Overview

Have you ever wondered how equipment manufacturers set their prices? It’s a bit of a puzzle, right? Well, this article dives into some interesting pricing techniques that can really make a difference. We’re talking about strategies like:

- Cost-plus pricing

- Value-based pricing

- Dynamic costing

- Tiered pricing

- Pay-per-use pricing

These methods are crucial for manufacturers trying to thrive in competitive markets. By aligning pricing with production costs, perceived value, and market demand, they can not only boost profitability but also enhance customer satisfaction. Imagine being a manufacturer who understands exactly how to price their products to meet customer expectations while still making a profit!

So, what do you think? Could these strategies help your business? It’s definitely worth considering how these techniques can be implemented to improve your pricing approach. Let’s explore these ideas further and see how they can work for you!

Introduction

Have you ever thought about how crucial pricing techniques are for equipment manufacturers trying to stand out in a crowded market? These strategies do more than just determine profit margins; they play a big role in customer satisfaction and loyalty, too. As manufacturers face rising costs and changing market demands, a key question pops up: how can they use different pricing methods to boost profits while keeping customers happy?

Exploring the various pricing approaches not only uncovers the challenges but also highlights the opportunities that await those in the equipment manufacturing world. So, let’s dive into this fascinating topic together and see what we can discover!

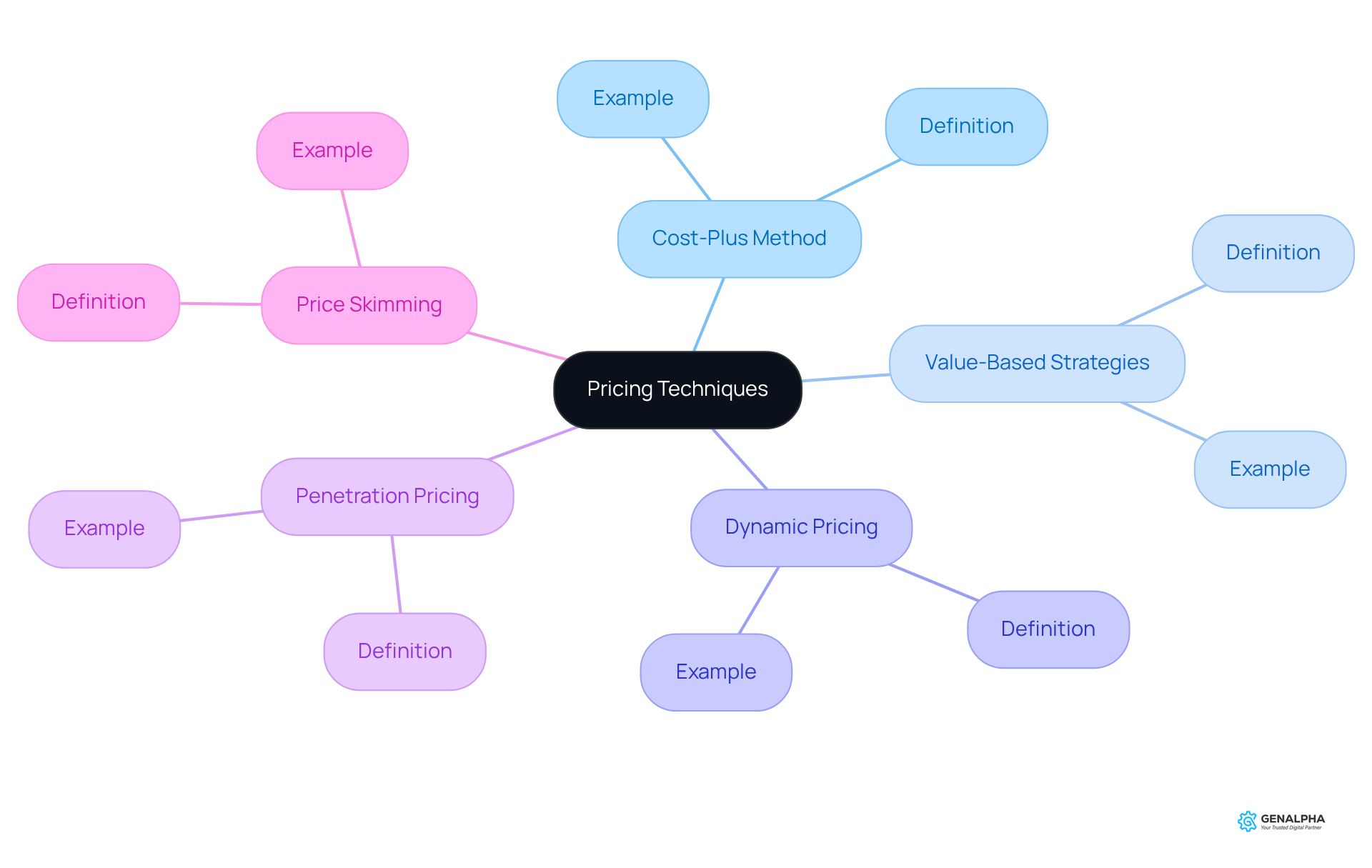

Define Pricing Techniques: A Comprehensive Overview

Have you ever wondered what are pricing techniques that businesses use to determine the prices for their products or services? What are pricing techniques? They refer to the various methods that are used and can be quite fascinating! For instance, some companies use a cost-plus method, where they simply add a fixed percentage to the production cost. Others might opt for more complex approaches like value-based strategies, which consider how much a product is worth to the customer.

For equipment manufacturers, understanding what are pricing techniques is super important. Why? Because they need to navigate competitive markets while trying to boost their profits and meet customer expectations. So, next time you think about pricing, consider how these strategies play a role in the bigger picture. What pricing method do you think would work best for your business?

