Overview

Have you ever thought about how product configurators can transform the way equipment manufacturers operate? These tools offer some fantastic benefits that can really boost customer satisfaction. Imagine being able to create personalized solutions that cater specifically to your needs! Not only do they reduce errors, but they also enhance operational efficiency.

Let’s dive into what makes these configurators so special. They:

- Streamline the configuration process

- Allow for real-time visualization and pricing

- Seamlessly integrate with existing systems

This means that manufacturers can enjoy higher productivity and profitability, which is crucial in today’s competitive market.

So, if you’re looking to elevate your business, consider how implementing a product configurator could be the game-changer you need. Why not explore this option and see how it can work for you?

Introduction

Have you noticed how customization is changing the game in manufacturing? It’s reshaping how equipment producers connect with their clients. At the heart of this shift are product configurators, which empower manufacturers to tailor products to fit specific customer needs while making operations smoother. As more people seek personalized solutions, a big question pops up: how can these amazing tools not only boost customer satisfaction but also drive efficiency and profitability in such a competitive market? By diving into the key benefits of product configurators, we can see their potential to transform the manufacturing process and elevate the customer experience. So, let’s explore this exciting journey together!

Define Product Configurator: An Overview

Have you ever wanted something that’s just perfect for you? That’s where a configurator comes in! It’s a cool product configurator that allows you to customize items exactly how you like them. Imagine being able to pick the dimensions, colors, and features of a product to match your unique needs. This is super important in manufacturing, where customization is often key to meeting specific application requirements.

Using predefined rules and logic, these item customizers help ensure that your configurations stick to the manufacturer's specifications. This means fewer errors and happier customers! As we look ahead to 2025, the trend of utilizing product configurators in manufacturing is really taking off. It’s all driven by a growing demand for tailored solutions and the need for operational efficiency.

Did you know that the product configurator software market is projected to reach USD 3.5 billion by 2033? That’s a huge indicator of how important these tools are becoming! Plus, with advancements in technologies like AI and cloud computing, configurator software is getting even better at meeting user needs.

Take a look at companies like Nike and BMW—they’ve jumped on the customization bandwagon, allowing customers to personalize their choices. This shift towards personalization is definitely making waves in the industry. So, what are you waiting for? Dive into the world of configurators and see how they can work for you!

