Introduction

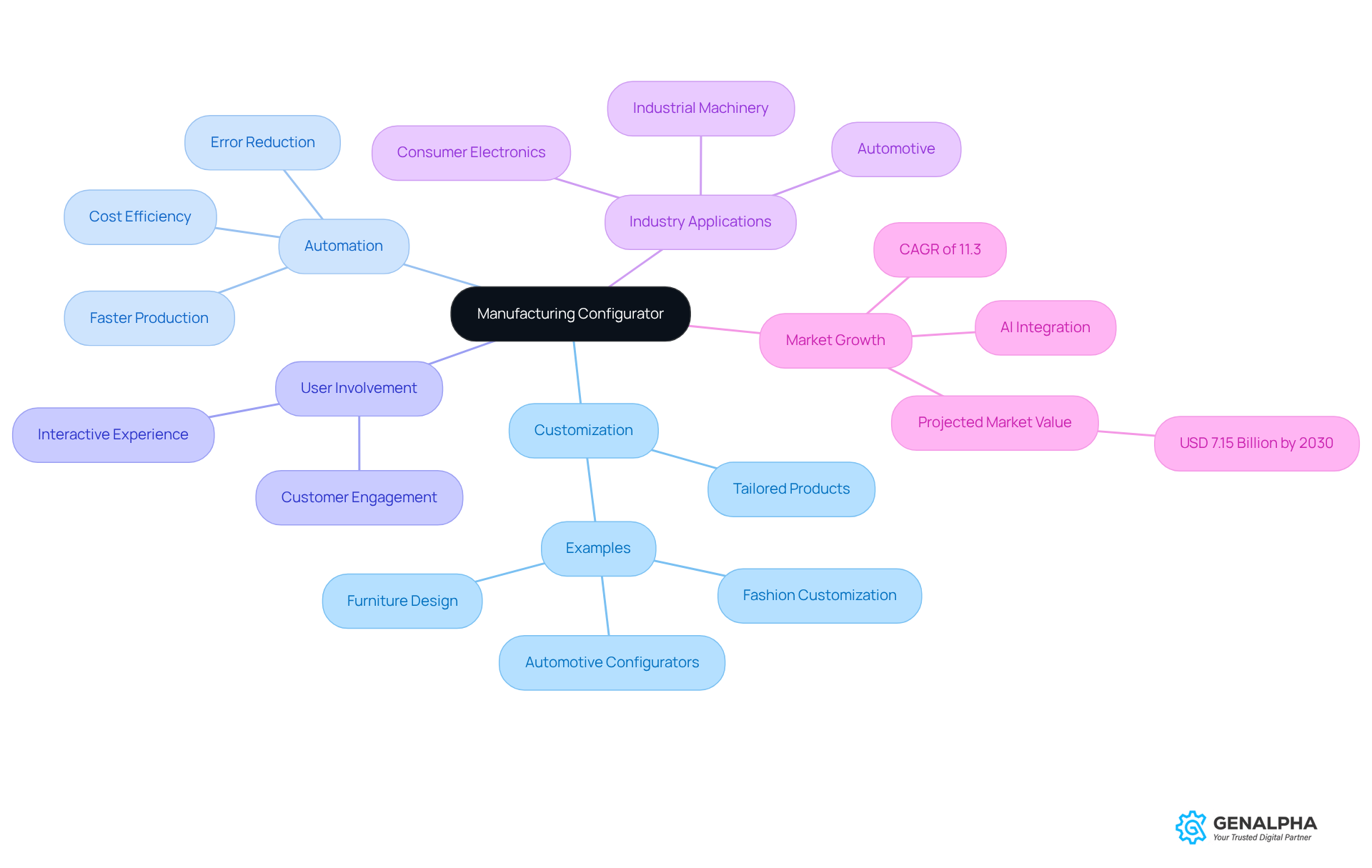

Customization in manufacturing is changing the game for how products are designed and delivered. Think about it: we all want things that fit our unique needs, right? That’s where the manufacturing configurator comes in. It’s a nifty tool that helps businesses create products tailored just for you, all while making the production process smoother.

But here’s the kicker: as more industries jump on board with this technology, a big question pops up. How can manufacturers use configurators not just to boost customer satisfaction, but also tackle the challenges of integration and cost? Let’s dive into this together!

Define Manufacturing Configurator: Key Concepts and Functions

Have you ever wished you could customize a product to fit your exact needs? That’s where the role of a manufacturing configurator becomes important! This advanced manufacturing configurator allows manufacturers to tailor items to meet specific client requirements. Imagine being able to choose everything from size and color to material and features, ensuring the final product is just right for you.

