Introduction

Mastering product specification management is super important for organizations that want to boost quality and operational efficiency. Think about it: when teams keep a close eye on product details throughout their lifecycle, they can streamline workflows, improve communication, and make sure they’re meeting industry standards. But here’s the catch - many organizations hit roadblocks that slow them down. So, how can businesses tackle these challenges and harness the power of detailed specifications to drive success?

In this guide, we’ll explore six easy steps to transform product specification management. By following these steps, you’ll empower your team to achieve better outcomes and keep your customers smiling.

Define Product Specification Management

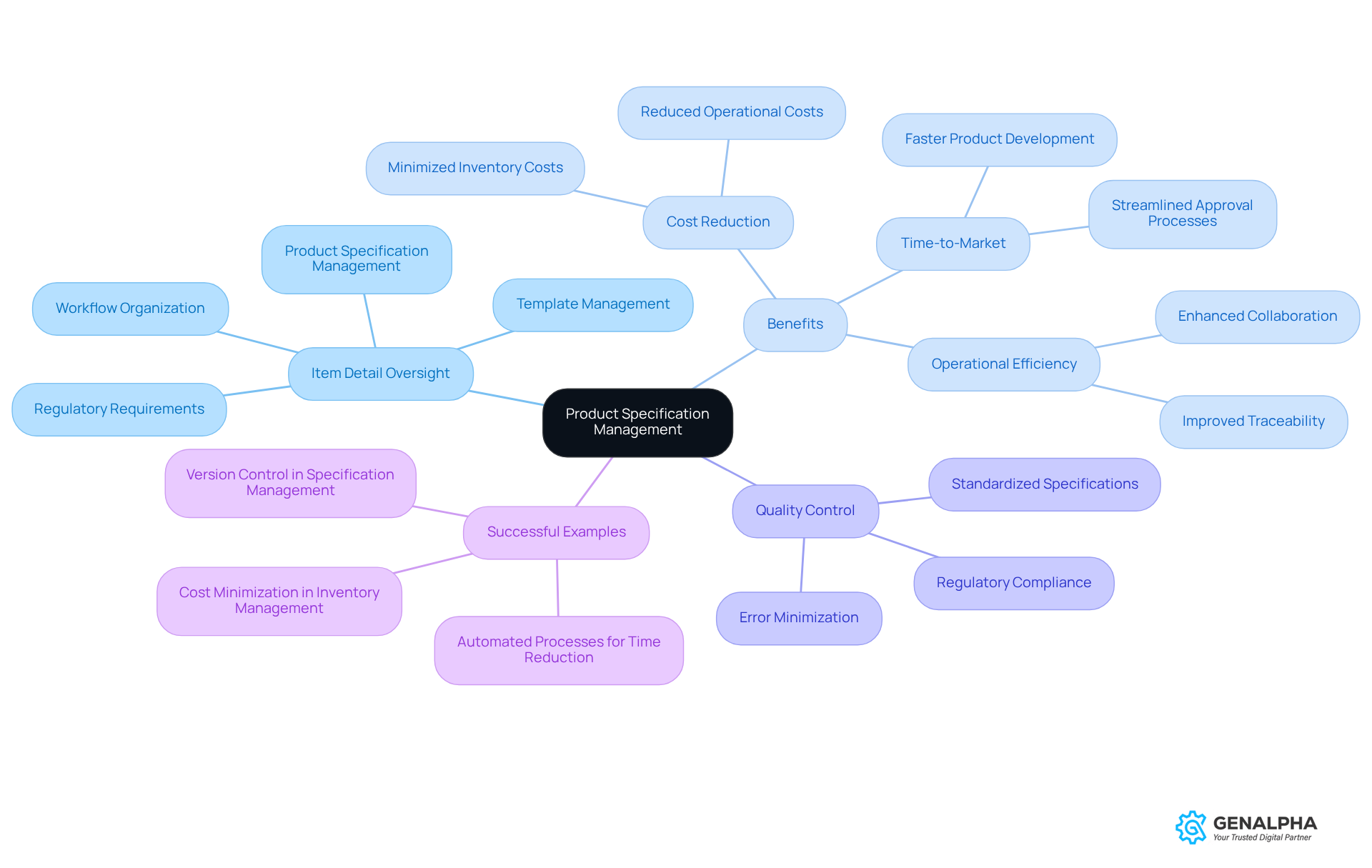

Item detail oversight is fundamentally about product specification management, which ensures that product details are tracked throughout their lifecycle in a structured way. Think of it as a method for organizing, managing templates, workflows, and even regulatory requirements. This ensures everyone involved has access to accurate and up-to-date information. By implementing product specification management to centralize product data, teams can work better together and make smarter decisions, which ultimately leads to higher quality outcomes.

