Overview

Have you ever thought about how crucial a Bill of Materials (BOM) is in manufacturing? It’s not just a list—it's a game changer for efficiency, inventory management, and keeping costs in check. When we talk about effective BOM management, we’re really diving into how accurate BOMs can prevent those pesky production delays and boost quality control. Plus, integrating technology into the mix can elevate operational outcomes for manufacturers. So, let’s explore these best practices together and see how they can make a real difference!

Introduction

Have you ever thought about how manufacturing is a bit like cooking? Just as a recipe outlines every essential ingredient needed for a delicious dish, a well-structured Bill of Materials (BOM) serves a similar purpose in the manufacturing world. This comprehensive document not only makes inventory management and cost estimation easier but also plays a vital role in maintaining quality control and ensuring operational efficiency.

However, as manufacturers aim for excellence, they often face hurdles like data inaccuracies and poor communication that can throw a wrench in the production process. So, how can organizations tackle these challenges effectively? Let’s explore how mastering BOM management can be the key to driving manufacturing success.

Define the Bill of Materials (BOM) and Its Importance

Have you ever thought about what goes into making a product? A bill of materials management system serves as the ultimate recipe, detailing every raw material, component, sub-assembly, and part needed for manufacturing. It’s not just a list; it’s a comprehensive plan that ensures everything is ready when you need it. Let’s explore why BOMs are so important:

- Inventory Management: Think of a BOM as your inventory's best friend. It helps you keep track of what you have, ensuring you can order materials quickly and avoid any hiccups in production. When managed well, bill of materials management can significantly enhance your inventory accuracy, reducing both shortages and excess stock.

- Cost Estimation: Effective bill of materials management is key for nailing down costs, which is crucial for budgeting and financial planning. With all the details laid out, manufacturers can assess their production costs more accurately and make smarter pricing decisions.

- Planning: Bill of materials management lays out exactly what’s needed, helping you schedule and allocate resources efficiently. This clarity streamlines operations and keeps everyone on the same page for the manufacturing process.

- Quality Control: By listing every component, bill of materials management is essential for maintaining quality throughout production. It ensures that all materials meet the required standards, reducing defects and boosting overall product quality.

- Categories of bill of materials management: Understanding the —like engineering and sales—is important because each serves a unique purpose throughout the product lifecycle.

- Integration with project oversight: Merging project management with bill of materials management is vital. It ensures that accurate product information is always available to the team, preventing miscommunication and mistakes.

- Consequences of Inaccurate BOMs: Let’s face it, inaccurate BOMs can lead to material shortages, higher production costs, and unhappy customers. This highlights just how crucial it is to maintain accuracy in your bill of materials management.

- The role of technology, like Acumatica Cloud ERP, can significantly elevate your bill of materials management. It allows for real-time updates and seamless integration with other business processes.

In short, a BOM is more than just a basic list; it's a vital tool that impacts the entire manufacturing process, influencing efficiency, cost control, and product quality. Managing it effectively is key for any manufacturer looking to optimize operations and meet customer demands. So, how are you managing your BOM today?