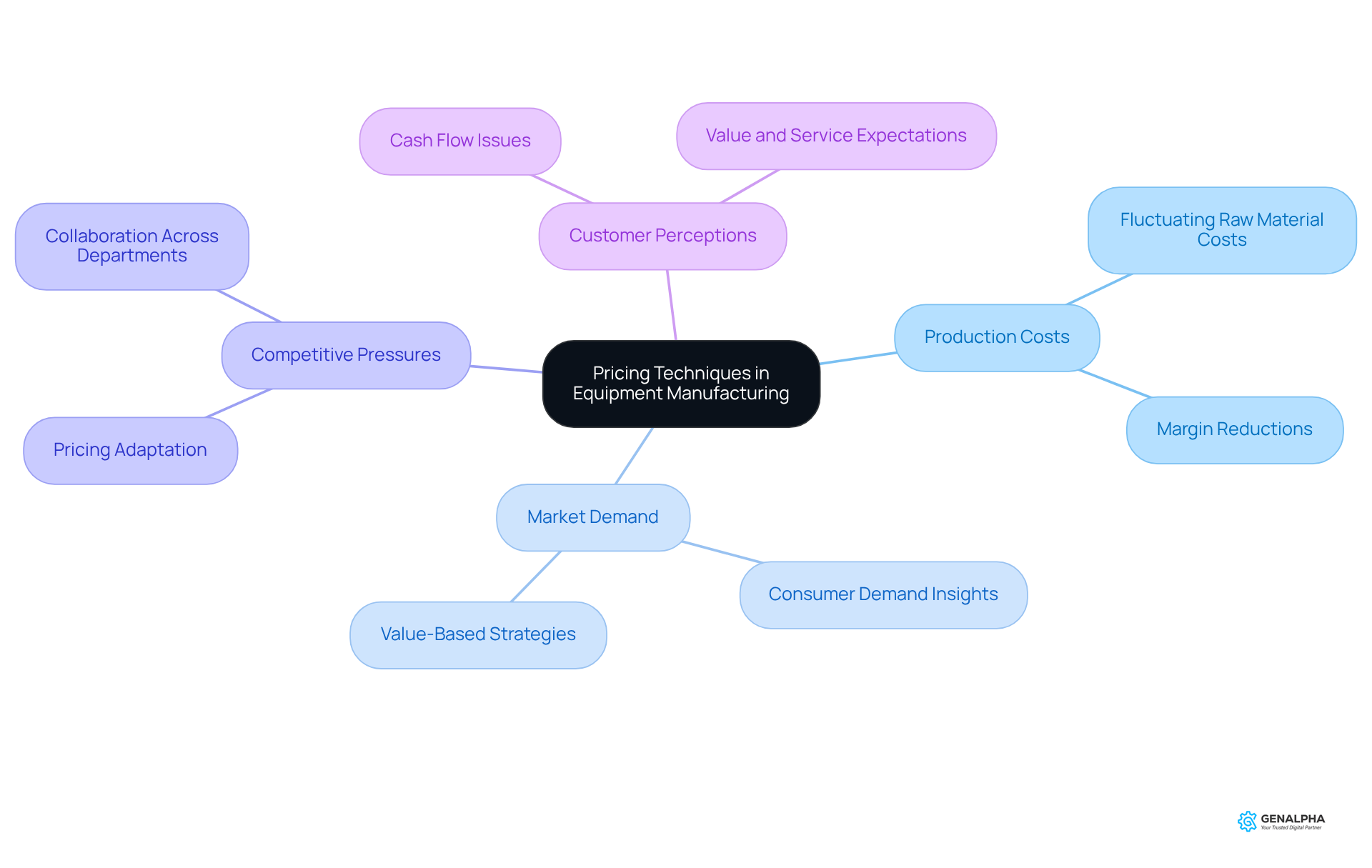

Contextualize Pricing Techniques in Equipment Manufacturing

In the equipment manufacturing sector, cost strategies are influenced by a variety of factors—think production costs, market demand, and competitive pressures. Producers face challenges like fluctuating raw material costs and significant margin reductions when their sales strategies don’t keep pace with rising costs. It’s a tough balancing act to stay profitable while meeting customer expectations for value and service. Manufacturers are constantly trying to align their offerings with what customers perceive as valuable.

Now, consider this: 82% of contractors are waiting over 30 days for payment. That’s a big deal! Cash flow issues can really mess with cost strategies. As the industry shifts toward customer-focused cost structures, it’s crucial to grasp the bigger picture of how these strategies play out. Understanding consumer demand is key. Producers who embrace sophisticated methods—like value-based and demand-oriented strategies—can see impressive revenue boosts.

For instance, OEMs in the heavy machinery sector have reported revenue growth of 5% to 10% by using these approaches. This clearly shows how market dynamics can shape effective cost decisions. Plus, collaboration across departments is vital for successful cost strategies. When insights from various teams come together, financial decisions improve.

Ultimately, having a nuanced understanding of these factors—especially with the integration of AI, ML, and big data technologies—is essential for manufacturers who want to thrive in today’s competitive landscape. So, how can you leverage these insights in your own strategies?