Have you ever thought about how effective requirement oversight can save you from costly mistakes? It’s crucial for managing expenses and sticking to industry standards. For instance, organizations that embrace solid requirement oversight practices often see a significant drop in time-to-market and improved operational efficiencies. Industry experts agree: effective product specification management not only streamlines workflows but also boosts traceability and accountability. These elements are essential in today’s fast-paced manufacturing world.

Successful examples from equipment manufacturing show that companies utilizing product specification management software can cut costs, speed up innovation, and maintain high quality standards. This leads to project success and happy clients. Plus, as Specright points out, 'With digitized, shareable specs, you can ensure your teams and suppliers are on the same page-at all times.' This really underscores the importance of teamwork and communication in managing requirements.

And here’s something to think about: improving item oversight procedures can increase company earnings by 34.2%. That’s a pretty compelling reason to focus on efficient requirement handling! Quality control in requirements management is also key, as it ensures that all regulatory obligations and industry standards are accurately reflected in project documents, contributing to overall project success.

Understand the Importance of Product Specifications

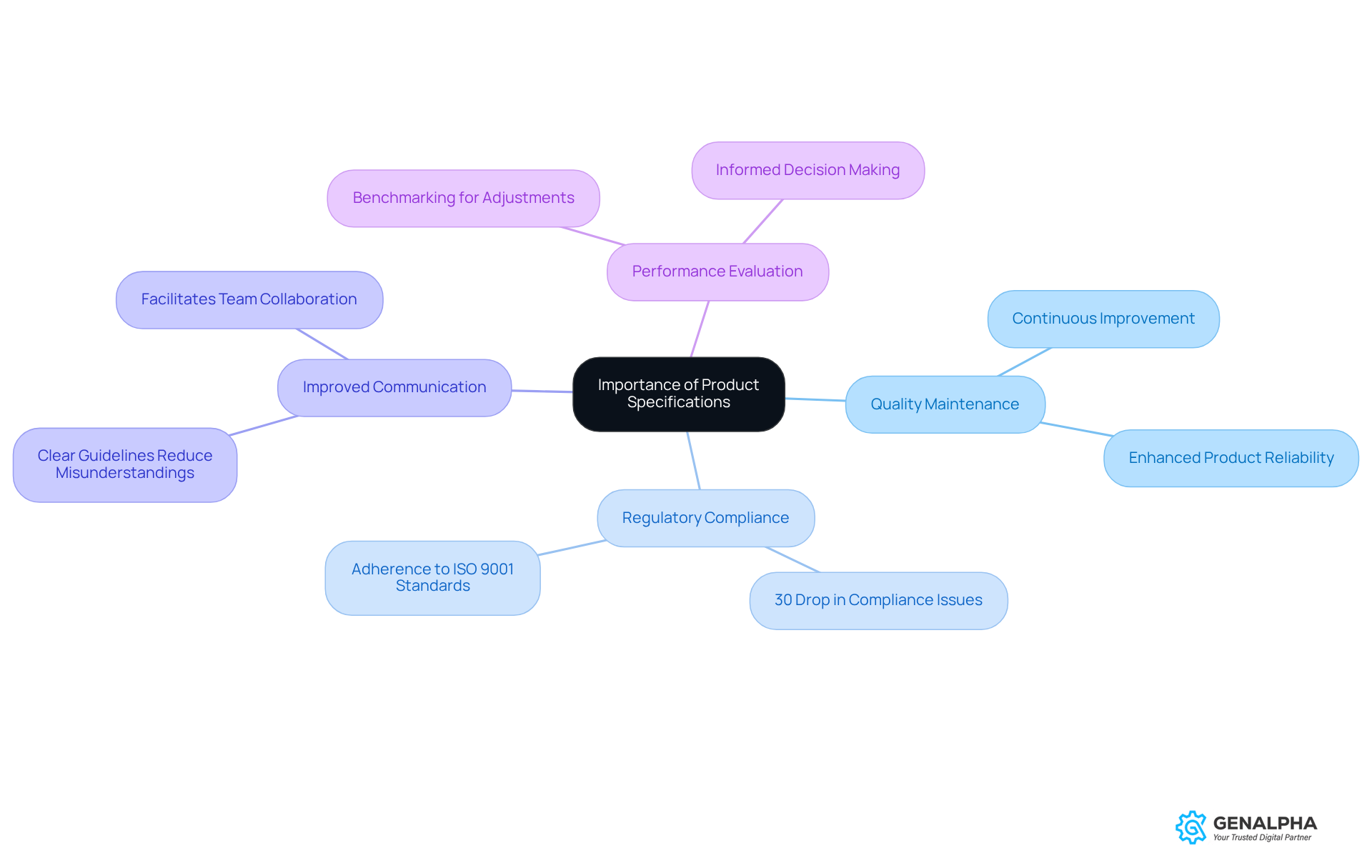

Item details are super important for making sure we maintain quality, follow industry regulations, and keep communication flowing smoothly among teams. When manufacturers create clear and detailed guidelines, they can really cut down on misunderstandings and mistakes during production. This, in turn, leads to happier customers! For instance, organizations that have clear guidelines often see a 30% drop in compliance issues. That really shows how crucial clarity is in setting requirements.

But that’s not all! These guidelines also serve as a benchmark for evaluating performance. They help teams make informed adjustments that drive continuous improvement. This proactive approach doesn’t just boost quality; it also reinforces adherence to standards like ISO 9001. In the end, this means we can offer something more reliable and trustworthy.

So, how can your team start implementing clearer guidelines today?

