Introduction

In the fast-paced world of equipment manufacturing, have you ever thought about how the precision and accessibility of product information can really make or break a business? That’s where product database software comes into play. It’s not just a place to store specs and inventory; it’s a game-changer for boosting operational efficiency and fostering collaboration across departments.

But here’s the kicker: many manufacturers are still stuck with fragmented data and outdated practices. So, what’s at stake if they ignore this essential technology? And how can embracing it truly transform their operations for the better? Let’s dive into this together!

Understand the Role of Product Database Software in Equipment Manufacturing

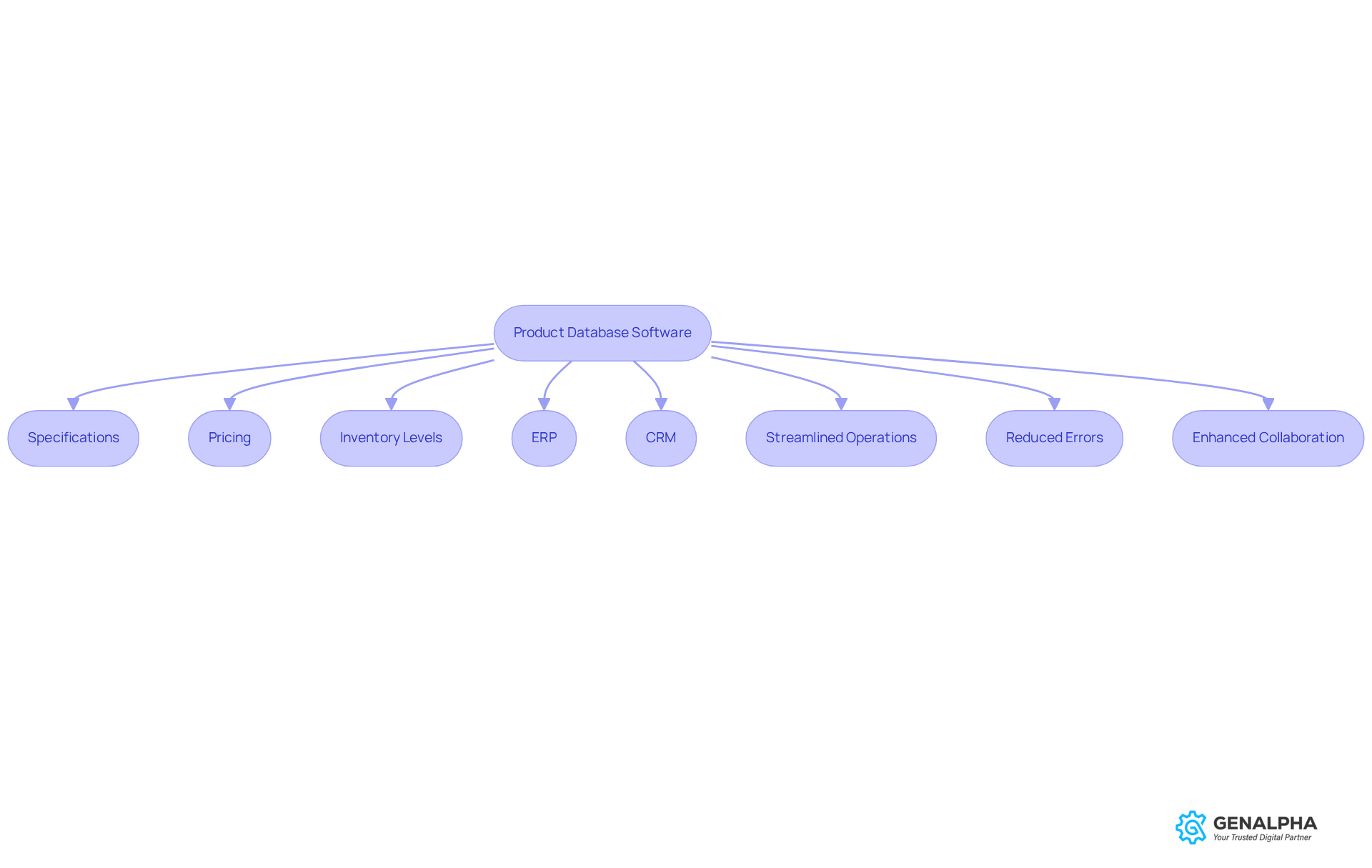

Have you ever considered how product database software serves as a central hub for everything related to products? It’s like having a one-stop shop for specifications, pricing, and inventory levels. In the equipment production world, where every detail counts, product database software helps producers keep their records fresh and accurate, making decision-making a breeze.

Imagine combining product info with product database software and integrating it with other systems like ERP and CRM. This integration isn’t just a nice-to-have; it streamlines operations, cuts down on errors, and boosts collaboration across departments. When everyone has access to the same accurate information, communication flows better, and operational efficiency skyrockets.

Recent trends show that the demand for information centers is pushing significant investments in manufacturing. This highlights just how crucial information management has become. As one industry expert put it, "Nothing undermines trust quicker than misalignment." This really drives home the need for precise information management in our decision-making processes.

But there’s more! With predictive analytics in play, producers can anticipate client needs and spot market trends. This foresight enhances decision-making even further. Plus, real-time information analysis means quick tweaks to strategies like pricing and promotions, helping producers stay competitive in a fast-paced market.

So, how are you leveraging these tools in your operations? Let’s chat about it!

Identify Key Challenges in Equipment Manufacturing Addressed by Product Databases