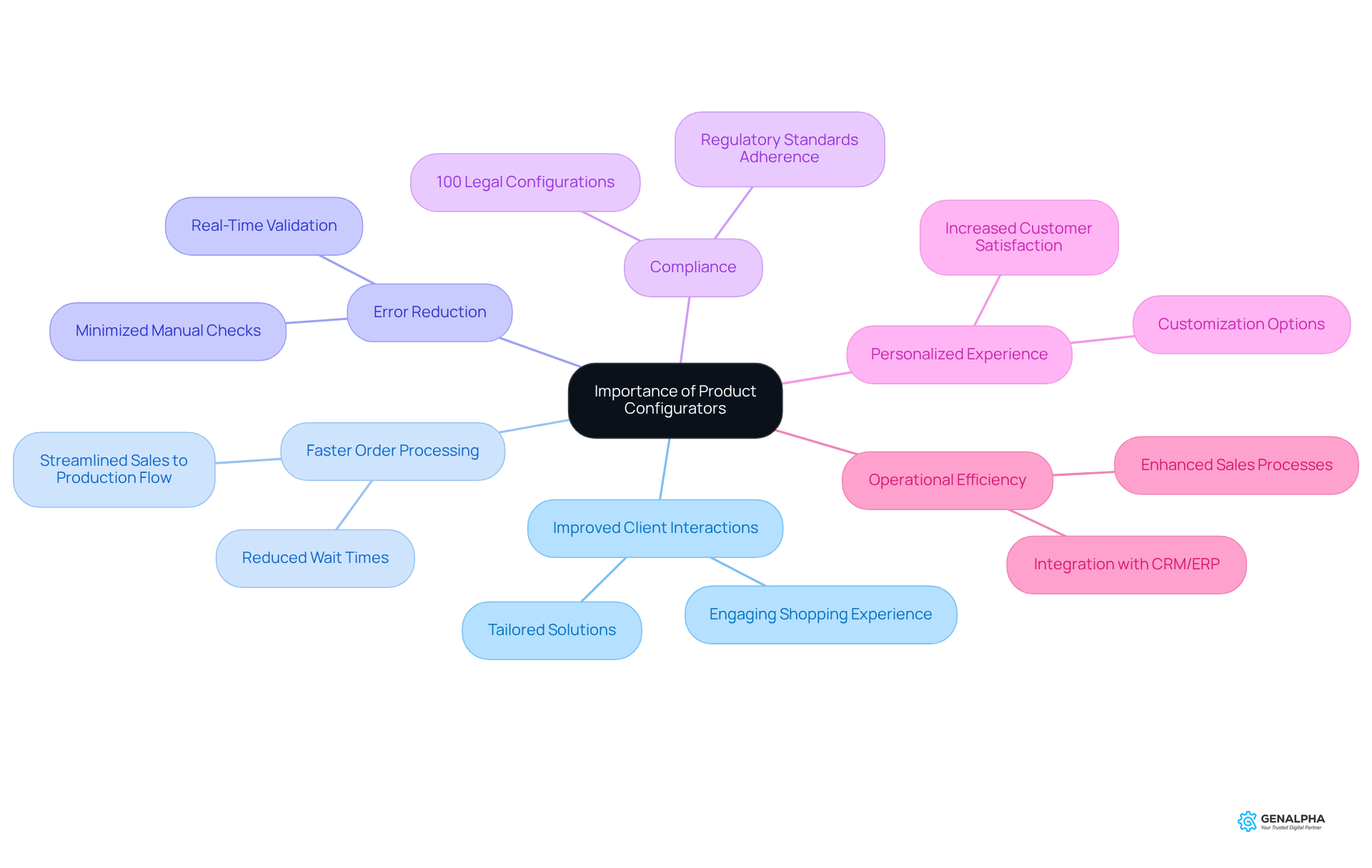

Importance of Product Configurators for Equipment Manufacturers

Have you ever thought about how a product configurator can transform the way we purchase equipment? These tools are game-changers for producers, making client interactions smoother and sales processes a breeze. By letting clients visualize and personalize products in real-time, we create an engaging shopping experience that meets today’s expectations.

This not only strengthens client connections but also speeds up order processing and cuts down on errors—something that’s super important in an industry where precision matters. For instance, when producers use a product configurator, they can ensure that all configurations are compliant. This means we can say goodbye to those costly and time-consuming verifications that engineers usually handle.

Plus, offering customized solutions helps producers maintain a competitive edge. When clients feel like they’re getting a tailored experience, it leads to higher satisfaction and loyalty. As Daniel Joseph Barry, VP of Product Marketing at Configit, puts it, 'With this level of configuration technology, the product configurator will generate 100% legal items, making the process much smoother and safer for both the client and producer.'

And it doesn’t stop there! When item customizers integrate with existing systems like CRM, ERP, or CPQ, operational efficiency gets a serious boost. This means smooth data transfer and enhanced sales processes. Just look at the success stories with tools like WPConfigurator, where producers have not only met but exceeded client expectations. This ultimately leads to improved operational performance and profitability. So, how can you leverage these customizers in your own business to enhance your sales efficiency?

