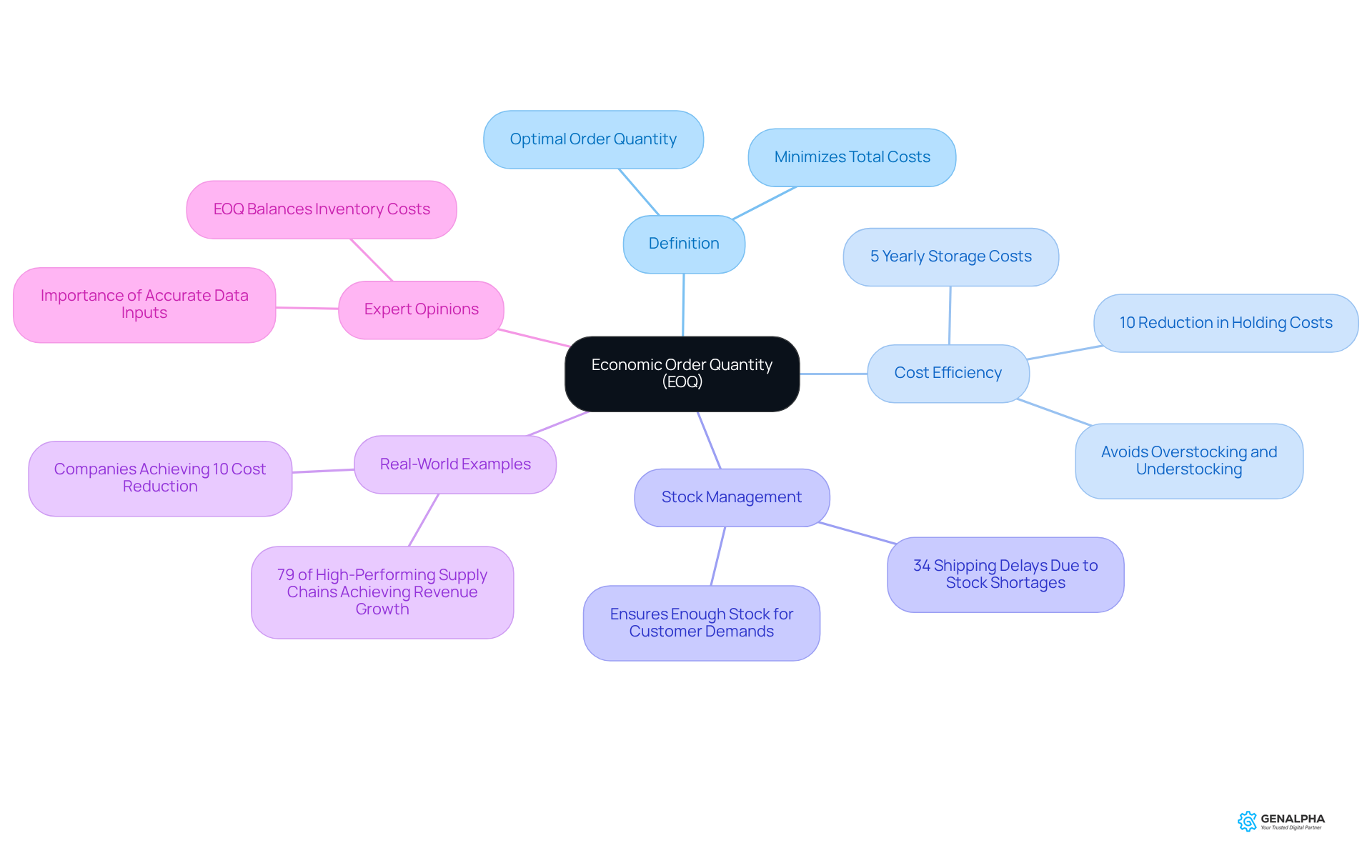

Economic Order Quantity (EOQ) is a key formula that helps you figure out the perfect purchase size to minimize total stock costs, including holding and purchasing expenses. By nailing down EOQ, manufacturers can significantly cut down on holding costs, which can often take a big bite out of overall stock expenses. Did you know that yearly storage costs typically hover around 5% of the stock value? This makes it super important to strike a balance between how often you buy and how much stock you keep on hand.

Using EOQ strategies doesn't just boost ; it also ensures that businesses have enough stock to meet customer demands without ending up with too much. This is especially vital in today’s fast-paced market. In fact, 34% of retail companies have reported shipping delays due to stock shortages. This really highlights how EOQ can help tackle those issues through better stock control.

