Overview

Have you ever thought about how crucial pricing strategies are for equipment manufacturers? They’re not just numbers on a spreadsheet; they play a significant role in boosting profitability and keeping a competitive edge. Effective pricing is more than just covering production costs; it’s about really understanding market demand and what customers value.

For example, did you know that advanced pricing strategies can significantly enhance profit margins and customer satisfaction? It’s true! When manufacturers take the time to analyze their pricing approach, they often see a noticeable difference in their bottom line.

So, how can you implement these strategies? Start by considering what your customers truly want and how much they’re willing to pay. By aligning your pricing with customer expectations, you can not only increase sales but also build lasting relationships.

In conclusion, don’t underestimate the power of effective pricing. It’s a game-changer in the equipment manufacturing industry, and it’s time to take action. What steps will you take to refine your pricing strategy?

Introduction

In the world of equipment manufacturing, pricing strategies are a game changer. They can either make or break a business. With profit margins often razor-thin and market dynamics constantly shifting, manufacturers face a tricky landscape. Understanding the ins and outs of pricing can lead to significant financial rewards. So, let’s dive into the core concepts of pricing strategies. We’ll explore how effective approaches not only boost profitability but also build customer loyalty in this fast-paced marketplace.

What challenges do manufacturers encounter when trying to implement these strategies? And how can they use modern tools to stay ahead of the curve? These are crucial questions that we’ll tackle together, as we navigate this complex yet fascinating topic.

Define Pricing Strategies: Core Concepts and Importance

Let’s discuss what are pricing strategy. These are the different ways businesses understand what are pricing strategy to charge for their products or services. In the equipment manufacturing world, where profit margins can be tight and competition is intense, having a solid approach to costs is crucial for boosting profitability and keeping a competitive edge.

