Introduction

Manufacturing can feel like a complex web of collaboration and innovation, right? At the heart of it all are the unsung heroes - the OEM brands. These specialized manufacturers whip up essential components that boost the quality and functionality of products across various industries, from automotive to electronics.

So, why should equipment manufacturers care about OEM brands? Well, understanding their significance can lead to some pretty impressive benefits. Think improved efficiency, reduced costs, and access to cutting-edge technologies. Sounds great, doesn’t it?

But here’s the kicker: with the rise of aftermarket and ODM products, how can companies ensure they’re forming the right partnerships to keep their competitive edge? It’s a question worth pondering as we navigate this ever-evolving landscape.

Define OEM Brand: Core Concept and Significance

Have you ever wondered who makes the parts that go into your favorite products? That’s where the OEM brand comes into play. These firms create items or components that are used in the final assembly of another company’s offerings. By focusing on producing these components, an OEM brand allows the purchasing companies to concentrate on marketing and sales.

The significance of the OEM brand labels can’t be overstated. They provide specialized components that significantly enhance the quality and functionality of final goods. This relationship is crucial across various sectors - think automotive, electronics, and machinery - where high-quality parts from an OEM brand can lead to better performance and reliability.

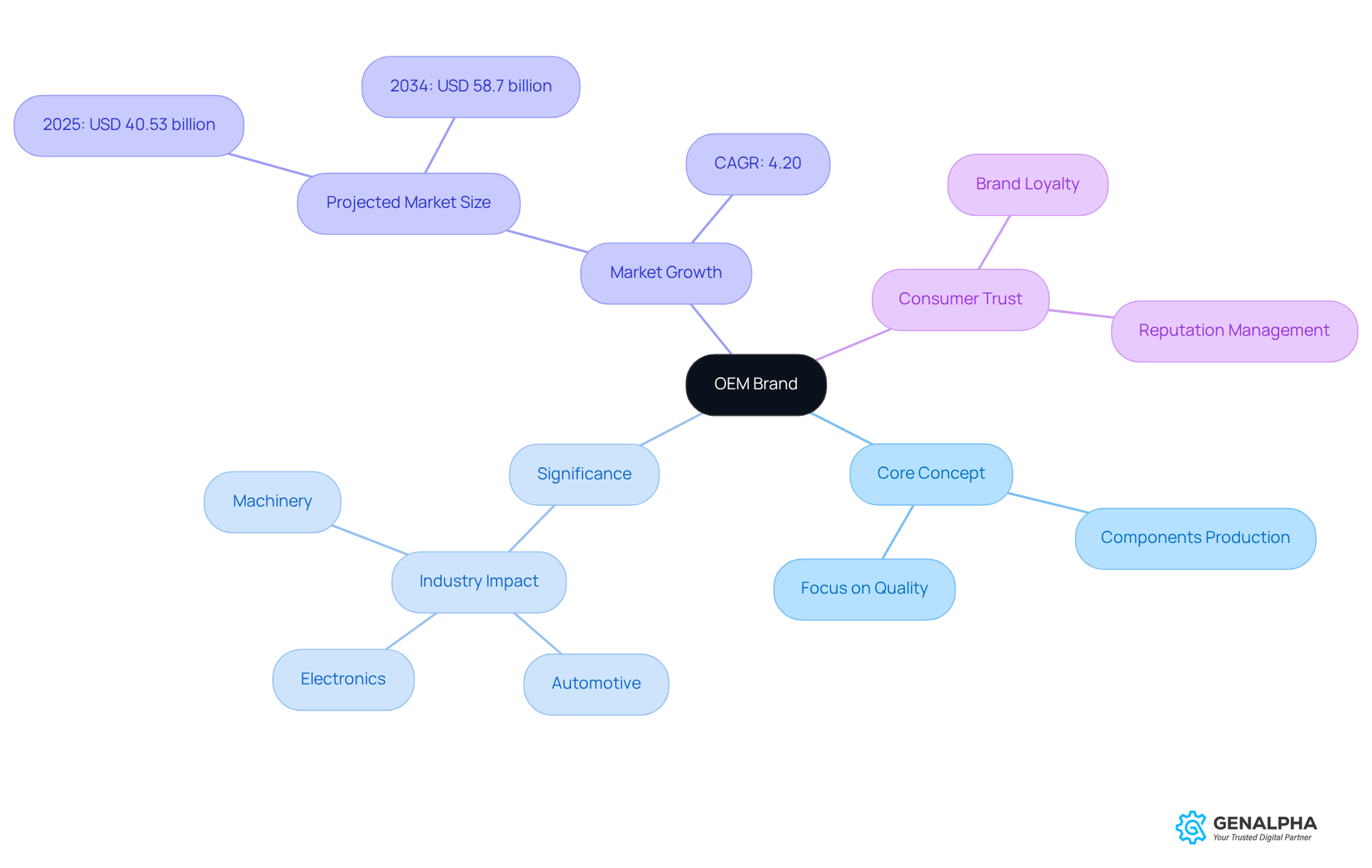

For example, in the automotive industry, the global OEM market is expected to grow from USD 40.53 billion in 2025 to around USD 58.7 billion by 2034. That’s a compound annual growth rate (CAGR) of 4.20%! This growth shows a rising demand for quality components that meet consumer expectations.

Industry leaders emphasize that a strong OEM brand identity not only enhances quality but also fosters trust and loyalty among consumers. As Jeff Bezos wisely noted, "A label for a company is akin to a reputation for an individual. You earn reputation by trying to do hard things well."

Ultimately, the OEM brand manufacturers are key players in production. They drive innovation and ensure that end products meet the highest standards of quality. So, next time you enjoy a well-made product, remember the vital role OEMs play in making it happen!