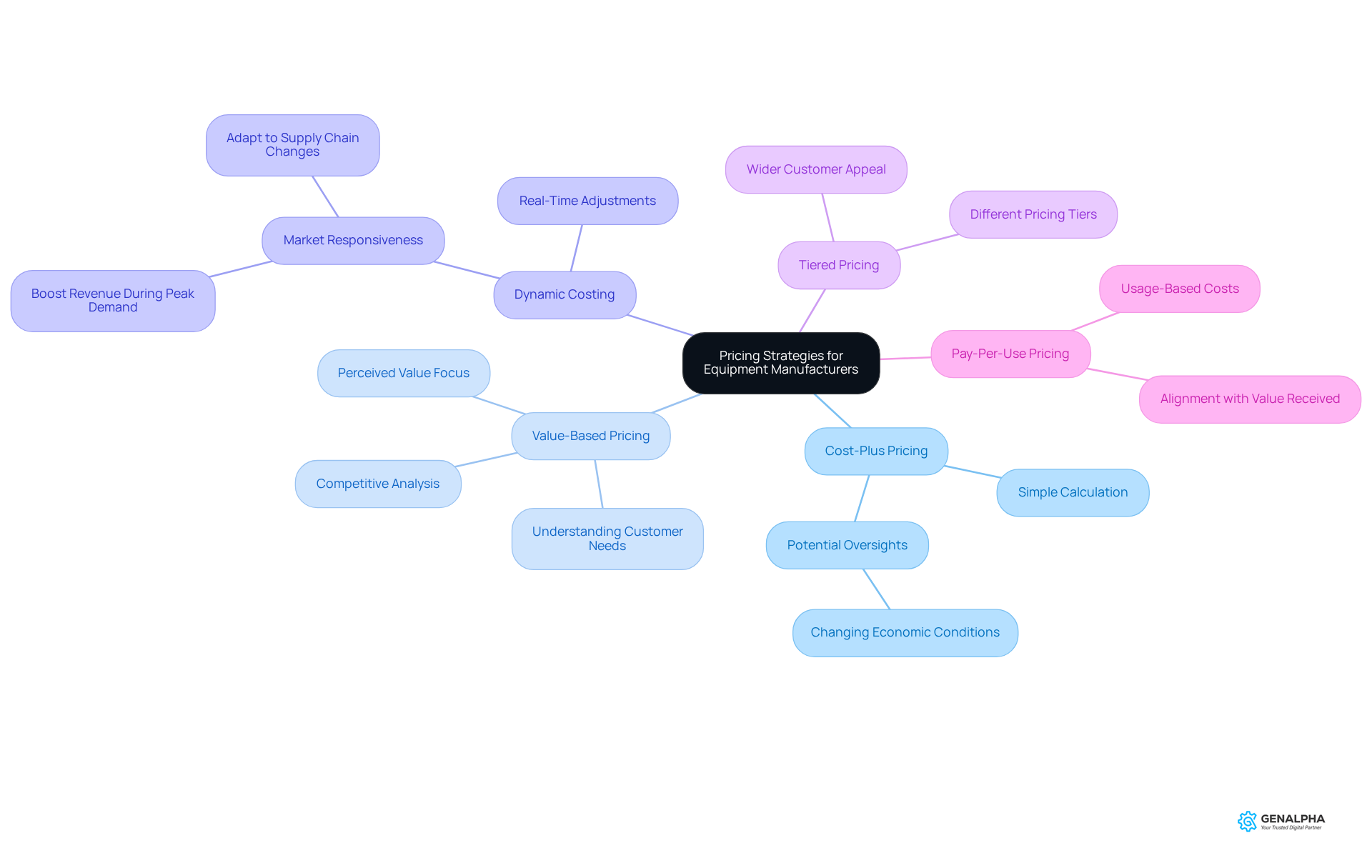

Explore Key Pricing Strategies for Equipment Manufacturers

When it comes to pricing strategies for equipment manufacturers, there are a few key approaches that can really make a difference:

-

Cost-Plus Pricing: This is a pretty straightforward method where you calculate the total production cost and then add a markup for profit. It’s easy to understand, but watch out! It often overlooks changing economic conditions, which means you might miss out on some great opportunities.

-

Value-Based Pricing: Here’s where things get interesting. This method sets prices based on the perceived value to the client, not just on production costs. To do this well, you need to really understand what your customers want and how the industry works. As Jose Paez, Director of Solution Strategy at Pricefx, points out, knowing customer value in relation to competitive options is crucial for determining effective costs.

-

Dynamic Costing: This flexible approach lets producers adjust costs in real-time based on demand, competitor pricing, and other external factors. By using these adaptable rates, manufacturers can boost revenue during peak demand times and respond quickly to market changes. This agility is super important, especially with challenges like supply chain disruptions and fluctuating raw material costs.

-

Tiered Pricing: Offering different pricing tiers based on features or service levels can attract a wider range of customers and accommodate various budgets. This strategy not only enhances accessibility but also maximizes revenue potential.

-

Pay-Per-Use Pricing: This emerging model allows users to pay according to their actual equipment usage. It aligns costs with the value received, which can really boost client satisfaction and loyalty.

By applying these strategies, producers can adjust their costs to better fit industry conditions and meet consumer expectations, illustrating what are pricing techniques. This ultimately leads to increased profitability and a stronger competitive edge. For instance, one manufacturing client successfully transitioned to a solutions-oriented cost structure, leading to a 4% price increase and improved client satisfaction by measuring the financial value of optimized processes. It’s a great example of how tweaking cost approaches can meet the ever-changing needs of the market.

