Introduction

Navigating today’s competitive landscape can be tough for equipment manufacturers, right? That’s why understanding product content data management (PCDM) is so crucial. This system doesn’t just organize product information; it also boosts operational efficiency and keeps customers happy. But let’s be real-many manufacturers struggle with issues like inconsistent data and compliance risks that can really throw a wrench in their success.

So, how can embracing effective PCDM practices turn these challenges into opportunities for growth and innovation? Imagine transforming those hurdles into stepping stones that lead to a more streamlined operation and satisfied customers. It’s all about making the right moves!

Let’s dive into how you can harness the power of PCDM to not only tackle these issues but also propel your business forward. Are you ready to explore the possibilities?

Define Product Content Data Management and Its Importance for Equipment Manufacturers

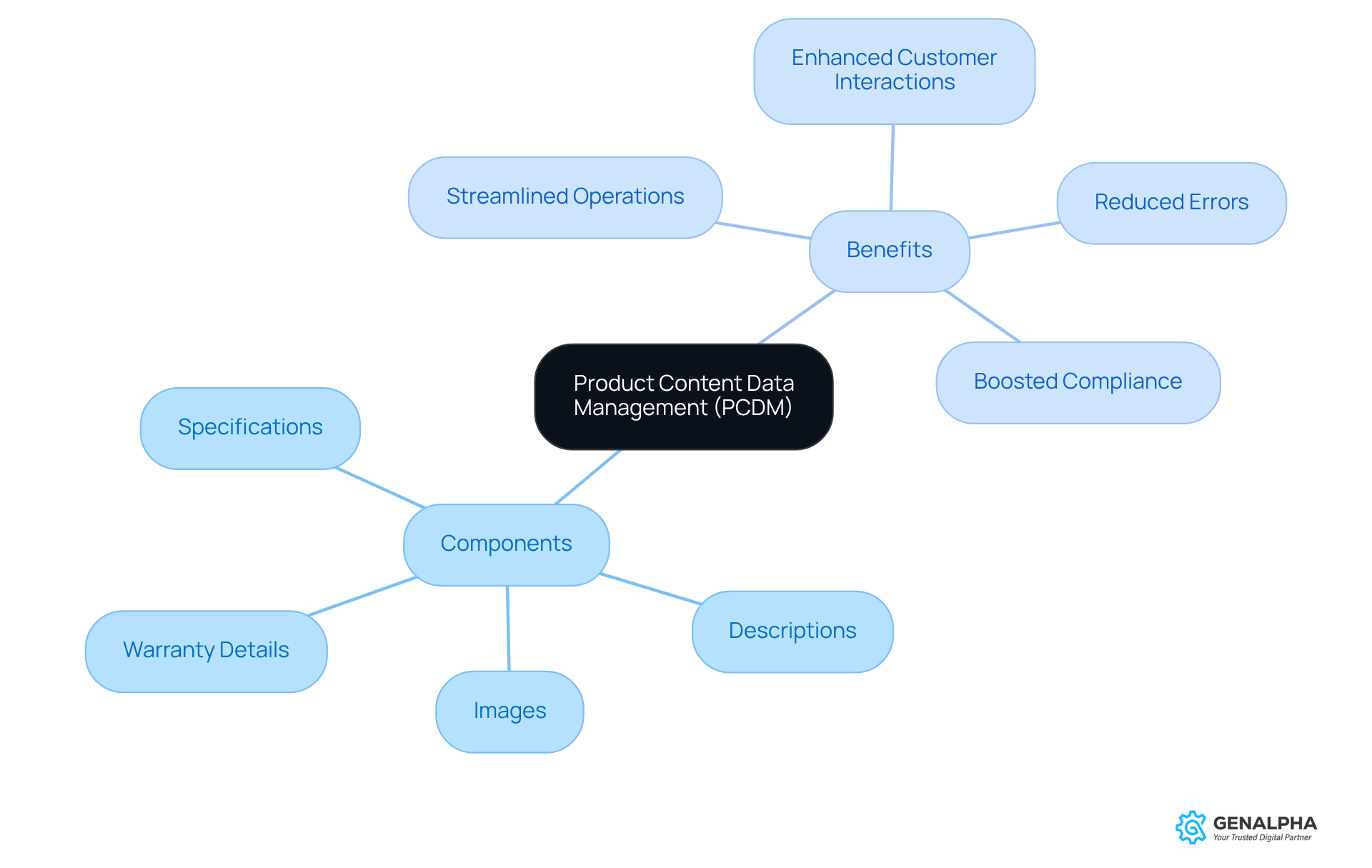

Have you ever wondered how product information stays organized and accessible? That’s where product content data management comes into play! It’s all about gathering, arranging, and keeping track of product details throughout their lifecycle. For equipment producers, this system is a game changer. It ensures that accurate and up-to-date information is just a click away, no matter where you are or what platform you’re using.