By automating the creation of specifications and pricing, the manufacturing configurator helps reduce mistakes and enhance overall client satisfaction. It’s a win-win! Not only does this streamlined design and ordering process reduce misunderstandings, but it also speeds up the time it takes to get products to market.

What’s really cool is the intuitive interface of the manufacturing configurator tools for customization. They encourage user involvement in the design process, creating a more personalized buying experience. This technology shines in industries where products are complex and highly customizable, such as automotive, machinery, and consumer electronics, thanks to the use of a manufacturing configurator. For instance, think about car manufacturers that allow buyers to design their dream vehicles by selecting various options. This leads to happier customers and fewer order errors.

Industry leaders are raving about how the manufacturing configurator transforms client satisfaction. By enabling real-time customization, they enhance the shopping experience, which can lead to increased loyalty and repeat business. As manufacturers adopt these tools, they’re not just meeting the growing demand for personalized products; they’re also improving their operations, which can boost profitability and customer loyalty.

Did you know that manufacturers make up the largest end-user segment in the Product Configurator Market? It’s projected to grow at a CAGR of 11.3% from 2024 to 2030! Plus, AI-driven tools are expected to become as common as online checkouts, with the potential to increase conversions by five times. That really highlights their importance in today’s market!

Trace the Evolution of Manufacturing Configurators: Historical Context and Development