Explore the Role of OEM Brands in Equipment Manufacturing

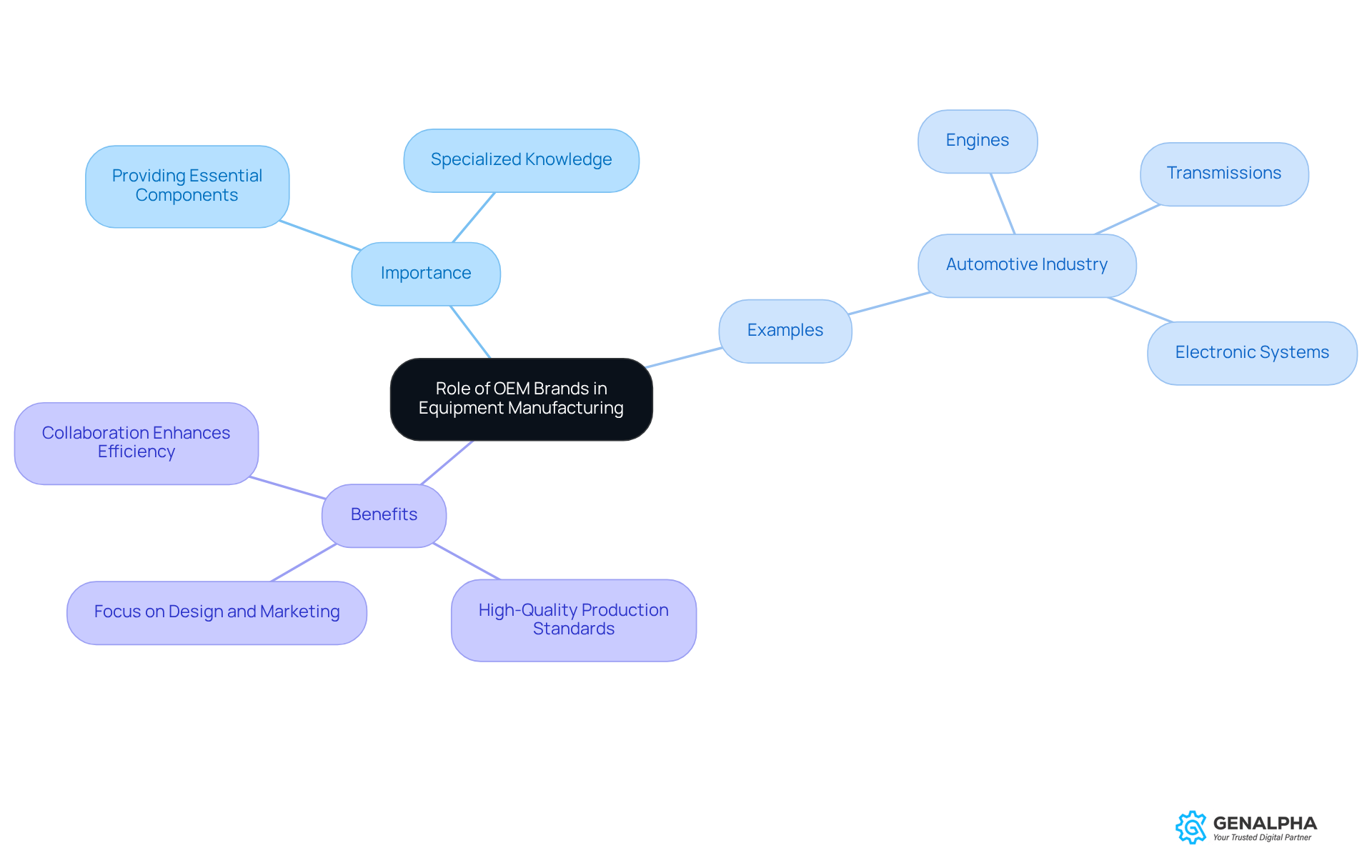

The oem brand really is the backbone of equipment manufacturing, isn’t it? They provide those essential components that meet specific design and performance criteria. This means producers can tap into specialized knowledge and advanced technologies without needing to have extensive in-house production capabilities.

Take the automotive industry, for example. OEMs produce critical parts like engines, transmissions, and electronic systems that are vital for vehicle performance. This kind of collaboration allows equipment producers to focus on what they do best, such as design and marketing, while still maintaining high-quality production standards through their OEM brand partners.

Isn’t it fascinating how this teamwork works? It’s all about leveraging strengths and ensuring that every piece fits perfectly into the bigger picture. So, next time you think about the equipment you use, consider the role of the OEM brand in making it all happen!

