Overview

Have you ever wondered how ERP system integrators play a crucial role in manufacturing? They’re like the unsung heroes connecting various software and hardware systems to optimize operations and enhance efficiency. It’s fascinating to see how these integrators facilitate real-time data processing, streamline workflows across departments, and provide customized solutions that can lead to increased productivity and significant cost savings for manufacturers.

Think about it: with the right integration, manufacturers can not only improve their processes but also adapt quickly to changing demands. By leveraging these systems, companies can respond to challenges more effectively and maintain a competitive edge. So, if you’re in the manufacturing sector, it might be time to consider how an ERP integrator could transform your operations.

In short, the role of ERP system integrators is pivotal. They don’t just connect systems; they create a smoother, more efficient workflow that benefits everyone involved. What do you think? Could your operations use a little boost from these integrators?

Introduction

In the bustling world of manufacturing, technology plays a pivotal role, and at the heart of it all is the ERP system integrator. These pros are more than just tech whizzes; they're the masterminds behind smooth operational workflows, making sure that various software and hardware systems work together like a well-oiled machine.

Have you ever wondered how these integrators really boost efficiency, optimize resources, and pave the way for business success? As the manufacturing landscape continues to evolve, it's worth asking: how can organizations tap into the expertise of these integrators to not just keep up, but truly excel in a competitive market?

Let's dive in and explore!

