Introduction

In the fast-paced world of industrial operations, have you ever thought about how the right equipment solutions can make or break your success? It’s true! Organizations that take the time to assess their operational needs and implement effective practices often see big boosts in efficiency and customer satisfaction. But here’s the kicker: navigating the complexities of technology selection, employee training, and keeping up with market demands can be quite the challenge.

So, how can companies ensure they’re not just picking the right tools but also creating a culture of continuous improvement? It’s all about staying ahead of the competition and fostering an environment where innovation thrives. Let’s dive into this together and explore how you can make a real difference in your operations!

Assess Operational Needs and Goals

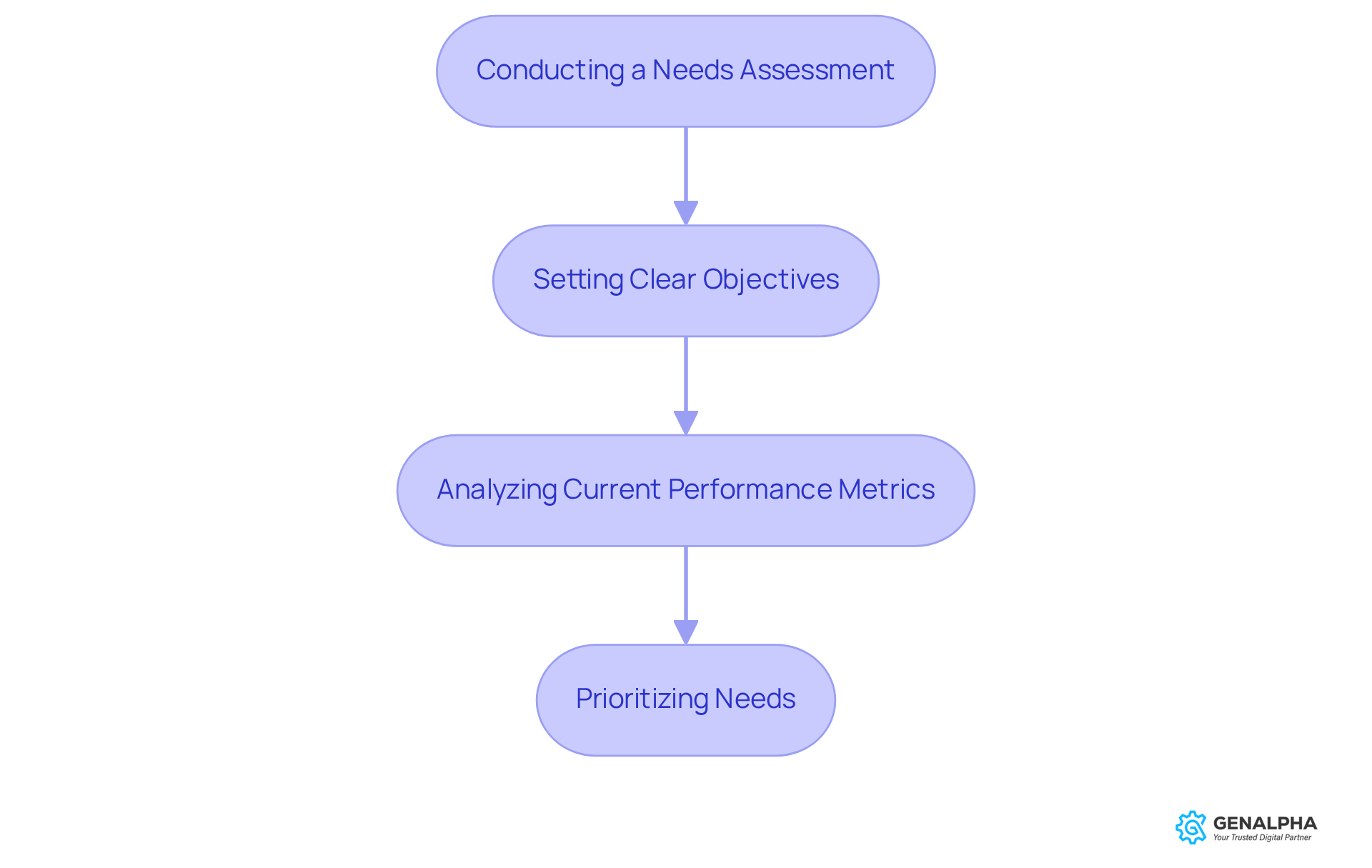

To successfully implement an industrial equipment solution, organizations need to start with a solid understanding of their operational needs and goals. Think of it like laying the groundwork for a house; without a strong foundation, everything else can crumble. This process involves diving deep into current workflows, spotting inefficiencies, and really getting to know what customers expect. Here are some key steps to consider:

-

Conducting a Needs Assessment: Bring together stakeholders from different departments to gather insights on operational challenges and customer feedback. You can do this through surveys, interviews, or even collaborative workshops. It’s interesting to note that companies investing in site-specific education see a whopping 215% increase in adherence to procedures. This really highlights how crucial thorough evaluations are!

-

Setting Clear Objectives: It’s essential to establish specific, measurable, achievable, relevant, and time-bound (SMART) goals that align with your overall business strategy. For instance, you might aim to cut down order processing time by 20% within six months. Sounds doable, right?

-

Analyzing Current Performance Metrics: Take a good look at your existing performance data to uncover trends and identify areas for improvement. Metrics like order fulfillment rates, customer satisfaction scores, and equipment downtime should be examined closely. With 45% of manufacturers reporting production delays at least once a week, understanding these metrics is key to making informed decisions.

-

Prioritizing Needs: Once you’ve completed your assessment, it’s time to prioritize the operational needs that will have the biggest impact on efficiency and customer satisfaction. This prioritization will help you choose the right tools and training initiatives, ultimately boosting operational performance. As Michael Sharov from Oliver Wyman pointed out, embracing short-term initiatives and workforce development is vital for tackling today’s challenges.

So, what do you think? Are you ready to take these steps and enhance your operational efficiency?

