Overview

B2B manufacturing companies play a vital role in the success of our supply chains. Think about it: they’re the essential links connecting raw material providers to end users, navigating complex networks to ensure products are delivered efficiently.

What’s really interesting is how these companies adapt to market changes and embrace new technologies. This not only boosts their operational efficiency but also builds resilience. As a result, they drive logistical success and meet customer expectations in a way that keeps everyone happy.

So, next time you think about the supply chain, remember the B2B manufacturers. They’re not just behind the scenes; they’re at the forefront of innovation and efficiency. How can we support them in this journey?

Introduction

B2B manufacturing is a vital part of the logistics ecosystem, connecting raw material suppliers to end users in a way that’s essential for everyone involved. But as these manufacturers face a host of challenges—from rising costs to rapid technological changes—they’re doing more than just producing goods; they’re actually shaping efficient supply chains.

With market demands evolving quickly and the complexities of 2025 on the horizon, you might be wondering: how can B2B manufacturers not just keep up but really thrive? In this article, we’ll dive into the crucial role B2B manufacturing plays in supply chain success. We’ll explore the innovations and strategies that are set to redefine the future of logistics, and trust me, you won’t want to miss this!

Establish the Role of B2B Manufacturing in Supply Chains

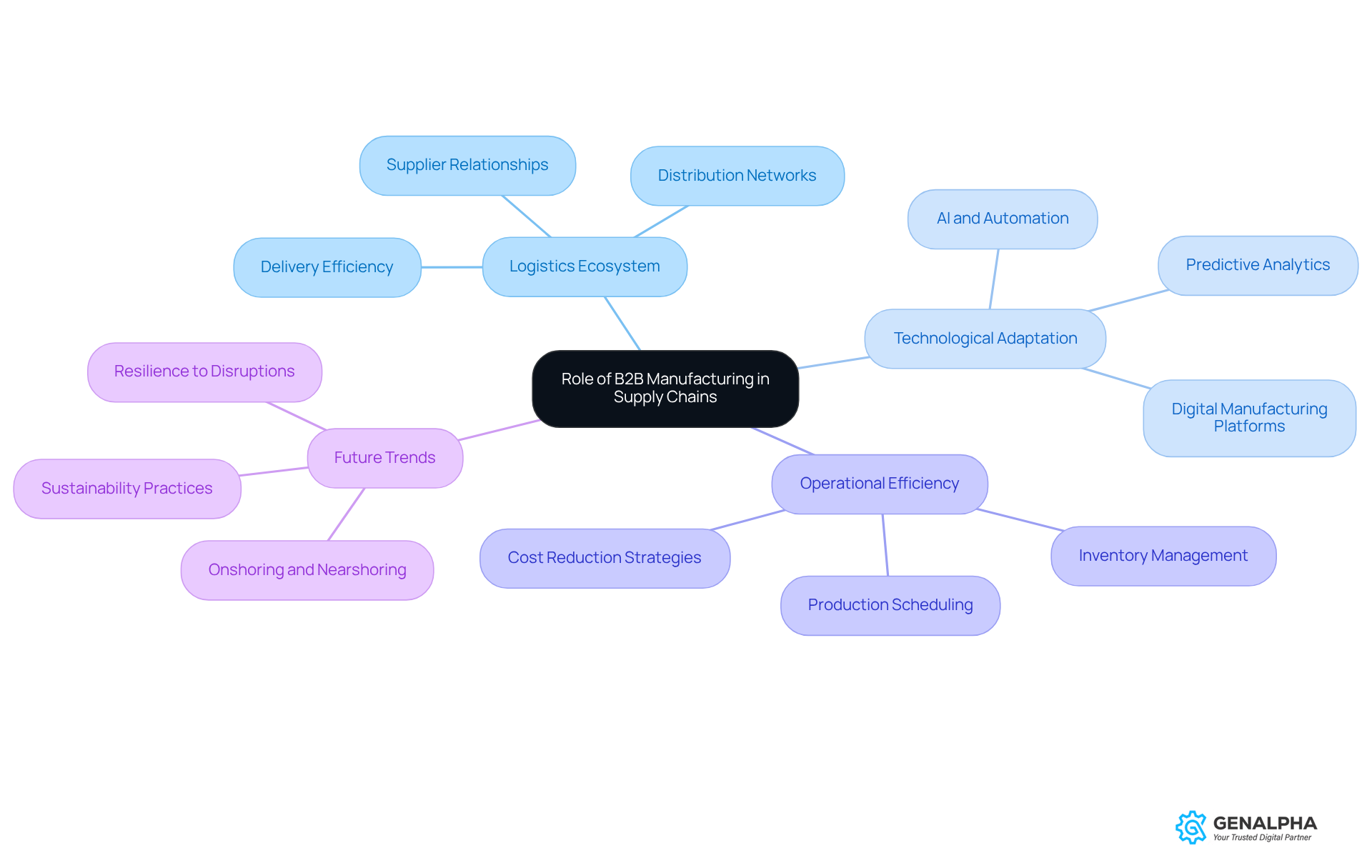

B2B manufacturing is a key player in the logistics ecosystem, acting as the vital link between raw material providers and end users. But manufacturers are more than just producers; they’re the ones who orchestrate complex networks of suppliers and distributors, making sure products get delivered efficiently and effectively. Have you ever thought about how they adapt to changing market needs? Their ability to work with various logistics partners is crucial for keeping operations running smoothly.

For example, manufacturers that embrace advanced technologies can really boost their production schedules, cut down lead times, and improve inventory management. This tech-savvy approach not only enhances their operational efficiency but also fortifies the entire logistics network’s resilience. It’s fascinating to see how these interconnected relationships highlight the role of B2B producers in driving logistical success, enabling the essential flow of goods and information that meets customer expectations.

As we approach 2025, the impact of producers on logistics efficiency will become even more apparent. With a growing emphasis on sustainability and adaptability to global challenges, it’s clear that the future of B2B manufacturing is not just about keeping up—it's about leading the way. What do you think will be the biggest changes in this space?

