Overview

Have you ever wondered how B2B ERP systems can transform the way equipment manufacturers operate? These systems are game-changers, enhancing operational efficiency by seamlessly integrating various business processes. They improve inventory management and automate those routine tasks that can eat up so much time.

For example, manufacturers using these systems have reported remarkable efficiency gains—think about a 40% boost in operational efficiency and a 28% drop in stock holding costs! That’s pretty impressive, right? This means they can respond quickly to market demands and, ultimately, improve customer satisfaction.

So, if you’re in the manufacturing game, it might be time to consider how a B2B ERP system could work for you. After all, who wouldn’t want to streamline operations and keep customers happy?

Introduction

In the competitive world of equipment manufacturing, operational efficiency isn’t just a nice-to-have—it’s essential. Think about it: B2B ERP systems are leading the charge in this transformation, giving manufacturers the tools they need to streamline processes, improve communication, and ultimately ramp up productivity.

But here’s the kicker: how do we tailor these systems to meet the unique challenges of our industry? What specific perks do B2B ERP solutions offer that can help manufacturers not just survive but really thrive in a market that’s always changing?

Let’s dive in and explore!

Enhance Operational Efficiency with ERP Systems

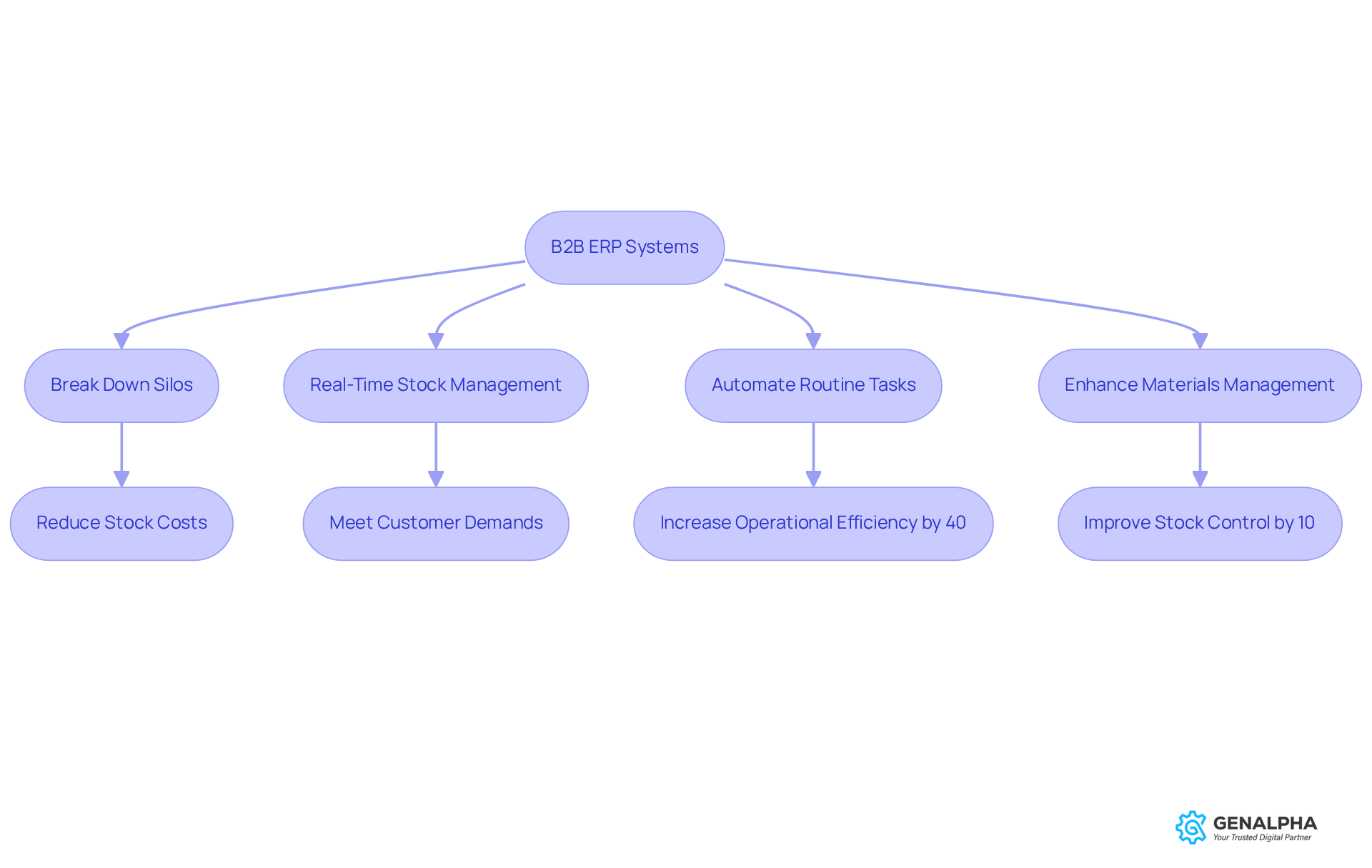