Identify Key Components of a Product Specification Sheet

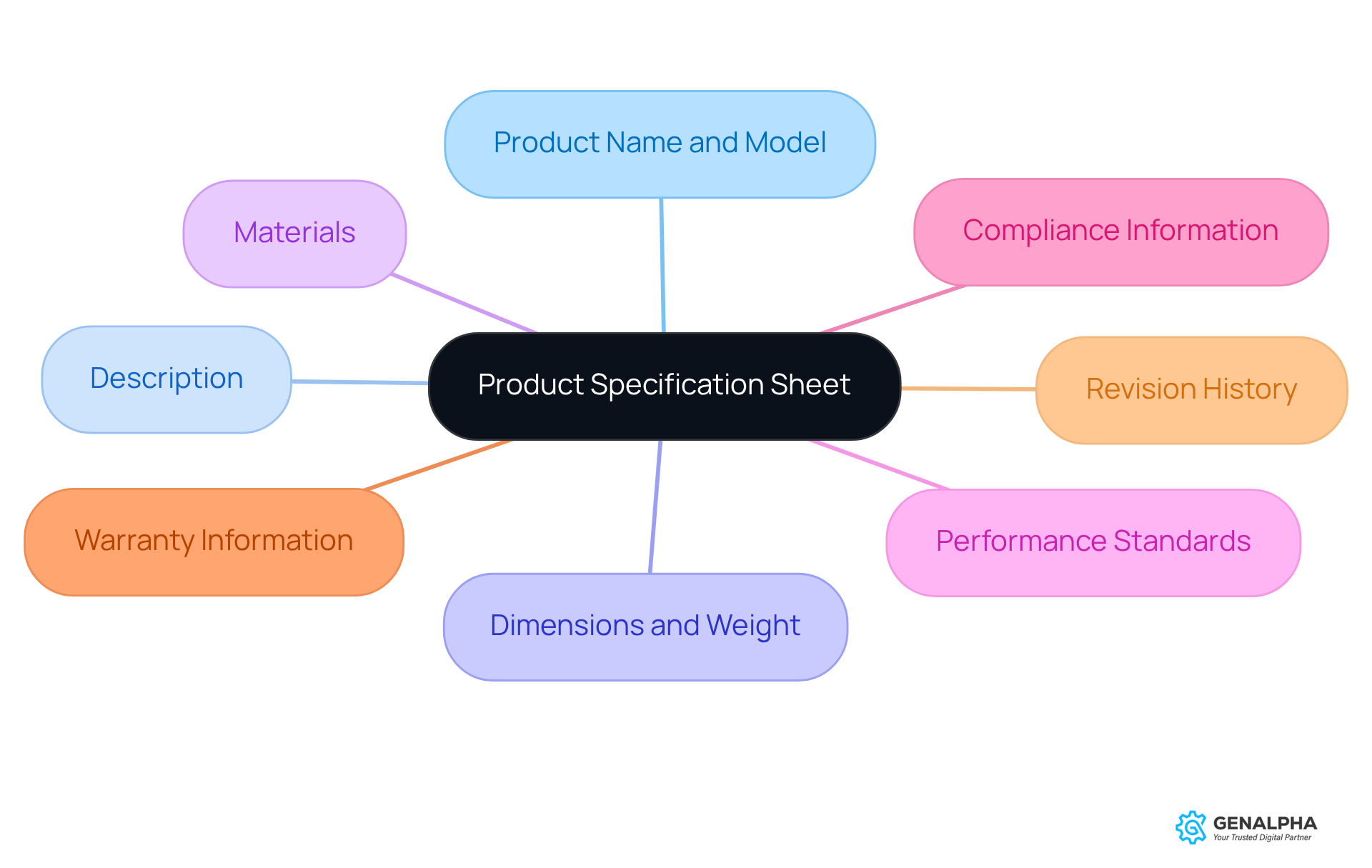

Creating a solid product specification management sheet is key to nailing product development. So, what should you include? Let’s break it down:

- Product Name and Model: Start with the basics - make sure to clearly state the product's name and model number. This helps everyone identify it easily.

- Description: Give a detailed overview of what the item is all about. What’s its purpose? What features set it apart from the competition?

- Dimensions and Weight: Don’t forget the nitty-gritty! Include the exact dimensions and weight. These details can really sway customer decisions and usability.

- Materials: List out the materials used in making the item. This can affect durability and how well it meets industry standards.

- Performance Standards: Outline any performance metrics or standards the item needs to meet. This ensures it aligns with what customers expect and any regulatory requirements.

- Compliance Information: Include relevant compliance details to reassure customers that the item meets safety and environmental standards.

- Warranty Information: Specify the warranty terms and conditions. This can boost customer trust and satisfaction.

- Revision History: Keep track of any changes made over time. Documenting this helps maintain a clear record of the item's evolution.

By weaving these elements together, manufacturers can craft effective product specification management sheets that act as a blueprint for creation. This not only promotes alignment among teams but also improves communication, leading to successful launches. Remember, collaboration among stakeholders in developing these guidelines is crucial. It ensures that the offering meets user needs and expectations, ultimately enhancing the chances of market success. So, are you ready to get started?