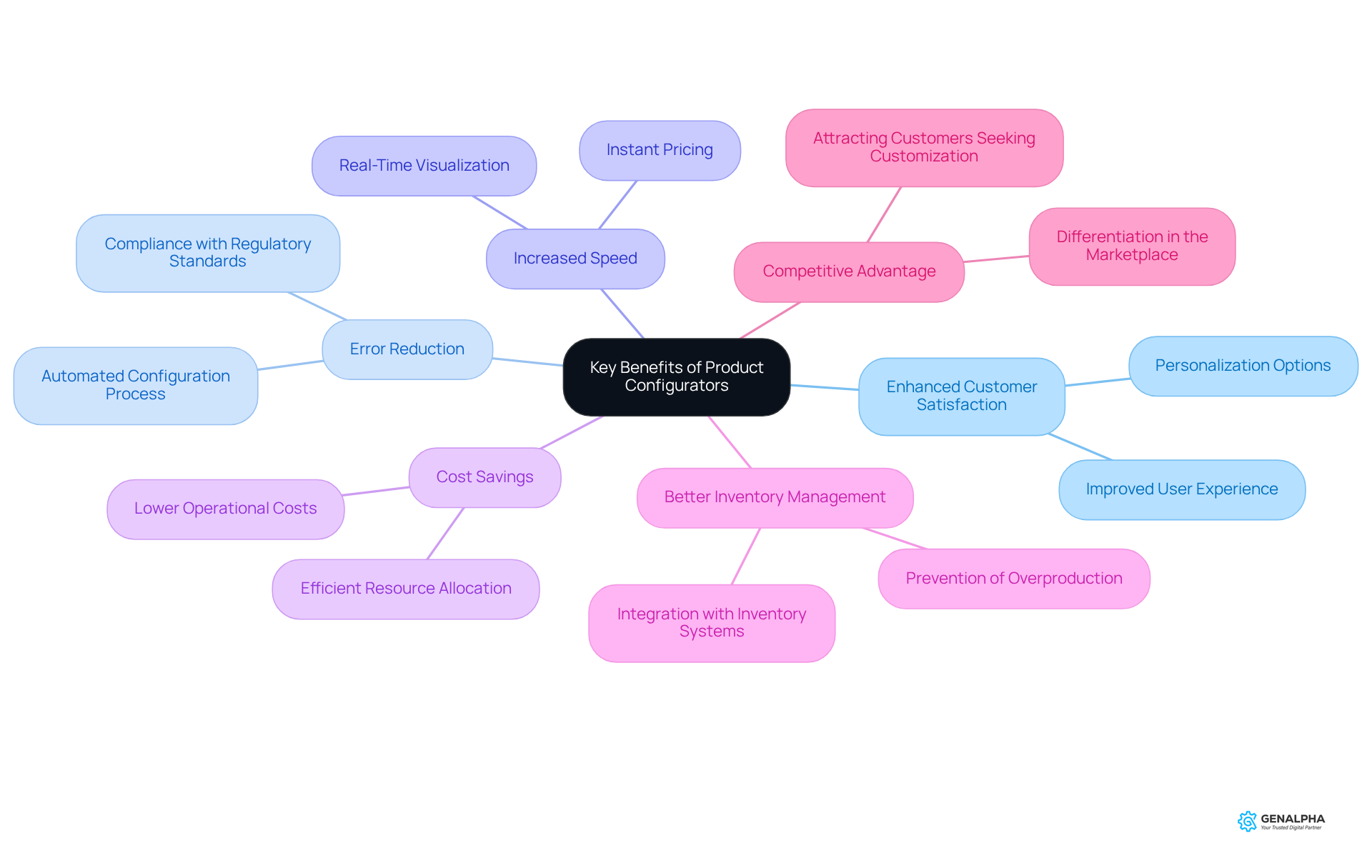

Key Benefits of Product Configurators for Equipment Manufacturers

Let’s discuss the key benefits of using a product configurator for equipment manufacturers. Have you ever wished for a product that fits your exact needs? Well, that’s the magic of configurators! They allow customers to create items that align perfectly with their specifications, leading to happier customers and fewer returns. Personalization is essential in today’s market, where tailored solutions are in high demand.

Next up, let’s consider errors. Nobody likes mistakes, right? By using a product configurator to automate the configuration process and reduce manual input, product designers can significantly cut down on order errors. This not only makes production smoother but also ensures compliance with regulatory standards, so all configurations meet the necessary requirements.

Now, how about speeding things up? With real-time visualization and instant pricing, these tools really kick the sales cycle into high gear. Quicker decision-making and order fulfillment are crucial in our fast-paced manufacturing world.

And who doesn’t want to save money? Streamlining design and ordering methods through custom tools leads to lower operational costs. By minimizing production mistakes and delays, manufacturers can allocate resources more efficiently, boosting profitability.

Let’s not forget about inventory. Integrating customization tools with inventory systems gives producers a clear view of stock levels, which helps manage resources better. This integration prevents overproduction and stockouts, optimizing inventory control overall.

In a crowded marketplace, standing out is vital. Offering a product configurator can set producers apart. Customers are increasingly looking for customization and flexibility in their buying decisions, and a product configurator can attract those seeking personalized solutions.

In summary, adopting customization tools not only enhances customer satisfaction but also drives operational efficiencies. They’re essential for equipment makers aiming to thrive in a competitive landscape. Did you know the configurator market is projected to reach $8.2 billion by 2032? That’s a clear sign of their growing importance in manufacturing. For instance, the use of 3D item customizers in retail has significantly boosted sales by enabling real-time personalization and providing clear visuals. As Ksenia Vasileva, Marketing Manager, puts it, "3D modular tools can revolutionize your sales results with real-time customization, clear visuals, and streamlined operations." This really highlights how the use of a product configurator can enhance both customer satisfaction and operational efficiency.

Conclusion

Exploring product configurators really opens up a world of possibilities for equipment manufacturers. They’re not just tools; they’re game-changers that help create personalized solutions tailored to what customers actually need. Imagine how much smoother the customization experience becomes! Plus, they streamline manufacturing processes, which can lead to happier customers and increased loyalty.

Throughout this article, we've seen how product configurators can significantly cut down on errors, speed up sales cycles, and make inventory management a breeze. When manufacturers integrate these systems into their existing operations, they can save money and boost efficiency. This is crucial for standing out in such a competitive market. And let’s not forget, the configurator market is projected to grow, highlighting just how relevant these tools are becoming. It’s clear that manufacturers need to jump on board with this technology.

But embracing product configurators isn’t just a passing trend; it’s a smart strategy that can reshape how companies engage with customers and achieve operational success. As the demand for tailored solutions grows, manufacturers must use these tools to keep up, enhance their offerings, and ultimately drive profitability. The future of manufacturing is all about customization, and product configurators are the key to unlocking that potential. So, are you ready to take the leap and transform your approach?

Frequently Asked Questions

What is a product configurator?

A product configurator is a tool that allows customers to customize items according to their preferences, such as dimensions, colors, and features, to meet their unique needs.

Why are product configurators important in manufacturing?

Product configurators are important in manufacturing because they help ensure that customizations adhere to the manufacturer's specifications, resulting in fewer errors and increased customer satisfaction.

What is the projected market value of product configurator software by 2033?

The product configurator software market is projected to reach USD 3.5 billion by 2033.

What factors are driving the trend of product configurators in manufacturing?

The trend is driven by a growing demand for tailored solutions and the need for operational efficiency in manufacturing processes.

How are advancements in technology impacting product configurators?

Advancements in technologies like AI and cloud computing are improving the capabilities of configurator software, making it better at meeting user needs.

Can you provide examples of companies using product configurators?

Companies like Nike and BMW are examples of businesses that allow customers to personalize their choices through product configurators.