Define ERP System Integrator

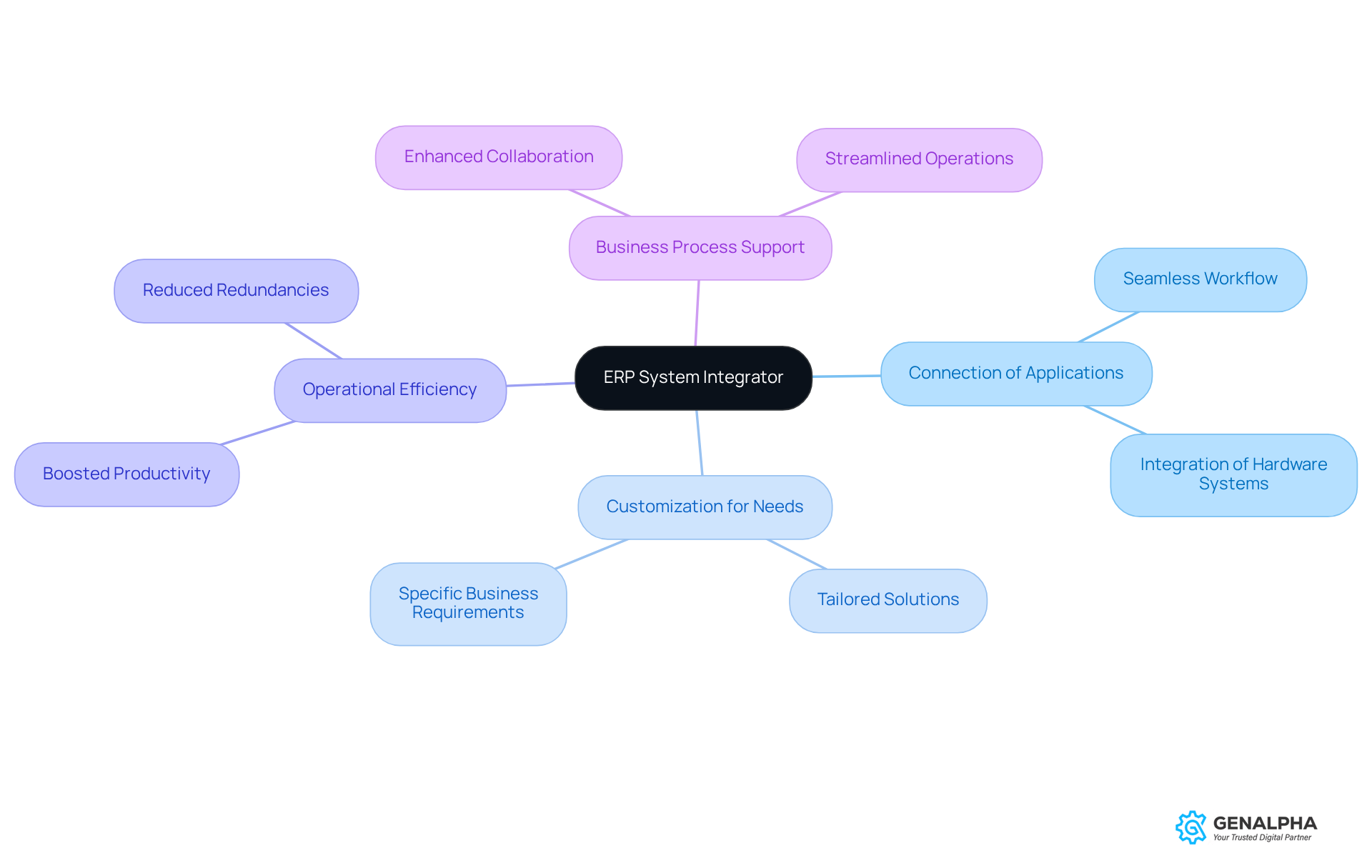

Have you ever wondered how different software applications and hardware systems within a company come together to create a seamless workflow? That’s where an ERP system integrator comes into play! This specialized professional or team is all about connecting various applications and hardware frameworks in an organization, making sure everything works efficiently and cohesively.

But it’s not just about the technical side of things. Integrators ensure that these platforms don’t just exist side by side; they work in harmony to support your business processes. Imagine the ease of having customized solutions tailored specifically to your organization’s needs. This customization facilitates smoother data flow and boosts operational efficiency across departments.

So, if you’re looking to streamline your operations and enhance collaboration within your team, consider the pivotal role of an ERP integrator. They’re here to make your life easier and your business more efficient!

