Introduction

Maximizing equipment uptime is a big deal for manufacturers looking to boost productivity and profits. Did you know that unplanned downtime can cost around $50 billion a year? That’s a staggering amount! It really shows how important it is to have a smart approach to maintenance and operations.

In this article, we’ll explore four best practices that not only help reduce downtime but also empower your team, make the most of technology, and put proactive maintenance strategies into action. But let’s pause for a moment - what challenges do you think manufacturers face when trying to achieve optimal uptime? And how can they tackle these hurdles effectively?

Stick around as we dive into these insights!

Understand Equipment Uptime and Its Importance

When we talk about equipment uptime, we're really looking at how long our machinery is up and running during those planned production periods. And let me tell you, this is super important! High availability levels are crucial for manufacturers because they directly tie into increased productivity, lower operational costs, and happier customers.

For example, think about a manufacturing facility that hits 95% operational time. That place can churn out way more goods than one that's only at 80%, which means more profits in the bank. But here's the catch: chasing high availability percentages without the right context can backfire. It might lead to more scrap and rework, which can hurt overall performance. In fact, producers lose about $50 billion each year due to unexpected machinery downtime. That really highlights the financial impact of keeping equipment uptime high.

So, how can producers boost availability? Well, it starts with focusing on a few key elements, like having efficient service plans and reliable machinery.

- Setting up a proactive, data-driven maintenance program can cut unplanned downtime by 30-50% and even extend the lifespan of your machines by 20-40%.

- This strategy not only ramps up productivity but also enhances overall operational efficiency.

- As industry leaders often remind us, achieving high equipment availability isn’t just about hitting those high percentages; it’s about finding a balance that considers quality and performance alongside operational effectiveness.

- Plus, using visual management tools can provide valuable insights and help teams stay on track with maintenance tasks.

By prioritizing equipment uptime, manufacturers can significantly enhance their productivity and profitability.