B2B ERP solutions are super important for boosting operational efficiency among equipment producers. By bringing together various business processes into one unified platform, B2B ERP systems help break down silos and encourage smooth communication across departments. For example, real-time stock management allows manufacturers to keep an eye on stock levels continuously, which greatly reduces the chances of overstocking or running out of stock. This optimization not only cuts down on stock costs but also ensures that customer demands are met on time through a B2B ERP system, leading to happier customers. Plus, B2B ERP solutions can enhance materials management by 10% throughout the production process, further improving stock control.

But that’s not all! B2B ERP systems automate routine tasks like order processing and invoicing, allowing employees to focus on more strategic initiatives. This shift makes organizations more agile and better equipped to adapt quickly to market demands and operational challenges. Real-world examples show that businesses can achieve a 40% boost in operational efficiency after adopting B2B ERP solutions, with production planning times slashed from weeks to days and stock holding costs reduced by 28%.

Industry leaders are well aware of the game-changing impact of ERP on inventory management. As experts point out, incorporating B2B ERP solutions not only enhances visibility throughout the supply chain but also promotes data-driven decision-making, which is vital for staying competitive in today’s fast-paced market. Ultimately, embracing B2B ERP solutions enables equipment producers to drive growth and profitability in an increasingly competitive landscape. So, are you ready to explore how ERP can transform your operations?