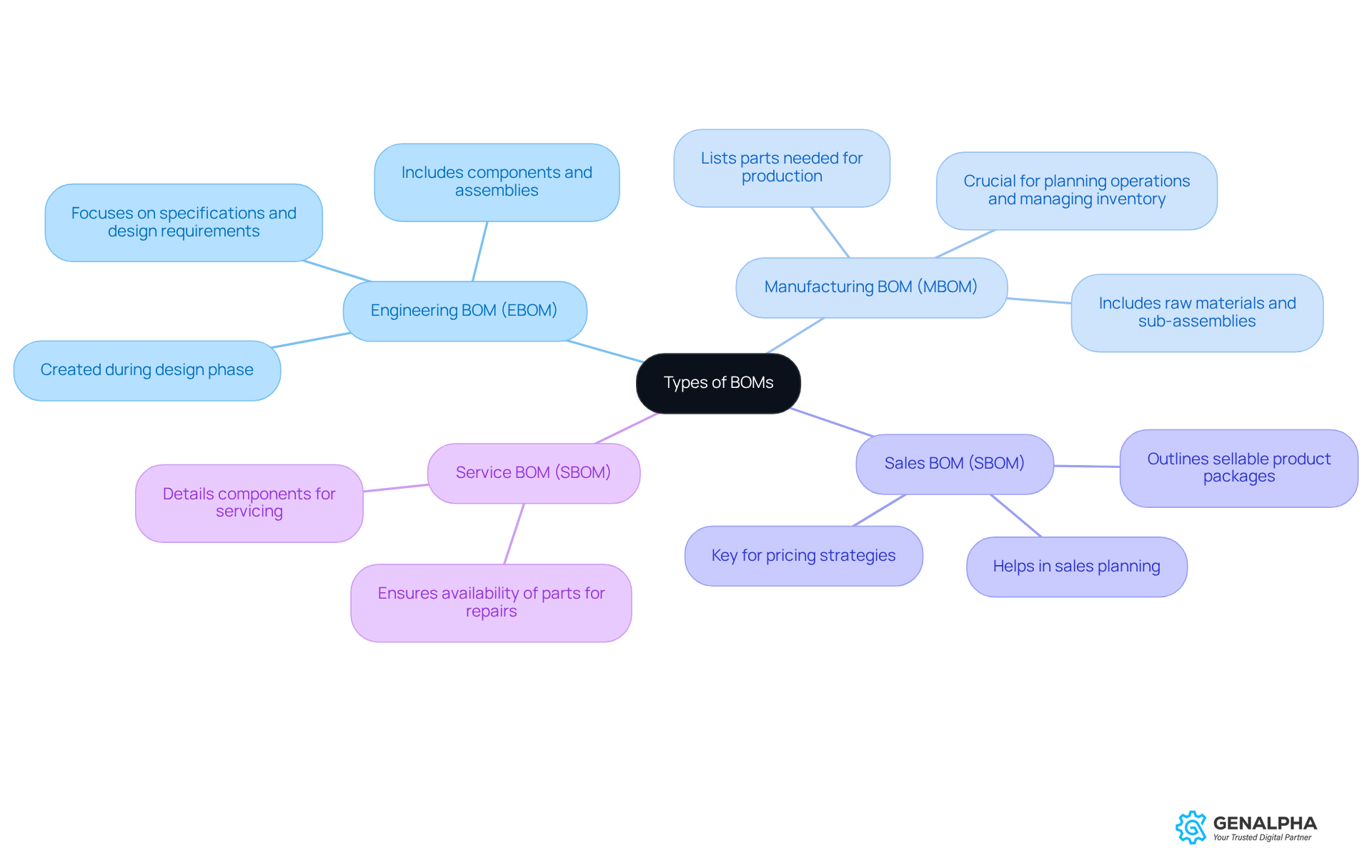

Explore Different Types of BOMs: Engineering, Manufacturing, and More

In the manufacturing world, different types of Bills of Materials (BOMs) each have their own special roles. Let’s break them down:

- Engineering Bill of Materials (EBOM): This one is created during the design phase. The EBOM includes all the components and assemblies that the engineering team dreams up. It focuses on how the product should function, detailing all the specifications and design requirements.

- [Manufacturing Bill of Materials](https://genalpha.com/ecommerce) (MBOM): When it comes to actually making the product, the MBOM steps in. It lists all the parts needed—think raw materials, sub-assemblies, and components. This BOM is crucial for planning operations and managing inventory efficiently. With precise BOMs, manufacturers can , cut down on waste, and dodge costly mistakes, paving the way for long-term success.

- Sales Bill of Materials (SBOM): Tailored for sales, this BOM outlines everything that can be sold as part of a product package. It’s key for pricing strategies and sales planning, helping businesses fine-tune their offerings.

