Introduction

Navigating the B2B buying process can feel pretty overwhelming for manufacturers, especially when it comes to picking the right suppliers. Have you ever thought about how a Request for Proposal (RFP) can help? It’s a key tool that gives organizations a clear way to express their needs and gather competitive bids. But here’s the real kicker: how well can these RFPs actually reshape procurement strategies and build strong, lasting relationships with suppliers?

Let’s dive into the role of RFPs. Not only do they have a rich history, but they also reveal some best practices that can boost efficiency and save costs in today’s fast-paced market. So, what do you think? Are you ready to explore how RFPs can make a difference in your procurement process?

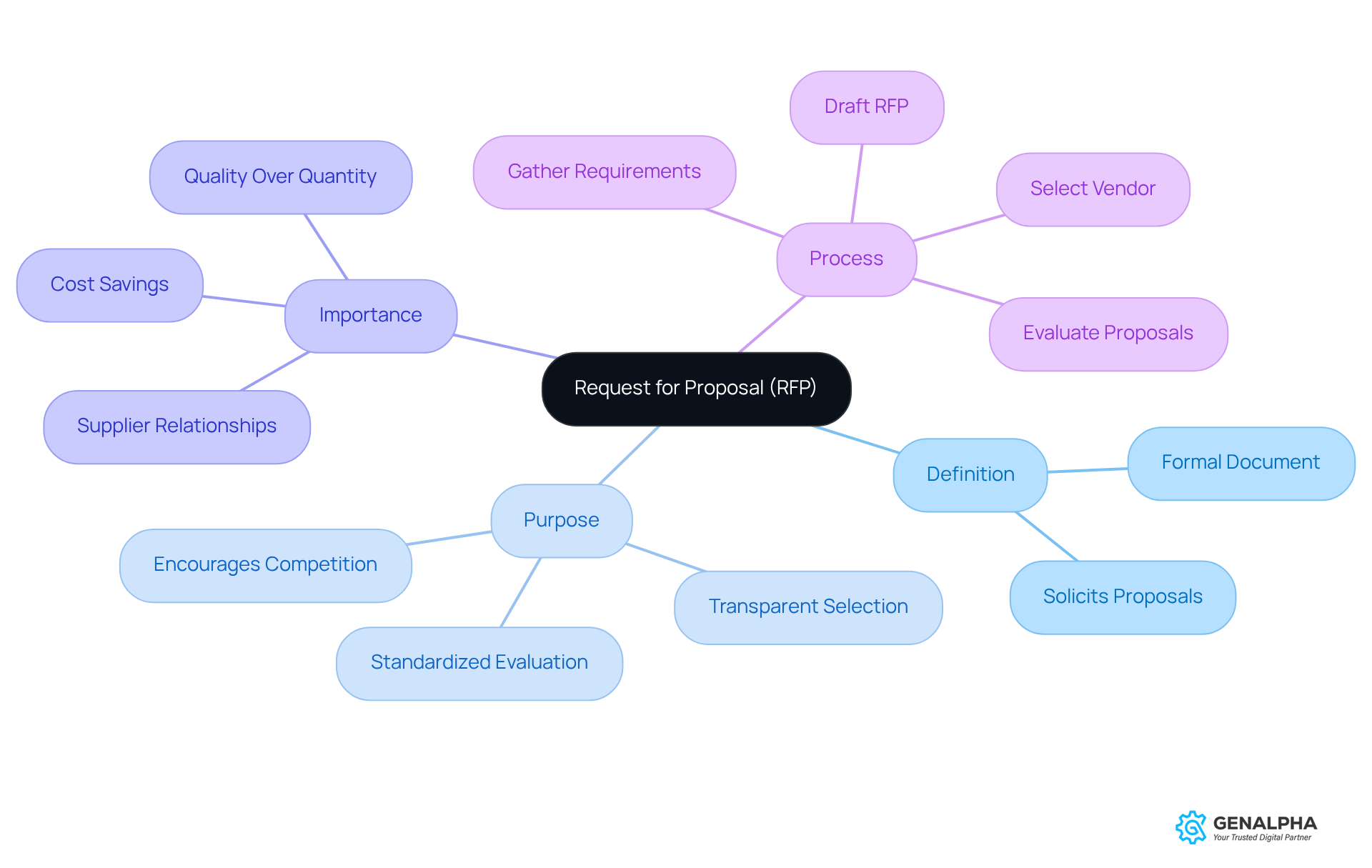

Define RFP: Key Elements and Purpose

Have you ever wondered how organizations find the right suppliers for their projects? Well, that’s where a Request for Proposal (RFP) comes into play! It’s a formal document that businesses use to gather proposals from potential suppliers for specific projects or services. An RFP lays out the project’s requirements, objectives, and assessment criteria, making it easier for companies to compare different supplier offerings. In the B2B sector, understanding in the B2B buying process what is an RFP is especially crucial, as projects can become quite complex and require detailed proposals that hit the mark. By sending out an RFP, companies can ensure they get competitive bids that align with their needs, leading to smarter decisions and better project outcomes.

Now, let’s talk about why RFPs are so vital in selecting suppliers. They create a standardized way to evaluate suppliers, helping manufacturers assess pricing, capabilities, and service quality effectively. Did you know that organizations typically respond to about 63% of the RFPs they receive? This shows a clear focus on quality over quantity! This organized approach not only minimizes bias in evaluations but also encourages vendors to put their best foot forward, resulting in better pricing and value for the buyer.

When it comes to successful RFP procedures in manufacturing, clear communication and well-defined expectations are key. For example, high-performing teams that use RFP software report responding to an average of 175 requests for proposals each year. That’s a testament to the efficiency gains technology can bring! Plus, industry leaders emphasize that in the B2B buying process, what is an RFP can lead to significant cost savings and stronger supplier relationships when executed well. As one expert put it, 'An RFP is utilized to request detailed proposals from various suppliers for intricate projects, ensuring a competitive, transparent, and equitable selection method based on more than just cost.' This really highlights how crucial RFPs are in helping manufacturers secure the best solutions at the best prices.