Think about it: from product specifications and descriptions to images and warranty details, product content data management encompasses it all. This seamless flow of data not only streamlines internal operations but also enhances customer interactions. In an industry where precision and reliability are key, effective product content data management can really make a difference. It helps reduce errors, boosts compliance, and ultimately leads to happier customers who keep coming back for more.

So, why not take a closer look at how PCDM can benefit your business? It’s time to embrace a system that keeps your product information organized and your customers satisfied!

Identify Key Challenges in Equipment Manufacturing Addressed by PCDM

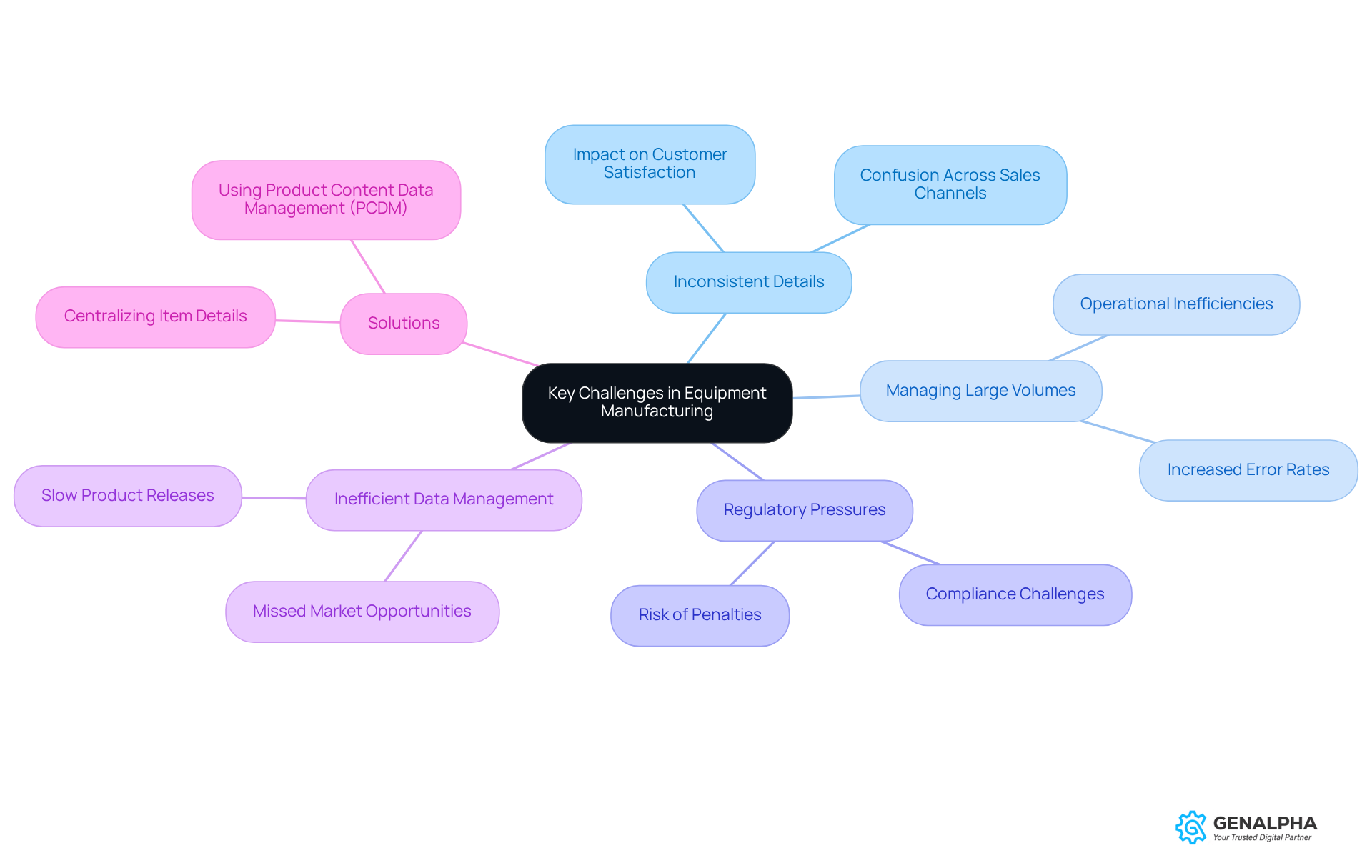

Equipment manufacturers often run into a few bumps in the road that can really throw a wrench in their operational efficiency and customer satisfaction. Think about it: inconsistent details across various sales channels, the headache of managing large volumes of items, and the constant pressure to stick to industry regulations. Plus, there’s the frustration of slow releases caused by inefficient product content data management processes, which can lead to missed market opportunities.

So, how do we tackle these challenges? That’s where centralizing item details comes into play. By ensuring consistency and optimizing workflows, manufacturers can really turn things around. With product content data management (PCDM) in their toolkit, they can overcome these hurdles, reduce errors, and enhance their responsiveness to market demands.

Isn’t it time to take action? Let’s embrace these solutions and see how they can transform our operations!