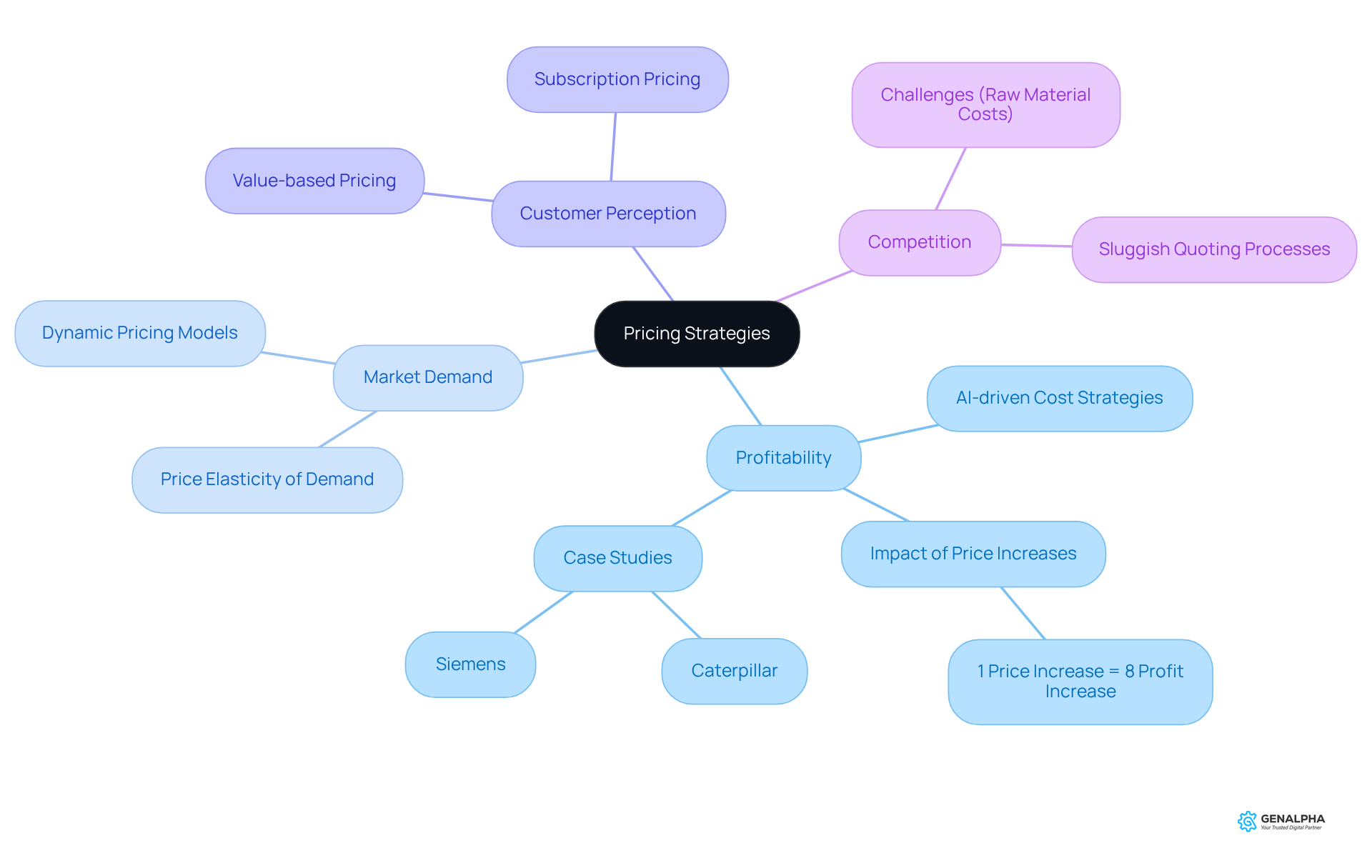

Effective setting of prices requires knowledge of what are pricing strategy, not just about covering production costs. It’s also about understanding market demand and what are pricing strategy, how customers perceive value, and where you stand against competitors. For instance, did you know that manufacturers using AI-driven cost strategies can see their gross margins improve by 100 to 300 basis points? That’s a serious boost to profits!

Here’s something to think about: a mere 1% increase in price can lead to an 8% jump in operating profit. That really shows how impactful pricing decisions can be on a company's financial health. Take a look at Caterpillar and Siemens; their case studies reveal how tailored cost strategies can enhance margin stability and keep customers coming back, even in unpredictable markets.

But it’s not all smooth sailing. Producers face 6-10 shifts in raw material costs each year, which is higher than what we’ve seen historically. This makes managing costs even trickier. Plus, relying on outdated cost assessment tools is a big headache, emphasizing the need for modern solutions.

So, understanding these key concepts is vital for manufacturers who want to navigate today’s complex marketplace and understand what are pricing strategy to achieve sustainable growth. What strategies are you considering to tackle these challenges?