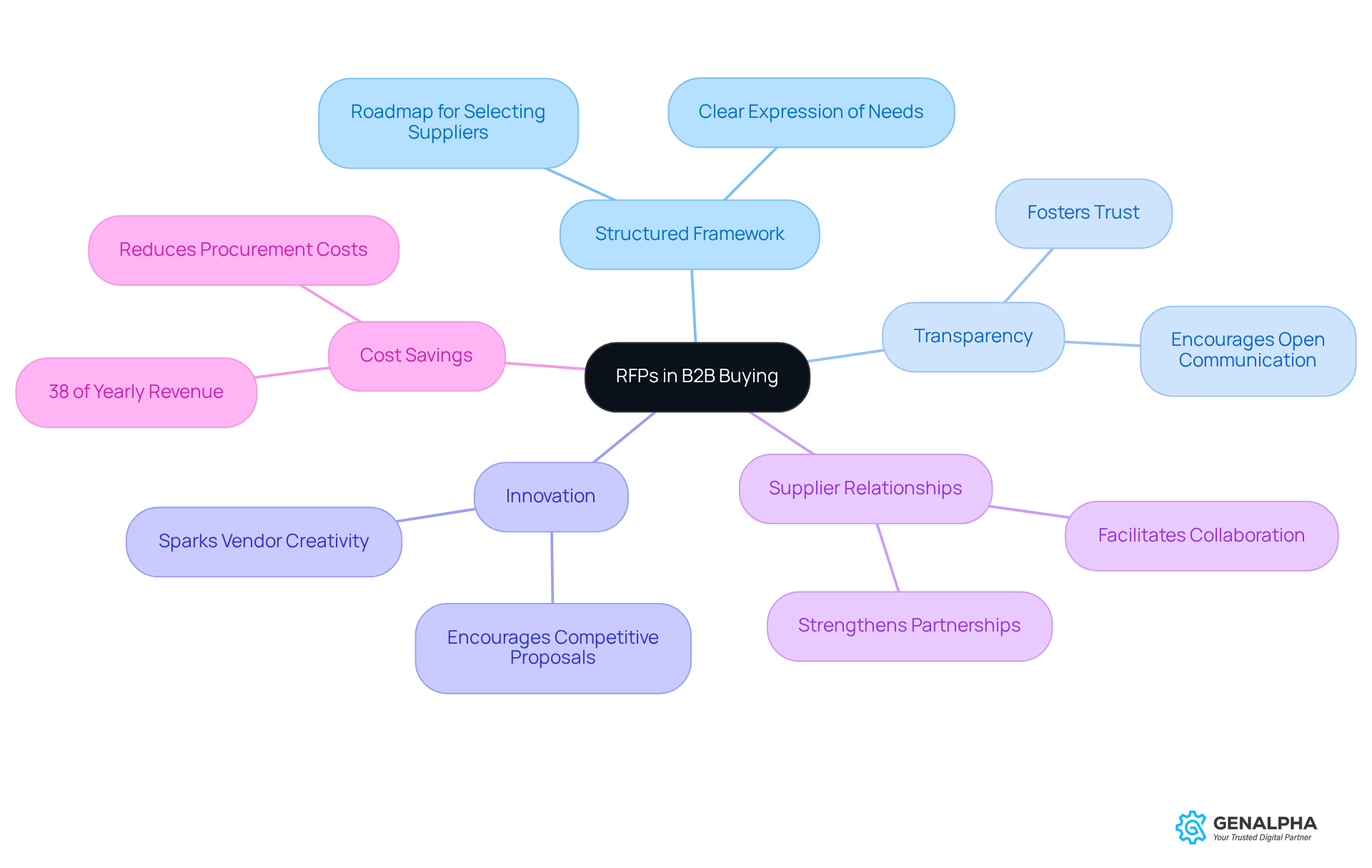

Contextualize RFP in B2B Buying: Importance for Manufacturers

In the B2B buying process what is an RFP, as Request for Proposals (RFPs) play a crucial role for manufacturers seeking to procure goods and services efficiently. Think of RFPs as a roadmap - they provide a structured framework for selecting suppliers, allowing manufacturers to clearly express their needs and invite competitive proposals. This approach not only boosts transparency but also sparks innovation among vendors, who are eager to present their best solutions.

By using RFPs, manufacturers can really strengthen their supplier relationships. These processes encourage open communication and collaboration, which is a win-win for everyone involved. Plus, let’s talk about cost savings! Organizations that effectively utilize RFPs often find that they account for about 38% of their yearly revenue. That’s significant! For example, companies that embrace strategic sourcing practices frequently see a drop in procurement costs and better project outcomes.

Overall, in the B2B buying process what is an RFP, RFPs are an essential part of a manufacturer’s procurement strategy. They drive efficiency and help foster long-term partnerships. So, if you’re not already leveraging RFPs, now might be the perfect time to start!