Examine the Benefits of Implementing Product Content Data Management

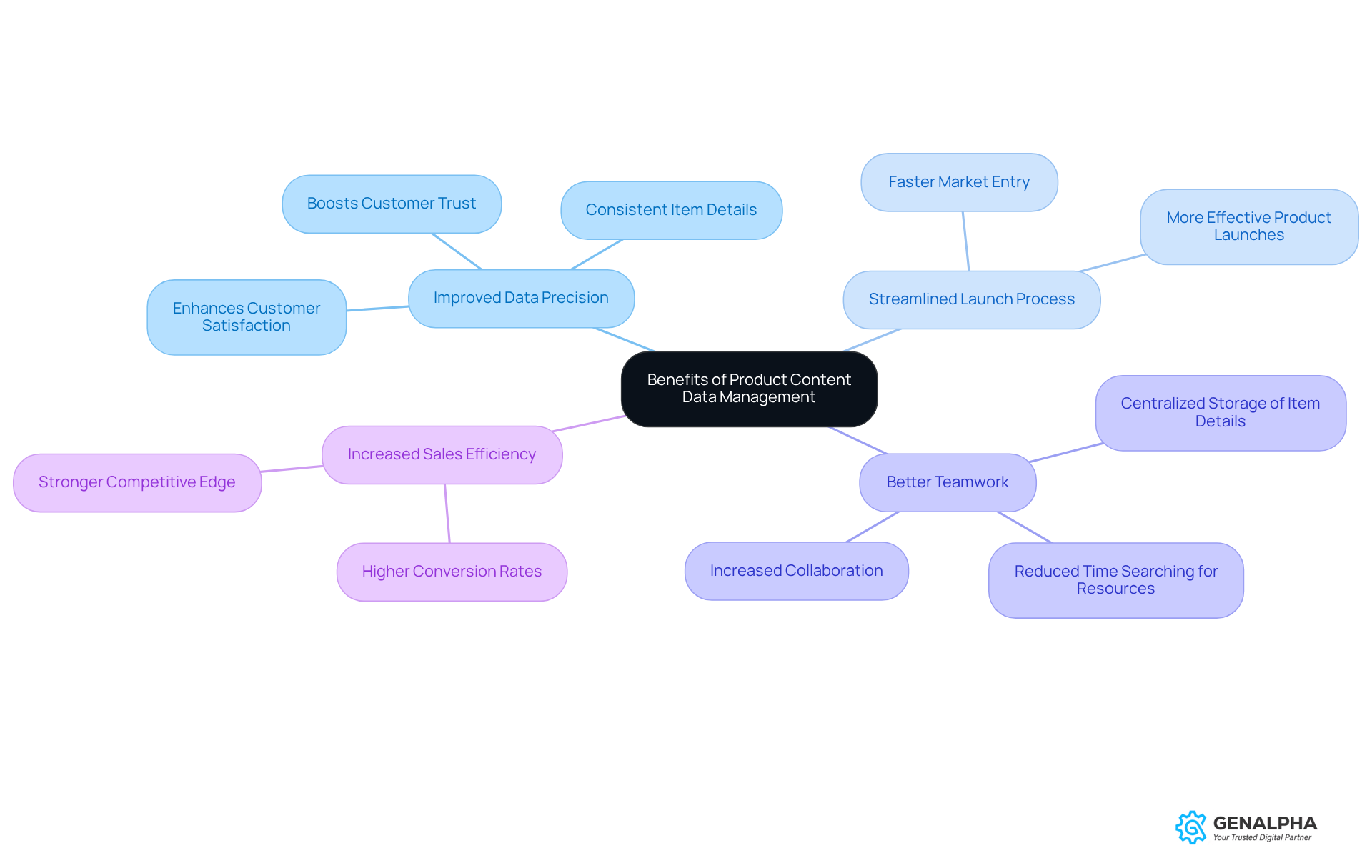

Have you ever wondered how product content data management can truly transform the landscape for equipment manufacturers? Well, let’s dive in!

First off, it’s all about improving data precision. Imagine having all your item details consistent and trustworthy across every platform. This not only boosts customer trust but also enhances satisfaction. When clients have accurate information at their fingertips, making purchasing decisions becomes a breeze.

But that’s not all! This system also streamlines the launch process. Manufacturers can get their goods to market faster and more effectively. Who wouldn’t want that?

Additionally, it fosters better teamwork. With a centralized storage of item details, teams spend less time searching for resources and more time collaborating.

In the end, these benefits lead to increased sales efficiency and a stronger competitive edge in the marketplace. So, why not consider implementing product content data management? It could be the key to unlocking your business’s potential!