Contextualize the Role in Manufacturing

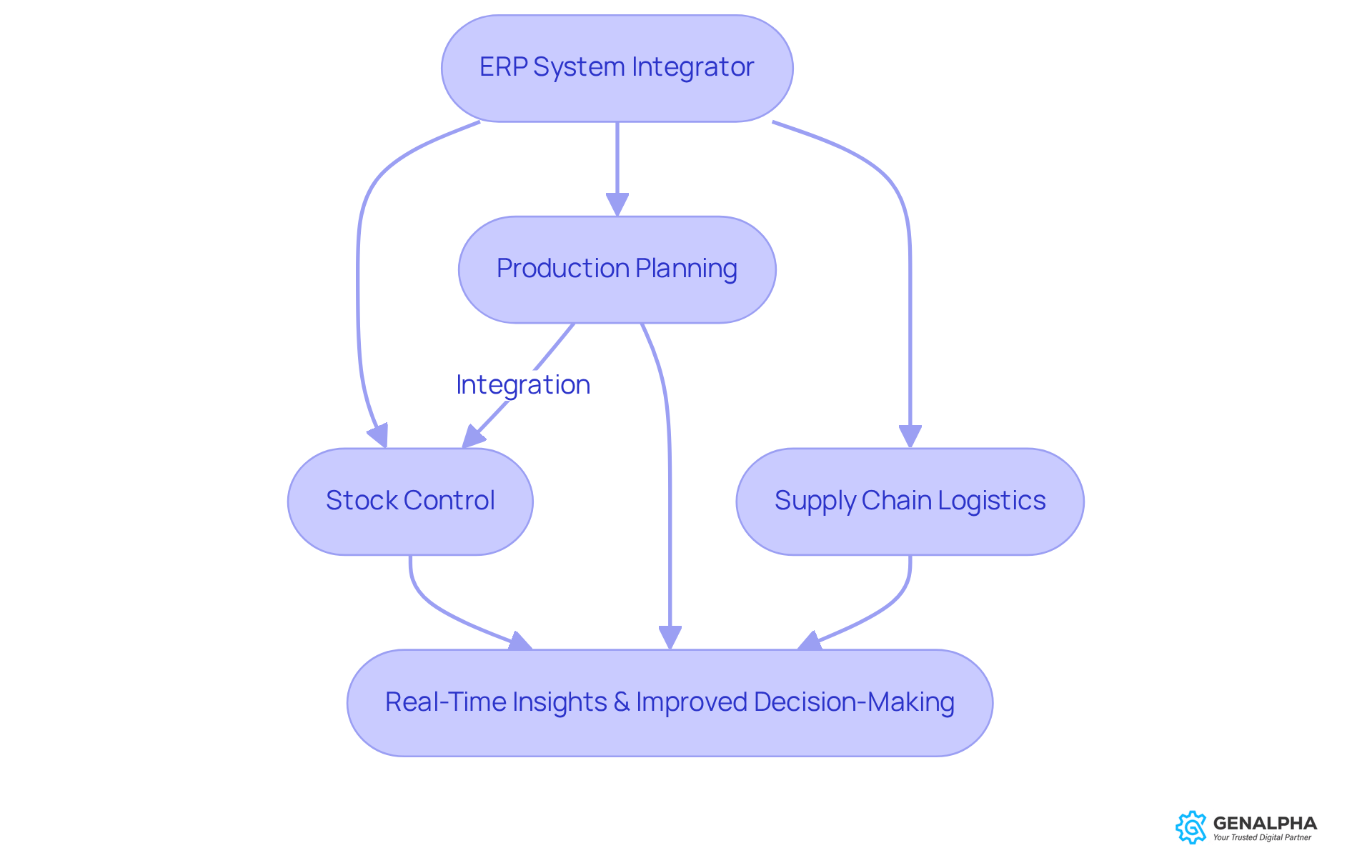

In the manufacturing world, have you ever wondered how ERP system integrators can really make a difference? They serve as an ERP system integrator, playing a vital role in optimizing operations by connecting various platforms like stock control, production planning, and supply chain logistics. By bringing these frameworks together, manufacturers gain real-time insights into their operations. This not only helps in making better decisions but also in responding quickly to market demands.

For instance, imagine an integrator linking a production planning tool with stock control software. This setup allows for automatic updates on stock levels and production timelines. As a result, delays are reduced, and resource allocation is enhanced. Isn’t it fascinating how such integrations can streamline processes and boost efficiency? It’s a game-changer for manufacturers looking to stay ahead!

