Introduction

Understanding product data management solutions is crucial for manufacturers looking to thrive in today’s competitive landscape. Think of these systems as the backbone of product information management - they help organizations streamline operations, boost collaboration, and cut down on errors. But as the industry keeps evolving, how can manufacturers really make the most of these solutions? How can they not just keep up, but actually gain a competitive edge?

Exploring the potential of product data management could open up exciting new pathways for innovation and efficiency in manufacturing processes. Imagine being able to enhance your operations while staying ahead of the curve! So, let’s dive into how these solutions can transform your approach and drive success.

Define Product Data Management Solutions

Have you ever wondered how companies keep track of all the details about their products? That’s where the product data management solution plays a crucial role! These handy software systems act as a product data management solution, designed to manage and control product-related information throughout its lifecycle. They help organize, store, and share everything from design to development and manufacturing.

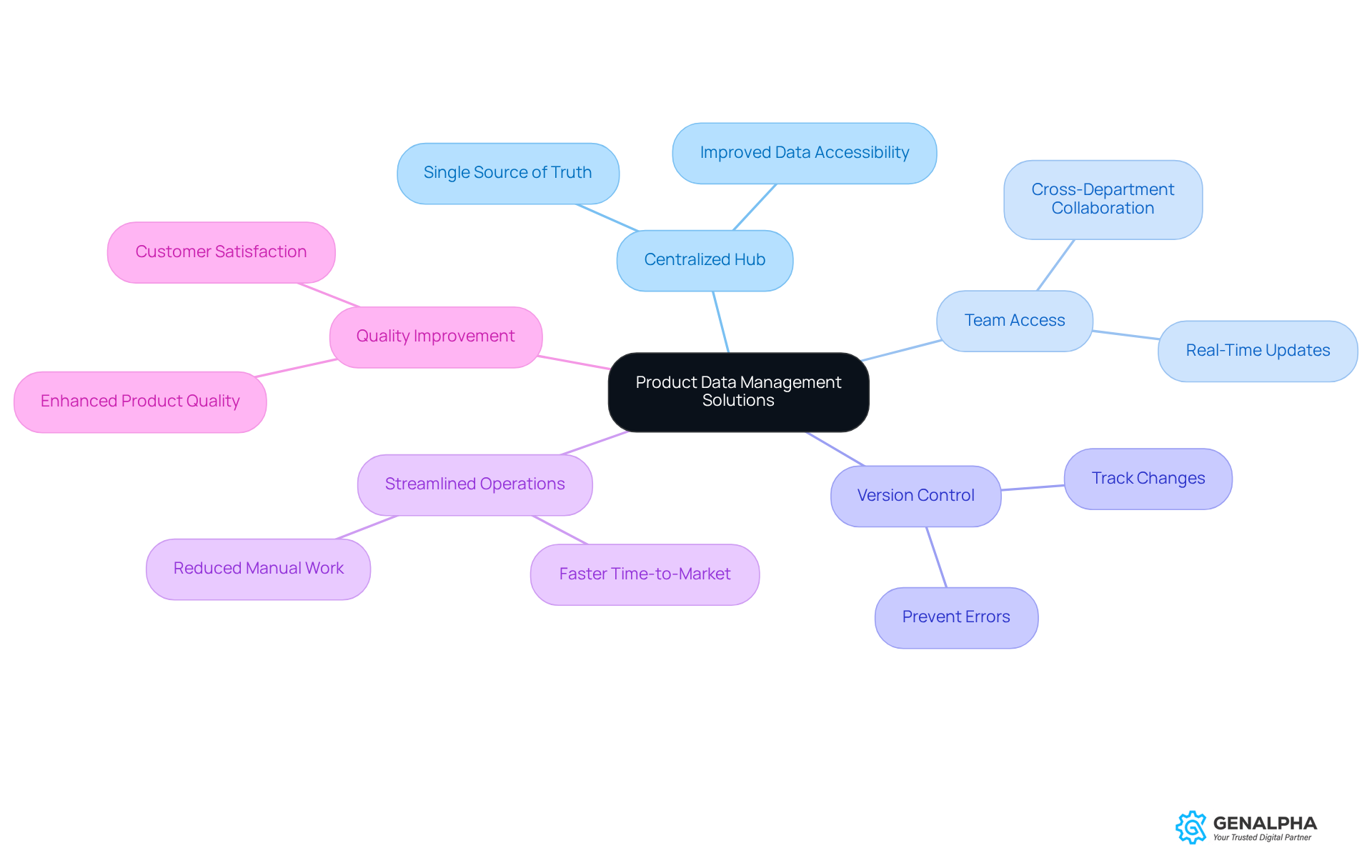

Consider a product data management solution as a centralized hub for all product information. This means that teams from different departments can easily access accurate and up-to-date details. By promoting teamwork and managing version control, PIM systems help manufacturers streamline their operations and reduce errors. This not only boosts quality but also speeds up time-to-market.

So, if you’re in the manufacturing game, why not consider implementing a PIM system? It could be the key to optimizing your processes and enhancing collaboration across your teams!