Implement Proactive Maintenance Strategies

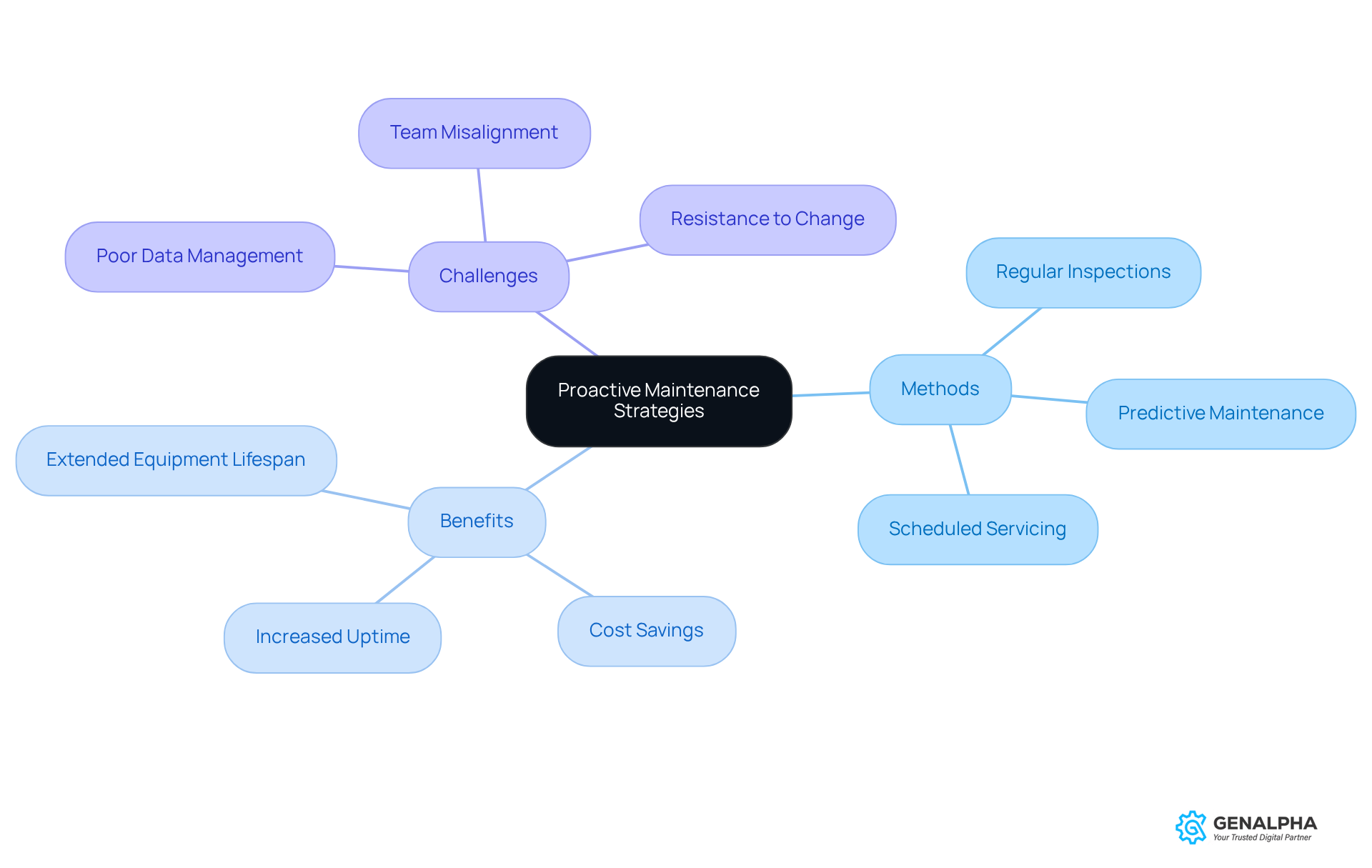

Have you ever thought about how much a single equipment failure can cost? Proactive care strategies are key to ensuring equipment uptime by preventing those costly breakdowns before they even happen. Think about it: regular inspections, predictive maintenance using IoT sensors, and scheduled servicing based on how much the equipment is used can make a world of difference. For instance, producers who have jumped on the predictive maintenance bandwagon have seen their equipment uptime increase, leading to unplanned downtime dropping by as much as 30%!

Now, let’s talk numbers. Unplanned downtime can hit industrial manufacturers hard, costing them around $50 billion a year. That’s a staggering amount! But here’s the good news: by tapping into data from machinery sensors, companies can spot potential issues early on. This means they can step in before things go south, saving themselves from those expensive breakdowns.

Industry experts, like Anbarasu Reddy, emphasize that taking a proactive approach not only extends the life of machinery but also boosts overall operational efficiency. Sounds great, right? But hold on - it's important to be aware of common pitfalls when implementing these strategies. Issues like poor data management or team misalignment can derail your efforts. So, what can you do to ensure success? Let's keep the conversation going!