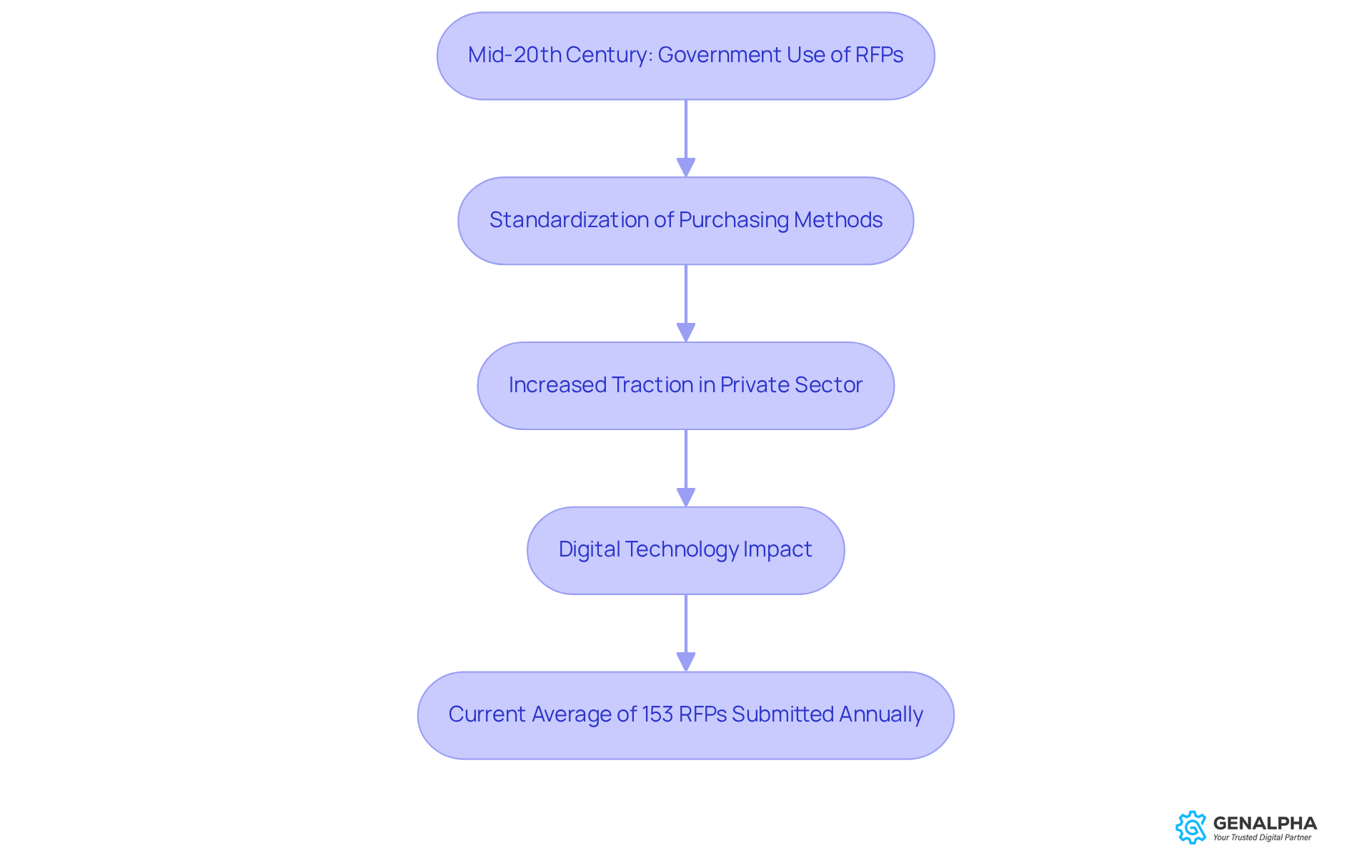

Trace the Evolution of RFPs: Historical Significance and Development

Have you ever wondered how the concept of RFPs in the B2B buying process has changed over the years? It’s pretty fascinating! Initially, RFPs were mostly used by government bodies back in the mid-20th century. They aimed to standardize purchasing methods and ensure fairness in vendor selection. As businesses began to see the perks of organized procurement, they started to understand what an RFP is in the B2B buying process, leading to its increased traction in the private sector and making it a go-to practice for manufacturers and distributors alike.

Fast forward to today, and digital technology has really shaken things up. RFP processes are now more efficient than ever, making communication and proposal management a breeze. In fact, what an RFP is in the B2B buying process has become essential for requests for proposals in strategic sourcing. They empower organizations to quickly adapt to market changes and seize competitive advantages. Did you know that 84 percent of Chief Procurement Officers (CPOs) believe that digitization is key to boosting procurement efficiency? This reflects a larger trend of integrating advanced technologies into RFP management.