Explain the Importance of PDM for Manufacturers

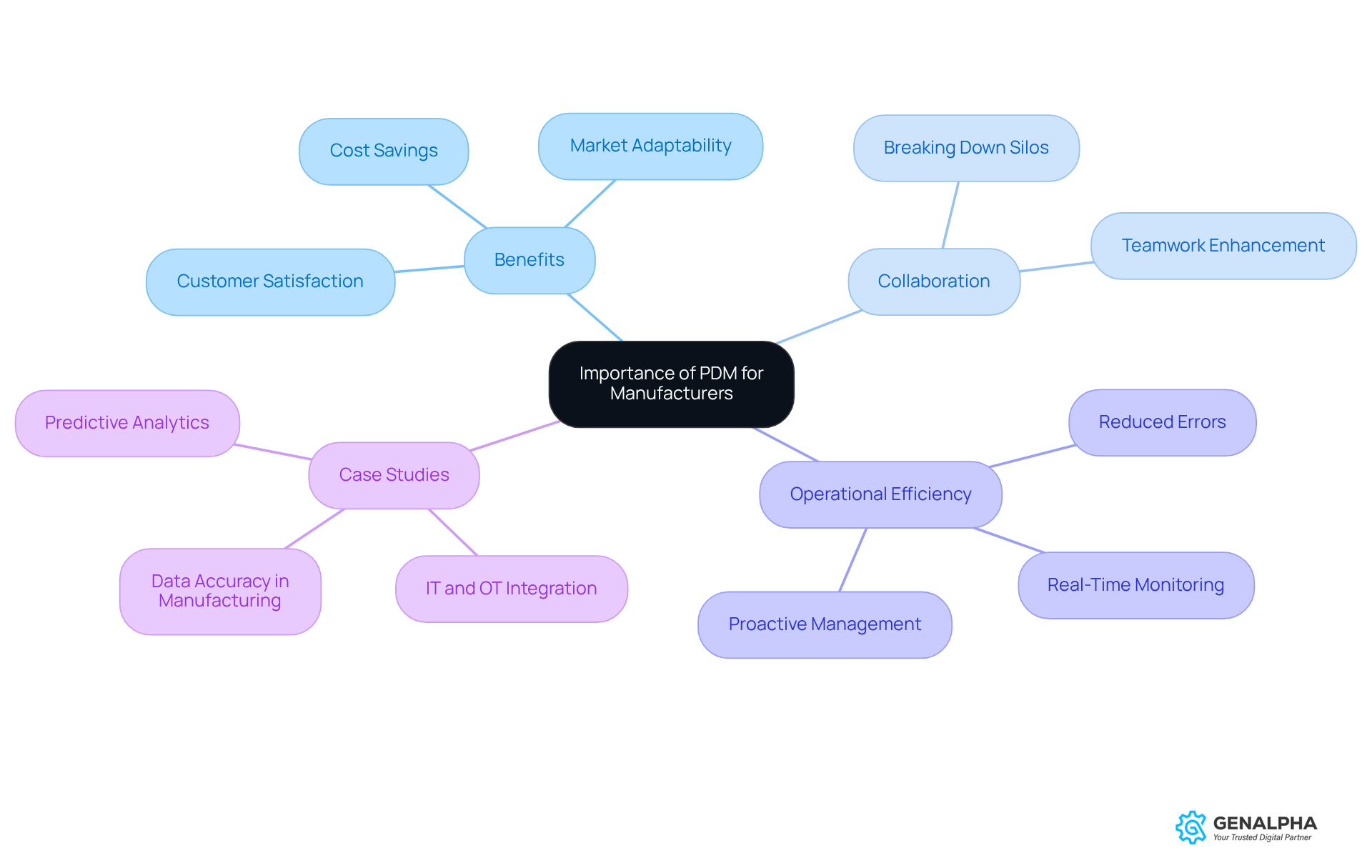

Have you ever thought about how crucial a product data management solution is for manufacturers today? In a world where competition is fierce, having precise, easily accessible, and well-organized information can make all the difference. A product data management solution creates a solid source of truth for item information, which helps break down those pesky silos and encourages teamwork. This kind of integration allows manufacturers to quickly adapt to market changes, speed up development cycles, and boost customer satisfaction.

As Henry Ford once said, "Quality means doing it right when no one is looking." This really drives home the importance of precision in managing product information. Plus, when companies implement efficient PDM practices, they often see significant cost savings by reducing errors and cutting down on management time. For instance, businesses that focus on accurate information have reported better operational efficiency and responsiveness. This clearly shows the tangible benefits of a robust product data management solution in driving innovation and maintaining a competitive edge.

A case study highlighting the importance of precise information in manufacturing reveals that having accurate data allows for real-time monitoring and decision-making. This proactive approach helps identify issues before they escalate, leading to improved collaboration and innovation. So, how can your organization leverage PDM to enhance its operations? Let's explore the possibilities together!