Leverage Technology for Enhanced Uptime Management

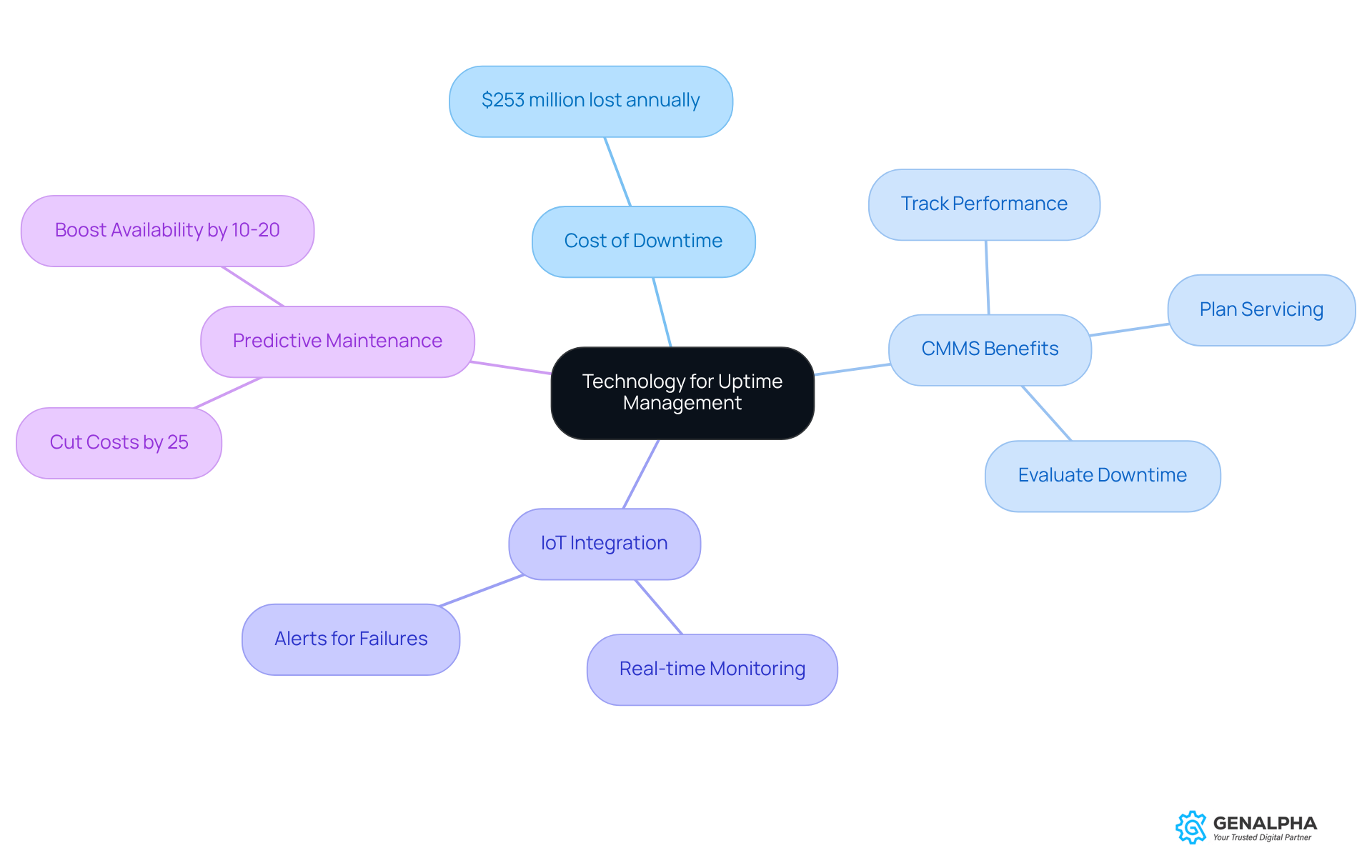

Incorporating advanced technology into equipment uptime management is key to boosting operational efficiency. Have you ever thought about how much unplanned downtime can cost? Well, the average large manufacturing plant loses a staggering $253 million each year due to these disruptions! That’s a hefty price tag, right?

Now, let’s talk about how Computerized Maintenance Management Systems (CMMS) can help. These systems allow producers to plan servicing, track equipment performance, and evaluate downtime information with ease. For example, one producer that used IoT sensors for real-time monitoring saw an impressive 25% drop in downtime. That’s the power of proactive upkeep strategies!

Advanced CMMS platforms are pretty cool, too. They integrate IoT sensors to monitor signs like pressure changes and temperature fluctuations, alerting teams to potential failures before they turn into costly problems. Imagine being able to catch issues before they escalate! Predictive maintenance can even cut maintenance costs by up to 25% and boost operational availability by 10% to 20%.