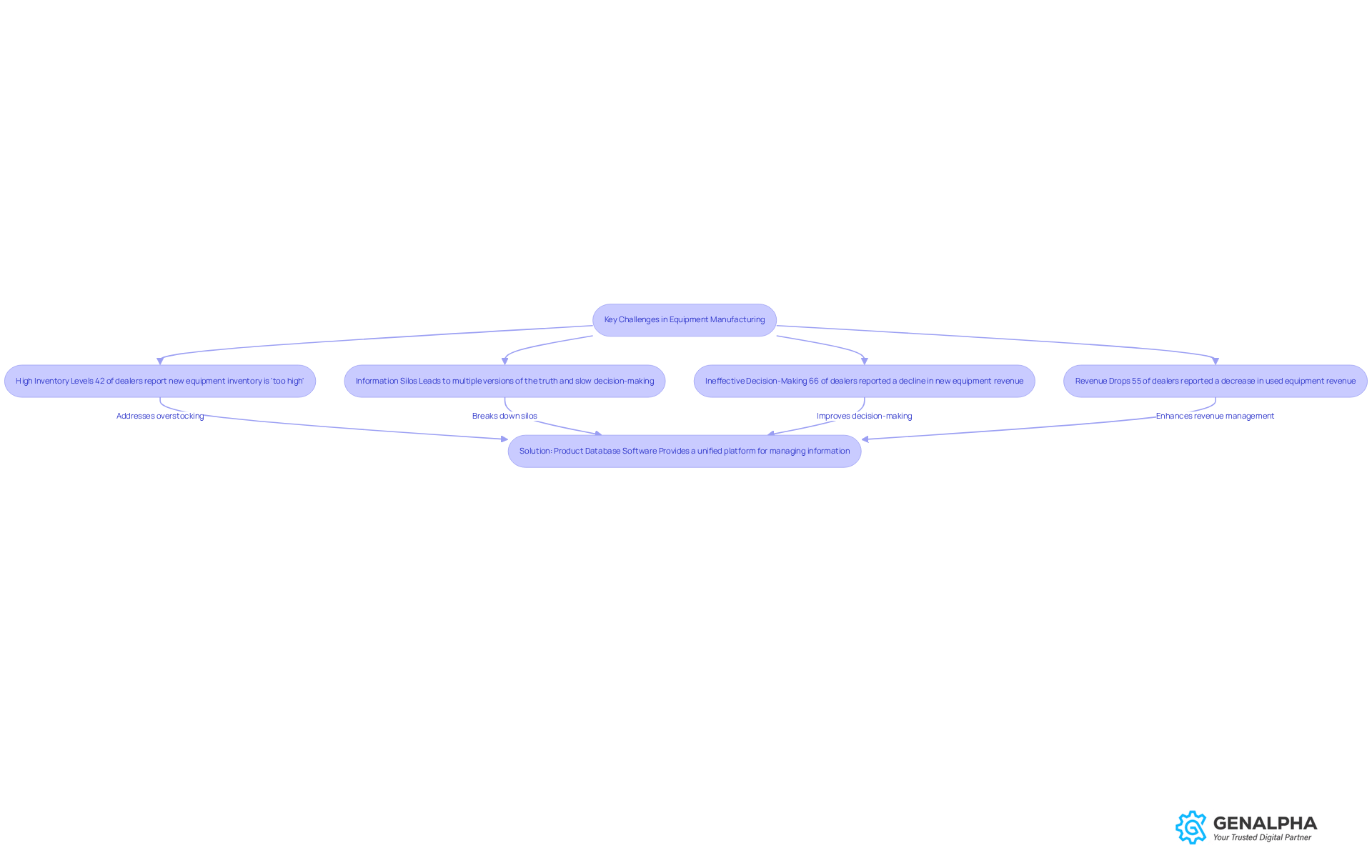

Equipment producers face some pretty significant hurdles, especially when it comes to managing inventory effectively and dealing with those pesky information silos. These issues can really throw a wrench in production efficiency and customer satisfaction. For instance, did you know that over 42% of dealers say their new equipment inventory levels are 'too high'? That’s a clear sign of overstocking, and 27% are struggling with similar problems for used equipment. These inefficiencies often stem from a lack of centralized information, making it tough to access real-time inventory levels. The result? Costly stockouts or surplus inventory. As noted by Surface & Panel Magazine, information silos can lead to multiple versions of the truth, slow decision-making, and incorrect information bouncing around between departments, complicating matters even further.

Additionally, when information is fragmented across different systems, it can really hinder effective decision-making, leading to mistakes in production and fulfillment. A staggering 66% of dealers reported a drop in new equipment revenue for 2025 compared to the previous year. That’s a wake-up call for better operational strategies! Proficy for Sustainability Insights points out that being able to integrate, overlay, and contextualize your organization’s information can pave the way for managing expenses and making smarter choices.

So, what’s the solution? Here, product database software can really step up to the plate. It offers a unified platform for managing information with product database software, ensuring that all teams have access to consistent and accurate data. This not only helps with better inventory control but also boosts overall operational efficiency. Isn’t it time we tackled these challenges head-on?