And here’s something to think about: organizations now submit an average of 153 RFPs each year! This highlights just how much reliance there is on this structured approach to vendor selection. As the landscape continues to evolve, the role of RFPs in both government and private sectors remains crucial. They drive transparency and help foster long-term partnerships. So, what do you think? Are you ready to embrace the power of RFPs in your organization?

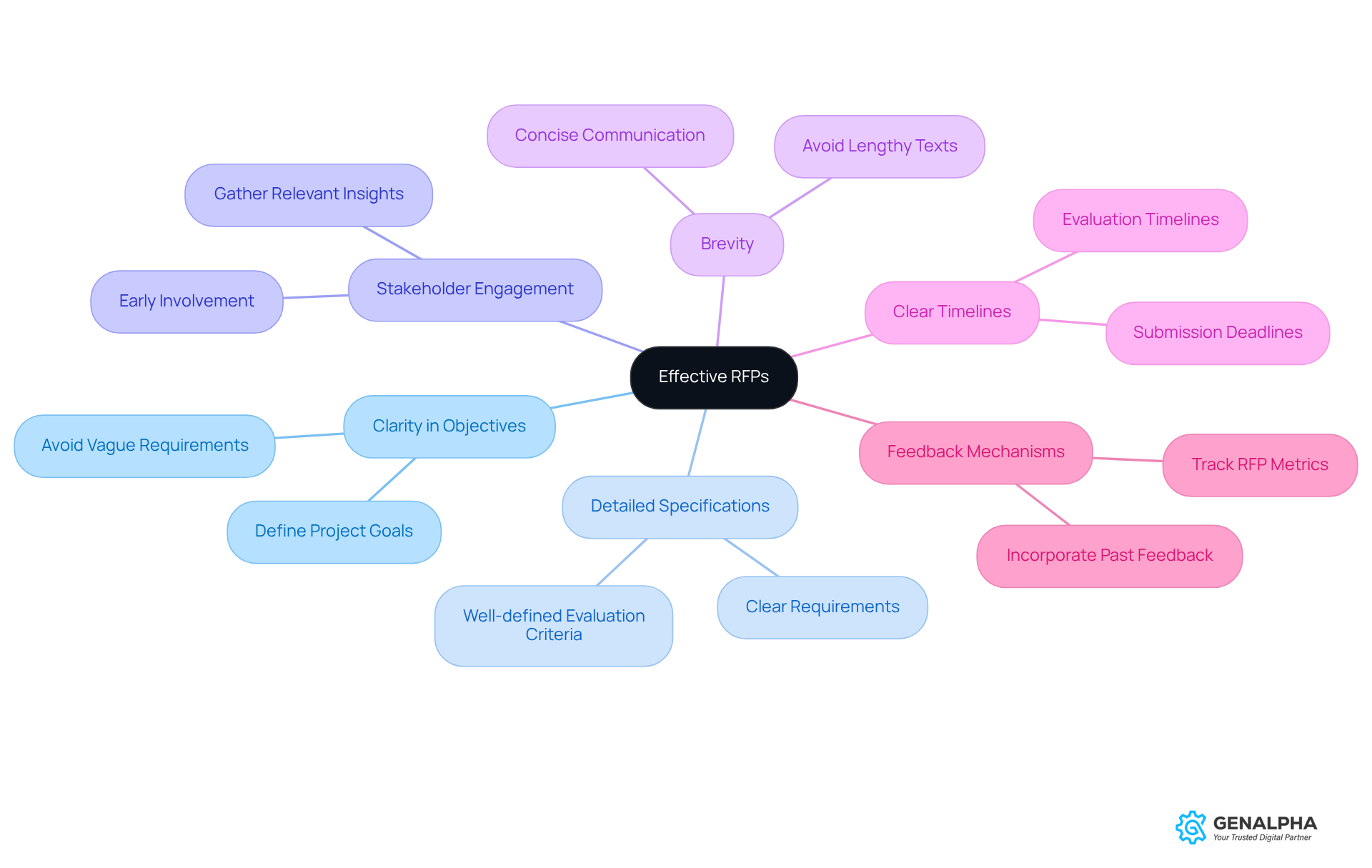

Identify Key Characteristics of Effective RFPs: Components and Best Practices

When it comes to crafting effective requests for proposals (RFPs), understanding in the b2b buying process what is an RFP can significantly enhance the procurement process. First off, clarity in project objectives is essential. You want to be clear about what you’re aiming for. Detailed specifications and well-defined evaluation criteria also play a huge role. Have you ever been confused by vague requirements? It’s frustrating, right? Engaging stakeholders early on is crucial, too. This not only fosters alignment but also ensures that all relevant insights are brought to the table.

Now, let’s talk about brevity. It’s important to be thorough, but keeping things concise helps prospective suppliers grasp your requirements quickly. Nobody wants to wade through pages of text! Providing a clear timeline for submissions and evaluations is another must-have. It helps manage expectations and makes sure everyone can respond in a timely manner.

Incorporating feedback mechanisms is vital as well. This allows organizations to refine future RFPs based on past experiences. Think about it: organizations that track RFP metrics can pinpoint common challenges and areas for improvement. This leads to better proposal quality and, ultimately, higher win rates.

By adhering to these principles, manufacturers can significantly enhance their chances of selecting the best partners in the b2b buying process what is an RFP for their projects. So, why not take a moment to reflect on your current RFP process? Are there areas where you could improve? Let’s make the procurement process smoother and more successful together!

Conclusion

Understanding the role of a Request for Proposal (RFP) in the B2B buying process is crucial for manufacturers looking to streamline their procurement strategies. Think of RFPs as a vital tool that helps organizations gather detailed proposals from potential suppliers. This way, they can ensure they’re getting competitive bids that really fit their specific project needs. It’s a structured approach that not only boosts transparency but also builds strong relationships with suppliers, leading to better project outcomes.