Identify Key Characteristics and Benefits of OEM Brands

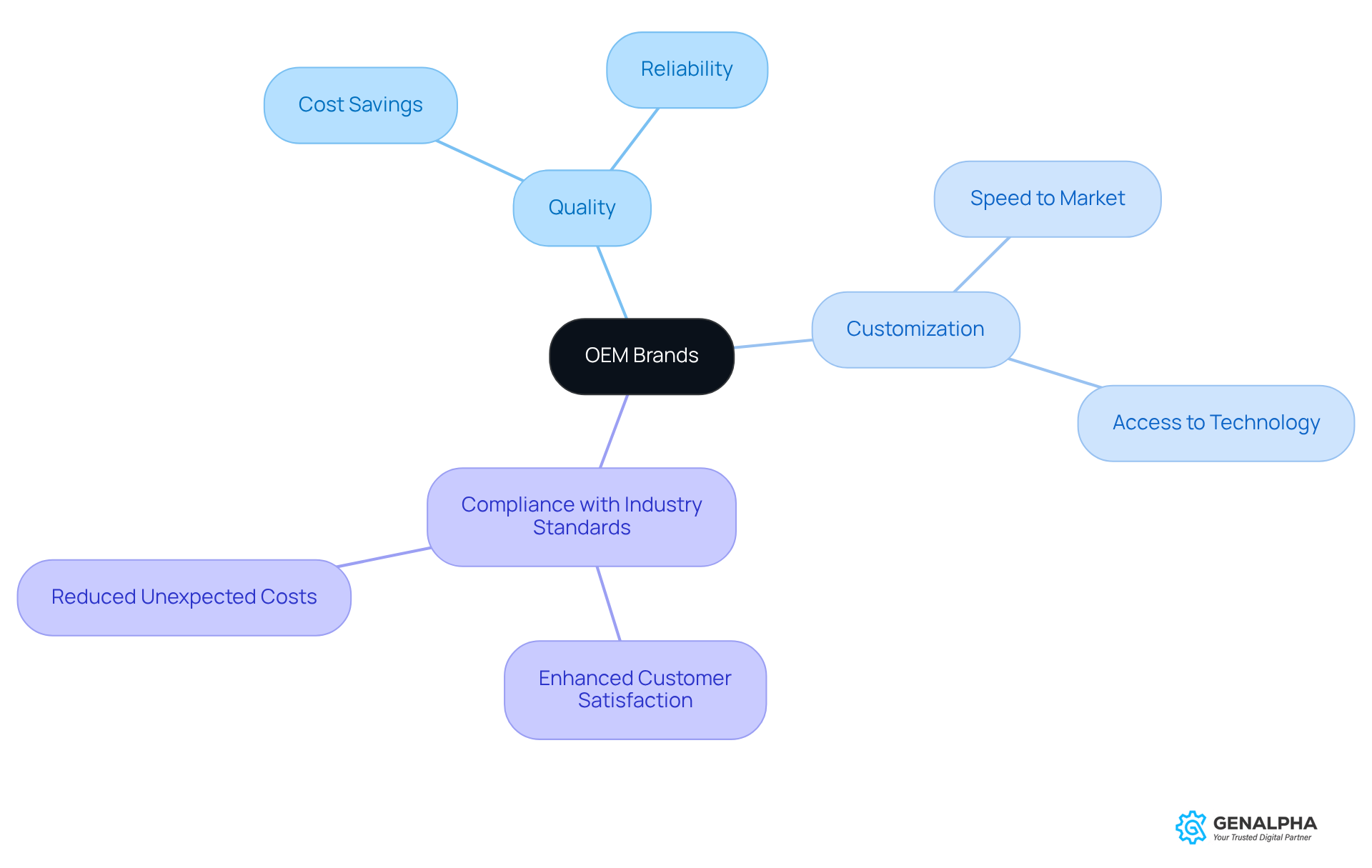

When we think about an OEM brand, a few key characteristics come to mind: quality, customization, and compliance with industry standards. These producers really know their stuff, using specialized expertise to create high-performance components tailored to their clients' unique needs.

So, why should producers consider teaming up with an OEM brand? The benefits are pretty significant! For starters, they can cut costs through economies of scale. Plus, they can speed up their time-to-market by tapping into established production capabilities. And let’s not forget about reliability - sourcing components that meet strict quality standards can make all the difference.

OEMs often back their products with warranties and ongoing support, which boosts customer satisfaction and confidence in the final offering. Take, for example, a case study where Gilson partnered with a medical college. They quickly customized workflows, enabling the processing of over 100,000 tubes of viral transport media each week during the pandemic. This really shows how OEM partnerships can enhance operational efficiency and responsiveness in critical situations.

Industry experts emphasize that these collaborations not only help reduce unexpected costs but also provide access to cutting-edge technologies and expertise. This makes them a smart choice for producers looking to thrive in a competitive landscape.

As we’ve seen, working with OEMs leads to fewer surprises in expenses, creates a buffer in resource allocation, and helps creators benefit from a solid contractual commitment for the goods and services they receive. Plus, partnering with an OEM brand opens the door to technical know-how, modern analytical tools, and innovative workflows, further boosting the value of these partnerships.

So, what do you think? Are you ready to explore the potential of OEM collaborations?