Analyze the Consequences of Ignoring Product Content Data Management

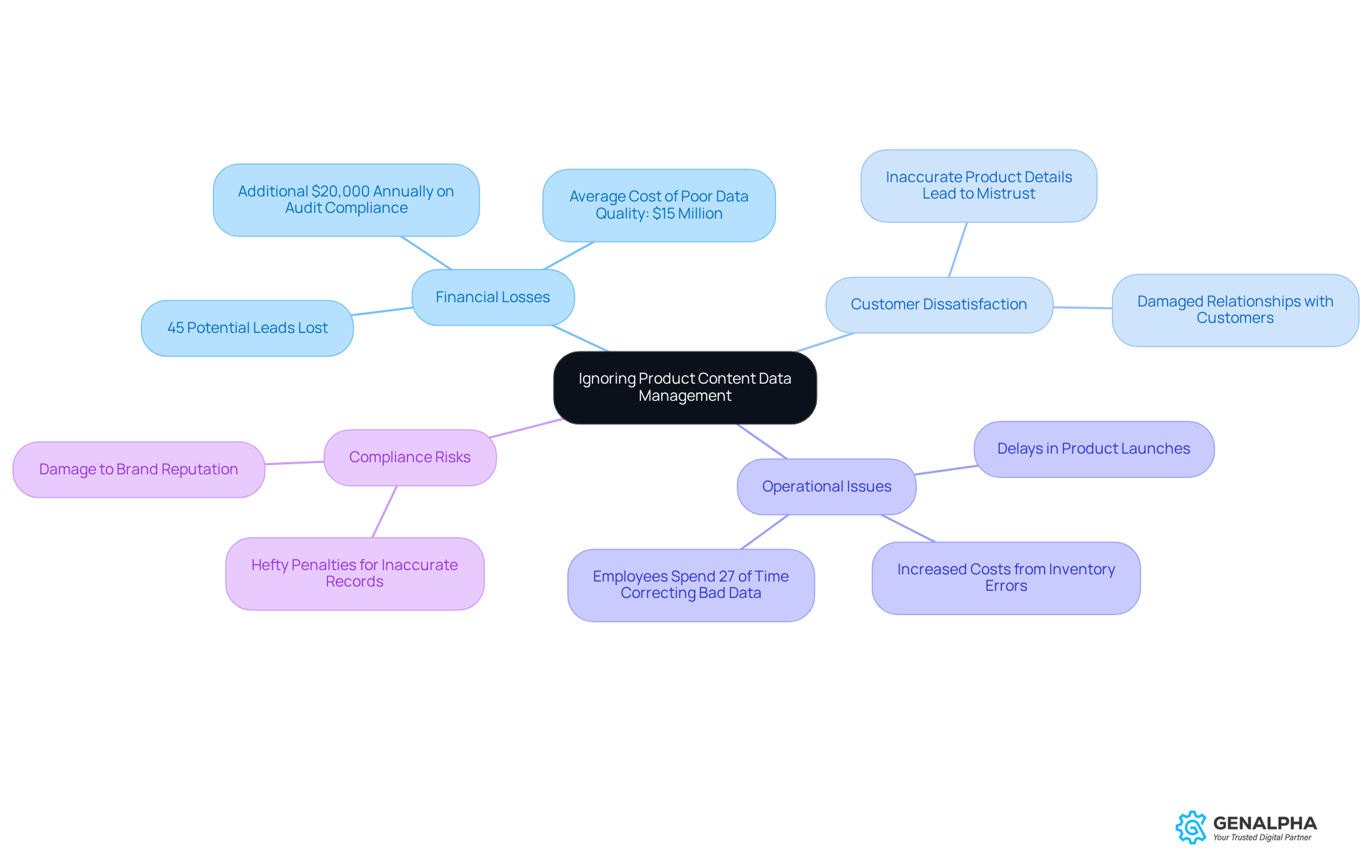

Neglecting product content data management can really hurt equipment manufacturers. Have you ever thought about how incorrect or outdated information about products can lead to unhappy customers? Research shows that companies can lose up to 45% of potential leads due to poor quality information. That’s a big deal! According to Gartner, the cost of inadequate information quality hits organizations with an average of $15 million each year. Just imagine the financial impact of these issues!

When customers get inaccurate product details, it can lead to mistrust. This not only results in lost sales but also damages relationships. Plus, poor information management can create operational headaches, like delays in product launches and increased costs from inventory errors. For instance, companies might spend an extra $20,000 a year just on personnel time to deal with audit compliance issues stemming from inaccurate data.

And let’s not forget about compliance risks. If manufacturers don’t keep accurate records, they could face hefty penalties and damage to their reputation. Case studies have shown that customer dissatisfaction often stems from weak product content data management practices, which highlights just how crucial effective practices are in this area.

So, what’s the takeaway? Neglecting product content data management can seriously hurt a manufacturer’s ability to compete in today’s fast-paced market. It’s time to take action and prioritize effective data management!

Conclusion

Product content data management (PCDM) is a game changer for equipment manufacturers aiming for operational excellence and happy customers. By centralizing and organizing product information, manufacturers can keep their data accurate, up-to-date, and easily accessible. This not only builds trust but also enhances the customer experience. Embracing PCDM isn’t just a nice-to-have; it’s a must for anyone wanting to thrive in today’s competitive landscape.