Write an Effective Product Specification Sheet

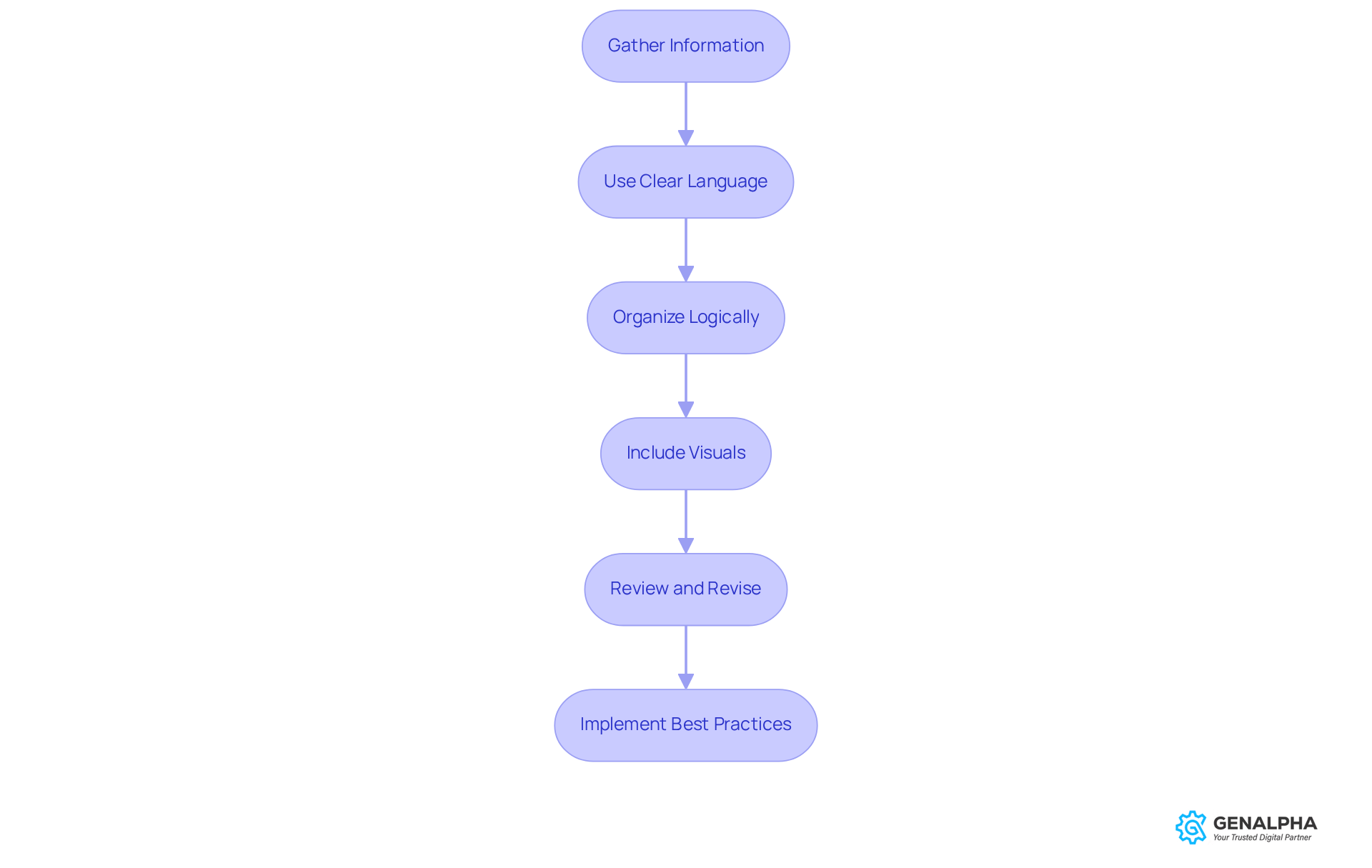

Are you writing a solid product specification management sheet? Let’s break it down into some easy steps:

-

Gather Information: First things first, collect all the necessary data about your item. This includes technical details and compliance requirements. Think of this as laying the groundwork - getting all the essential details in one place.

-

Use Clear Language: Next up, write in a way that everyone can understand. Clear and concise language is key! As Hans Hofmann put it, "The ability to simplify means to eliminate the unnecessary so that the necessary may speak." So, steer clear of jargon unless it’s absolutely needed. Clarity is crucial for effective communication.

-

Organize Logically: Now, let’s talk structure. Organize your document logically - start with general info and then dive into the specifics. A coherent flow makes it easier for everyone to read and understand.

-

Include Visuals: If you can, add diagrams or images to highlight key features. Visual aids can really boost comprehension and help people remember the information better.

-

Review and Revise: Once you’ve drafted your sheet, take a moment to review it for accuracy and completeness. Don’t hesitate to seek feedback from your team. They might spot areas for improvement that you missed!

-

Implement Best Practices: Finally, look at successful examples from industry leaders. For instance, the case study 'Quality Takes Time' shows that creating quality items takes time and can’t be rushed. Learning from these examples can give you valuable insights into effective strategies and common pitfalls to avoid.

By following these steps, you’ll not only ensure that your item details are clear and comprehensive, but you’ll also improve communication within your team about product specification management. And who doesn’t want to enhance quality and operational efficiency? Let’s get started!