Examine Challenges Facing B2B Manufacturers in Supply Chain Dynamics

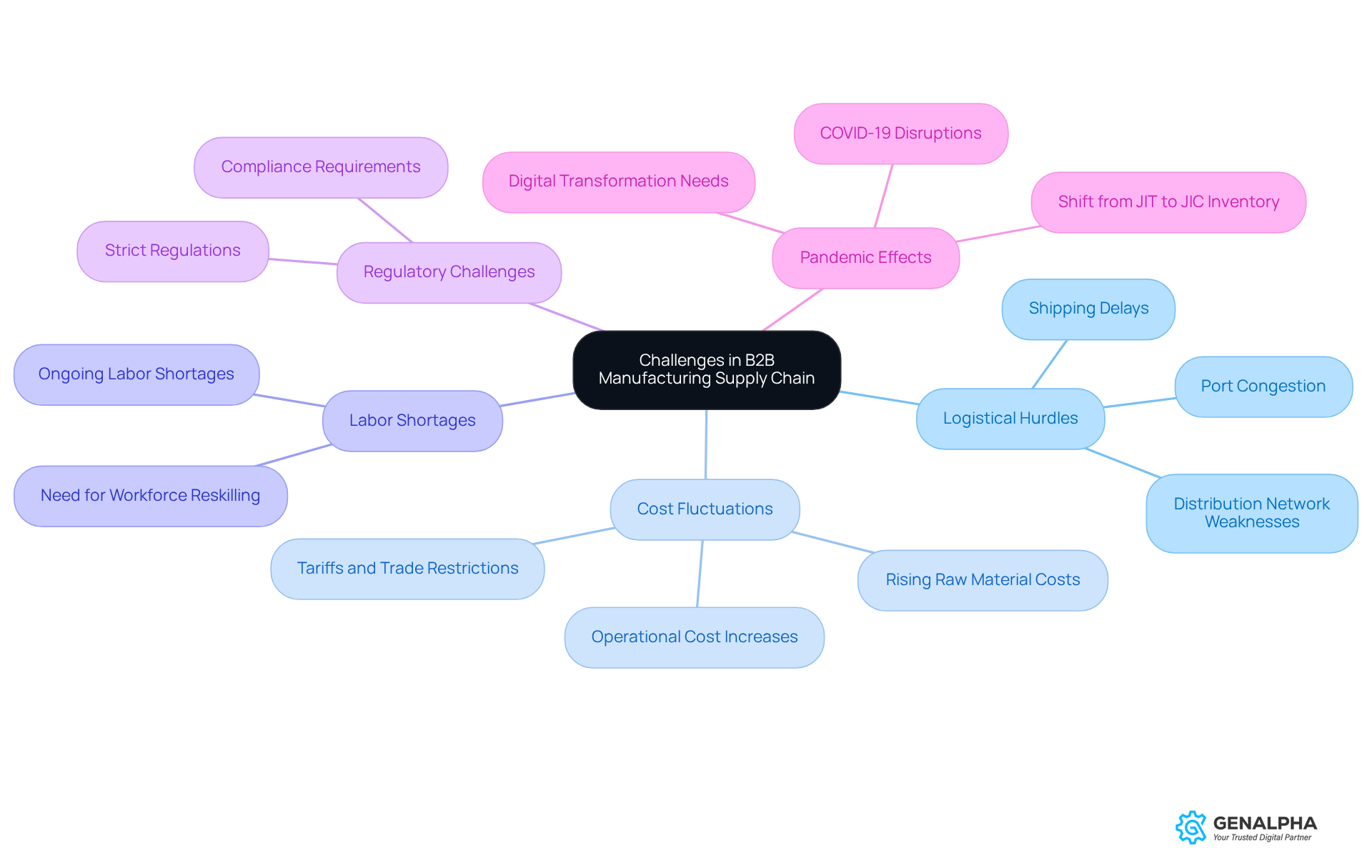

B2B manufacturing companies are navigating a tricky landscape filled with logistical hurdles. Think about it: fluctuating raw material costs, ongoing labor shortages, and strict regulations are just the tip of the iceberg. On top of that, tariffs and trade restrictions have made things even more complicated, pushing producers to adapt quickly to safeguard their profits.

The COVID-19 pandemic really brought to light the weaknesses in distribution networks, causing significant disruptions that affected production timelines and stock management. In fact, did you know that 94% of Fortune 1000 firms reported logistics disruptions during this time? This highlights just how urgent it is for producers to rethink their strategies. Alarmingly, only 2% of companies surveyed in 2020 felt fully prepared for the pandemic. This situation underscores the critical need for proactive management and digital transformation in B2B manufacturing companies.

Additionally, many producers are shifting from just-in-time (JIT) to just-in-case (JIC) inventory systems to mitigate risks associated with distribution vulnerabilities. Rising operational costs due to tariffs are further squeezing profitability, making it crucial for manufacturers to enhance data integration for better supply-and-demand visibility. In fact, 53% of U.S. executives are planning to improve this aspect.

So, what’s the takeaway? To thrive in this challenging environment, a proactive resource management strategy is essential. B2B manufacturing companies must embrace innovation and foster collaboration with partners to build resilience and boost operational efficiency. How are you planning to adapt to these changes?