Let’s face it: equipment manufacturers face some serious challenges. We’ve talked about inconsistencies in product details, compliance pressures, and the headaches of outdated processes. But here’s the good news - implementing PCDM can tackle these issues head-on. It streamlines workflows, cuts down on errors, and speeds up the time-to-market for new products. Plus, the perks go beyond just operational improvements; better data management helps forge stronger relationships with customers and partners alike.

So, what happens if manufacturers ignore product content data management? The consequences can be pretty severe - think lost sales, damaged reputations, and compliance risks. The evidence is clear: effective PCDM is crucial for keeping a competitive edge and ensuring long-term success in the equipment manufacturing sector. It’s time for manufacturers to see the value in robust data management practices and take proactive steps to implement them. The future of manufacturing depends on our ability to manage product content effectively, and the time to act is now. What are you waiting for?

Frequently Asked Questions

What is product content data management (PCDM)?

Product content data management (PCDM) is the process of gathering, arranging, and keeping track of product details throughout their lifecycle, ensuring that accurate and up-to-date information is accessible.

Why is PCDM important for equipment manufacturers?

PCDM is crucial for equipment manufacturers as it ensures that product information, such as specifications, descriptions, images, and warranty details, is organized and easily accessible, which enhances both internal operations and customer interactions.

How does effective PCDM benefit businesses?

Effective PCDM helps reduce errors, boosts compliance, and leads to happier customers, ultimately resulting in increased customer loyalty and satisfaction.

What types of information does PCDM encompass?

PCDM encompasses various types of information, including product specifications, descriptions, images, and warranty details.

How does PCDM improve customer interactions?

By providing accurate and organized product information, PCDM enhances customer interactions, making it easier for customers to find the information they need and improving their overall experience.