Trace the Evolution of ERP Systems

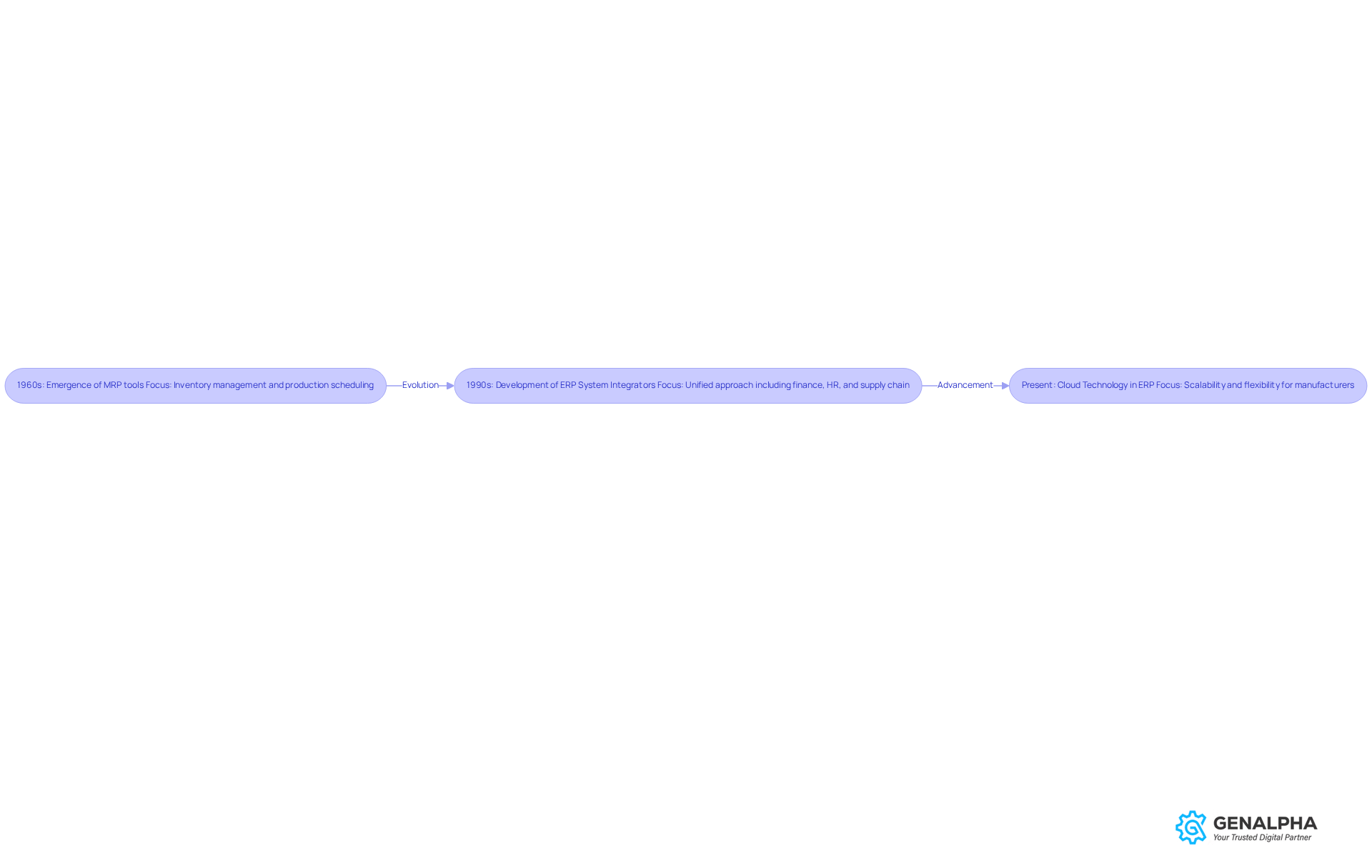

Did you know that the roots of ERP solutions go all the way back to the 1960s? That's when Material Requirements Planning (MRP) tools first emerged, focusing mainly on inventory management and production scheduling. As businesses grew more complex, it became clear that a unified approach was needed. This realization led to the development of an ERP system integrator in the 1990s, which expanded to include a variety of business functions like finance, human resources, and supply chain management.

Fast forward to today, and we see contemporary solutions from ERP system integrators leveraging cloud technology. This shift brings scalability and flexibility, allowing manufacturers to adapt quickly to changing market conditions and operational needs. Isn’t it fascinating how far we’ve come? The evolution of ERP is a testament to the ever-changing landscape of business, and it invites us to think about how we can embrace these advancements. What do you think about the future of ERP solutions in your industry?