Leverage ERP Integration for Tailored Solutions

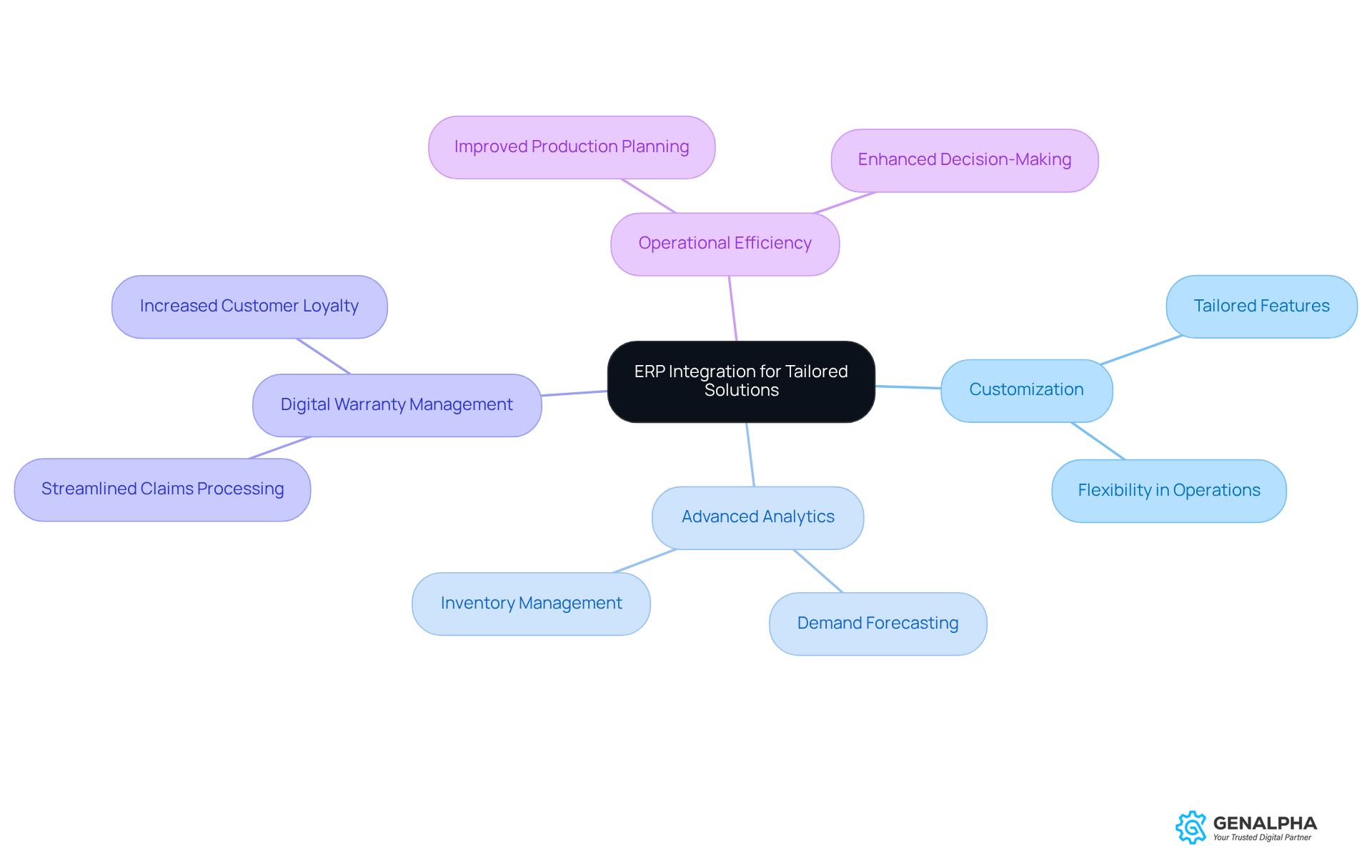

Have you ever thought about how b2b erp platforms can truly change the game for equipment producers? These integration features allow them to craft solutions that fit their operational needs like a glove. By tapping into ERP technology, producers can tweak modules to tackle unique hurdles, whether it’s complex supply chain logistics or specialized customer service demands.

For instance, imagine an ERP solution that’s customized with advanced analytics for demand forecasting. This empowers producers to make smart, data-driven decisions that boost inventory management and streamline production planning. Plus, with digital warranty management integrated into ERP platforms, processing warranty claims becomes a breeze, leading to happier customers and increased loyalty.

This level of customization not only ramps up operational efficiency but also helps producers respond nimbly to their clients' evolving needs, ultimately driving sales and expanding market share. And let’s not forget, the manufacturing software sector is set to skyrocket from $123.78 billion in 2024 to a whopping $358.85 billion by 2032. This clearly shows the growing need for tailored B2B ERP solutions.

ERP experts point out that these customized B2B ERP solutions can effectively address issues such as outdated processes and supply chain hiccups. This makes them essential for producers who want to thrive in today’s competitive landscape. So, how are you planning to leverage ERP solutions in your operations?