So, by embracing these technologies, manufacturers can make informed, data-driven choices that not only enhance machinery performance but also significantly improve equipment uptime by reducing operational interruptions. Isn’t it time we took a closer look at how we can leverage these tools for better efficiency?

Empower Employees Through Training and Ownership

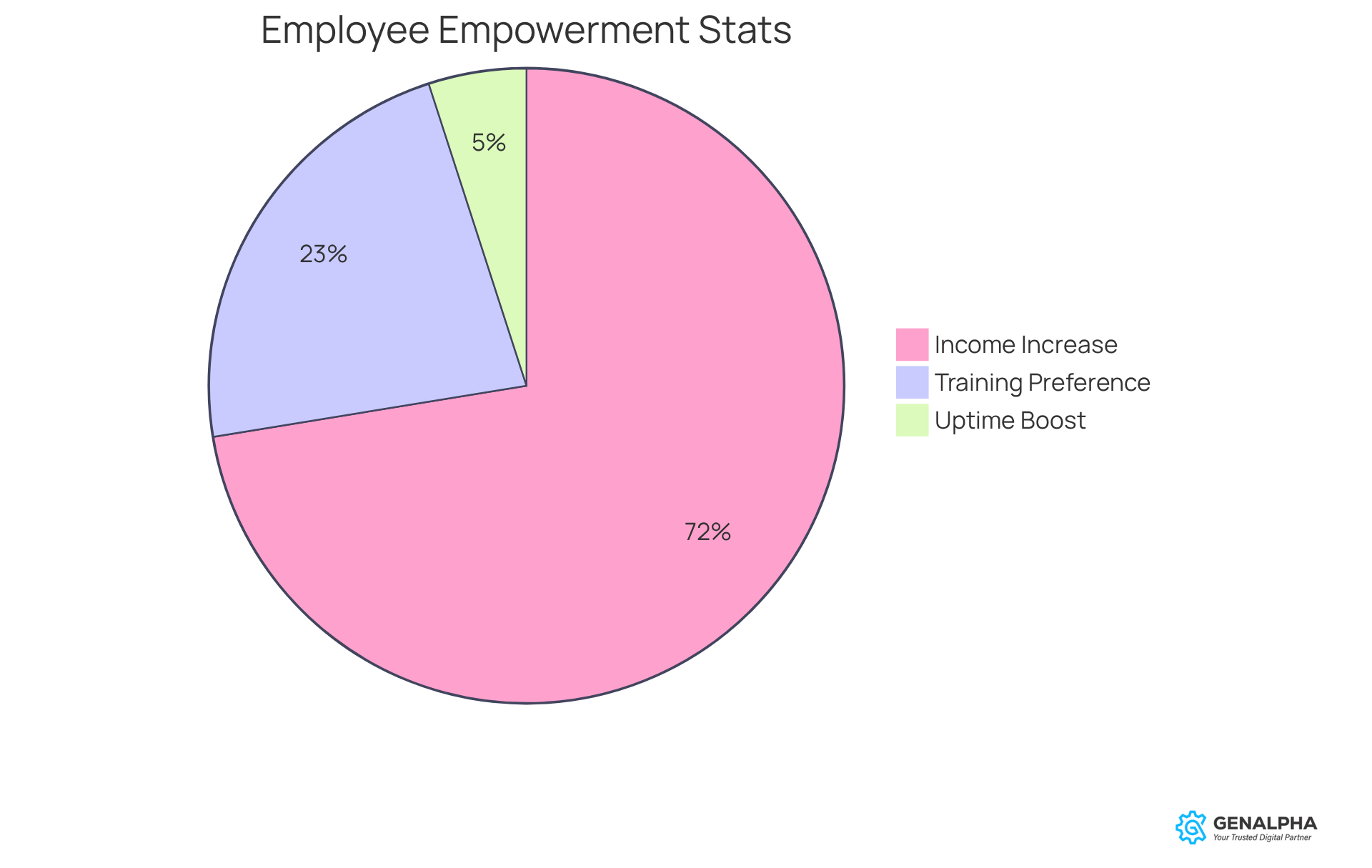

Empowering our staff is key to maximizing machinery availability. Think about it: when employees receive thorough training on how to operate and maintain machinery, they’re much better equipped to tackle any issues that pop up. Plus, when we foster a sense of ownership among our team, it often leads to greater accountability and proactive behavior. For instance, a manufacturing company that implemented an employee ownership program experienced a 15% boost in equipment uptime as workers felt more responsible for their roles.