Contextualize Pricing Strategies in Equipment Manufacturing

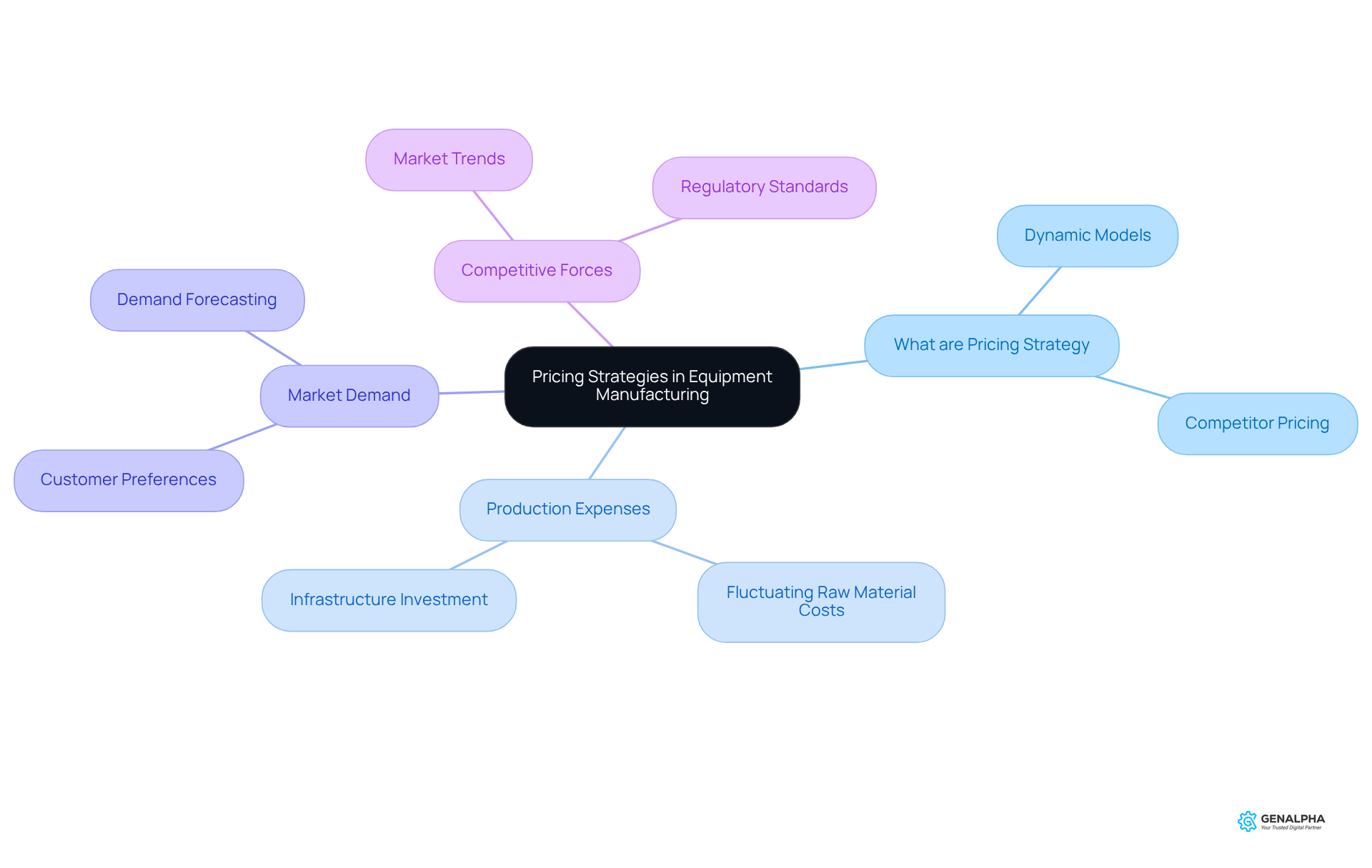

In the equipment manufacturing industry, have you ever wondered what are pricing strategy and how cost approaches really work? They are influenced by a mix of factors, including:

- What are pricing strategy

- Production expenses

- Market demand

- Competitive forces

Producers navigate a landscape filled with fluctuating raw material costs and shifting customer preferences, which means they need to understand what are pricing strategy for effectively managing their costs.

With the rise of eCommerce, things have changed dramatically. Manufacturers are now embracing more dynamic and adaptable models. For example, many companies are tapping into real-time data analysis and predictive modeling to adjust prices based on current conditions and demand forecasts. This shift is crucial, especially since equipment purchases often represent significant investments for clients. It’s essential for cost strategies to not only reflect the current market but also anticipate future trends.

Additionally, successful manufacturers are adopting advanced cost strategies to explore what are pricing strategy, such as:

- Dynamic models that allow for real-time adjustments based on demand fluctuations

- Competitor pricing

This kind of adaptability is vital for keeping profitability up and ensuring customer satisfaction in a competitive marketplace. What do you think? Are these strategies something your business could benefit from?