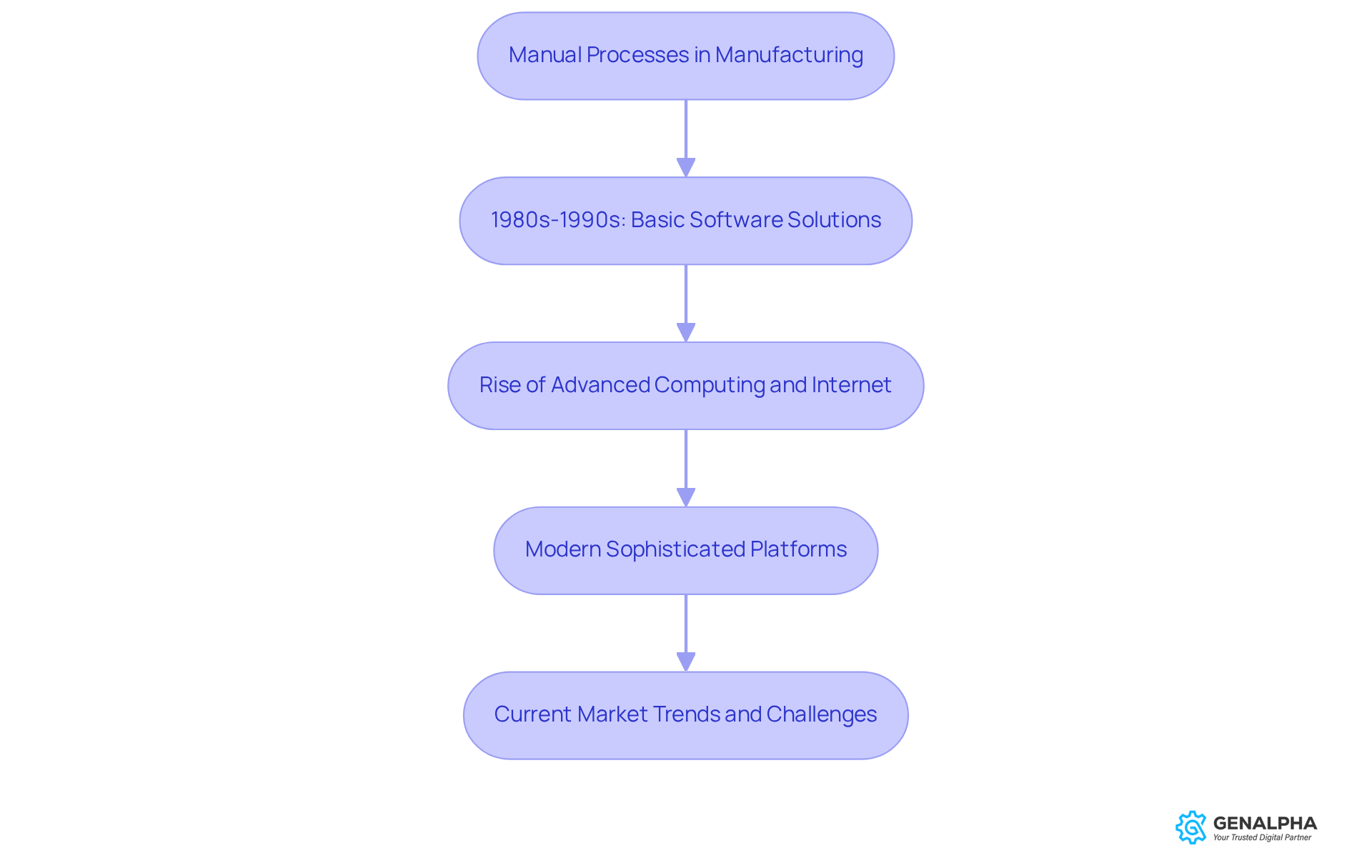

Remember when customization in manufacturing was all about manual processes? It feels like ages ago, right? As industries evolved, the need for quicker and more precise customization kicked off a wave of software solutions in the 1980s and 1990s. Initially, these tools were pretty basic, letting users pick from a set list of options. But then, with the rise of advanced computing and the internet, everything changed. Now, we have sophisticated platforms that offer 3D visualization, real-time pricing, and smooth integration with ERP systems.

Fast forward to today, and using a manufacturing configurator has become essential for companies that want to offer personalized products while boosting efficiency. It’s a big shift towards mass customization in the manufacturing world! Just think about it: the market for manufacturing configurators is projected to hit a whopping USD 6.972 billion by 2035, driven by tech advancements and a growing appetite for customized solutions. Plus, it’s expected to grow at a compound annual growth rate (CAGR) of 10.52% from 2025 to 2035. That’s some serious growth!

Companies like Tacton are at the forefront with their AI-driven guided selling engines, showcasing just how far manufacturing configurator technology has come. But let’s not forget, there are still challenges to tackle. High initial costs and integration issues can be real roadblocks for many organizations trying to jump on board with these innovative tools. So, what do you think? Are you ready to explore how these advancements can benefit your business?