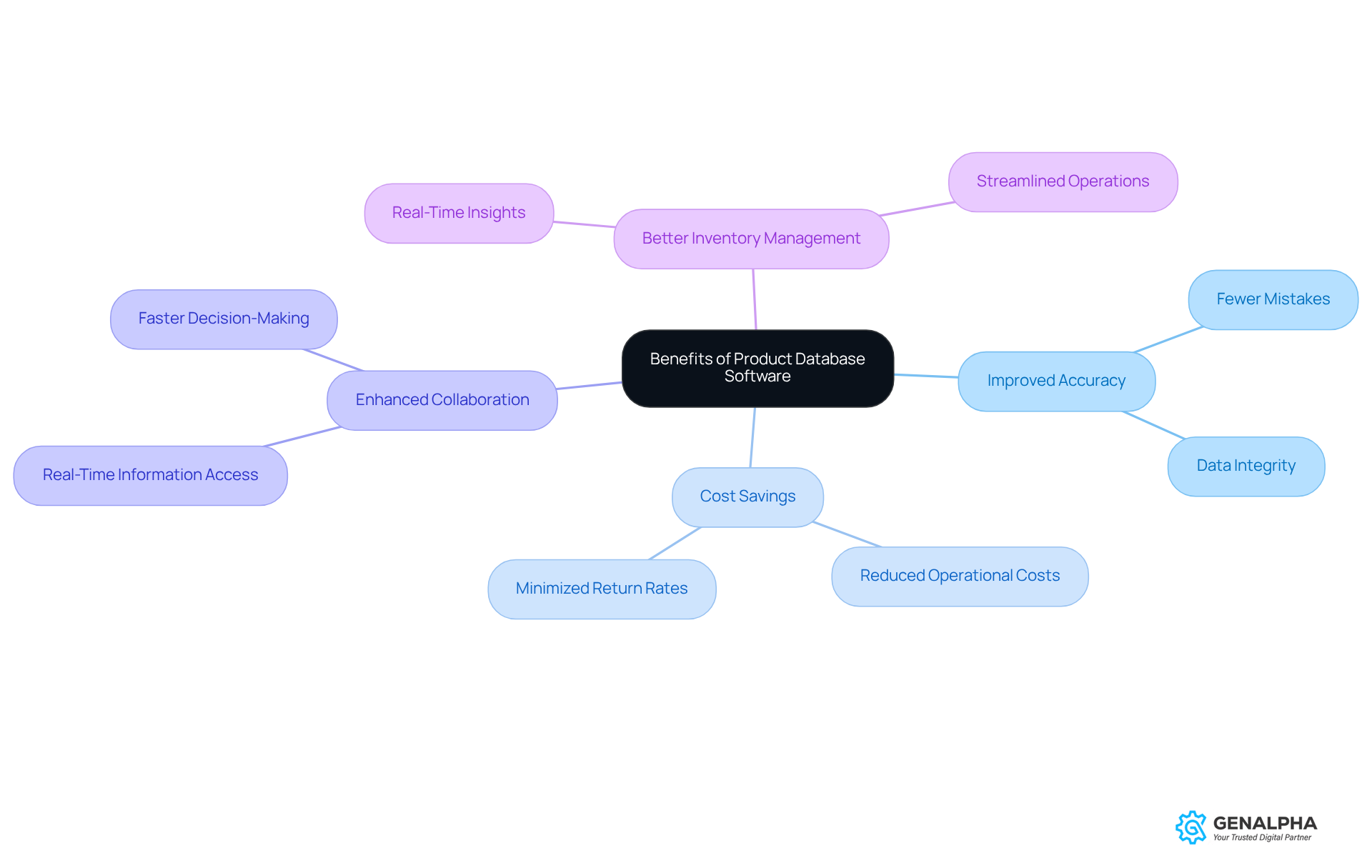

Explore the Benefits of Product Database Software for Manufacturers

Implementing product database software for goods can really change the game for equipment manufacturers. Think about it: when information is accurate, it’s a game-changer for quality and compliance with industry regulations. Accurate item details mean fewer mistakes, which can save a lot of money and keep customers happy. Plus, this software makes inventory management a breeze by giving real-time insights into stock levels. This means producers can really step up their supply chain operations. For instance, companies using automated information processing systems often see improved efficiency and fewer manual errors, leading to better product quality. In fact, automating data processing can significantly cut costs for producers, showing just how valuable these systems can be.

But that’s not all! Product database software also boosts collaboration among teams by ensuring that everyone has access to the same up-to-date information. This cuts down on miscommunication and speeds up decision-making, allowing producers to respond quickly to client inquiries and fulfill orders more effectively. Using real-time information synchronization tools is key to keeping item details consistent across platforms, which further enhances operational effectiveness. As a result, businesses that adopt these solutions often notice a big boost in client satisfaction. After all, having accurate and timely information leads to a more reliable purchasing experience. Companies that maintain precise item information can lower return rates and build stronger customer loyalty, highlighting how efficient inventory management impacts both operational success and customer relations.

