Introduction

Product specification management software has become a must-have for manufacturers looking to keep their operations accurate and efficient. Imagine having all your item data in one place and automating those tedious manual processes. Sounds great, right? Not only does this boost collaboration across departments, but it also cuts down on errors significantly.

But let’s be real - getting to that seamless integration and making the most of this software isn’t always a walk in the park. So, how can manufacturers tackle these challenges and truly tap into the amazing benefits that product specification management tools offer? Let's dive in!

Understand the Role of Product Specification Management Software

Have you ever wondered how manufacturers keep everything organized when it comes to product specifications? Well, product specification management software serves as a central hub for creating, organizing, and maintaining those specs throughout the item's lifecycle. They help manufacturers manage detailed item data, making sure everything is accurate and meets industry standards.

By automating those tedious manual processes and providing real-time updates, these tools really cut down on errors and boost collaboration across different departments. For example, imagine a producer who can quickly revise item details. This means that all teams have access to the latest information, which is crucial for maintaining quality and meeting customer expectations.

So, if you're looking to streamline your processes and enhance teamwork, consider diving into product specification management software. They could be just what you need to keep everything running smoothly!

Identify Key Benefits for Manufacturers

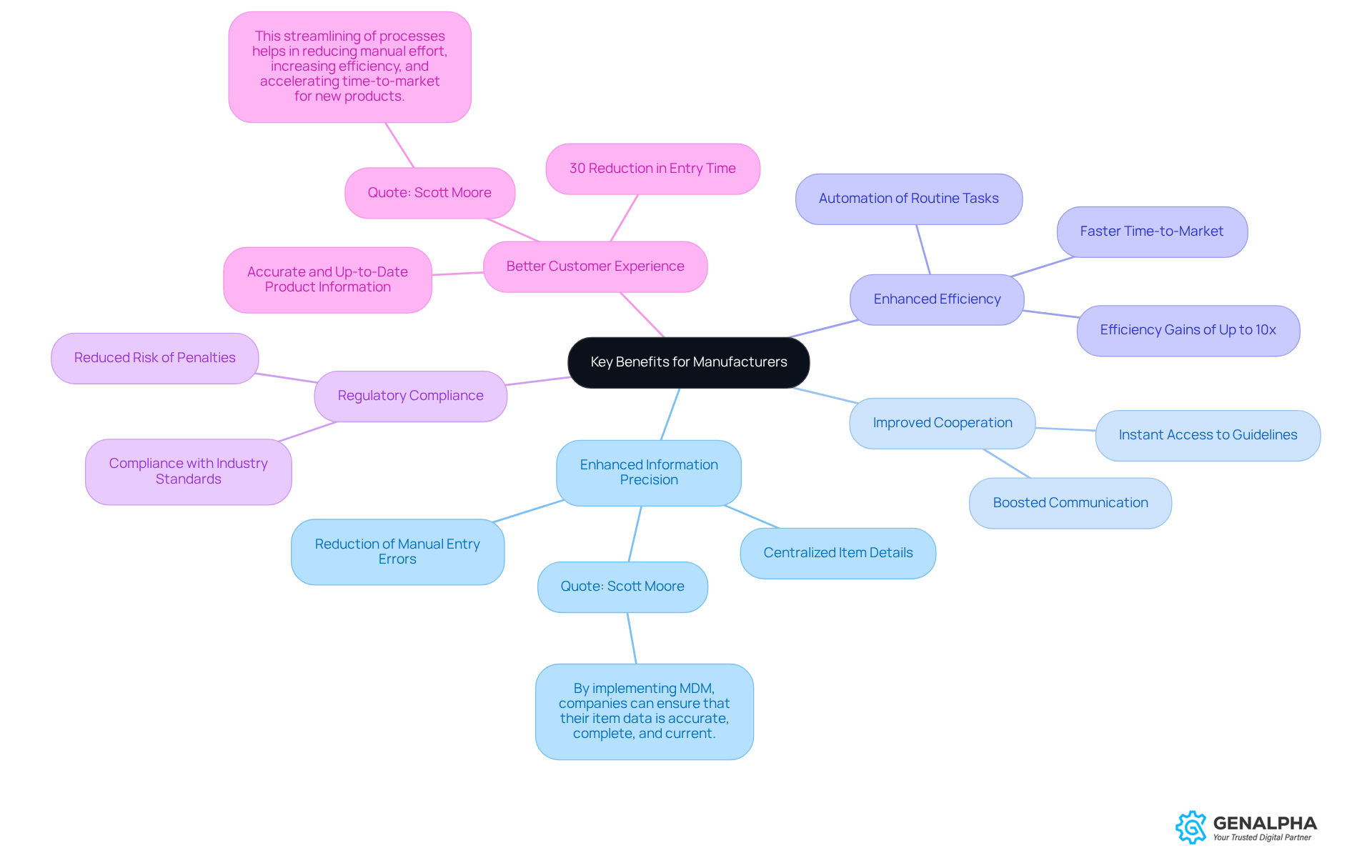

The implementation of product specification management software can truly revolutionize the manufacturing process. Let’s dive into some of the significant advantages:

-

Enhanced Information Precision: Imagine centralizing all your item details. It’s a game changer! This approach cuts down on mistakes that come from manual entry and outdated criteria, making your item information more trustworthy. As Scott Moore puts it, "By implementing MDM, companies can ensure that their item data is accurate, complete, and current."

-

Improved Cooperation: Think about how much easier it would be if your teams could access guidelines instantly. This kind of access allows cross-departmental teams to revise and share information effortlessly, boosting communication and speeding up development schedules.

-

Enhanced Efficiency: By automating those routine tasks, your teams can focus on what really matters - higher-value activities. This shift can lead to a quicker time-to-market for new offerings. In fact, businesses using AI-optimized PIM platforms have reported efficiency gains of up to tenfold!

-

Regulatory Compliance: Staying compliant is crucial. This product specification management software ensures that all item details comply with industry standards, which can significantly reduce the risk of penalties and enhance information governance.

-

Better Customer Experience: When your product information is accurate and up-to-date, it leads to better customer interactions. This can boost satisfaction and loyalty. For instance, one producer that adopted management tools saw a 30% reduction in entry time and a notable drop in customer complaints about inaccuracies.

While these advantages are impressive, it’s important to acknowledge the challenges. Manufacturers need dedicated resources and effective procedures to manage information efficiently. Keeping item information current can be a tough nut to crack, but the benefits of adopting product specification management software far outweigh these hurdles. In the end, these advantages can really enhance manufacturing processes, helping organizations thrive in a competitive landscape.