Explore Types of Pricing Strategies: Options for Manufacturers

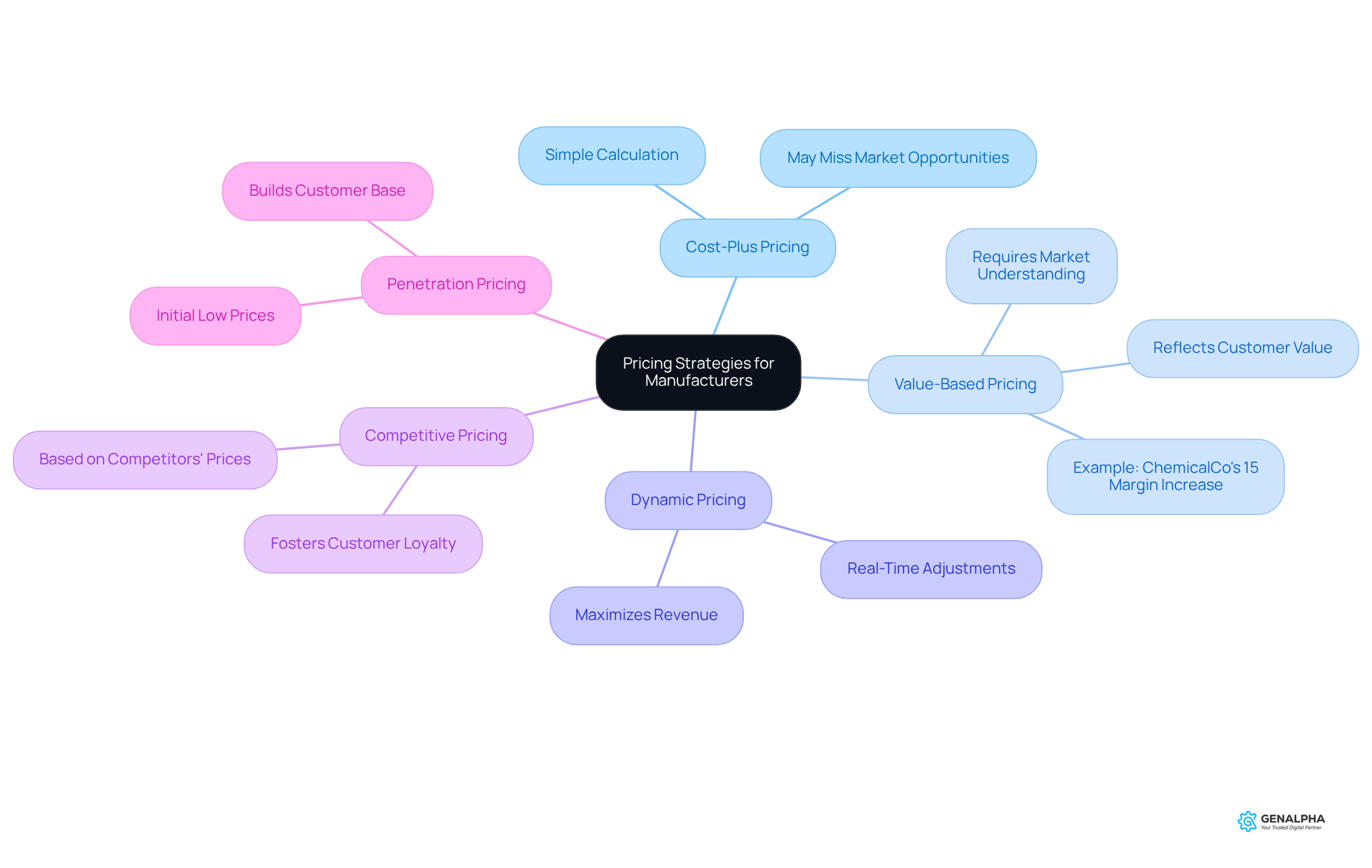

Producers have a variety of pricing strategies to choose from, each with its own perks and considerations. Let's dive into some common types:

-

Cost-Plus Pricing: This straightforward strategy involves figuring out the total cost of production and then adding a markup to ensure profitability. While it’s easy to understand, it might not always reflect the current economic landscape, which could lead to missed opportunities.

-

Value-Based Pricing: Here, prices are set based on how much value the product brings to the customer rather than just the costs involved. This approach requires a deep understanding of customer needs and market dynamics. Interestingly, companies that adopt value-based strategies often see a significant boost in net margins. For instance, ChemicalCo reported a 15% increase in net margin after shifting from cost-plus to value-based pricing.

-

Dynamic Pricing: This method allows manufacturers to adjust prices in real-time based on market fluctuations, demand changes, and competitive pressures. It's especially handy in industries where prices can swing dramatically, helping manufacturers maximize revenue and stay competitive.

-

Competitive Pricing: In this approach, producers set their prices based on what their competitors are doing. This strategy keeps them attractive in a crowded marketplace, fostering customer loyalty and helping maintain market share.

-

Penetration Pricing: This tactic involves starting with lower prices to attract customers, with plans to increase them once a solid base is established. It can be a great way to launch new products and carve out a space against established competitors.

By understanding pricing strategy models, producers can tailor their strategies to align with specific market conditions and business objectives. Regularly reviewing and adjusting these approaches is crucial to avoid missing out on opportunities and to remain competitive. Plus, integrating pricing strategies with current systems like ERP and CRM can enhance operational efficiency. As Chris Lema points out, having a solid cost structure is key for business success and future growth.

Highlight Benefits of Effective Pricing Strategies for Manufacturers

Understanding what are pricing strategy can bring a host of benefits for equipment manufacturers. Let's dive into some of these advantages together!