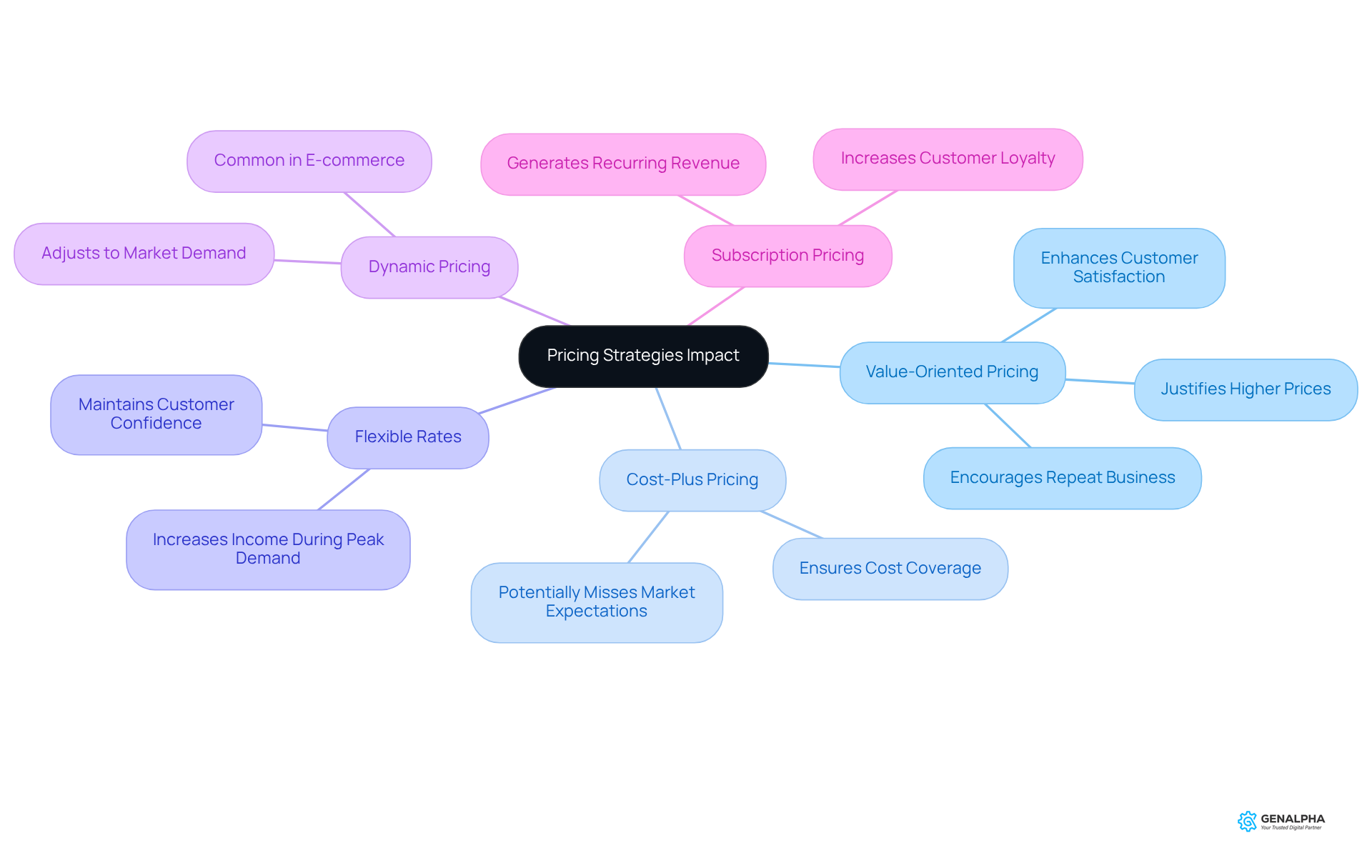

Assess the Impact of Pricing Strategies on Profitability and Customer Satisfaction

In the equipment manufacturing world, understanding what are pricing techniques is crucial for shaping both profitability and client satisfaction. Have you ever thought about what are pricing techniques that can really boost sales and profits through the right cost approach? When done right, effective cost strategies are examples of what are pricing techniques that can enhance sales volume and profit margins. But if they miss the mark, they risk pushing clients away and damaging brand loyalty.

For example, consider value-oriented pricing. This method aligns fees with the perceived worth of products, which not only enhances client satisfaction but also encourages repeat business and referrals. On the flip side, cost-plus pricing might overlook what the market actually expects, leading to missed opportunities.

Now, let’s talk about flexible rates. When executed carefully, they can ramp up income during peak demand while keeping clients happy and confident in their choice. Continuous evaluation of what are pricing techniques is essential for manufacturers aiming to achieve their profitability targets and enhance customer satisfaction. So, what steps can you take today to refine your pricing approach for long-term success?

Conclusion

Understanding pricing techniques is crucial for equipment manufacturers trying to navigate a competitive landscape. These strategies—like cost-plus, value-based, dynamic, tiered, and pay-per-use pricing—offer a solid framework for setting prices that not only cover costs but also resonate with customer perceptions and market demands. By leveraging these methods, manufacturers can boost profitability while keeping customers happy.