Real-world examples show just how effective EOQ can be in enhancing operational efficiency. For instance, companies that have fine-tuned their stock control using EOQ have achieved an impressive 10% reduction in holding costs by addressing the challenges of overstocking and understocking. Plus, 79% of firms with top-notch supply chains have experienced revenue boosts that outpace their industry averages, largely thanks to smart stock management techniques, including EOQ.

Industry experts emphasize the importance of EOQ in managing inventory costs:

"EOQ balances these elements by discovering the most economical strategy for reducing total inventory costs — without sacrificing stock."

It’s worth noting that having accurate data inputs is crucial for effective EOQ calculations, as this helps steer clear of inflated order and carrying costs. This approach not only improves cash flow but also ramps up overall operational efficiency, making EOQ an essential tool for manufacturers looking to thrive in a competitive landscape. So, are you ready to embrace EOQ and transform your inventory management?

Conclusion

You know, the importance of effective order management software solutions for manufacturers really can’t be overstated. These tools are absolutely essential for streamlining operations, enhancing inventory control, and ultimately boosting customer satisfaction. Imagine integrating advanced systems like those offered by GenAlpha Technologies and NetSuite—suddenly, manufacturers can automate processes, reduce errors, and respond swiftly to market demands. This not only leads to a more efficient workflow but also provides a significant competitive edge in the ever-evolving manufacturing landscape.

Throughout this article, we’ve explored various software solutions, highlighting their unique features and benefits. For instance, GenAlpha focuses on operational efficiency and customer engagement, while NetSuite shines with its capabilities in multichannel sales and fulfillment. Each solution brings its own distinct advantages to the table. We also touched on strategies like just-in-time inventory management and economic order quantity calculations, which are critical for optimizing stock levels and minimizing costs. These insights really show how leveraging these tools and techniques can transform manufacturing processes and drive business success.

In a world where efficiency and customer satisfaction are paramount, it’s clear that manufacturers must embrace these order management solutions and strategies. The potential for improved operational performance and stronger client relationships is immense. So, as the market for order management software continues to grow, now is the perfect time for manufacturers to invest in these essential tools and position themselves for future success. What’s holding you back from making this leap?

Frequently Asked Questions

What is GenAlpha Technologies known for?

GenAlpha Technologies offers advanced order management software that integrates seamlessly with existing ERP systems to enhance operational efficiency for manufacturers.

How does GenAlpha's software improve manufacturing operations?

The software boosts inventory management, streamlines processing, and elevates client engagement by automating essential processes, reducing errors, speeding up deliveries, and improving client experiences.

What is the Equip360 platform?

Equip360 is a platform by GenAlpha that helps businesses manage their online sales effectively while ensuring prompt and accurate fulfillment of client needs.

What is the projected market growth for order management software?

The market for order management software is projected to reach USD 6.1 billion by 2030, growing at a CAGR of 13.2%.

What partnership does GenAlpha Technologies have to enhance operational efficiency?

GenAlpha has a strategic partnership with Optessa to address challenges like stock management and customer service.

What is the main focus of NetSuite order management software?

NetSuite order management software focuses on simplifying multichannel sales and fulfillment processes for manufacturers.

How does NetSuite improve inventory control?

NetSuite provides real-time stock visibility, allowing businesses to respond quickly to customer demands and ensuring prompt deliveries to enhance customer satisfaction.

What benefits does automating order processing with NetSuite provide?

Automating order processing reduces manual errors and speeds up the fulfillment cycle, which is essential for efficiency in a fast-paced market.

What is Brightly's role in manufacturing maintenance?

Brightly offers work task coordination solutions that streamline the creation, monitoring, and fulfillment of work requests to enhance maintenance efficiency and reduce equipment downtime.

How much can unplanned downtimes cost industrial manufacturers annually?

Unplanned downtimes can cost industrial manufacturers around $50 billion each year, which is between 5% and 20% of their productive capacity.

What impact can Brightly's analytics capabilities have on machine downtime?

Brightly's analytics can cut machine downtime by an impressive 30-50% by helping organizations spot trends and optimize maintenance schedules.

What is the significance of effective work request oversight in manufacturing?

Effective work request oversight can elevate overall equipment effectiveness (OEE) to over 90%, significantly improving performance across manufacturing operations.