Introduction

Managing product information can feel like navigating a maze, right? Especially when businesses are trying to keep up with the twists and turns of modern manufacturing. That’s where PDM software comes in. Think of it as your go-to hub that not only organizes all that essential data but also makes teamwork a breeze.

But here’s the kicker: with technology changing faster than we can blink and market demands shifting all the time, how can organizations make sure they’re using PDM tools effectively? How can they boost productivity and stay ahead of the competition? Let’s dive into this together!

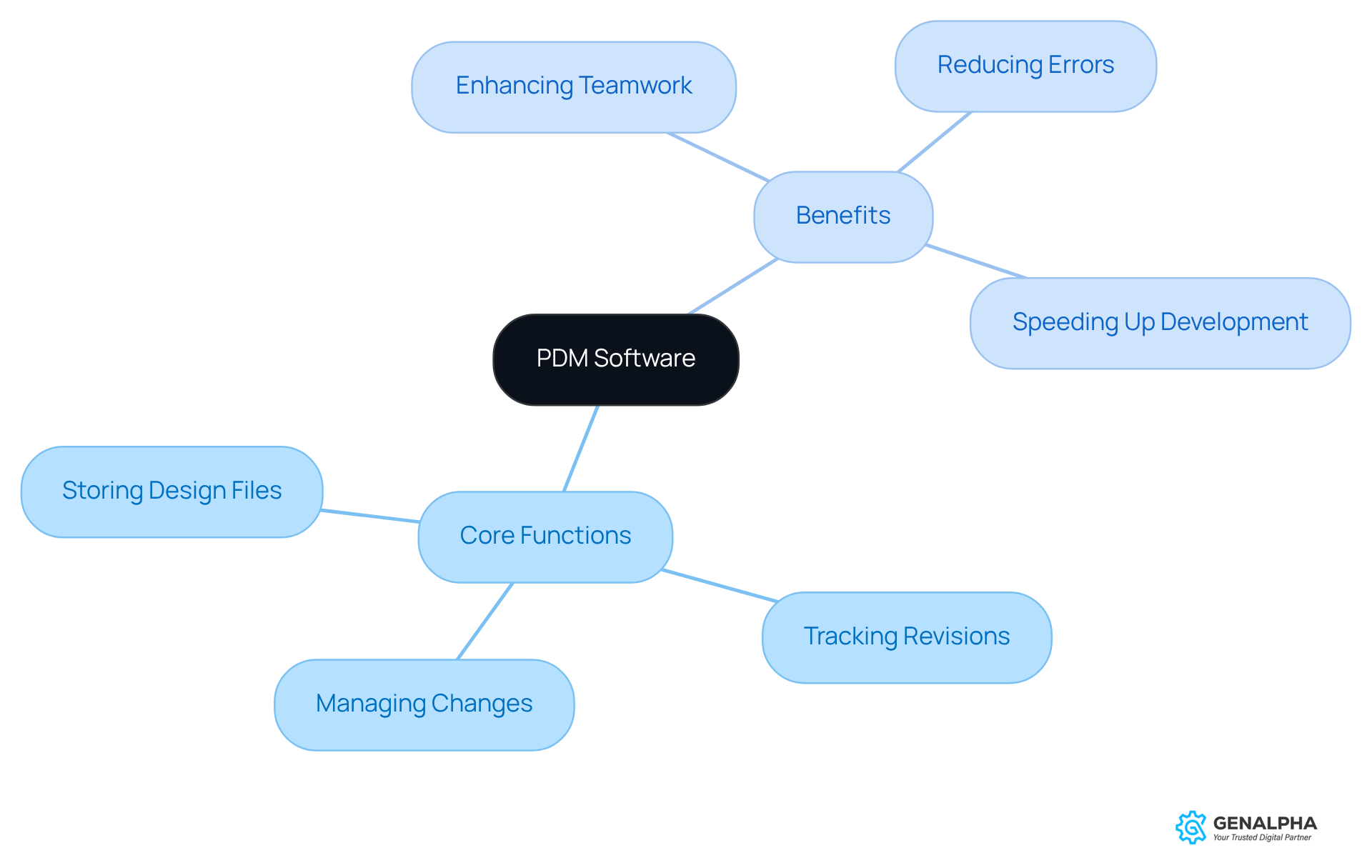

Define PDM Software: Core Concepts and Functionality

Have you ever felt overwhelmed by managing product information? That’s where pdm-software applications come into play! Think of them as your go-to hub for all things product-related, keeping everything organized throughout its lifecycle. They store everything from design files to specifications and documentation, making it easy to find what you need when you need it.