- Service Bill of Materials (SBOM): This one is all about maintenance and repair. It details the components needed for servicing a product, ensuring that service teams have the right parts handy to get repairs done smoothly.

By understanding these different BOM types, manufacturers can pick the right one to meet their operational needs, ultimately boosting efficiency and accuracy in their processes. To avoid common pitfalls in bill of materials management—like inaccuracies that can lead to manufacturing delays—producers should establish standardized procedures and utilize technology, such as Acumatica Cloud ERP, for real-time updates and oversight. As Melanie Chan wisely points out, "If anything is left off the manufacturing Bill of Materials, it stands to reason that it will be left out of the manufacturing process too." This really underscores how vital it is to keep BOMs accurate and detailed.

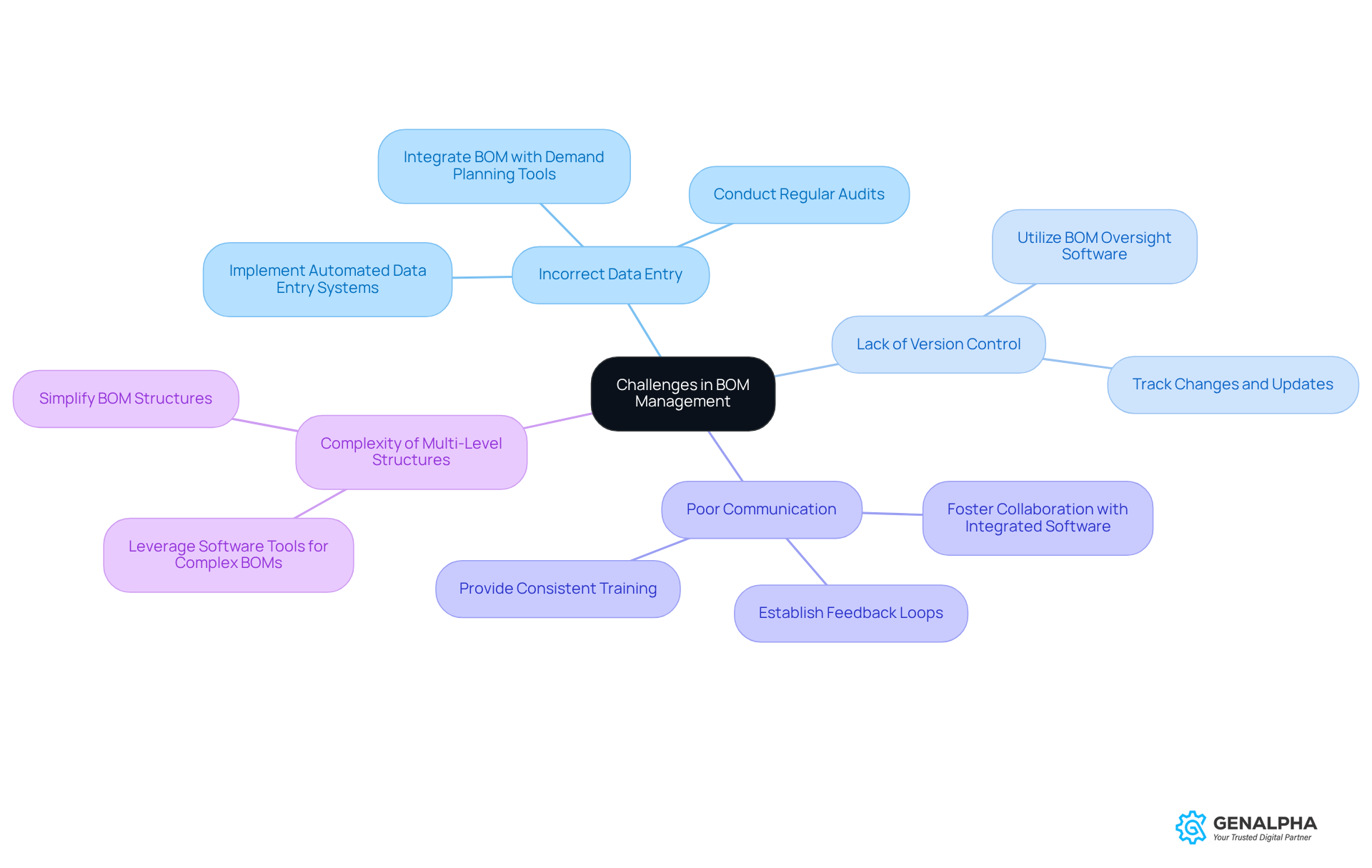

Identify Common Challenges in BOM Management and Solutions

BOM oversight can be a tricky business, and it comes with its fair share of challenges that can really impact manufacturing efficiency. Let’s dive into some common issues and explore effective solutions together:

-

Incorrect Data Entry: We’ve all been there—data input mistakes can lead to significant delays and increased costs. Did you know that poor bill of materials management can drive up the cost of goods sold and even lead to revenue loss? Manufacturers often find themselves facing surplus or insufficient inventory due to discrepancies, which can stretch lead times and complicate scheduling.

- Solution: Consider implementing automated data entry systems to reduce human error, and don’t forget to conduct regular audits to ensure everything is accurate. This not only streamlines your processes but also boosts overall operational efficiency. Plus, integrating your BOM with demand planning tools like Netstock can enhance forecasting accuracy and cut down lead times.