Implement Effective Strategies for Adoption

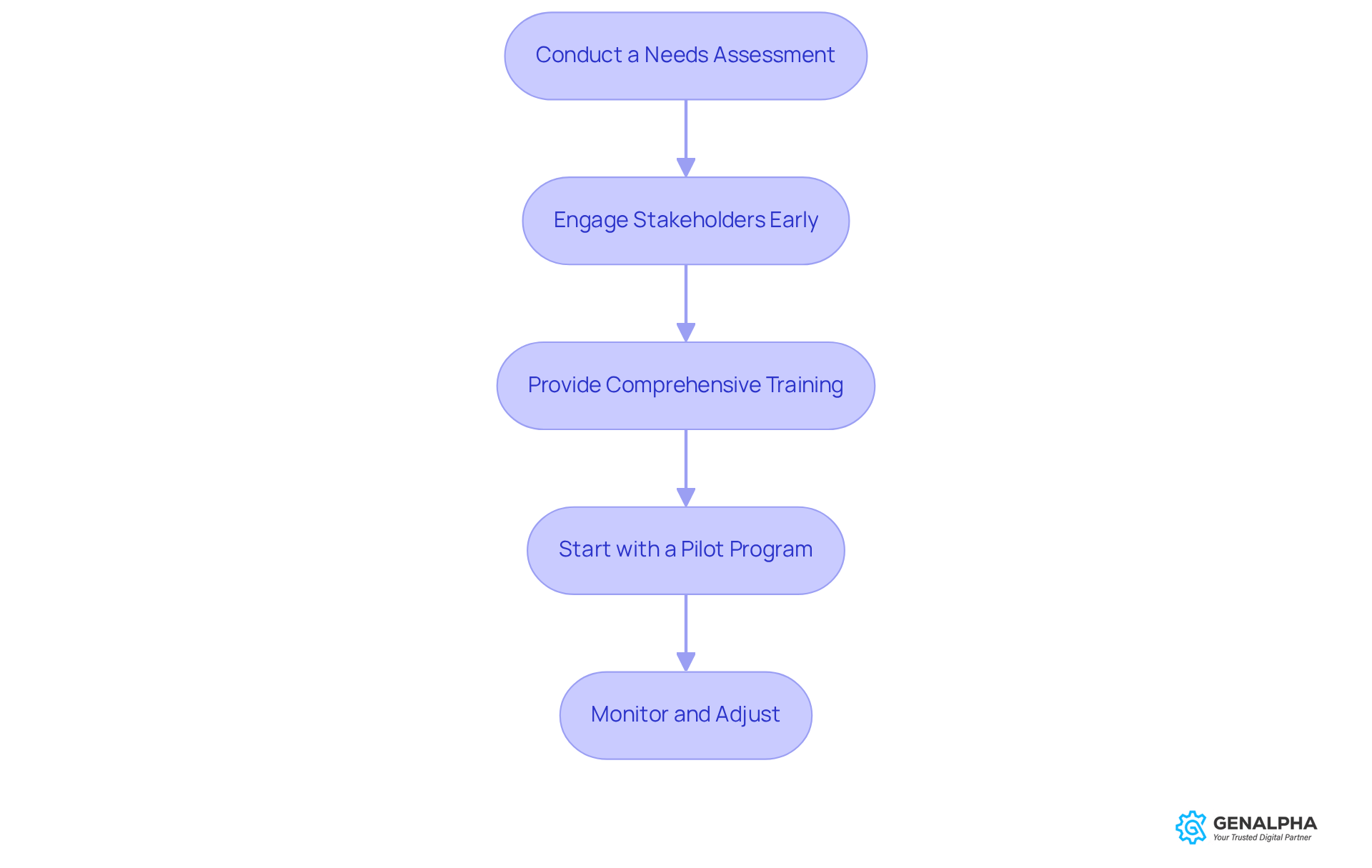

If you're looking to adopt product specification management software, here are some strategies that can really help you out:

- Conduct a Needs Assessment: Start by pinpointing the specific challenges and requirements within your organization. This way, you can make sure the software fits your business's unique needs.

- Engage Stakeholders Early: Get key players from different departments involved right from the start. This not only helps in selecting the right software but also addresses any concerns and fosters buy-in.

- Provide Comprehensive Training: Don’t skip on training! Offering sessions for all users ensures everyone knows how to use the application effectively, which can really boost adoption rates.

- Start with a Pilot Program: Why not test the waters first? Implement the application in just one department or product line to see how it works and gather feedback before rolling it out company-wide.

- Monitor and Adjust: Keep an eye on how the program is performing and listen to user feedback. This way, you can make any necessary tweaks and enhancements along the way.

By following these strategies, you can make the transition smoother and really tap into the benefits of the product specification management software. So, what do you think? Ready to give it a shot?