-

Increased Profit Margins: Optimizing pricing is a game changer for profit margins, even in those tough competitive markets. Just think about it—a slight price hike can lead to significant revenue growth! Producers in the heavy machinery sector have seen revenue rises of 5% to 10% by using advanced cost approaches. This isn’t just a fluke; OEMs in the heavy equipment industry have reported similar successes.

-

Enhanced Client Satisfaction: Have you ever thought about how well-organized cost strategies can boost client satisfaction? When prices reflect the value clients see, it can really encourage loyalty and repeat business. Customers often assess their willingness to pay based on perceived value, which includes user experience and product support options. Interestingly, 60% of consumers are ready to spend a bit more for eco-friendly products if they understand the impact, highlighting the importance of aligning costs with what consumers value.

-

Market Responsiveness: Now, let’s talk about being quick on your feet. Dynamic cost adjustments let manufacturers respond swiftly to market changes, keeping them competitive and relevant. Organizations that leverage AI-powered cost strategies have reported margin enhancements of up to 10%! This means they can make real-time adjustments based on demand and buyer behavior, showcasing the efficiency of these methods.

-

Improved Competitive Edge: Understanding and effectively applying cost strategies can really set manufacturers apart from the competition. This tactical approach is crucial, especially since 45% of manufacturing leaders stress revenue growth when adjusting cost strategies. So, how can you make your mark?

-

Improved Inventory Management: Efficient pricing can also optimize inventory levels by aligning prices with demand. This alignment reduces excess stock and associated costs, leading to better cash flow and enhanced operational efficiency.

These benefits really highlight what are pricing strategies and their vital role in the success of equipment manufacturers, driving both profitability and customer loyalty. So, what steps will you take to refine your pricing strategies?

![]()

Conclusion

Understanding pricing strategies is crucial for equipment manufacturers who want to boost profitability and stay ahead in a tough marketplace. It’s not just about crunching production costs; it’s about really getting to grips with market demand, how customers see your products, and where you stand against the competition. As we've discussed, the right pricing approach can lead to impressive profit margins and happier clients, making it a key area to focus on.

So, what do we learn from our discussion? Manufacturers have a range of pricing strategies to choose from—think cost-plus, value-based, dynamic, competitive, and penetration pricing. Each one has its perks and requires careful thought about market conditions and business goals. Plus, leveraging advanced tools and real-time data analysis is becoming more vital. This allows manufacturers to react swiftly to demand changes and fine-tune their pricing for the best results.

In closing, we can’t underestimate how important effective pricing strategies are in the equipment manufacturing sector. By embracing innovative pricing models and regularly reviewing their tactics, manufacturers can tap into new revenue streams, strengthen customer loyalty, and improve their market position. The time to refine pricing strategies is now—what steps will you take to ensure sustainable growth and profitability in this competitive landscape?

Frequently Asked Questions

What is a pricing strategy?

A pricing strategy refers to the various methods businesses use to determine how much to charge for their products or services, taking into account production costs, market demand, customer perceptions of value, and competitive positioning.

Why is pricing strategy important for equipment manufacturers?

Pricing strategy is crucial for equipment manufacturers because profit margins can be tight and competition is intense. A solid pricing approach helps boost profitability and maintain a competitive edge in the market.

How can artificial intelligence (AI) impact pricing strategies?

Manufacturers that utilize AI-driven cost strategies can experience significant improvements in their gross margins, with reported increases of 100 to 300 basis points, enhancing overall profitability.

What effect does a small increase in price have on operating profit?

A mere 1% increase in price can lead to an 8% increase in operating profit, highlighting the significant impact that pricing decisions can have on a company's financial health.

Can you provide examples of companies that have successfully implemented tailored cost strategies?

Companies like Caterpillar and Siemens have demonstrated how tailored cost strategies can enhance margin stability and retain customers, even in unpredictable market conditions.

What challenges do producers face regarding raw material costs?

Producers face 6-10 shifts in raw material costs each year, which complicates cost management and requires businesses to adapt their pricing strategies accordingly.

What is the risk of relying on outdated cost assessment tools?

Relying on outdated cost assessment tools can create significant challenges for businesses, emphasizing the need for modern solutions to effectively manage pricing strategies in a complex marketplace.

Why is it essential for manufacturers to understand pricing strategies in today's market?

Understanding pricing strategies is vital for manufacturers to navigate the complexities of today's marketplace and achieve sustainable growth, allowing them to respond effectively to market changes and customer needs.