Differentiate OEM Brands from Aftermarket and ODM Manufacturers

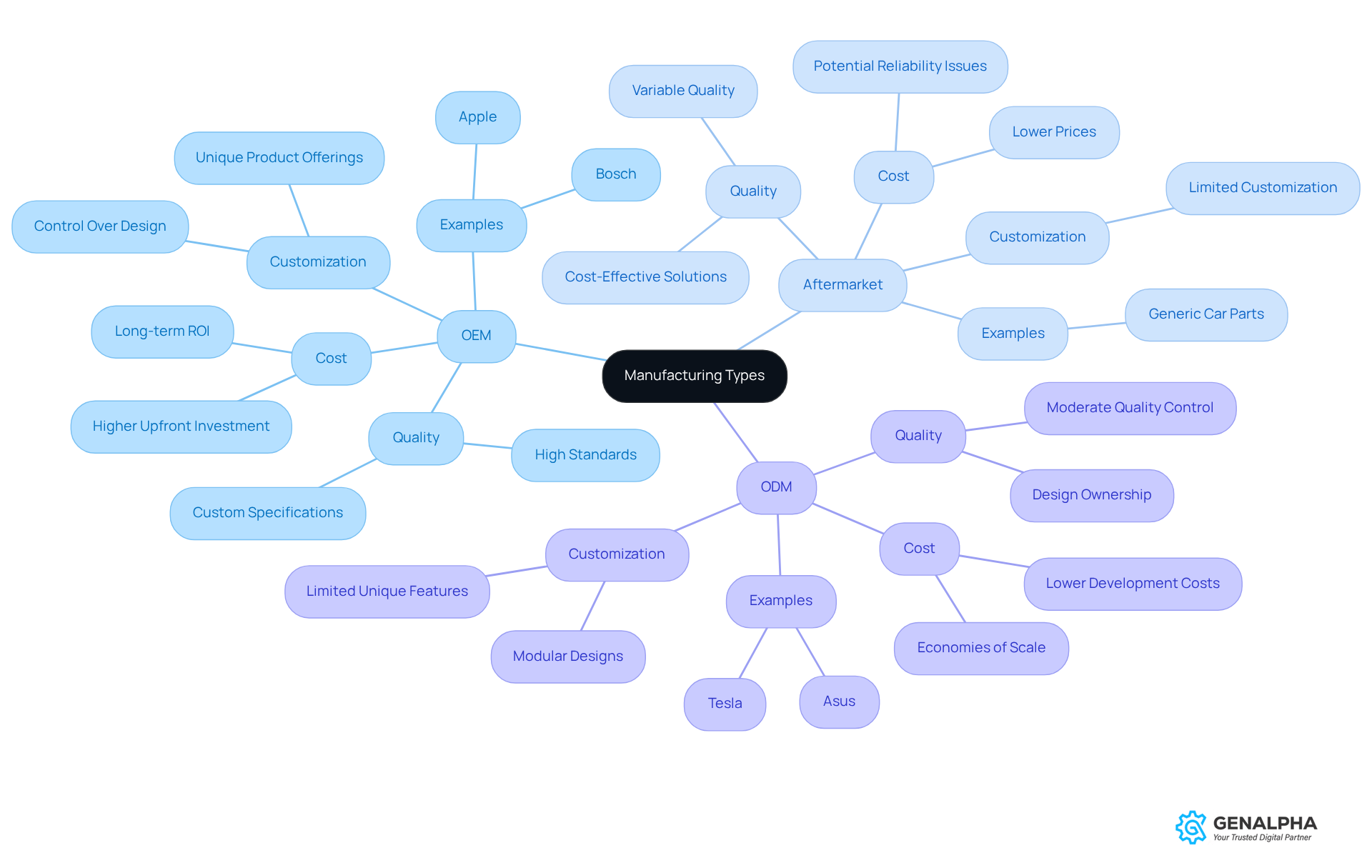

When it comes to understanding the differences between an OEM brand, aftermarket products, and Original Design Manufacturers (ODM), it’s essential to break it down. Have you ever wondered what sets these apart? Let’s dive in!