Explore Technological Innovations Transforming B2B Manufacturing Supply Chains

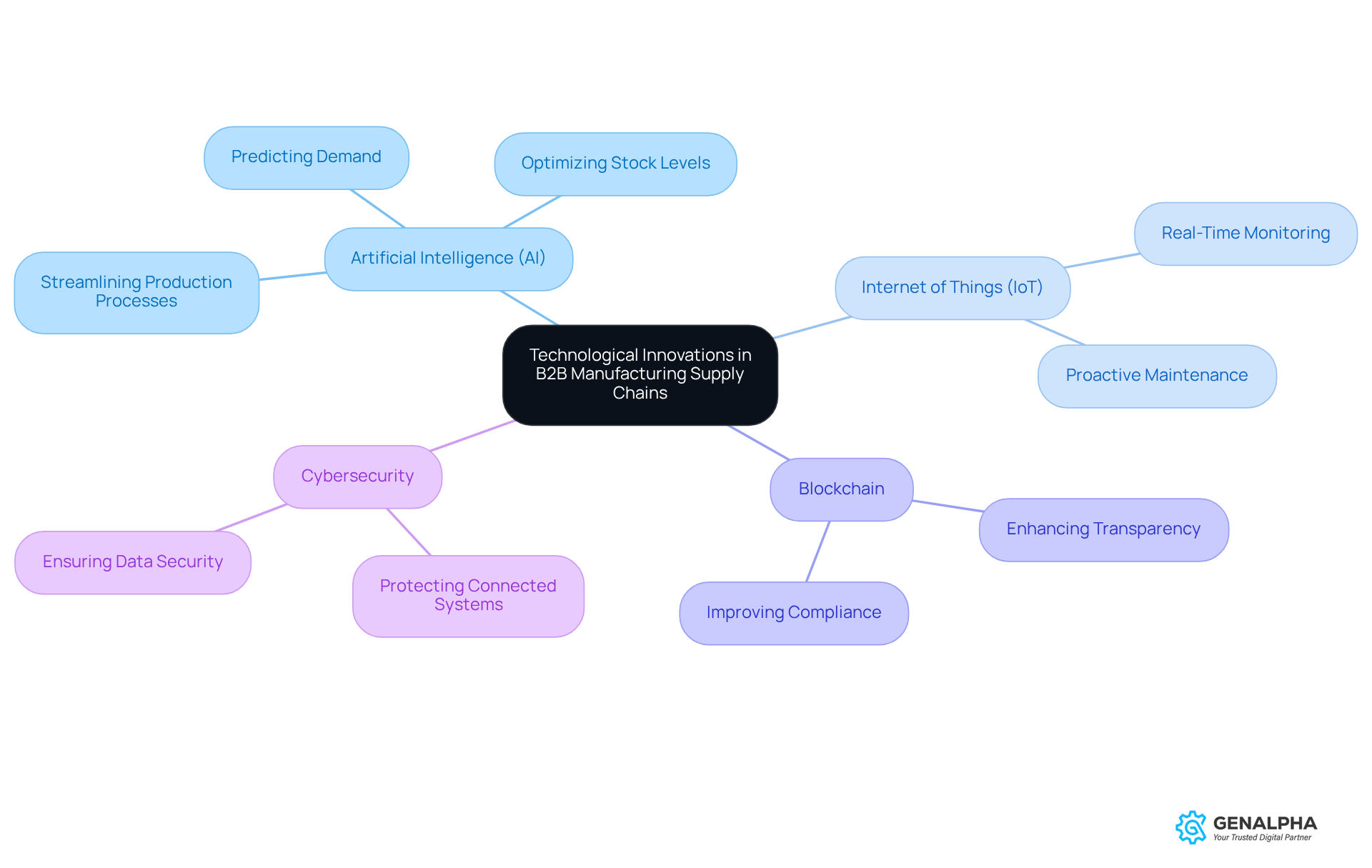

Technological advancements are really shaking things up in the supply chains of b2b manufacturing companies! Innovations like artificial intelligence (AI), the Internet of Things (IoT), and blockchain are stepping into the spotlight. For instance, AI-driven analytics help producers predict demand more accurately, optimize stock levels, and streamline production processes. Did you know that a recent survey showed 69% of manufacturing CEOs plan to allocate up to 20% of their budget to AI over the next year? That’s a clear sign of growing investment in this technology.

On top of that, IoT devices are making it possible to monitor equipment and inventory in real time. This means proactive maintenance can reduce downtime, which is a game changer. And let’s not forget about digital twins—they allow producers to replicate real-world operations, helping to pinpoint bottlenecks and enhance workflows.