Outline Key Features and Benefits of PDM Solutions

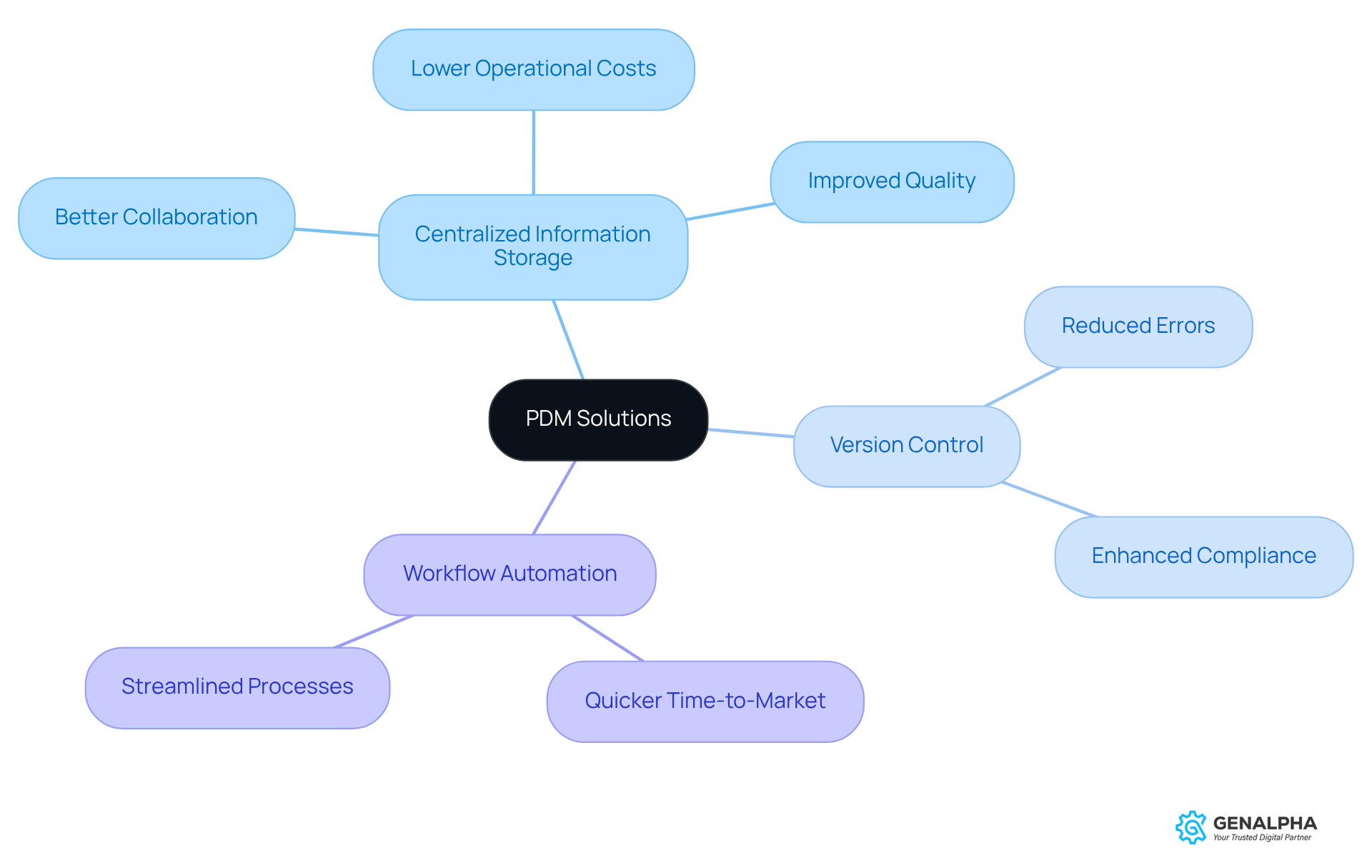

Have you ever felt overwhelmed by managing product information? Well, that’s where the product data management solution, or PIM systems, come into play! These systems are all about making life easier with key features like centralized information storage, version control, and workflow automation.

Imagine having all your product-related info in one place - sounds great, right? Centralized data storage means everything is easily accessible, so you’re never scrambling to find the latest details. Plus, with version control, your team can rest easy knowing they’re always working with the most current data, which cuts down on errors. And let’s not forget workflow automation! It streamlines processes like approvals and change management, making everything run smoother and faster.

So, what’s in it for you? Implementing a product data management solution can lead to better collaboration among teams, quicker time-to-market, improved quality, and even lower operational costs. Who wouldn’t want that? By integrating these systems, organizations can also ensure they’re compliant with industry standards and regulations, which helps solidify their position in the market.

Ready to take the plunge? Embracing PIM could be the game-changer your organization needs!