Adapt to Market Changes with ERP Technology

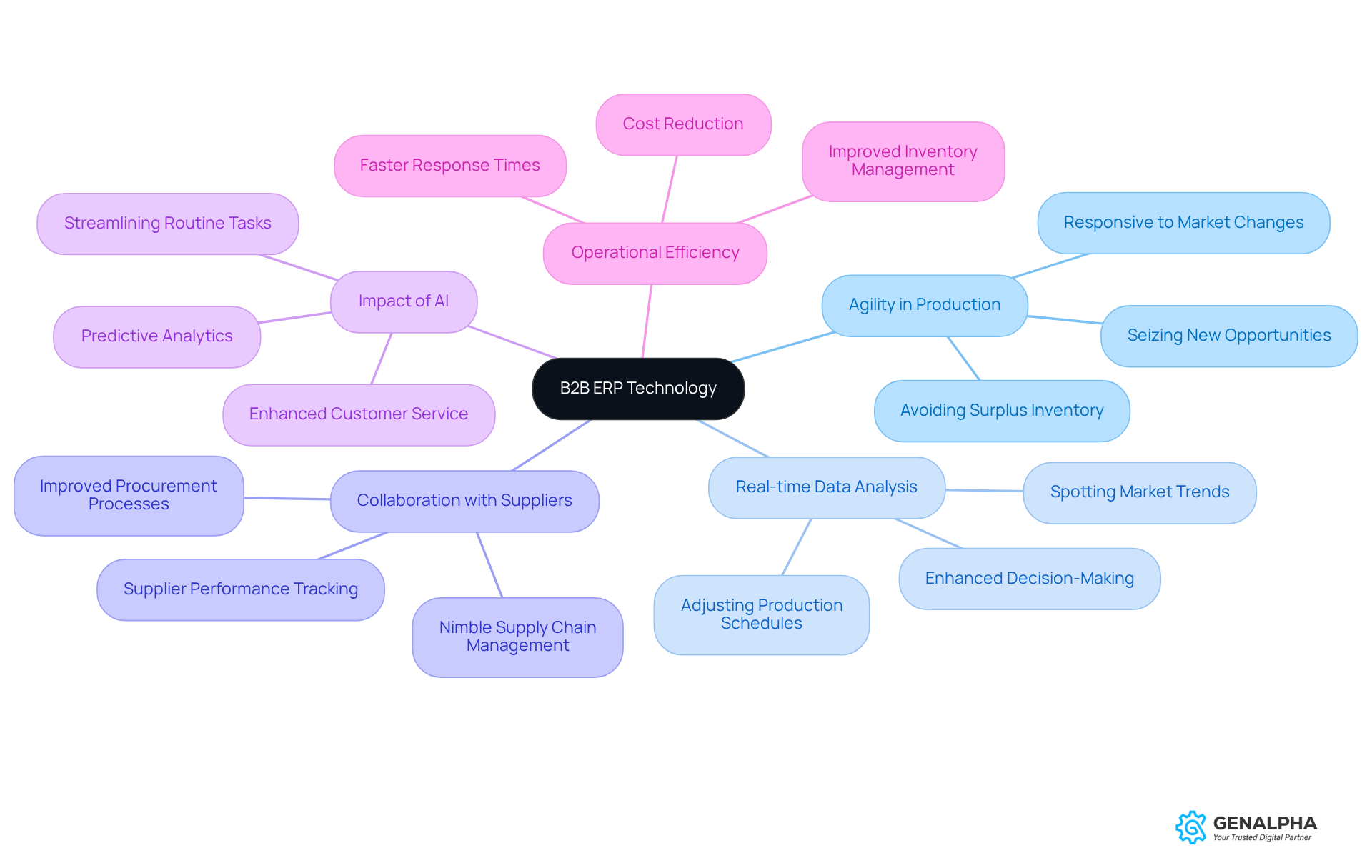

In today’s fast-paced manufacturing world, adapting to market changes is crucial for survival. Have you ever wondered how some companies seem to pivot effortlessly? That’s where B2B ERP technology becomes essential! It empowers equipment producers to respond swiftly to shifts in demand, supply chain hiccups, and changing customer preferences.