PIM tools are like a safety net for organizations. They help track revisions, manage changes, and ensure everyone involved has access to the latest information. This is especially crucial in manufacturing, where getting things right the first time can save a lot of headaches down the line. By streamlining information management, pdm-software not only enhances teamwork but also reduces errors and speeds up development cycles.

So, why not consider implementing a pdm-software solution? It could be the key to boosting your team's efficiency and collaboration. After all, who wouldn’t want to work smarter, not harder?

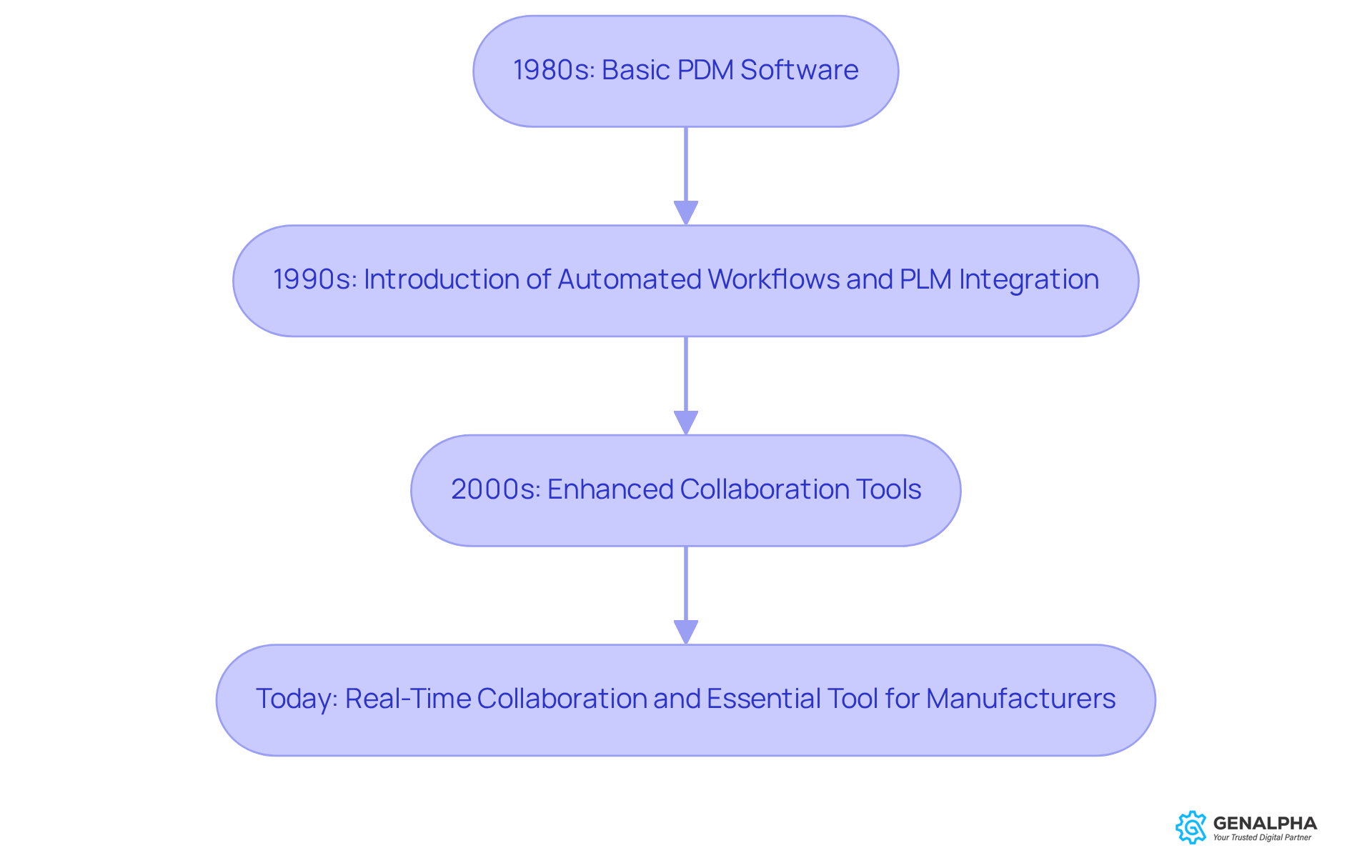

Trace the Evolution of PDM Software in Manufacturing

Let’s take a trip back to the 1980s, when Product Information Management (PIM) applications first started to take shape alongside Computer-Aided Design (CAD). Back then, engineers were grappling with the growing complexity of item information and needed a way to manage it all. Initially, pdm-software was pretty basic - just simple repositories for CAD files that offered some version control and document management.