Choose Appropriate Technology and Tools

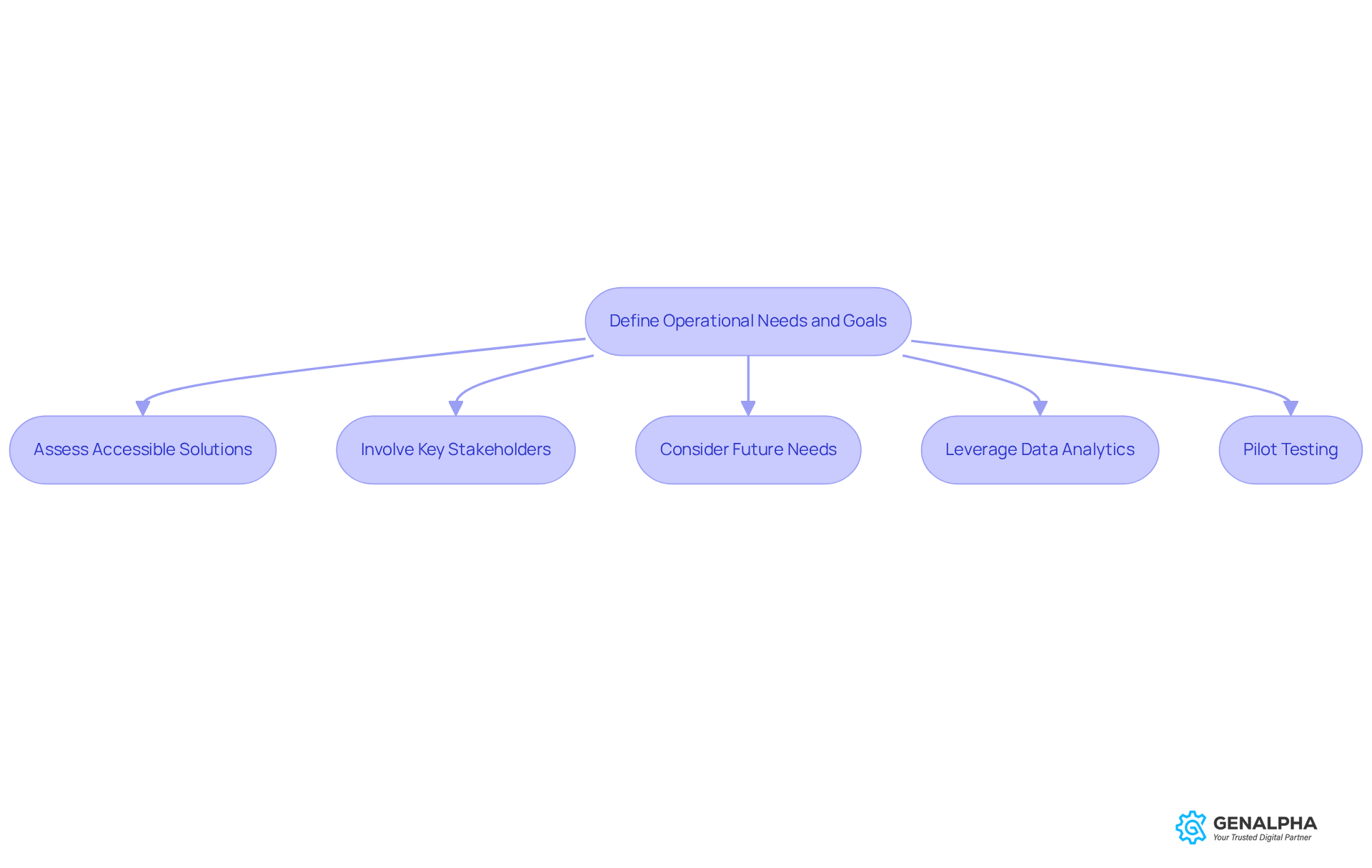

Once we’ve got our operational needs and goals clearly defined, the next step is to pick the right resources and tools that align with these objectives. Here are some best practices to keep in mind:

-

Assess Accessible Solutions: Take a moment to investigate and compare different methods that meet your identified needs. Think about factors like scalability, how well they integrate with your existing systems, and whether they’re user-friendly.

-

Involve Key Stakeholders: Don’t forget to engage the employees who will actually be using the system in the selection process. Their insights can help spot potential challenges and ensure that the tools you choose really meet practical requirements.

-

Consider Future Needs: It’s smart to choose solutions that not only meet your current demands but also have the flexibility to adapt to future shifts in the industry. This foresight can save you from costly upgrades later on.

-

Leverage Data Analytics: Implement tools that offer data analytics capabilities to keep an eye on performance and customer interactions. This data can guide ongoing improvements and help you make informed, data-driven decisions.

-

Pilot Testing: Before rolling out on a large scale, run some pilot tests of the chosen solution to see how effective it is and gather feedback from users. This step can help you identify any necessary tweaks before a broader rollout.