Blockchain technology is also playing a key role by enhancing transparency and traceability within the supply chain. This fosters trust among partners and improves compliance with regulations. However, it’s not all smooth sailing. Producers are facing challenges like economic uncertainty and sourcing issues, which can complicate the implementation of these technologies. As Brian Higgins from KPMG pointed out, "Economic policy uncertainty has been difficult to navigate, to say the least."

And we can’t overlook the importance of cybersecurity. As producers rely more on connected systems, ensuring security becomes crucial. These technologies not only address current challenges but also empower b2b manufacturing companies to create more flexible and responsive logistics. Ultimately, this leads to enhanced customer satisfaction and a competitive edge. So, what do you think? Are you ready to embrace these changes?

Highlight the Strategic Benefits of Optimized Supply Chain Processes for B2B Manufacturers

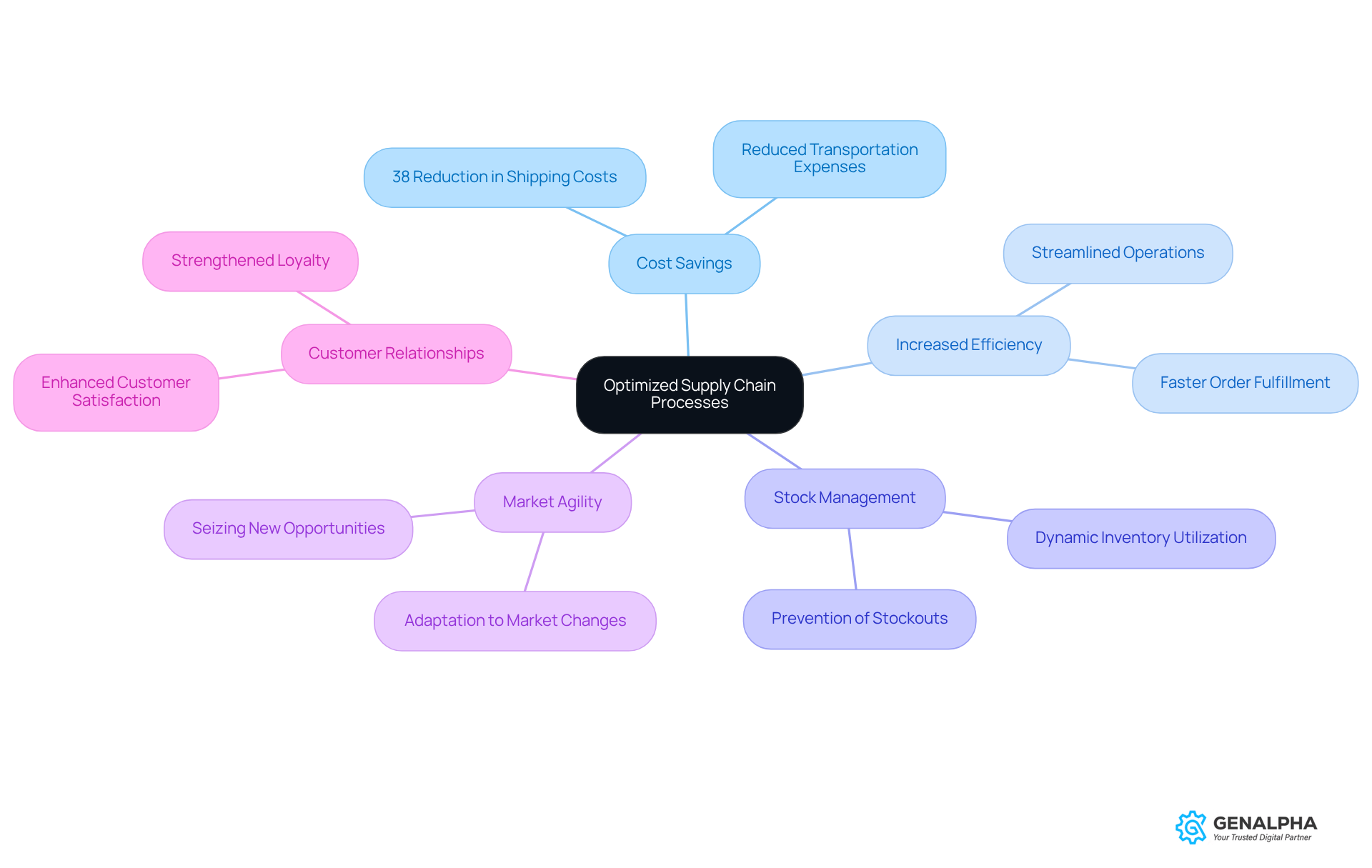

Enhancing logistical processes can really transform the game for B2B producers. Think about it: who wouldn’t want significant cost savings, increased efficiency, and happier customers? When operations are streamlined, it can lead to major operational cost savings. For instance, a canned beverage brand saw a whopping 38% reduction in parcel shipping costs after setting up a two-node network. That’s a clear win for strategic network optimization!

And let’s not forget about stock management. Efficient stock management ensures that products are available when customers want them, preventing those annoying stockouts and backorders that can frustrate anyone. Plus, a robust logistics system allows producers to quickly adapt to market changes. This agility means they can seize new opportunities and dodge potential threats.

Understanding where customers are and how much they order is crucial for enhancing logistics. These details directly influence inventory placement and delivery strategies. By investing in logistics optimization, B2B manufacturing companies not only enhance their operational capabilities but also strengthen customer relationships. This approach is essential for growth and profitability, especially in today’s competitive landscape.

Did you know that companies investing in optimized supply chains often see an average market growth exceeding 10%? That really underscores how vital efficient supply chain management is for hitting business goals. So, why not take action and explore how optimizing your logistics can lead to remarkable benefits?

Conclusion

B2B manufacturing is truly a cornerstone of supply chain success, acting as the vital link between raw materials and end users. These manufacturers don’t just whip up products; they play a crucial role in managing the intricate networks of suppliers and distributors. Their ability to adapt to ever-changing market demands and embrace cutting-edge technologies significantly boosts operational efficiency, showcasing how essential they are in keeping the flow of products and information smooth.