But as manufacturing processes grew more intricate and global, pdm-software had to step up its game. They evolved to include features like automated workflows, integration with Product Lifecycle Management (PLM) systems, and better collaboration tools. Fast forward to today, and pdm-software does so much more than just manage product information; it enables real-time collaboration among teams spread across different locations. In our fast-paced manufacturing world, these tools have become essential.

Of course, the journey hasn’t been smooth sailing. Changes in customer needs and management priorities have thrown some curveballs, often messing with deployment schedules. Still, around 70% of manufacturers are now utilizing pdm-software, which really highlights how crucial it is in today’s manufacturing landscape.

Take Swagelok, for example. They’ve integrated SmarTeam’s pdm-software, illustrating how these advancements can simplify information management and enhance operational efficiency. This kind of innovation helps companies stay competitive in the market. So, what do you think? Are you ready to explore how PDM can transform your operations?

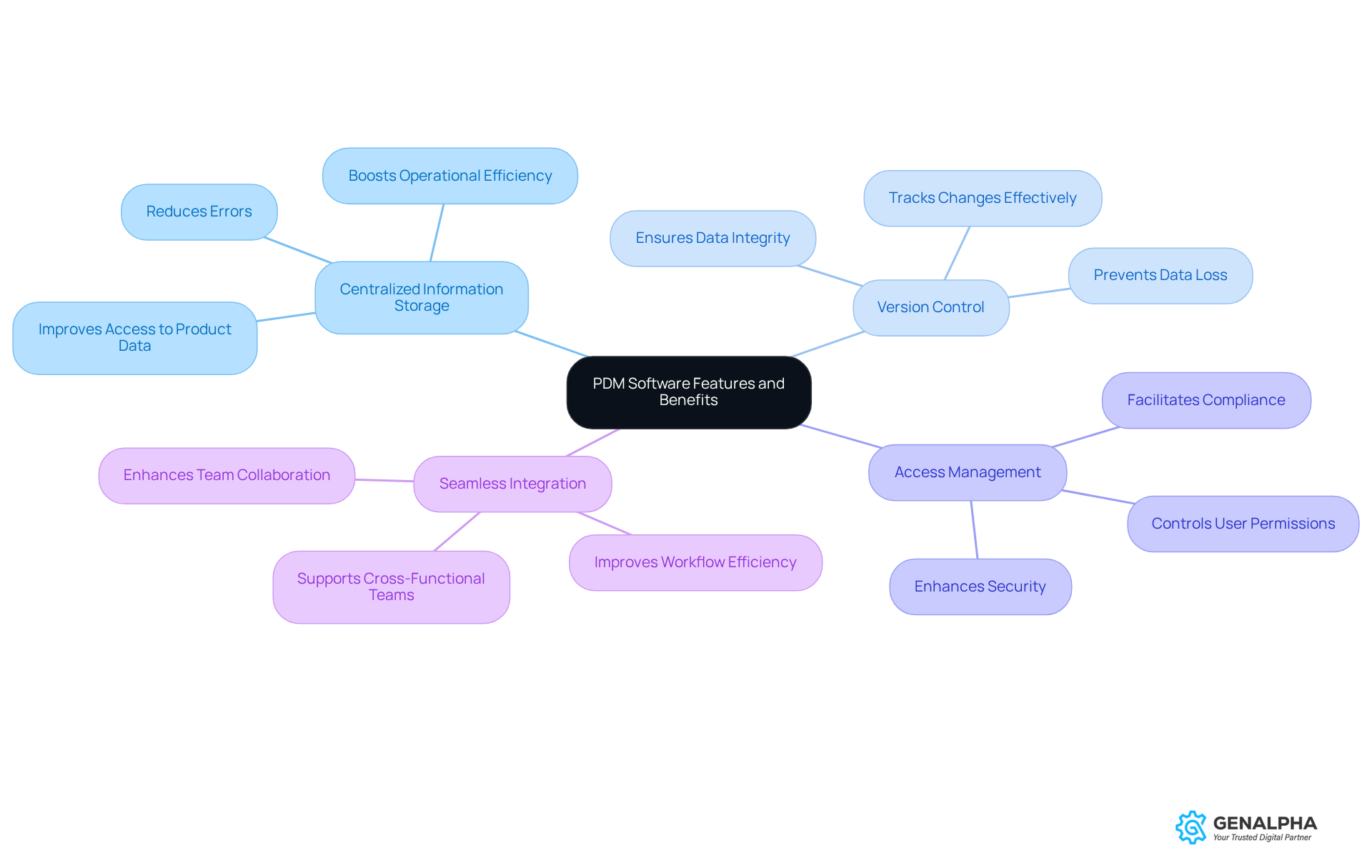

Explore Key Features and Benefits of PDM Software

Have you ever felt overwhelmed by managing product details? Well, that’s where pdm-software comes in! It’s got some key features that can really make a difference:

- Centralized information storage

- Version control

- Access management

- Seamless integration with systems like ERP and CAD

Centralized information storage means all your product details are right at your fingertips and regularly updated, which can seriously boost your operational efficiency. And let’s not forget about version control - it’s crucial for keeping track of changes and ensuring that your information stays intact. Plus, with access management, you can decide who gets to view or edit specific info, which really helps with security and compliance.

But wait, there’s more! PDM tools also make it easier for remote employees, cross-functional teams, and external partners to collaborate on projects. This enhances teamwork and communication, which we all know is vital in today’s fast-paced environment.

So, what’s in it for you? Adopting pdm-software can lead to better collaboration among teams, speed up your time-to-market, improve information accuracy, and simplify regulatory compliance by keeping all those crucial details accessible. Plus, they can help cut down on costs related to scrap, rework, document reproduction, and IT overhead.

For instance, organizations using PDM tools often see a reduction in engineering time by up to 15%. That’s a game changer for faster product launches and a real boost to your competitive edge!

Real-world examples of version control show just how effective it is at maintaining accurate records and preventing data loss. Imagine tracking design changes so that everyone on your team is always working with the latest info. It really highlights the value of pdm-software in modern manufacturing environments.

So, are you ready to explore how PDM can transform your workflow?