Provide Comprehensive Training and Support

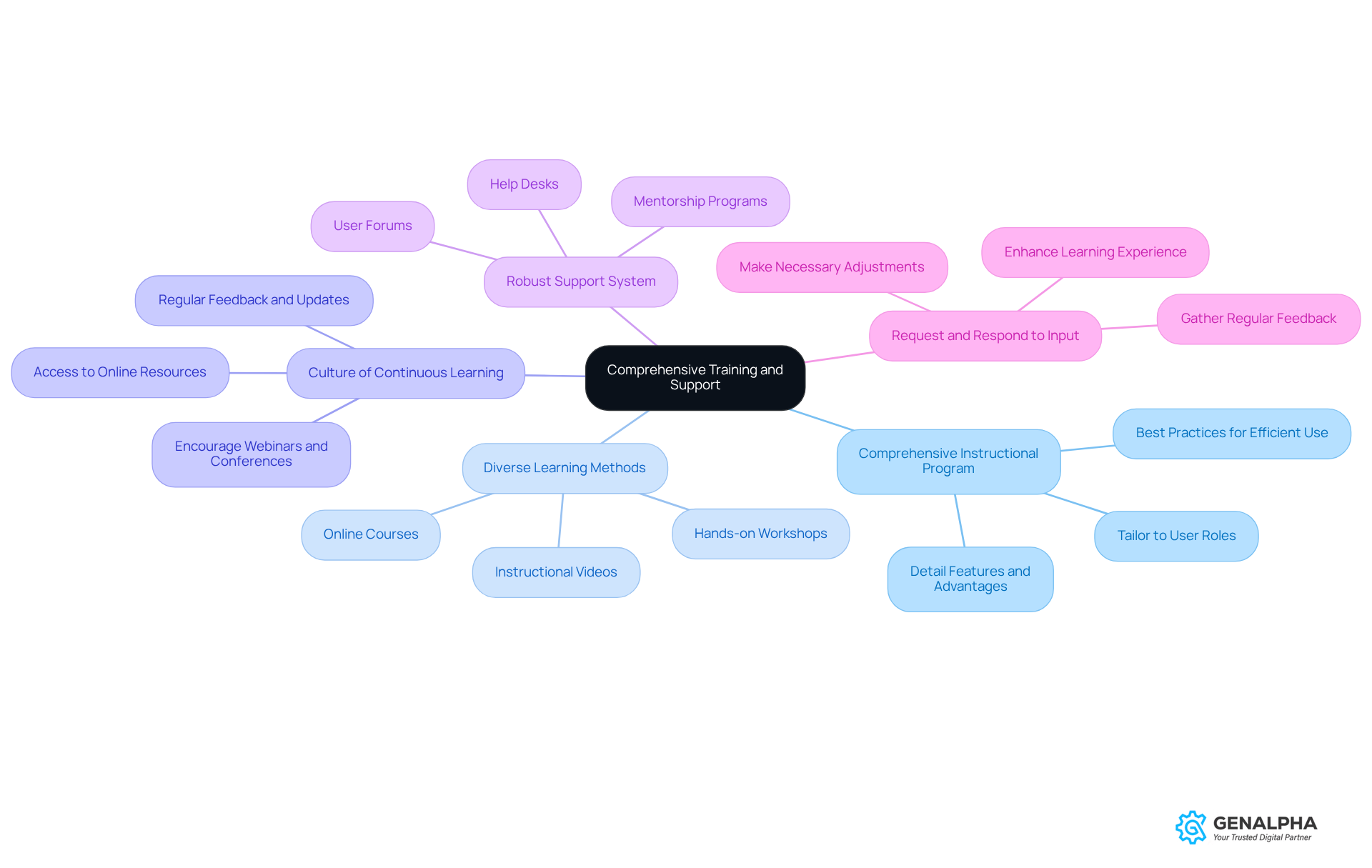

To ensure that an industrial equipment solution is executed effectively, organizations really need to focus on providing thorough instruction and support for their employees. Here are some key strategies to think about:

-

Create a Comprehensive Instructional Program: Start by building an educational plan that covers every aspect of the new system. This means detailing its features, advantages, and best practices for efficient use. Make sure to tailor this program to fit various user roles within the organization, so it’s relevant and applicable to everyone.

-

Incorporate Diverse Learning Methods: Mix things up with a variety of approaches! Hands-on workshops, online courses, and instructional videos can cater to different learning styles and preferences. This variety not only keeps things interesting but also helps with retaining information.

-

Promote a Culture of Continuous Learning: Let’s encourage ongoing education! Providing access to resources like online courses, webinars, and industry conferences keeps staff in the loop about the latest trends and advancements. Did you know that 92% of employees believe well-structured development programs boost their engagement? That’s a big deal!

-

Establish a Robust Support System: It’s crucial to have a solid support framework in place. Think help desks, user forums, and mentorship programs. This way, staff can easily get assistance when they face challenges with new technologies, which builds their confidence and competence.

-

Request and Respond to Input: Don’t forget to regularly gather feedback from staff about the development program and available support resources. Use this input to make necessary tweaks and improvements, enhancing the overall learning experience. Companies with comprehensive employee training programs actually see 218% higher income per employee compared to those without formal training.

So, what do you think? Ready to take these steps and boost your team's effectiveness?

Implement Continuous Evaluation and Adaptation

To keep up with changing market demands, organizations need to stay on their toes with ongoing assessments and adjustments. Here are some best practices to consider:

-

Establish Key Performance Indicators (KPIs): Start by defining KPIs that align with your operational goals and customer satisfaction metrics. Keep an eye on these indicators to evaluate performance and spot areas for improvement. Tracking KPIs effectively can really boost your operational efficiency and competitiveness. It helps manufacturers identify inefficiencies and fine-tune their processes. As Abby Jenkins puts it, "Manufacturing KPIs are quantifiable measurements that evaluate production processes against specific business objectives."