Throughout this article, we've highlighted the importance of adapting pricing strategies to various factors, such as production costs, market demand, and customer expectations. For instance, sophisticated approaches like value-based and dynamic pricing can lead to increased revenue and stronger client relationships. Case studies show that manufacturers who embrace these techniques can achieve impressive revenue growth and solidify their market position.

Ultimately, we can't underestimate the importance of effective pricing strategies. Manufacturers should continuously assess and refine their approaches, keeping an eye on industry trends and consumer insights. By doing so, they can not only enhance their profitability but also build lasting customer loyalty in a rapidly changing market. So, let’s adopt a proactive stance on pricing—it’s key to thriving in the equipment manufacturing sector. What steps will you take to refine your pricing strategy today?

Frequently Asked Questions

What are pricing techniques?

Pricing techniques refer to the various methods businesses use to determine the prices for their products or services.

Can you give an example of a pricing technique?

One example is the cost-plus method, where a fixed percentage is added to the production cost to set the price.

What is a value-based pricing strategy?

A value-based pricing strategy considers how much a product is worth to the customer, rather than just the cost of production.

Why is understanding pricing techniques important for equipment manufacturers?

Understanding pricing techniques is crucial for equipment manufacturers as it helps them navigate competitive markets while aiming to boost profits and meet customer expectations.

How can pricing techniques influence a business's success?

Pricing techniques can significantly impact a business's ability to attract customers, maximize profits, and maintain competitiveness in the market.