However, it’s important to keep in mind the challenges that come with managing item information, like data fragmentation and integration issues. If these aren’t tackled, they can really hinder the benefits of these systems.

Examine the Risks of Not Utilizing Product Database Software

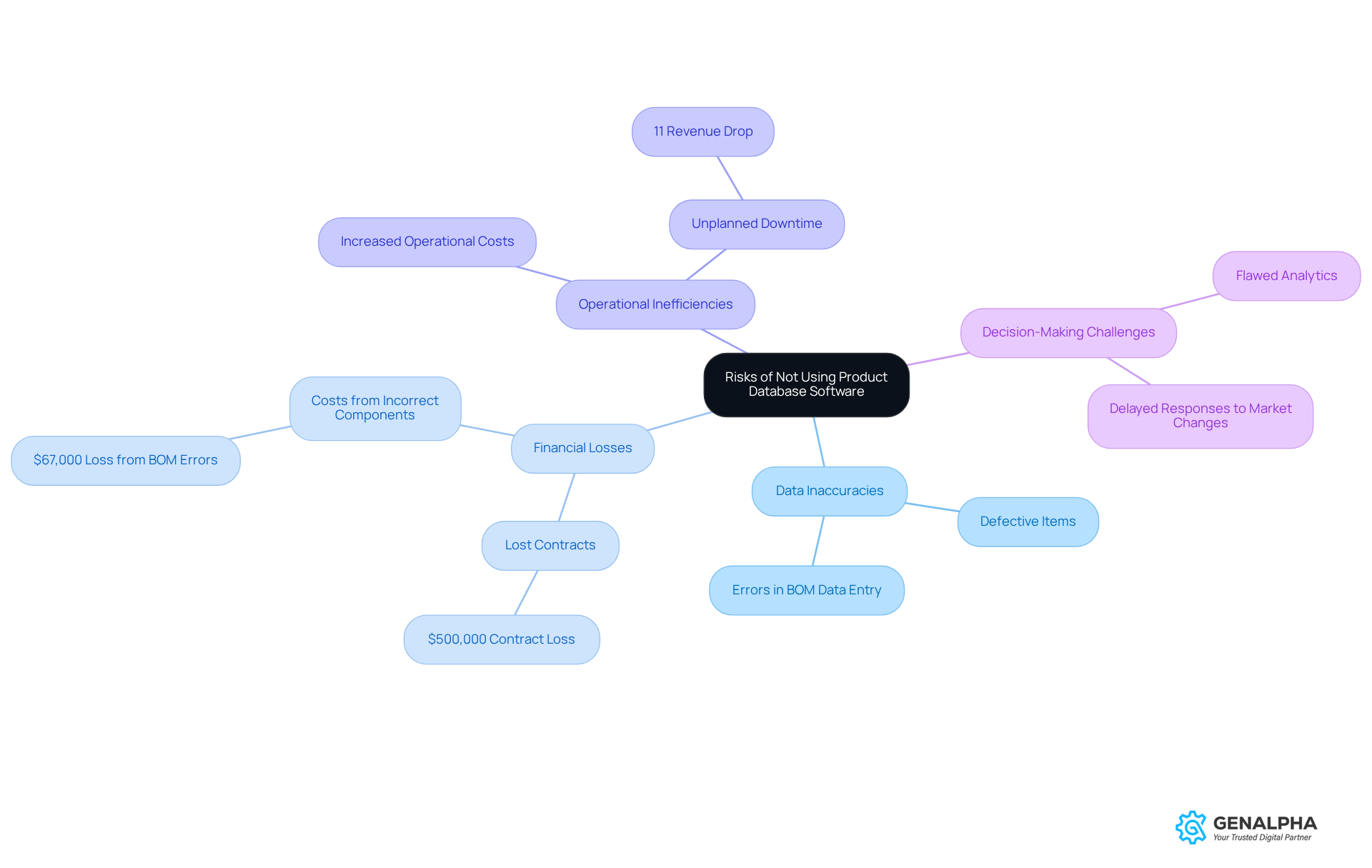

Neglecting to use product database software for items can really put equipment producers at risk. Think about it: data inaccuracies can lead to costly production and fulfillment mistakes. For example, if product specifications are outdated or incorrect, defective items might end up in customers' hands. That can seriously damage a producer's reputation and trust with their customers. Just look at the case of a custom machinery producer that lost a potential $500,000 contract because delays in quote generation were caused by manual bill of materials (BOM) processing. This really shows how inefficiencies in managing information can directly impact financial opportunities.

Additionally, without a centralized database, producers often face inefficient processes that drive up operational costs and hurt their competitiveness. Take a worldwide equipment producer that faced $67,000 in losses from improperly sourced components due to BOM transfer mistakes. This highlights the financial fallout from poor information quality. Did you know that unplanned downtime can lead to an 11% drop in annual revenue for the biggest companies? That’s a staggering $1.4 trillion in losses globally!

The lack of access to real-time information makes decision-making even trickier. It hampers producers' ability to respond quickly to market changes or customer demands. Inconsistent data can skew analytics, resulting in flawed strategies and delayed workflows. As manufacturers work to boost their operational efficiency, it is crucial to invest in solid product database software. It helps mitigate these risks and ensures that accurate, timely information flows smoothly throughout their operations.

Conclusion

Product database software is a game changer for equipment manufacturers. Think about it: managing all that product-related information can be a real headache. But with this software, you can centralize everything - specifications, pricing, inventory - making decision-making a breeze and boosting your operational efficiency. Plus, when it integrates with systems like ERP and CRM, it’s like having a superpower. Everyone in your organization gets access to accurate, timely information, which is crucial in today’s competitive manufacturing landscape.