Identify Key Characteristics and Functions

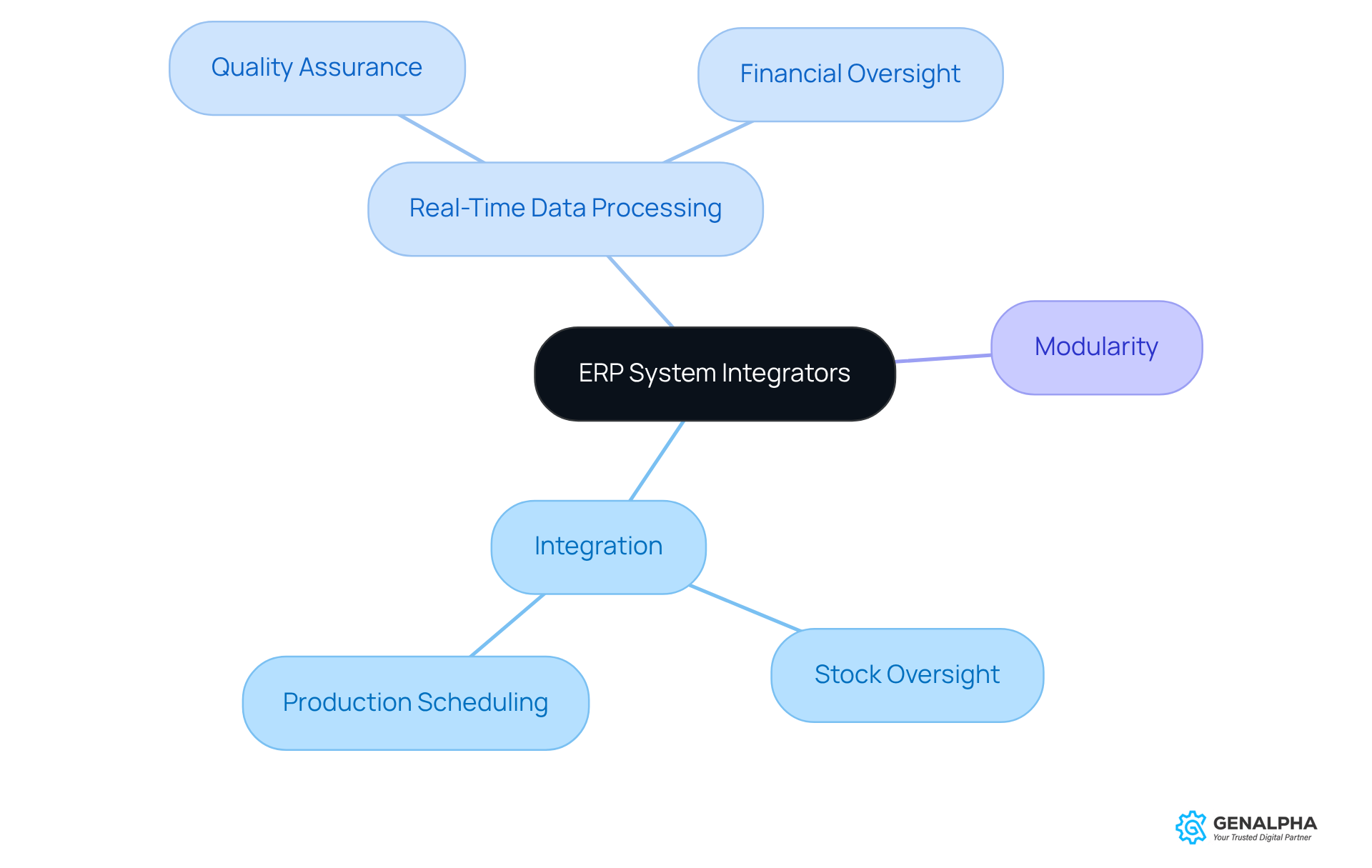

When you think about an ERP system integrator, what solutions come to mind? Key characteristics such as integration, real-time data processing, and modularity are essential for an ERP system integrator. An ERP system integrator allows different business functions to communicate seamlessly, making everything flow more smoothly. Real-time data processing? That’s what keeps decision-makers in the loop with the most current info at their fingertips. And let’s not forget about modularity—this feature allows manufacturers to customize their solutions through an ERP system integrator by adding or removing functionalities as needed.

Now, let’s dive into what an ERP system integrator actually does in manufacturing. They help with:

- Stock oversight

- Production scheduling

- Quality assurance

- Financial oversight

These roles not only enhance operational efficiency but also help lower expenses. Isn’t that something every manufacturer wants? So, how can you leverage these benefits in your own operations? It’s all about finding the right fit for your needs and making the most of these powerful tools.