Integrate Specifications with Digital Tools

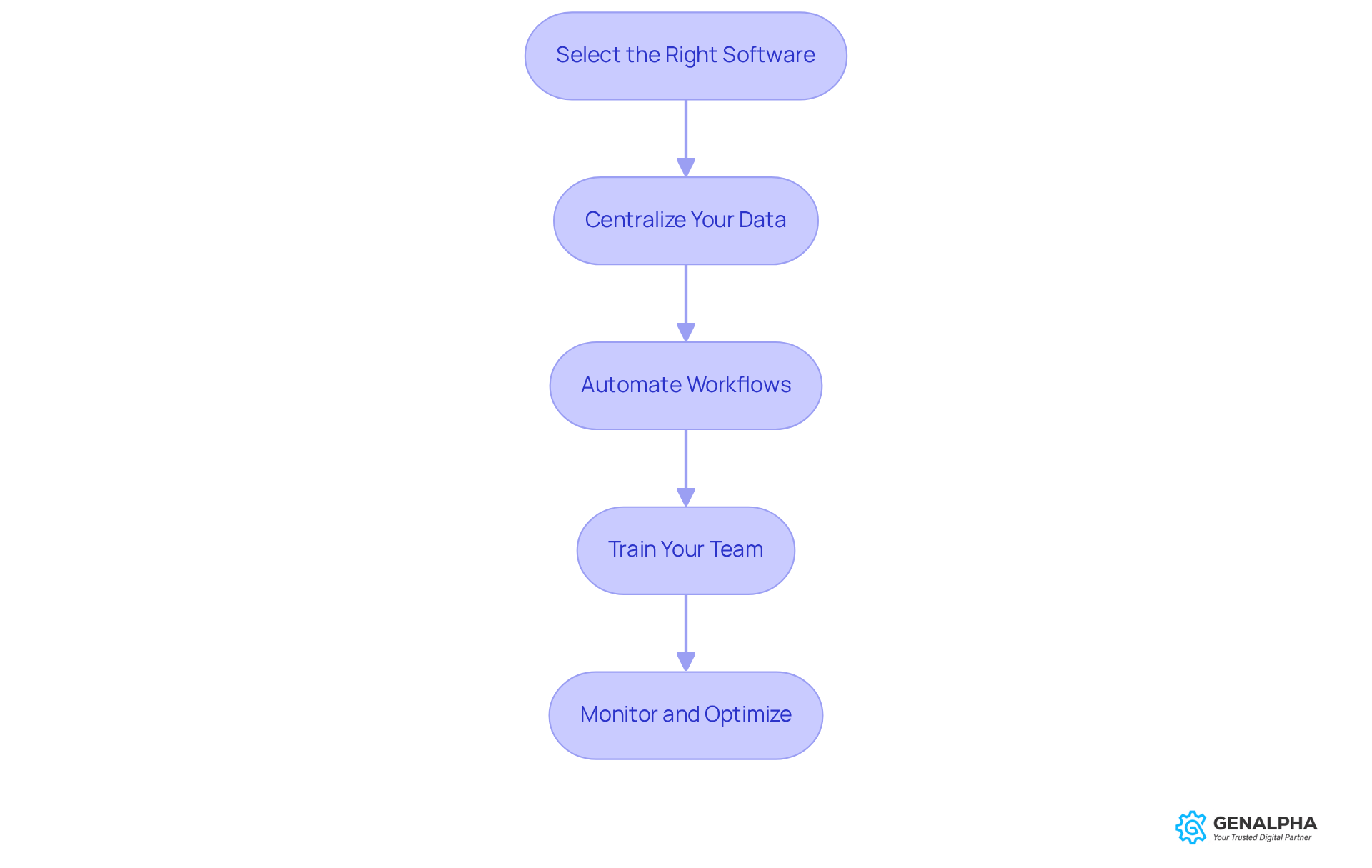

To effectively integrate product specifications with digital tools, let’s break it down into some essential steps:

-

Select the Right Software: First things first, you need to find a requirements tracking software that fits your organization’s unique needs. Think about what features are most important - like version control, collaboration tools, and solid data analytics. These will really boost usability!

-

Centralize Your Data: Next up, it’s time to move all your existing specifications into one digital platform. This centralization makes it super easy for everyone to access and oversee the information they need. No more hunting around!

-

Automate Workflows: Now, let’s talk automation. By leveraging automation features, you can streamline key processes like approvals and updates. This not only cuts down on manual work but also minimizes the risk of errors, which can really ramp up productivity. Did you know that companies embracing automation are often better equipped to handle rapid market changes?