-

Lack of Version Control: Without , teams might unknowingly work with outdated BOMs, creating inconsistencies across departments. This can mess with manufacturing timelines and increase the risk of using outdated components.

- Solution: Why not utilize BOM oversight software that has version control features? This way, you can effectively track changes and updates, ensuring everyone is on the same page with the most current information and reducing errors.

-

Poor Communication: Miscommunication between departments is another common pitfall. It can lead to discrepancies in BOM data, resulting in production inefficiencies and delays.

- Solution: Let’s foster collaboration! Integrated software solutions that allow for real-time updates and communication among teams can make a world of difference. Establishing feedback loops can help pinpoint bottlenecks and enhance processes related to bill of materials management. And remember, consistent training on bill of materials management for all teams is key to minimizing miscommunication and mistakes—this should definitely be part of onboarding for new staff.

-

Complexity of Multi-Level Structures: Managing multi-level structures can feel overwhelming, especially with large and intricate products. This complexity can lead to mismanagement and delays.

- Solution: Simplifying BOM structures where possible can help, and leveraging software tools designed to handle complex BOMs efficiently is a smart move. This can improve clarity and streamline oversight.

By proactively addressing these challenges, we can significantly enhance our BOM oversight processes, leading to better production efficiency and reduced operational expenses. So, what do you think? Ready to tackle these issues head-on?