And here’s something interesting: 68% of employees prefer to learn or train right at work. This really underscores how crucial accessible training is. Fast forward to 2026, and the perks of these ownership programs are clear. They not only ramp up operational efficiency but also help build a culture of engagement and commitment among employees.

Did you know that companies with comprehensive employee training programs enjoy 218% higher income per employee compared to those without formalized training? Plus, 92% of workers believe that workplace training positively influences their job engagement. So, by investing in employee development and nurturing a culture of ownership, manufacturers can significantly boost their operational resilience, which in turn enhances equipment uptime and overall productivity. What steps can you take today to start this journey?

Conclusion

Maximizing equipment uptime is crucial for manufacturers who want to boost productivity and profitability. Think about it: when equipment is running smoothly, everything else falls into place. This focus on high availability not only drives operational efficiency but also nurtures a culture of quality and performance. By grasping the importance of equipment uptime, manufacturers can roll out effective strategies that lead to real benefits, like lower operational costs and happier customers.

So, what are some key practices to consider? First off, adopting proactive maintenance strategies is a game changer. Pair that with advanced technology like IoT and CMMS, and you’re on the right track. Plus, empowering employees through comprehensive training can make a world of difference. Each of these elements is vital in cutting down unplanned downtime, which can really hit a company’s bottom line hard. With the right tools and proactive measures, manufacturers can significantly lower the risk of equipment failures, keeping production processes running smoothly and efficiently.

But here’s the thing: the journey to maximizing equipment uptime is ongoing. It takes commitment and strategic planning. By investing in maintenance practices, embracing technology, and fostering employee engagement, manufacturers not only enhance their operational resilience but also set themselves up for long-term success. So, why wait? Taking these steps today can lead to a more efficient and profitable manufacturing environment. It’s time for industry leaders to make equipment uptime a top priority in their operational strategy!

Frequently Asked Questions

What is equipment uptime?

Equipment uptime refers to the duration that machinery is operational and running during planned production periods.

Why is equipment uptime important for manufacturers?

High equipment uptime is crucial for manufacturers as it directly correlates with increased productivity, lower operational costs, and improved customer satisfaction.

How does a difference in operational time affect productivity?

For instance, a manufacturing facility operating at 95% uptime can produce significantly more goods than one operating at 80%, resulting in higher profits.

What are the potential downsides of focusing solely on high availability percentages?

Pursuing high availability without proper context can lead to increased scrap and rework, negatively impacting overall performance.

What is the financial impact of machinery downtime?

Producers lose approximately $50 billion annually due to unexpected machinery downtime, highlighting the importance of maintaining high equipment uptime.

How can manufacturers boost equipment availability?

Manufacturers can enhance availability by implementing efficient service plans, using reliable machinery, and establishing proactive, data-driven maintenance programs.

What benefits can a proactive maintenance program provide?

A proactive maintenance program can reduce unplanned downtime by 30-50% and extend the lifespan of machines by 20-40%, thereby increasing productivity and operational efficiency.

What should manufacturers consider when aiming for high equipment availability?

Manufacturers should aim for a balance that considers quality and performance alongside operational effectiveness, rather than solely focusing on high percentages.

How can visual management tools assist in maintaining equipment uptime?

Visual management tools can offer valuable insights and help teams stay organized and on track with maintenance tasks, contributing to improved equipment uptime.