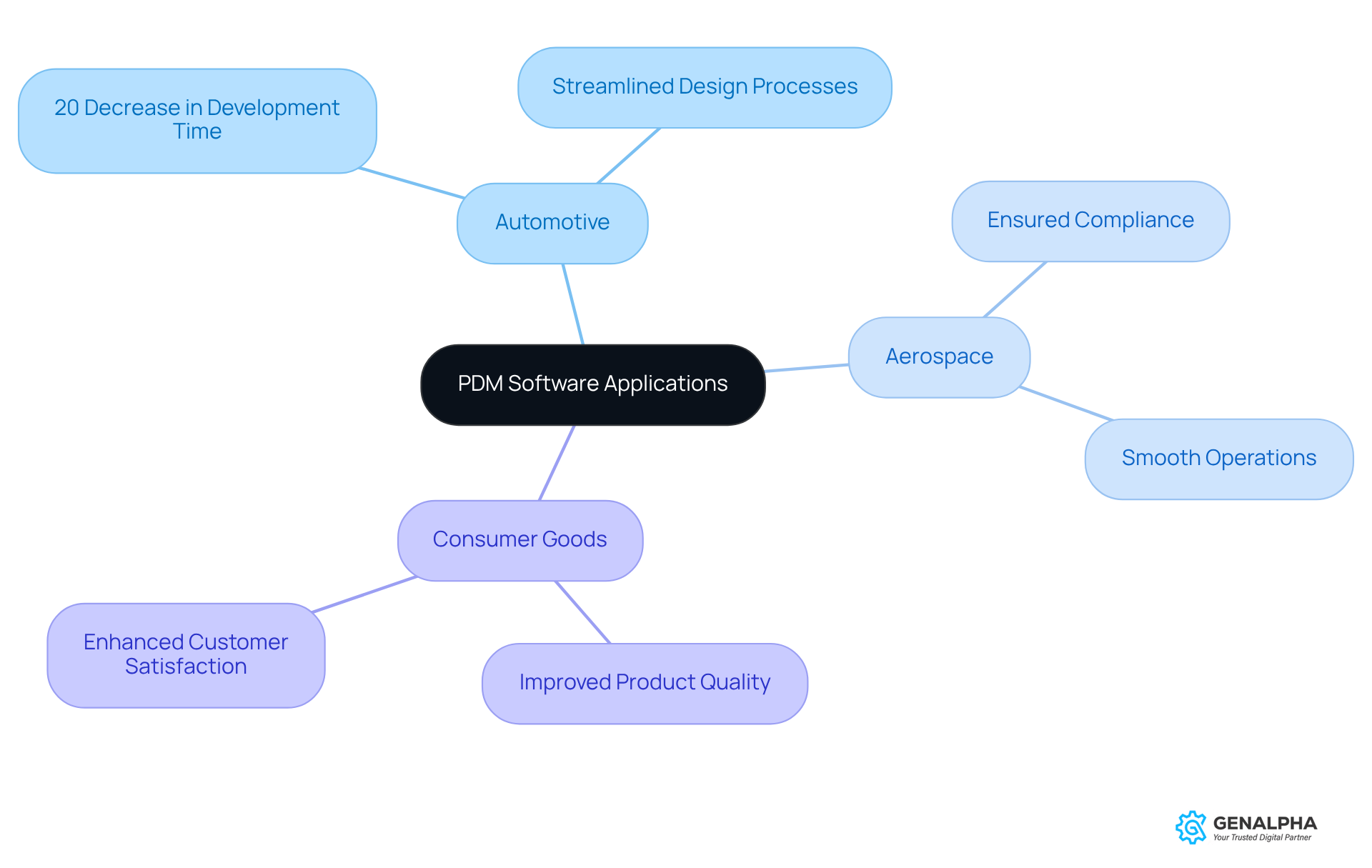

Examine Real-World Applications of PDM Software

Have you ever wondered how some of the biggest names in manufacturing stay ahead of the game? Well, the solution involves a significant role for pdm-software applications! They're widely used across various sectors like automotive, aerospace, and consumer goods. For example, a well-known automotive producer decided to adopt pdm-software to streamline its design processes. The result? A fantastic 20% decrease in development time!

But it doesn’t stop there. An aerospace company also turned to pdm-software to tackle complex regulatory requirements. This not only ensured compliance but also kept their operations running smoothly. These real-world examples show that pdm-software does more than just improve internal processes; it also boosts product quality and customer satisfaction.

By offering a structured approach to data management, pdm-software helps organizations respond quickly to market demands. So, if you’re looking to maintain a competitive edge, it might be time to consider how PDM can work for you!

Conclusion

PDM software is a game changer when it comes to managing product information. Imagine having a centralized hub for all your product-related data - sounds pretty great, right? This technology not only makes information management a breeze but also boosts collaboration and cuts down on errors. The result? Increased operational efficiency! By adopting PDM software, companies can work smarter, ensuring that their teams always have access to the latest and most accurate information.