As we dive deeper, several key insights come to light. B2B manufacturers face challenges like:

- Fluctuating costs

- Labor shortages

- The lingering effects of the COVID-19 pandemic

This reality calls for a proactive approach to resource management and a strong push towards digital transformation. By adopting innovative technologies such as AI, IoT, and blockchain, they’re not only reshaping the dynamics of the supply chain but also enhancing transparency and operational agility. Plus, optimizing these processes can lead to significant cost savings, increased efficiency, and happier customers, underscoring the strategic advantages of a well-managed logistics system.

Looking ahead, the future of B2B manufacturing hinges on the ability to innovate and adapt. As the industry navigates ongoing challenges and seizes new opportunities, embracing change and fostering collaboration will be key. Companies that focus on supply chain optimization won’t just boost their operational capabilities; they’ll also set themselves up for sustainable growth in a competitive landscape. So, why wait? Now is the perfect time to explore how optimizing logistics can unlock incredible benefits and drive success in the B2B manufacturing sector!

Frequently Asked Questions

What is the role of B2B manufacturing in supply chains?

B2B manufacturing acts as a vital link between raw material providers and end users, orchestrating complex networks of suppliers and distributors to ensure efficient and effective product delivery.

How do manufacturers adapt to changing market needs?

Manufacturers adapt by working with various logistics partners and embracing advanced technologies to enhance production schedules, reduce lead times, and improve inventory management.

What benefits do advanced technologies bring to B2B manufacturing?

Advanced technologies boost production schedules, cut down lead times, and improve inventory management, which enhances operational efficiency and strengthens the logistics network's resilience.

Why are the interconnected relationships between manufacturers and logistics partners important?

These interconnected relationships highlight the role of B2B producers in driving logistical success, enabling the essential flow of goods and information that meets customer expectations.

What changes are expected in B2B manufacturing as we approach 2025?

As we approach 2025, the impact of producers on logistics efficiency is expected to become more apparent, with a growing emphasis on sustainability and adaptability to global challenges. The future of B2B manufacturing will focus on leading rather than just keeping up.