Examine Key Features of Manufacturing Configurators: Components and Benefits

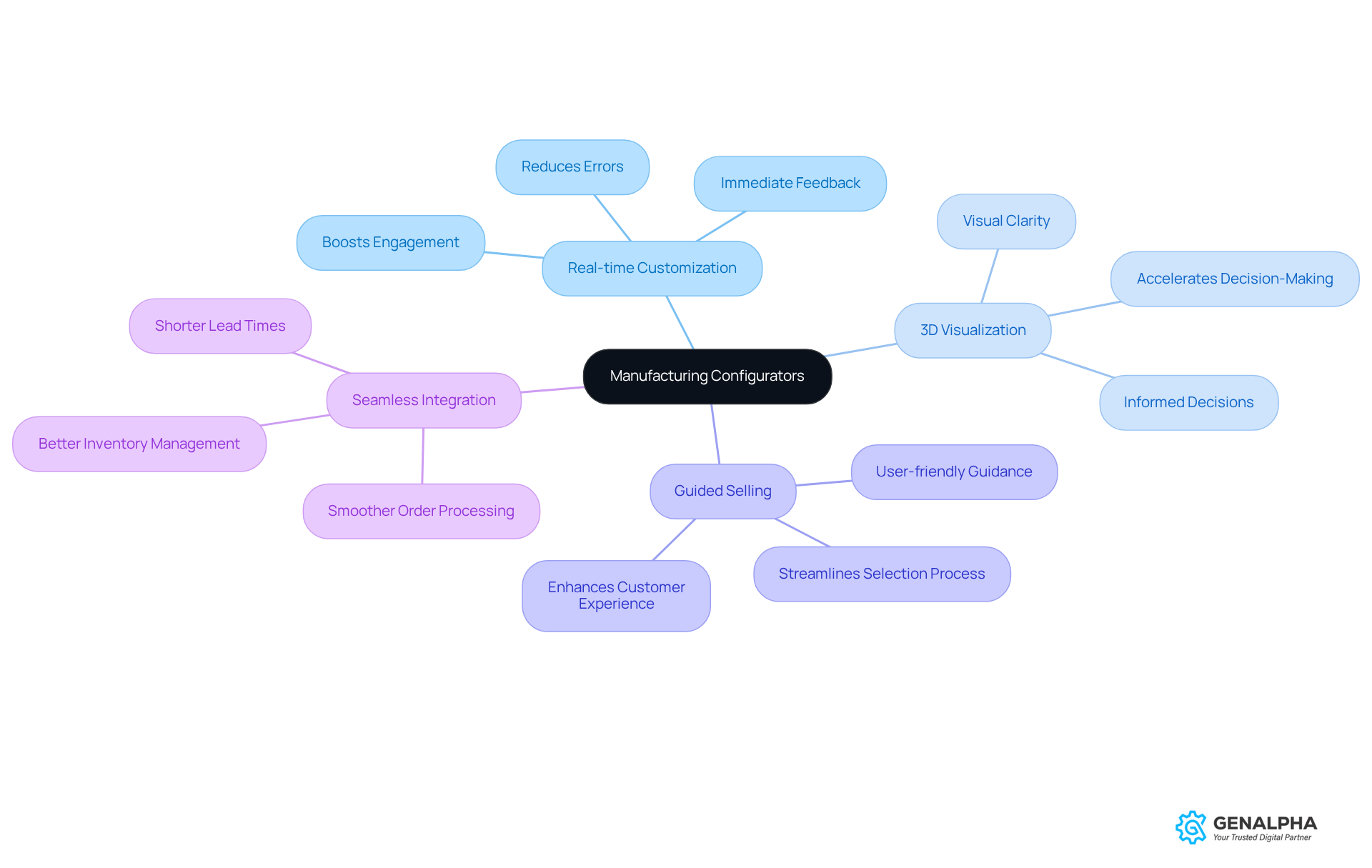

When it comes to the manufacturing configurator for tools, there are some key features that really stand out:

- Real-time customization

- 3D visualization

- Guided selling

- Seamless integration with existing systems

Imagine being able to see how your choices impact a product right away - pretty cool, right? That’s what real-time customization does. It boosts engagement and satisfaction, making the whole experience more enjoyable.

Did you know that companies using sales tools can cut their quote-to-cash time by a whopping 40%? That’s according to Gartner! This really shows how much efficiency these resources can bring to the table. Plus, manufacturers can expect to see quote times drop by as much as 90%. Talk about a game changer for operational efficiency!

Now, let’s talk about 3D visualization. It gives clients a lifelike view of the product, helping them make informed decisions. And those guided selling features? They’re like a friendly guide through a maze of options, ensuring you pick the right components that work well together.

On top of that, manufacturing configurators can easily integrate with ERP systems. This means smoother order processing and better inventory management, which ultimately leads to shorter lead times and fewer errors. As Meenakshi Mamgai puts it, "A configurator is a tool that is aimed at enhancing user experience by allowing individuals to customize various aspects of an item such as size, color, materials, and features."

All these features come together to create a better client experience, boost sales efficiency, and drive those conversion rates up. So, what do you think? Ready to explore how these tools can transform your manufacturing process?