Provide Real-World Examples of PDM Applications

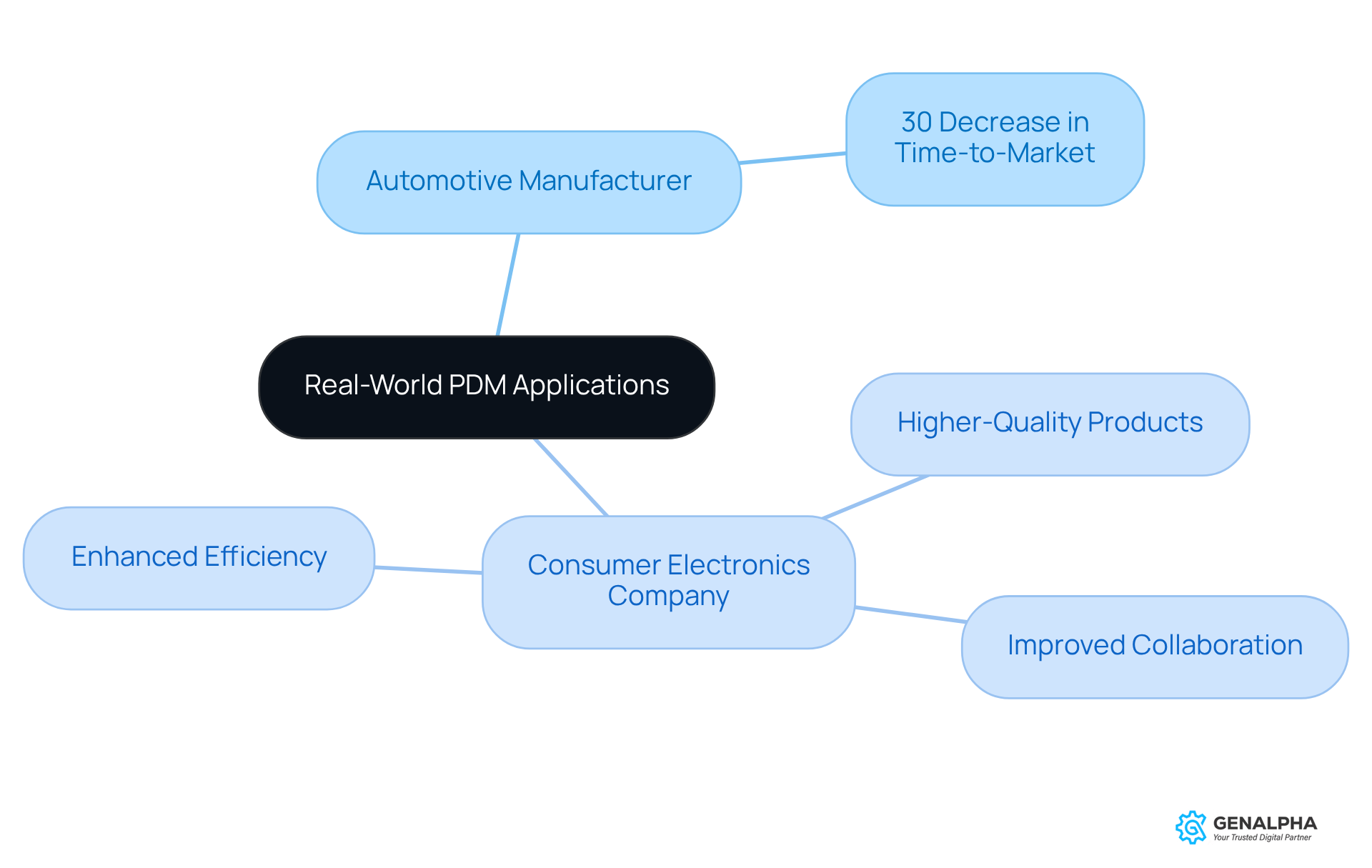

Have you ever wondered how a product data management solution really makes a difference in manufacturing? Let’s take a look at some real-world examples that show just how impactful these systems can be.

For instance, a well-known automotive manufacturer decided to adopt a PDM system to manage its complex information. The result? A remarkable 30% decrease in time-to-market for new vehicle models! That’s a game changer, right?

Another great example comes from a consumer electronics company that used PDM to streamline its design processes. This move not only improved collaboration between their engineering and marketing teams but also made their overall operations smoother. By centralizing product data, these companies enhanced their efficiency, reduced errors, and ultimately delivered higher-quality products to their customers.

These stories really highlight the powerful impact that effective product data management solutions can have on manufacturing operations. So, if you’re in the industry, isn’t it time to consider how PDM could benefit your organization?

Conclusion

In conclusion, embracing product data management solutions isn’t just a choice; it’s a strategic necessity for manufacturers who want to thrive in today’s fast-paced market. Think about it: how can these systems transform your operations, boost teamwork, and ultimately help you deliver superior products to your customers? As the manufacturing landscape keeps evolving, leveraging PDM effectively will be key to maintaining a competitive edge and fostering innovation.

So, why wait? Let’s explore how adopting PDM solutions can break down silos within your organization, facilitate real-time decision-making, and drive those all-important cost savings. For example, industries like automotive and consumer electronics have seen tangible benefits from these systems, leading to faster development cycles and improved operational efficiency.

With features like centralized storage, version control, and workflow automation, PDM solutions are designed to enhance collaboration and compliance. It’s time to consider how these tools can elevate your business and set you up for success in a competitive landscape. Are you ready to take the leap?

Frequently Asked Questions

What is a product data management solution?

A product data management solution is a software system designed to manage and control product-related information throughout its lifecycle, helping to organize, store, and share details from design to development and manufacturing.

How does a product data management solution benefit companies?

It acts as a centralized hub for product information, allowing teams from different departments to access accurate and up-to-date details, promoting teamwork, managing version control, streamlining operations, reducing errors, boosting quality, and speeding up time-to-market.

Who should consider implementing a product data management solution?

Companies in the manufacturing sector should consider implementing a product data management solution to optimize their processes and enhance collaboration across their teams.