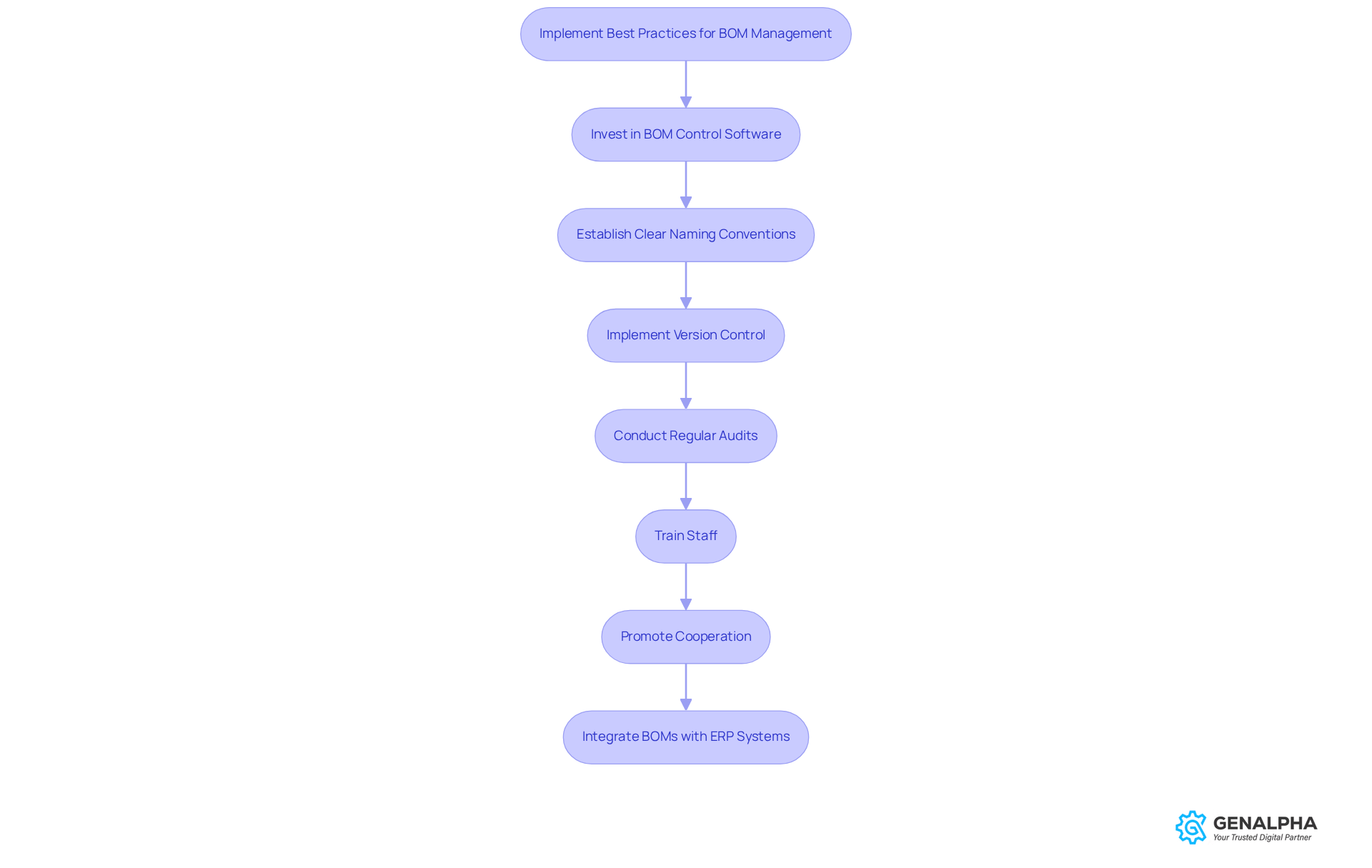

Implement Best Practices for Effective BOM Management

To optimize your Bill of Materials (BOM) management, let’s explore some best practices that can really make a difference:

- Invest in BOM Control Software: Think about how much easier life could be with specialized software! It simplifies creating, updating, and overseeing your BOM. Just look at Crazy Aaron Enterprises—they improved transparency and inventory management by using effective software solutions. They faced challenges with multi-level BOMs and inventory imbalances, which highlights how crucial modern software is in tackling these issues.

- Establish Clear Naming Conventions: Have you ever felt confused by inconsistent part names? Consistent naming conventions are key to avoiding that confusion and ensuring everyone is on the same page. This practice really boosts communication and coordination, especially in the context of for multi-level BOMs.

- Implement Version Control: Ever lost track of changes? A solid version control system helps you keep track of updates, ensuring that all teams are working with the latest BOM. This minimizes miscommunication between engineering and manufacturing teams, which is vital for keeping things running smoothly.

- Conduct Regular Audits: How often do you check your BOMs? Regular audits are essential for ensuring accuracy and relevance. These periodic reviews allow you to make necessary updates, preventing outdated information from causing production delays.

- Train Staff: Investing in training for your team on BOM processes and tools pays off. When your staff is well-prepared, they can manage BOMs efficiently. This investment fosters a culture of accuracy and efficiency in bill of materials management.