-

Train Your Team: Don’t forget about training! Investing in comprehensive training for your team is crucial. When they’re confident in using the new tools, you’ll see the software’s full potential come to life.

-

Monitor and Optimize: Finally, keep an eye on the integration process. Regularly assess how things are going and make adjustments as needed to boost efficiency. Remember, if businesses don’t adapt to new technologies, they risk failing - up to 40% might not make it in the next decade! Staying ahead in digital transformation is key.

By following these strategies, you can really enhance how your organization approaches product specification management, leading to better operational efficiency and alignment with digital transformation goals. For instance, look at Samuel Hubbard’s system integration - it not only improved customer experience but also significantly increased B2B orders. That’s the power of effective oversight!

As digital transformation expert Antonin Król puts it, "Engaging employees in the digital transformation process fosters a culture of innovation," which is essential for long-term success. So, what steps will you take to start this journey?

Troubleshoot Common Specification Management Challenges

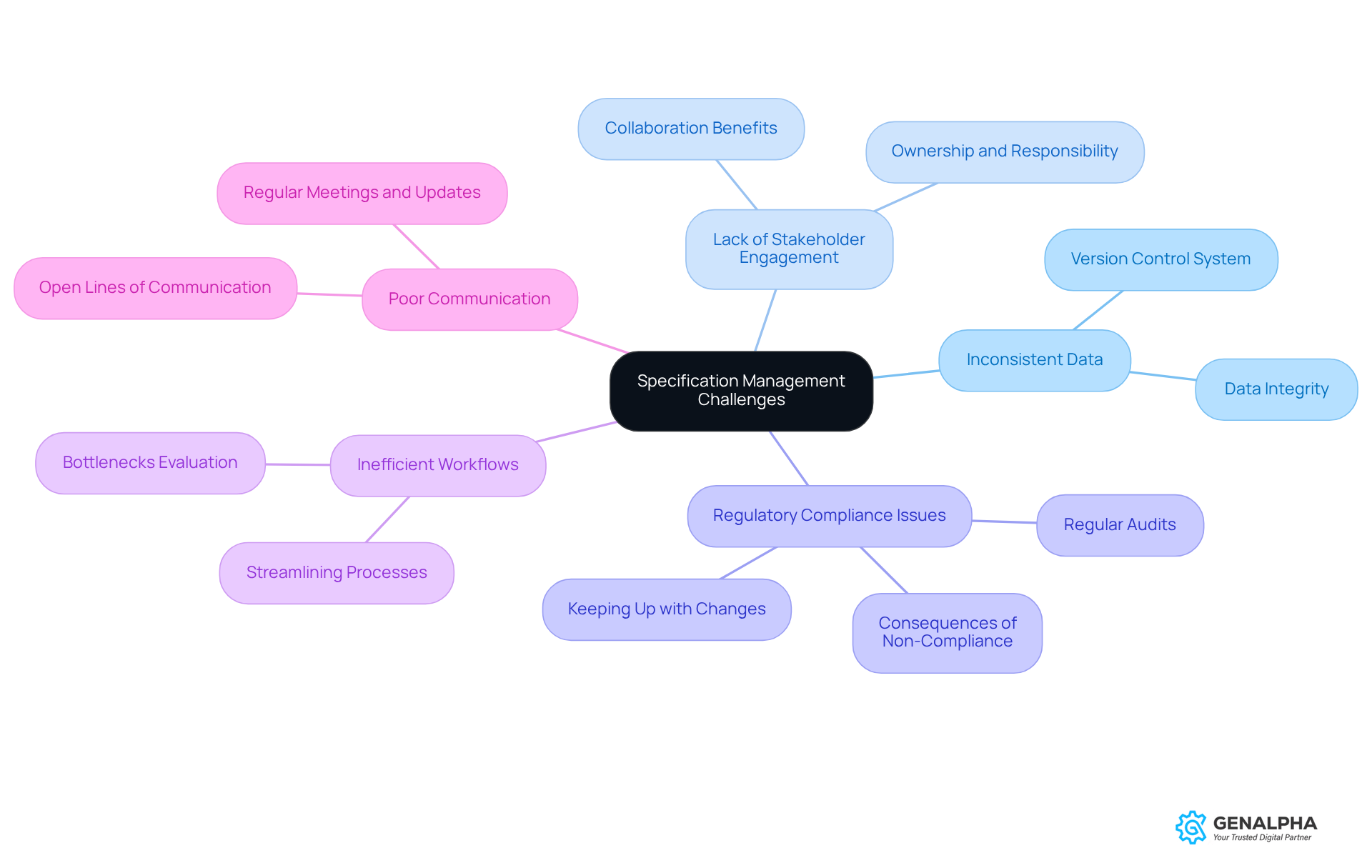

Common challenges in product specification management can really throw a wrench in the works, can’t they? Let’s break down a few of the big ones:

- Inconsistent Data: Ever found yourself wondering if everyone’s on the same page? To make sure your team is using the latest specs, it’s a good idea to set up a solid version control system. This way, you’ll cut down on discrepancies and keep your data integrity intact.

- Lack of Stakeholder Engagement: It’s crucial to get all relevant stakeholders involved in the detailing process. Why? Because collaboration not only brings in diverse insights but also fosters a sense of ownership and responsibility among team members.

- Regulatory Compliance Issues: Keeping up with industry regulations is no small feat. As Xantrion points out, "Keeping pace with regulatory changes can trip up even well-resourced organizations." Your specifications need to reflect the current standards, so regular audits can help you stay compliant and avoid those pesky penalties and operational hiccups.

- Inefficient Workflows: Take a moment to evaluate your existing workflows. Are there bottlenecks slowing you down? Streamlining processes with digital tools can really boost your operational efficiency and cut down on time spent on manual tasks.

- Poor Communication: Open lines of communication among teams are essential for staying aligned on requirements and changes. Regular meetings and updates can help keep everyone in the loop, leading to smoother project execution.

Addressing these challenges is key in the context of product specification management. Remember, "There is an immediate need to resolve data challenges to prevent inefficiencies." Plus, the case study on the "Consequences of Non-Compliance" really drives home the serious repercussions manufacturers face when specifications aren’t managed properly. So, let’s tackle these challenges head-on!

Conclusion

Mastering product specification management is crucial for organizations looking to boost collaboration, streamline operations, and stay compliant with industry standards. By putting structured processes in place to track product details throughout their lifecycle, companies can make better decisions, speed up their time-to-market, and ultimately deliver higher-quality products to their customers.

In this guide, we’ve highlighted some key strategies. We talked about:

- The importance of clear product specifications

- The essential components of a specification sheet

- Effective writing practices

- How digital tools can help

Each step underscores the need for accurate and accessible information, which fosters better communication among teams and stakeholders. Plus, tackling common challenges like inconsistent data and regulatory compliance is vital for achieving operational efficiency.

Embracing these practices not only brings immediate improvements in product specification management but also sets organizations up for long-term success in a competitive landscape. Taking steps to refine your specification processes can lead to better quality, lower costs, and happier customers. So, let’s make it a priority to develop and implement effective product specifications that can adapt and respond to the ever-changing market demands.

Frequently Asked Questions

What is product specification management?

Product specification management involves tracking product details throughout their lifecycle in a structured manner, organizing templates, workflows, and regulatory requirements to ensure access to accurate and up-to-date information.

How does effective requirement oversight benefit organizations?

Effective requirement oversight helps manage expenses, adhere to industry standards, reduces time-to-market, and improves operational efficiencies, leading to smarter decisions and higher quality outcomes.

What are the outcomes of utilizing product specification management software in manufacturing?

Companies using product specification management software can cut costs, accelerate innovation, and maintain high quality standards, resulting in project success and increased client satisfaction.

How can improving item oversight procedures impact company earnings?

Improving item oversight procedures can increase company earnings by 34.2%, highlighting the financial benefits of efficient requirement handling.

Why are item details important in manufacturing?

Item details are crucial for maintaining quality, following industry regulations, and ensuring smooth communication among teams, which helps reduce misunderstandings and mistakes during production.

What impact do clear guidelines have on compliance issues?

Organizations with clear guidelines often experience a 30% drop in compliance issues, demonstrating the importance of clarity in setting requirements.

How do guidelines serve teams in performance evaluation?

Guidelines provide a benchmark for evaluating performance, enabling teams to make informed adjustments that drive continuous improvement and reinforce adherence to standards like ISO 9001.