Introduction

Product Lifecycle Management (PLM) is shaking things up in the manufacturing world! It’s all about connecting the dots from the moment a product is conceived to when it’s finally disposed of. Imagine teams working together seamlessly, processes running like a well-oiled machine, and manufacturers being able to jump on market demands without missing a beat. Sounds great, right? But here’s the kicker: as competition heats up and customer expectations keep changing, how can manufacturers really make the most of PLM to not just get by, but truly thrive in this fast-paced environment?

Let’s think about it. What if PLM could be your secret weapon? It’s not just about keeping up; it’s about staying ahead. By enhancing collaboration and streamlining processes, PLM can help you maintain those high-quality standards that customers crave. So, what’s stopping you from diving in? How can you leverage PLM to not only survive but to shine in this dynamic landscape? Let's explore!

Define Product Lifecycle Management (PLM)

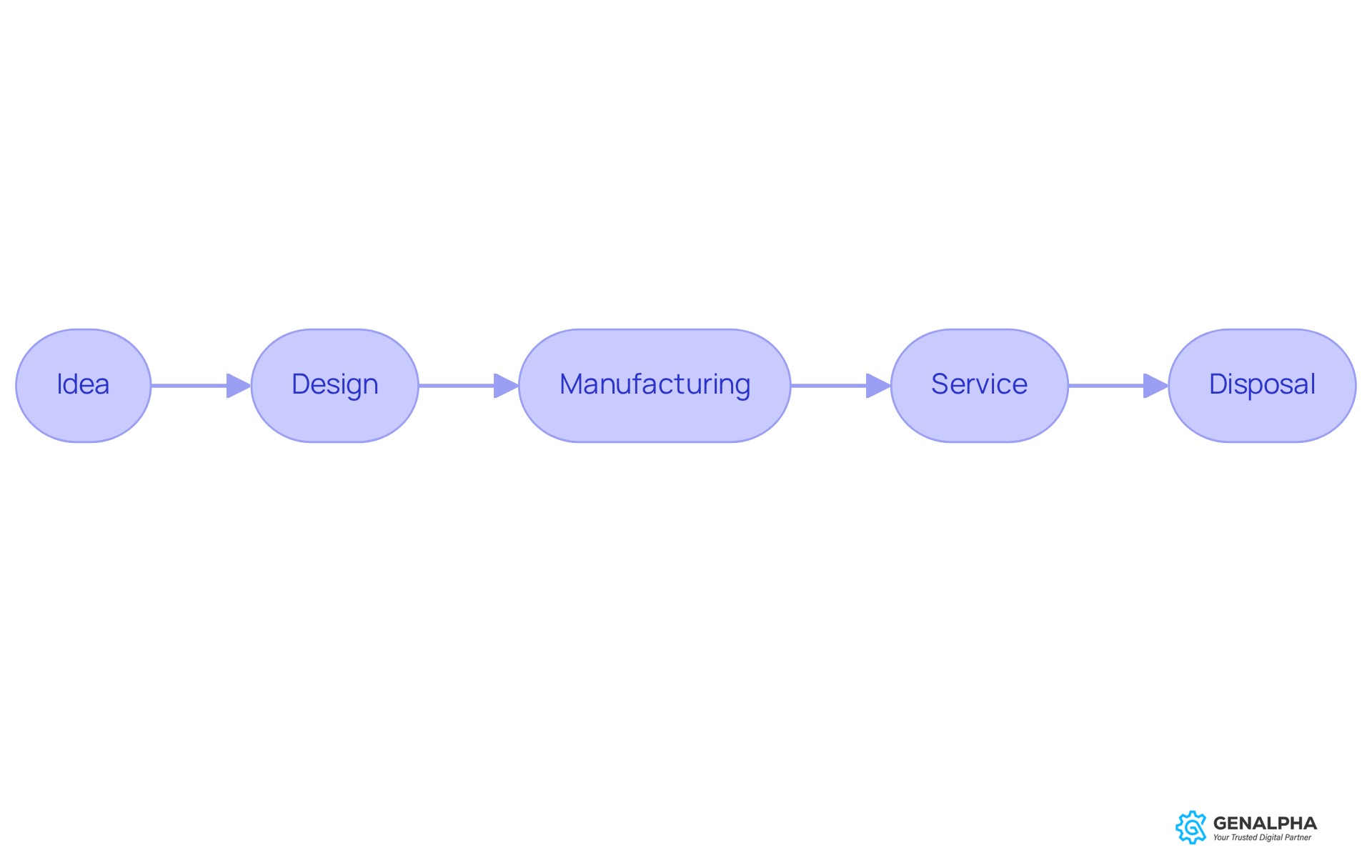

Lifecycle Management, or PLM, is all about managing an item's journey from the moment it’s just an idea, through design, manufacturing, service, and finally, disposal. Imagine having a system that brings together everyone involved - engineers, designers, and marketers - making sure they all have the right info at their fingertips to make smart decisions. Sounds great, right? This approach not only boosts teamwork but also streamlines processes, leading to better quality products and quicker time-to-market.

Now, think about 2026. As manufacturers face tougher competition and shifting industry demands, having effective PLM strategies will be crucial. These strategies help companies tackle the complexities of development, ensuring they can launch products on time and meet customer expectations. Did you know that PLM can significantly impact how quickly items hit the market? It helps with managing schedules and forecasting, which means faster market entry.