Aftermarket manufacturers whip up components that fit with OEM items, but here’s the catch - they’re not made by the OEM itself. These parts can vary quite a bit in quality and performance. Sure, they might save you some cash, but they could also compromise on reliability. On the flip side, ODMs take the reins by creating and producing items based on specifications from another company. They often take on a bigger role in the development process.

While OEMs focus on crafting elements that stick to the original standards, ODMs might come up with entirely new products that a brand can proudly showcase under its name. Understanding these differences is crucial for producers looking to boost their supply chains and product offerings.

As Hallmark Nameplate puts it, "Whether you’re looking for detailed customization or cost-effective solutions, our team is here to assist you in making the best choice for your needs." Companies like Bosch are prime examples of the practices associated with an OEM brand. They create specific components based on exact designs from automotive producers, ensuring quality and maintaining the OEM brand integrity. Think about it: Bosch produces parts like brakes, sensors, and fuel injectors tailored to the precise designs provided by car manufacturers like BMW or Ford.

Additionally, with the rise of e-commerce, there’s a growing demand for ODM products, opening doors for niche OEM offerings. But here’s a thought - producers need to weigh the potential for brand dilution when opting for ODM. Without clear differentiation, standing out in a crowded market can be tough.

So, what’s the takeaway? This nuanced understanding of OEM versus aftermarket and ODM roles is vital for equipment manufacturers navigating today’s complex manufacturing landscape. How will you leverage this knowledge in your own business?

Conclusion

When we think about OEM brands, it’s clear they play a crucial role in equipment manufacturing. They’re the backbone of producing high-quality components that really boost the functionality of final products. These brands don’t just supply essential parts; they allow companies to zero in on what they do best - like marketing and design. It’s a win-win situation that sparks innovation and efficiency.

Throughout our discussion, we’ve seen just how important OEM brands are across various industries, especially in automotive and electronics. Their contributions can lead to better performance and reliability. Plus, collaborating with OEMs brings a bunch of advantages: think cost savings, quicker time-to-market, and access to specialized knowledge. And let’s not forget the distinction between OEMs, aftermarket products, and ODM manufacturers. Each has its unique role in the manufacturing ecosystem, and understanding these differences helps in making smart choices about supplier partnerships.

So, why does all this matter? Well, grasping the role and benefits of OEM brands is key for equipment manufacturers looking to thrive in a competitive market. By tapping into these partnerships, businesses can boost product quality, streamline operations, and keep up with what consumers expect. Embracing the potential of OEM collaborations not only strengthens supply chains but also sets companies up for long-term success in a constantly changing industrial landscape.

What do you think? Are you ready to explore the possibilities that OEM partnerships can bring to your business?

Frequently Asked Questions

What does OEM stand for in the context of branding?

OEM stands for Original Equipment Manufacturer, which refers to firms that create items or components used in the final assembly of another company’s products.

What is the primary role of an OEM brand?

The primary role of an OEM brand is to produce specialized components that allow purchasing companies to focus on marketing and sales of the final products.

Why are OEM brands significant?

OEM brands are significant because they provide high-quality components that enhance the quality and functionality of final goods, which is crucial in various sectors such as automotive, electronics, and machinery.

What is the projected growth of the global OEM market in the automotive industry?

The global OEM market in the automotive industry is expected to grow from USD 40.53 billion in 2025 to around USD 58.7 billion by 2034, reflecting a compound annual growth rate (CAGR) of 4.20%.

How does a strong OEM brand identity impact consumer trust?

A strong OEM brand identity enhances quality and fosters trust and loyalty among consumers, as it is associated with a reputation for delivering high-quality components.

What role do OEM manufacturers play in production?

OEM manufacturers are key players in production as they drive innovation and ensure that end products meet the highest standards of quality.