Throughout this article, we’ve explored some key features of PDM software, like centralized information storage, version control, access management, and seamless integration with other systems. These elements come together to enhance teamwork, shorten development times, and elevate overall product quality. Real-world examples show just how beneficial PDM software can be, with significant drops in development time and improved compliance with regulations.

In a world where efficiency and accuracy are crucial, embracing PDM software can truly transform organizations across various industries. It not only creates a more collaborative work environment but also helps businesses respond quickly to market demands. As companies navigate the complexities of product development, leveraging PDM software will be vital for staying competitive and driving future success. So, why wait? Let’s embrace this technology and take our product development to the next level!

Frequently Asked Questions

What is PDM software?

PDM software, or Product Data Management software, is an application that serves as a central hub for managing all product-related information throughout its lifecycle, including design files, specifications, and documentation.

How does PDM software help organizations?

PDM software helps organizations by tracking revisions, managing changes, and ensuring that everyone involved has access to the latest information, which is crucial for reducing errors and improving teamwork.

Why is PDM software particularly important in manufacturing?

In manufacturing, PDM software is important because it helps ensure that products are developed correctly the first time, which can save time and reduce complications later in the process.

What are the benefits of implementing PDM software?

Implementing PDM software can boost team efficiency and collaboration, streamline information management, reduce errors, and speed up development cycles.