- Promote Cooperation: How about fostering a little teamwork? Encouraging dialogue among engineering, manufacturing, and sales teams ensures that your BOMs reflect the latest product designs and market demands. Real-time feedback from manufacturing can help procurement and engineering respond swiftly to changes, enhancing overall agility.

- Integrate BOMs with ERP Systems: Ever thought about how integration can streamline operations? Connecting your BOMs with ERP systems is a game-changer for decision-making across departments. This integration boosts efficiency, improves communication with suppliers, and gives you better control over production, making oversight a breeze.

By applying these best practices, you can significantly enhance your bill of materials management oversight processes. This leads to improved efficiency, reduced costs, and better product quality. Plus, integrating advanced BOM management software not only streamlines operations but also supports effective decision-making, driving your competitive advantage in the marketplace. So, why not start implementing these strategies today?

Conclusion

Mastering Bill of Materials (BOM) management is crucial for manufacturers who want to streamline operations and boost product quality. Think of a well-organized BOM as the backbone of your manufacturing process; it makes inventory management, cost estimation, and quality control a whole lot easier. By recognizing how vital BOMs are, you can steer clear of common pitfalls that often lead to inefficiencies and increased costs.

Let’s dive into some key aspects of effective BOM management. There are different types of BOMs—engineering, manufacturing, sales, and service—each with its own unique role in the product lifecycle. But, it’s not all smooth sailing; challenges like incorrect data entry, lack of version control, and poor communication can pop up. The good news? There are actionable solutions to tackle these hurdles. By investing in specialized software, establishing clear naming conventions, and promoting teamwork across departments, you can significantly improve BOM accuracy and efficiency.

In conclusion, we can’t stress enough how important it is to master BOM management. By embracing the strategies outlined here, manufacturers can enhance operational efficiency, reduce costs, and improve product quality. So, why not embrace technology and foster collaboration across your teams? Doing so will empower your organization to navigate the complexities of BOM management and lead to greater success in the competitive manufacturing landscape. Ready to take the plunge?

Frequently Asked Questions

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is a comprehensive list that details every raw material, component, sub-assembly, and part needed for manufacturing a product. It serves as a management system that ensures all necessary materials are ready when needed.

Why is BOM important for inventory management?

BOM is important for inventory management because it helps track available materials, allowing for quick ordering and reducing production interruptions. Well-managed BOMs enhance inventory accuracy, minimizing shortages and excess stock.

How does BOM contribute to cost estimation?

BOM aids in cost estimation by providing detailed information about all components, which helps manufacturers assess production costs accurately and make informed pricing decisions, crucial for budgeting and financial planning.

In what way does BOM assist in planning?

BOM assists in planning by clearly outlining the materials and components needed for production, which helps in scheduling and resource allocation, streamlining operations, and ensuring everyone is aligned in the manufacturing process.

How does BOM impact quality control?

BOM impacts quality control by listing every component required for production, ensuring that all materials meet the necessary standards, which helps reduce defects and improves overall product quality.

What are the different categories of BOM?

Different categories of BOM include engineering BOMs and sales BOMs, each serving a unique purpose throughout the product lifecycle.

Why is integration with project oversight important for BOM management?

Integration with project oversight is important for BOM management because it ensures that accurate product information is consistently available to the team, preventing miscommunication and mistakes during the manufacturing process.

What are the consequences of inaccurate BOMs?

Inaccurate BOMs can lead to material shortages, increased production costs, and dissatisfied customers, highlighting the importance of maintaining accuracy in BOM management.

How can technology improve BOM management?

Technology, such as Acumatica Cloud ERP, can enhance BOM management by providing real-time updates and seamless integration with other business processes, improving overall efficiency and accuracy.

What is the overall significance of managing BOM effectively?

Managing BOM effectively is crucial for optimizing manufacturing operations, influencing efficiency, cost control, and product quality, ultimately helping manufacturers meet customer demands.