Highlight Benefits for Manufacturing Businesses

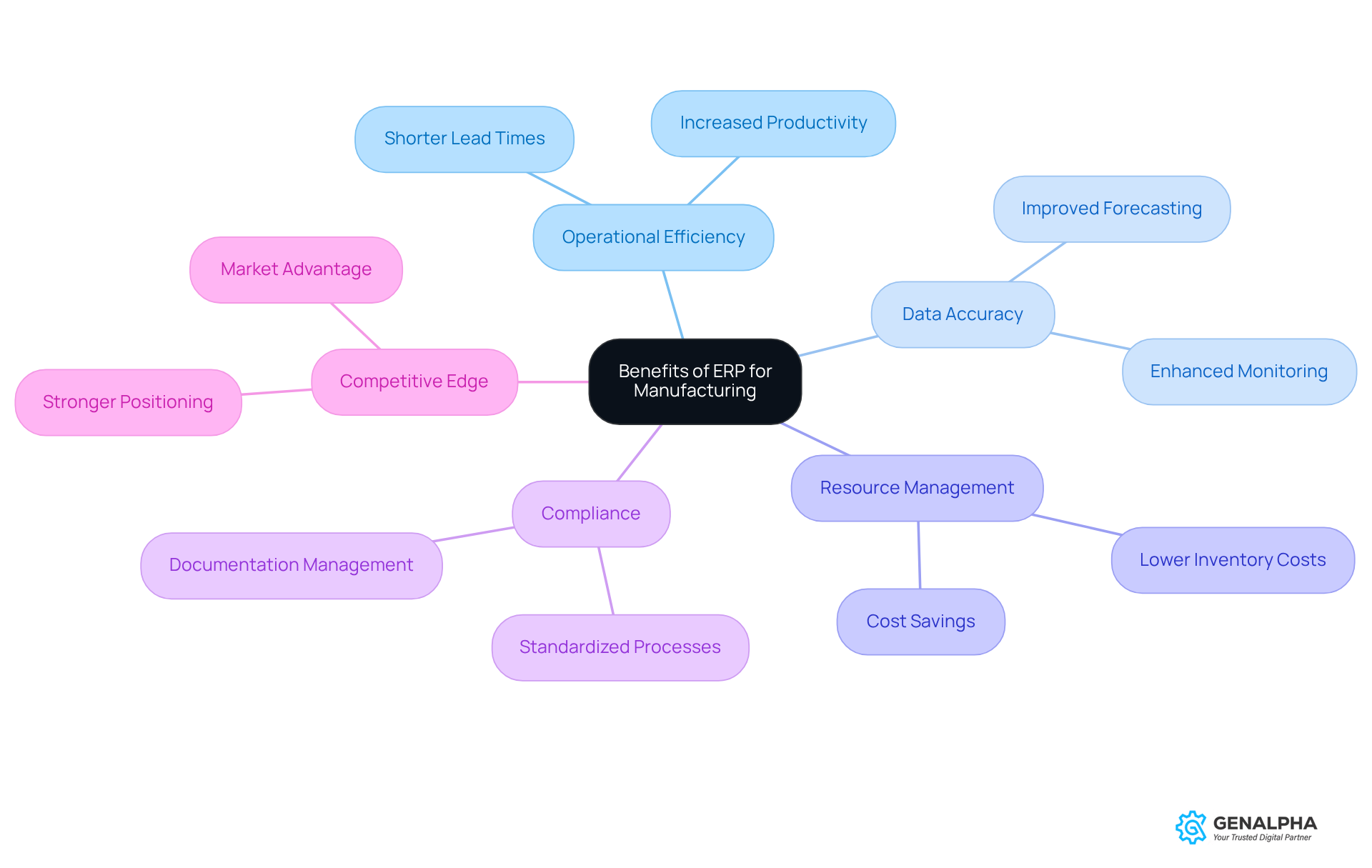

Have you ever considered how an ERP solution could transform your manufacturing business? Implementing one can bring a host of benefits, like boosting operational efficiency, improving data accuracy, and managing resources more effectively.

For example, manufacturers who embrace ERP solutions often see:

- Shorter lead times

- Lower inventory costs

This happens thanks to better forecasting and enhanced inventory monitoring capabilities. Additionally, ERP systems help you stay compliant with industry regulations by providing standardized processes and documentation.

So, what does this all mean for you? Well, an ERP system integrator can lead to:

- Increased productivity

- Significant cost savings

- A stronger competitive edge in the market

Isn’t it time to explore how ERP can work for you?

Conclusion

When we think about the role of an ERP system integrator in manufacturing, it’s hard to overstate how crucial it is for boosting operational efficiency. These integrators are the unsung heroes that make sure various software applications and hardware systems work together seamlessly. By connecting different platforms, they not only streamline processes but also create customized solutions that meet the unique needs of each manufacturing business. This integration is essential for fostering collaboration and enhancing overall productivity.

Throughout this article, we've explored some key insights, including how ERP systems have evolved from basic inventory management tools to the sophisticated, cloud-based solutions we see today. We’ve highlighted the significance of real-time data processing, modularity, and the specific roles of ERP system integrators—think stock oversight, production scheduling, and financial management. Each of these elements plays a vital role in cutting costs and improving decision-making capabilities within manufacturing operations.

So, what does all this mean for you? Embracing ERP system integration isn’t just about upgrading your technology; it’s a strategic move that can lead to significant competitive advantages. Manufacturers should really consider how these systems can transform their operations, enhance resource management, and ultimately drive success in today’s complex market. Investing in a solid ERP system integrator could be the key to unlocking a more efficient and responsive manufacturing process. Are you ready to take that step?

Frequently Asked Questions

What is an ERP system integrator?

An ERP system integrator is a professional or team that connects various software applications and hardware systems within an organization to create a seamless workflow, ensuring that all components work efficiently and cohesively.

How do ERP system integrators enhance business processes?

They ensure that different platforms work in harmony to support business processes, providing customized solutions tailored to the organization's needs, which facilitates smoother data flow and boosts operational efficiency across departments.

What role do ERP system integrators play in manufacturing?

In manufacturing, ERP system integrators optimize operations by connecting platforms such as stock control, production planning, and supply chain logistics, allowing manufacturers to gain real-time insights into their operations.

How do ERP system integrators improve decision-making in manufacturing?

By linking various tools, such as production planning and stock control software, integrators enable automatic updates on stock levels and production timelines, which helps manufacturers make better decisions and respond quickly to market demands.

What are the benefits of integrating ERP systems in manufacturing?

The integration of ERP systems in manufacturing reduces delays, enhances resource allocation, and streamlines processes, ultimately boosting efficiency and helping manufacturers stay competitive.