-

Conduct Regular Reviews: Make it a habit to schedule periodic evaluations of your processes, systems, and training programs. This can involve cross-departmental meetings to discuss findings and gather diverse perspectives, ensuring everyone is on the same page. Regular evaluations help you recognize trends and areas for development. Insightsoftware highlights the importance of monitoring KPIs in manufacturing, so don’t overlook this step!

-

Encourage Staff Input: Create an environment where your team feels comfortable sharing feedback on processes and technologies. Their insights can lead to valuable advancements and innovations. Engaged employees are more likely to contribute to quality and efficiency improvements. A culture of continuous enhancement can significantly boost operational performance, as shown in numerous case studies.

-

Adapt to Market Changes: Stay in the loop about industry trends and customer preferences. Be ready to tweak your processes and technologies to keep your competitive edge. Continuous improvement methodologies, like Kaizen, focus on small, incremental changes that add up to significant advancements. For instance, a manufacturing facility that embraced Kaizen practices saw remarkable improvements in efficiency and safety.

-

Invest in Continuous Improvement: Set aside resources for ongoing training, technology upgrades, and process enhancements. This commitment to continuous improvement will help your organization stay competitive in a fast-paced environment, ultimately boosting performance and customer satisfaction. Industry reports show that organizations investing in ongoing development see a solid return on investment (ROI) through increased productivity and reduced waste.

Common Pitfalls to Avoid: As you implement continuous evaluation and adaptation processes, watch out for common pitfalls like ignoring staff feedback, misaligning KPIs with strategic objectives, and neglecting regular reviews. Tackling these issues can lead to more effective implementation and better outcomes.

In conclusion, by setting up strong KPIs, conducting regular reviews, encouraging employee input, adapting to market changes, and investing in continuous improvement, organizations can enhance their operational efficiency and maintain a competitive edge through an industrial equipment solution in the sector.

Conclusion

You know, a successful implementation of industrial equipment solutions really depends on understanding what your operations need and what goals you’re aiming for. By starting off strong with thorough assessments, setting clear objectives, and analyzing performance, organizations can make sure their strategies hit the mark on both efficiency and customer satisfaction. Every step counts - from picking the right technologies to creating a culture of continuous learning, all of it plays a crucial role in boosting operational performance.

So, what’s the takeaway? Key insights from the article highlight how important it is to:

- Involve stakeholders in decision-making

- Offer solid training programs

- Set up a framework for ongoing evaluation and adaptation

By focusing on these practices, organizations can not only choose the right tools but also empower their teams to use these solutions effectively. And let’s not forget, continuous improvement through regular feedback and being responsive to market changes is key to staying ahead of the competition.

Ultimately, the journey to optimizing industrial equipment solutions is an ongoing one that requires dedication and strategic planning. Embracing these best practices won’t just enhance operational efficiency; it’ll also lead to better employee engagement and happier customers. So, why not take some actionable steps today? Let’s make sure your industrial equipment strategies are not just effective but also sustainable for the long haul!

Frequently Asked Questions

What is the first step in implementing an industrial equipment solution?

The first step is to assess operational needs and goals by understanding current workflows, identifying inefficiencies, and gathering insights on customer expectations.

How can organizations conduct a needs assessment?

Organizations can conduct a needs assessment by bringing together stakeholders from different departments to gather insights through surveys, interviews, or collaborative workshops.

Why is site-specific education important?

Site-specific education is important because companies that invest in it see a 215% increase in adherence to procedures, highlighting the value of thorough evaluations.

What are SMART goals?

SMART goals are specific, measurable, achievable, relevant, and time-bound objectives that align with an organization's overall business strategy.

What type of performance metrics should be analyzed?

Organizations should analyze metrics such as order fulfillment rates, customer satisfaction scores, and equipment downtime to uncover trends and identify areas for improvement.

Why is understanding performance metrics important?

Understanding performance metrics is important because 45% of manufacturers report production delays at least once a week, making informed decisions crucial for operational efficiency.

How should organizations prioritize their operational needs?

Organizations should prioritize operational needs based on their potential impact on efficiency and customer satisfaction, which will help in selecting the right tools and training initiatives.

What did Michael Sharov from Oliver Wyman emphasize regarding operational challenges?

Michael Sharov emphasized the importance of embracing short-term initiatives and workforce development to tackle today’s operational challenges effectively.