Throughout this article, we’ve seen just how many advantages product database software brings to the table. It tackles big challenges like inventory mismanagement, information silos, and data inaccuracies - issues that can lead to costly mistakes and inefficiencies. By tapping into real-time insights and predictive analytics, manufacturers can not only tighten up their inventory control but also foster better collaboration across teams. The result? Happier customers and increased loyalty.

So, why is adopting product database software so important? As equipment manufacturers face more complexities in their operations, investing in solid information management solutions is key to mitigating risks and staying competitive. Embracing these tools isn’t just about keeping up with industry trends; it’s about creating a culture of accuracy and efficiency that drives long-term success. Taking proactive steps to implement product database software is a smart move that can lead to significant benefits in the ever-evolving manufacturing sector. Ready to make that leap?

Frequently Asked Questions

What is the role of product database software in equipment manufacturing?

Product database software acts as a central hub for all product-related information, including specifications, pricing, and inventory levels, helping producers maintain accurate records and streamline decision-making.

How does product database software integrate with other systems?

It can be integrated with systems like ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management), which streamlines operations, reduces errors, and enhances collaboration across departments.

Why is accurate information management important in manufacturing?

Accurate information management is crucial because it fosters trust, improves communication, and boosts operational efficiency, which are essential for effective decision-making.

What recent trends are influencing investments in manufacturing?

The rising demand for information centers is driving significant investments, emphasizing the importance of information management in the manufacturing sector.

How does predictive analytics enhance decision-making in manufacturing?

Predictive analytics enables producers to anticipate client needs and identify market trends, allowing for more informed decision-making and quicker adjustments to strategies like pricing and promotions.

What benefits does real-time information analysis provide to manufacturers?

Real-time information analysis allows manufacturers to make swift changes to their strategies, helping them remain competitive in a rapidly changing market.