Explore Real-World Examples of Manufacturing Configurators in Action

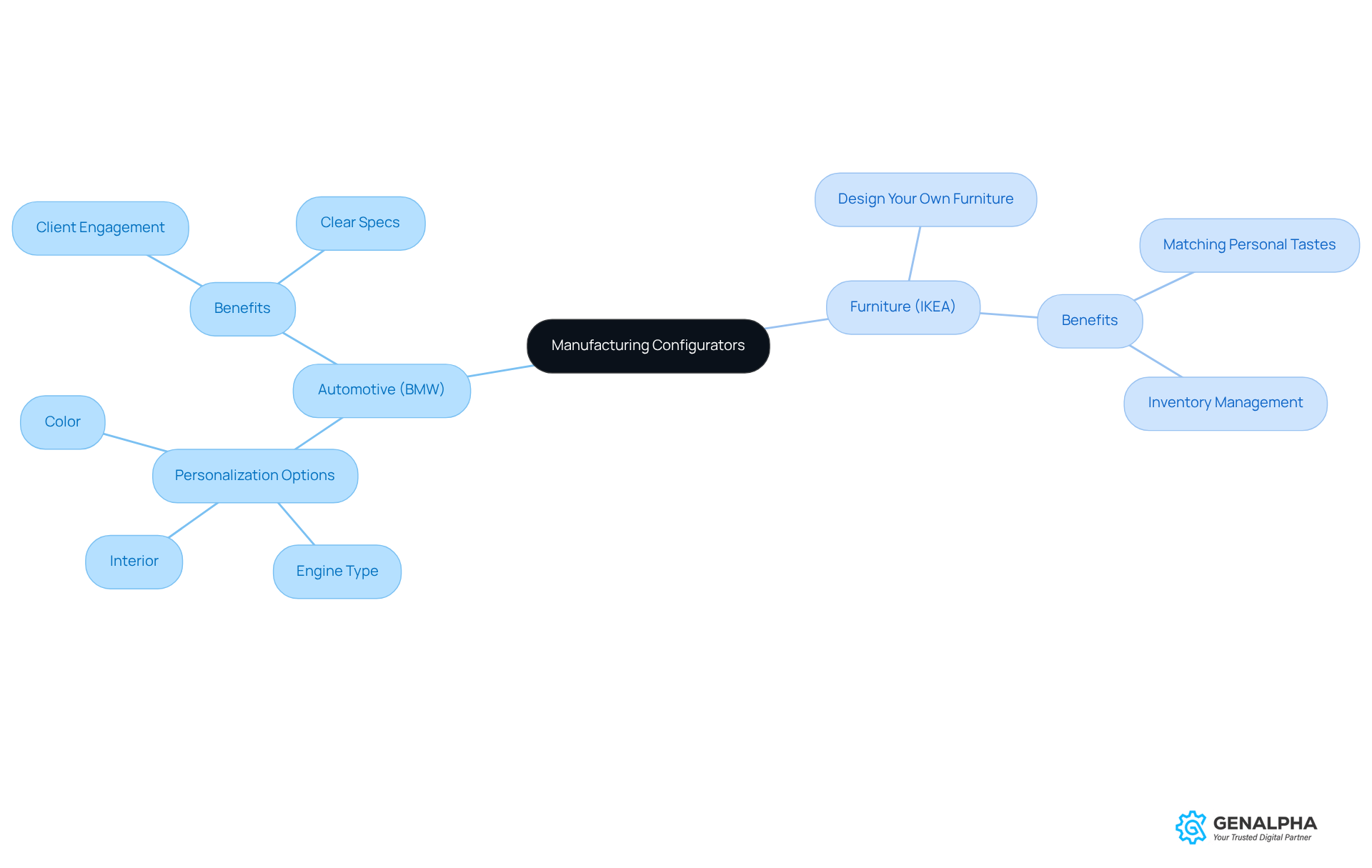

Have you ever thought about how manufacturers are stepping up their game with tools that really enhance what they offer? Take automotive giants like BMW, for instance. They’ve got these cool tools that let buyers personalize their vehicles - think color, engine type, and interior options. This not only boosts client engagement but also makes life easier for production teams by providing clear specs.

And it’s not just cars! Look at furniture makers like IKEA. They’ve jumped on the bandwagon too, allowing customers to design their own furniture pieces. This way, products match personal tastes perfectly, and it helps with keeping inventory in check.

These examples truly demonstrate the versatility of manufacturing configurators across various sectors. They’re not just about making things; they’re about improving customer satisfaction and operational efficiency. So, what do you think? How could these tools change your shopping experience?

Conclusion

Manufacturing configurators have really become a game-changer in custom product design. They help manufacturers meet specific client needs with incredible precision. By allowing real-time customization and automating the ordering process, these tools not only boost customer satisfaction but also streamline operations, leading to significant efficiency gains across various industries.

Think about how far we've come! The evolution of manufacturing configurators has taken us from basic manual processes to advanced software solutions that include cool features like 3D visualization and seamless ERP integration. It’s fascinating to see how these tools reduce errors and misunderstandings while driving profitability and customer loyalty in a competitive market. Just look at the automotive and furniture industries - real-world examples show the tangible benefits of adopting manufacturing configurators, enhancing user experience and operational efficiency.

As we continue to embrace new technologies, the potential for manufacturing configurators to revolutionize product customization is huge. Companies should really think about integrating these tools - not just to keep up with market demands but to build stronger connections with their customers. The future of manufacturing is all about adapting and innovating, and manufacturing configurators are leading the way in this exciting journey. So, why not take the leap and explore how these tools can transform your business?

Frequently Asked Questions

What is a manufacturing configurator?

A manufacturing configurator is a tool that allows manufacturers to customize products to meet specific client requirements, enabling choices in size, color, material, and features.

How does a manufacturing configurator benefit manufacturers and clients?

It automates the creation of specifications and pricing, reducing mistakes and enhancing client satisfaction, while also speeding up the product delivery process to market.

In which industries is the manufacturing configurator particularly useful?

The manufacturing configurator is especially beneficial in industries with complex and highly customizable products, such as automotive, machinery, and consumer electronics.

How does a manufacturing configurator improve the customer experience?

It provides an intuitive interface that encourages user involvement in the design process, leading to a more personalized buying experience and ultimately happier customers.

What impact does the manufacturing configurator have on client satisfaction and business operations?

By enabling real-time customization, it enhances the shopping experience, which can lead to increased customer loyalty and repeat business, while also improving operational efficiency and profitability for manufacturers.

What is the projected growth of the Product Configurator Market?

The Product Configurator Market is projected to grow at a CAGR of 11.3% from 2024 to 2030, with manufacturers being the largest end-user segment.

How might AI-driven tools influence the manufacturing configurator market?

AI-driven tools are expected to become as common as online checkouts and have the potential to increase conversions by five times, highlighting their significance in the current market.