For example, with real-time data analysis from B2B ERP solutions, producers can spot market trends and adjust their production schedules accordingly. This kind of agility not only helps avoid surplus inventory but also ensures that producers can seize new opportunities as they arise. Plus, B2B ERP solutions foster better collaboration with suppliers and distributors, making supply chain management more nimble.

By embracing B2B ERP technology, manufacturers can enhance their resilience and maintain a competitive edge, paving the way for long-term success in an ever-evolving marketplace. And let’s not forget about the rising significance of AI in ERP systems! It streamlines routine tasks and enhances decision-making capabilities.

According to industry analysts, businesses that utilize B2B ERP solutions benefit from improved decision-making through better access to data and insights. Additionally, B2B ERP solutions that are cloud-based are becoming increasingly popular, offering the flexibility and accessibility that today’s market demands.

So, why not leverage these advancements? By doing so, manufacturers can enhance their operational efficiency and secure a competitive advantage. What steps are you taking to stay ahead in this dynamic landscape?

Conclusion

B2B ERP systems aren’t just beneficial; they’re absolutely essential for equipment manufacturers aiming for operational excellence and a competitive edge. By bringing various business processes into one platform, these systems promote seamless communication and boost efficiency across departments. Imagine being able to manage your inventory in real-time, automate routine tasks, and customize solutions for specific challenges—this empowerment helps manufacturers not only meet customer demands but also drive growth and profitability.

Let’s take a look at the key insights from the article. They highlight the transformative impact of B2B ERP solutions on operational efficiency. For example, reducing stock holding costs and cutting down production planning times are just a couple of the substantial benefits. Customization options enable manufacturers to tackle unique challenges, fostering agility and responsiveness in a fast-paced market. Plus, integrating advanced analytics and digital tools enhances decision-making, allowing companies to adapt quickly to market trends and consumer needs.

So, what does this all mean? Embracing B2B ERP technology is a strategic move that can significantly strengthen a manufacturer’s resilience and market position. As the manufacturing software sector keeps growing, the need for tailored ERP solutions becomes clearer than ever. Manufacturers should definitely explore how these systems can streamline operations, enhance inventory management, and ultimately secure a competitive edge in a dynamic business environment. Taking proactive steps toward ERP adoption could be the key to thriving in the future of equipment manufacturing. What steps will you take today?

Frequently Asked Questions

What are B2B ERP systems and why are they important for equipment producers?

B2B ERP systems are software solutions that integrate various business processes into one unified platform, which is crucial for enhancing operational efficiency among equipment producers. They help break down silos and facilitate smooth communication across departments.

How do B2B ERP systems improve stock management?

B2B ERP systems enable real-time stock management, allowing manufacturers to continuously monitor stock levels. This reduces the chances of overstocking or running out of stock, optimizing stock costs and ensuring timely fulfillment of customer demands.

What specific improvements can B2B ERP solutions bring to materials management?

B2B ERP solutions can enhance materials management by up to 10% throughout the production process, which improves overall stock control.

How do B2B ERP systems automate routine tasks?

B2B ERP systems automate tasks such as order processing and invoicing, allowing employees to focus on more strategic initiatives, which increases organizational agility and responsiveness to market demands.

What operational efficiency gains can businesses expect from adopting B2B ERP solutions?

Businesses can achieve a 40% boost in operational efficiency after adopting B2B ERP solutions, with production planning times reduced from weeks to days and stock holding costs decreased by 28%.

How do B2B ERP systems impact inventory management and decision-making?

B2B ERP systems enhance visibility throughout the supply chain and promote data-driven decision-making, which is essential for maintaining competitiveness in a fast-paced market.

What are the overall benefits of embracing B2B ERP solutions for equipment producers?

Embracing B2B ERP solutions enables equipment producers to drive growth and profitability in a competitive landscape by improving operational efficiency, stock management, and decision-making processes.