Throughout this article, we’ve highlighted some key points about the importance of RFPs. They offer a standardized framework for evaluating suppliers, making it easier for manufacturers to assess pricing, capabilities, and service quality. RFPs have come a long way, evolving from government use to becoming a key part of private sector procurement, all thanks to technological advancements that enhance efficiency. Plus, effective RFPs are all about clarity, brevity, and incorporating feedback mechanisms, which together lead to improved proposal quality and higher win rates.

So, why should manufacturers embrace RFPs in their B2B buying process? It’s not just beneficial; it’s essential for optimizing procurement strategies. By leveraging RFPs, organizations can achieve significant cost savings while also fostering innovation and collaboration with suppliers. As the procurement landscape continues to change, now’s the perfect time for manufacturers to refine their RFP processes and tap into the full potential of their supplier partnerships. What steps will you take to enhance your RFP strategy?

Frequently Asked Questions

What is a Request for Proposal (RFP)?

A Request for Proposal (RFP) is a formal document that organizations use to gather proposals from potential suppliers for specific projects or services. It outlines the project's requirements, objectives, and assessment criteria to facilitate comparison of supplier offerings.

Why are RFPs important in selecting suppliers?

RFPs create a standardized method for evaluating suppliers, allowing organizations to assess pricing, capabilities, and service quality effectively. This organized approach minimizes bias and encourages vendors to present competitive bids, leading to better pricing and value for the buyer.

How often do organizations respond to RFPs?

Organizations typically respond to about 63% of the RFPs they receive, indicating a focus on quality over quantity in their evaluations.

What role does technology play in the RFP process?

High-performing teams that use RFP software report responding to an average of 175 requests for proposals each year, demonstrating the efficiency gains that technology can provide in the RFP process.

What benefits can result from a well-executed RFP process?

A well-executed RFP process can lead to significant cost savings and stronger supplier relationships, ensuring a competitive, transparent, and equitable selection method based on more than just cost.

What is the significance of clear communication in RFP procedures?

Clear communication and well-defined expectations are key to successful RFP procedures, helping to ensure that all parties understand the project requirements and evaluation criteria.