Address Challenges in Integration

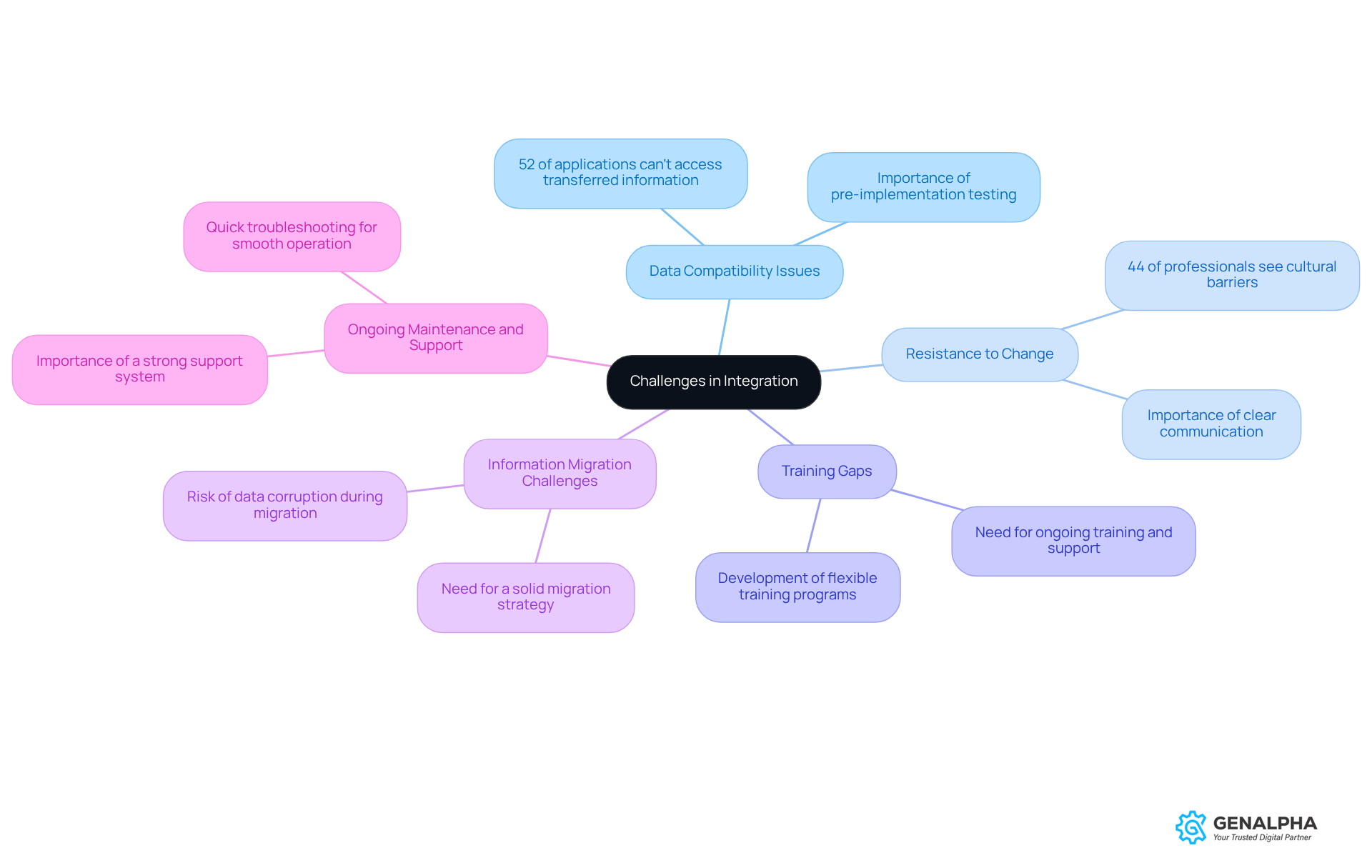

For manufacturers, integrating product specification management software can be a bit tricky, right? Let’s break down some of the challenges you might face:

-

Data Compatibility Issues: You want to make sure that your new application plays nice with your existing systems, like ERP and CRM platforms. Doing some thorough pre-implementation testing can help spot any potential compatibility hiccups, which can save you from disruptions later on. Did you know that 52% of current applications can’t access transferred information without some changes? That’s why planning is key!

-

Resistance to Change: It’s not uncommon for employees to be hesitant about adopting new technology. To ease this transition, it’s super important to clearly communicate the benefits and involve your team in the implementation process. This way, they’ll feel a sense of ownership, which can really help reduce resistance. Plus, addressing any organizational or cultural barriers is crucial-44% of manufacturing professionals see this as a major hurdle to digital adoption.

-

Training Gaps: If your team isn’t properly trained, the software might not get used to its full potential. Ongoing training and support are essential to help everyone feel confident and proficient with the new system. Think about developing flexible, on-the-job training programs to boost your team’s skills and adaptability.

-

Information Migration Challenges: Moving your existing data to the new system can be complex and risky. Crafting a solid migration strategy that includes data cleansing and validation is vital to ensure everything stays accurate and intact during the transition. Remember, migration failures can lead to data corruption and project delays, so meticulous planning is a must!

-

Ongoing Maintenance and Support: After implementation, having a strong support system in place for troubleshooting and maintenance is crucial. This ensures that any issues that pop up can be addressed quickly, keeping your application running smoothly.

By tackling these challenges head-on, manufacturers can boost their chances of successful integration and fully utilize their product specification management software. So, what steps will you take to ensure a smooth transition?

Conclusion

Maximizing efficiency in manufacturing processes really comes down to how well we implement product specification management software. Think of it as a central hub for all your item data. Not only does it streamline operations, but it also boosts collaboration across departments. The importance of adopting this kind of software is huge - it can completely change how manufacturers handle product information throughout its lifecycle.

Let’s look at some of the key benefits of product specification management software. You get:

- Improved information precision

- Better teamwork

- Increased efficiency

- Regulatory compliance

- An overall enhanced customer experience

These perks work together to create a more agile manufacturing environment, letting businesses respond quickly to market demands while keeping quality high.

Now, I know the journey to effectively integrate product specification management software can come with its challenges. But trust me, the rewards far outweigh the hurdles. Manufacturers should really consider embracing these technologies, plan their implementation carefully, and focus on training and support. By doing this, they can tap into the full potential of their operations, ensuring they stay competitive in a constantly changing industry landscape. So, why not take that first step towards transformation? It could be the key to achieving lasting success and operational excellence!

Frequently Asked Questions

What is product specification management software?

Product specification management software is a central hub for creating, organizing, and maintaining product specifications throughout the item's lifecycle.

How does product specification management software benefit manufacturers?

It helps manufacturers manage detailed item data, ensuring accuracy and compliance with industry standards, while also reducing errors and enhancing collaboration across departments.

What features do product specification management software typically offer?

These tools automate manual processes and provide real-time updates, allowing teams to quickly access the latest product information.

Why is real-time access to product specifications important?

Real-time access ensures that all teams have the latest information, which is crucial for maintaining quality and meeting customer expectations.

How can product specification management software improve teamwork?

By streamlining processes and providing a centralized platform for information sharing, it enhances collaboration among different departments within a manufacturing organization.