As industry insights suggest, timely launches are key to staying competitive and maximizing revenue. So, if you’re in manufacturing, it’s clear: embracing PLM isn’t just a good idea; it’s essential for thriving in today’s fast-paced landscape. What steps are you taking to enhance your PLM strategy?

Explain the Importance of PLM in Manufacturing

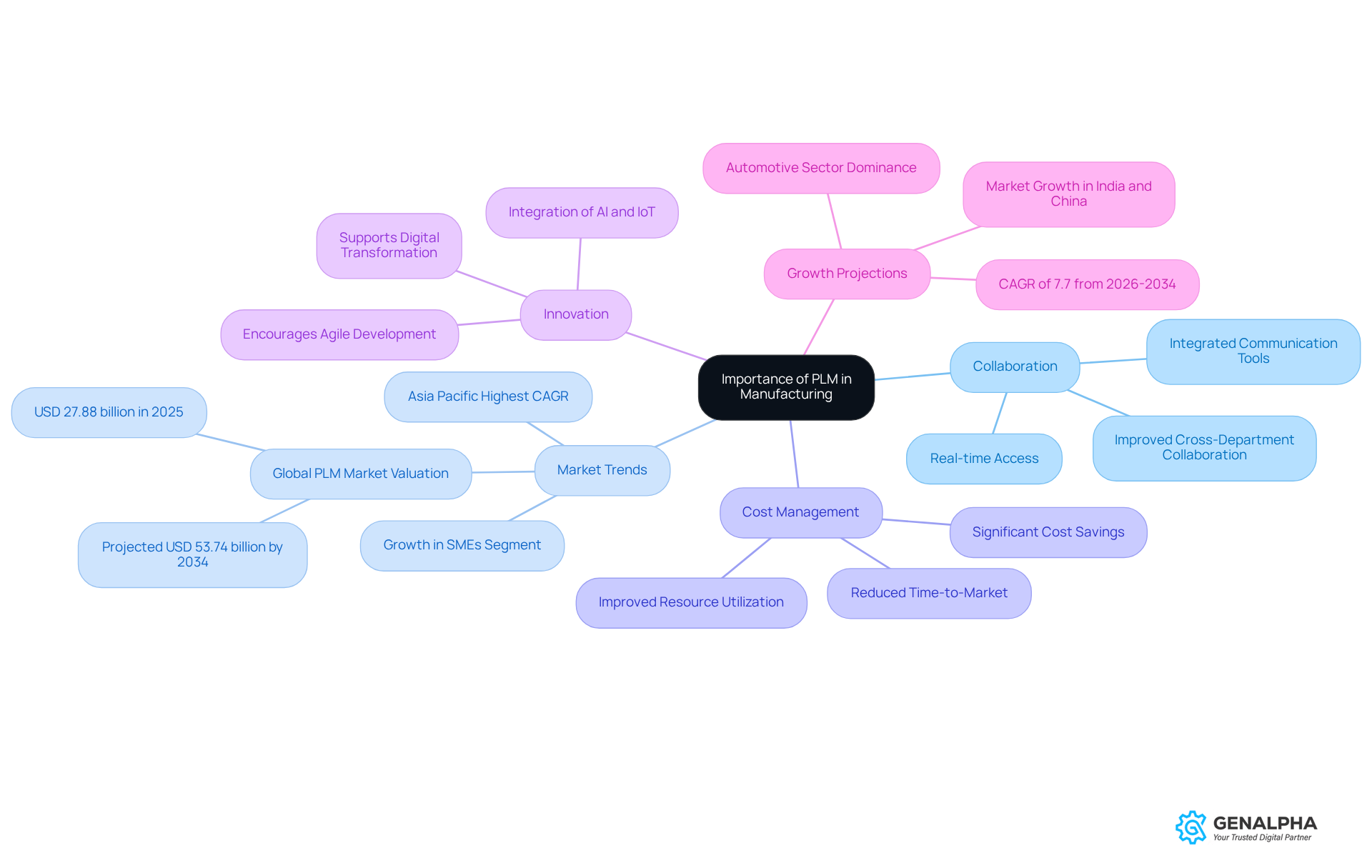

PLM for manufacturing is super important! Think of it as a strategic framework that helps streamline how we manage item data and processes. When manufacturers implement PLM for manufacturing, they can significantly enhance collaboration across different departments. This means fewer errors and better compliance with industry standards.

Imagine having real-time access to all the essential information you need. That’s what PLM offers! It allows teams to respond quickly to market changes, which is crucial as customer expectations keep evolving. Producers can deliver high-quality products while keeping costs and resource distribution in check with PLM for manufacturing.

But that’s not all! PLM for manufacturing also encourages innovation and agility in product development, making it a must-have for staying competitive in the industry. Have you noticed the trend? More and more companies are turning to PLM for manufacturing through cloud-based solutions. These not only enhance flexibility but also support manufacturers on their digital transformation journeys.

Here’s a fun fact: the global PLM sector was valued at USD 27.88 billion in 2025 and is expected to hit USD 53.74 billion by 2034! The Small and Mid-Sized Enterprises (SMEs) segment is projected to see the highest growth during this time.

Case studies show that PLM systems really do improve collaboration across departments and boost process efficiency. They’re not just theoretical; they have real-world applications and benefits. So, if you’re in manufacturing, have you considered how PLM could transform your operations?

Outline Key Components and Phases of PLM

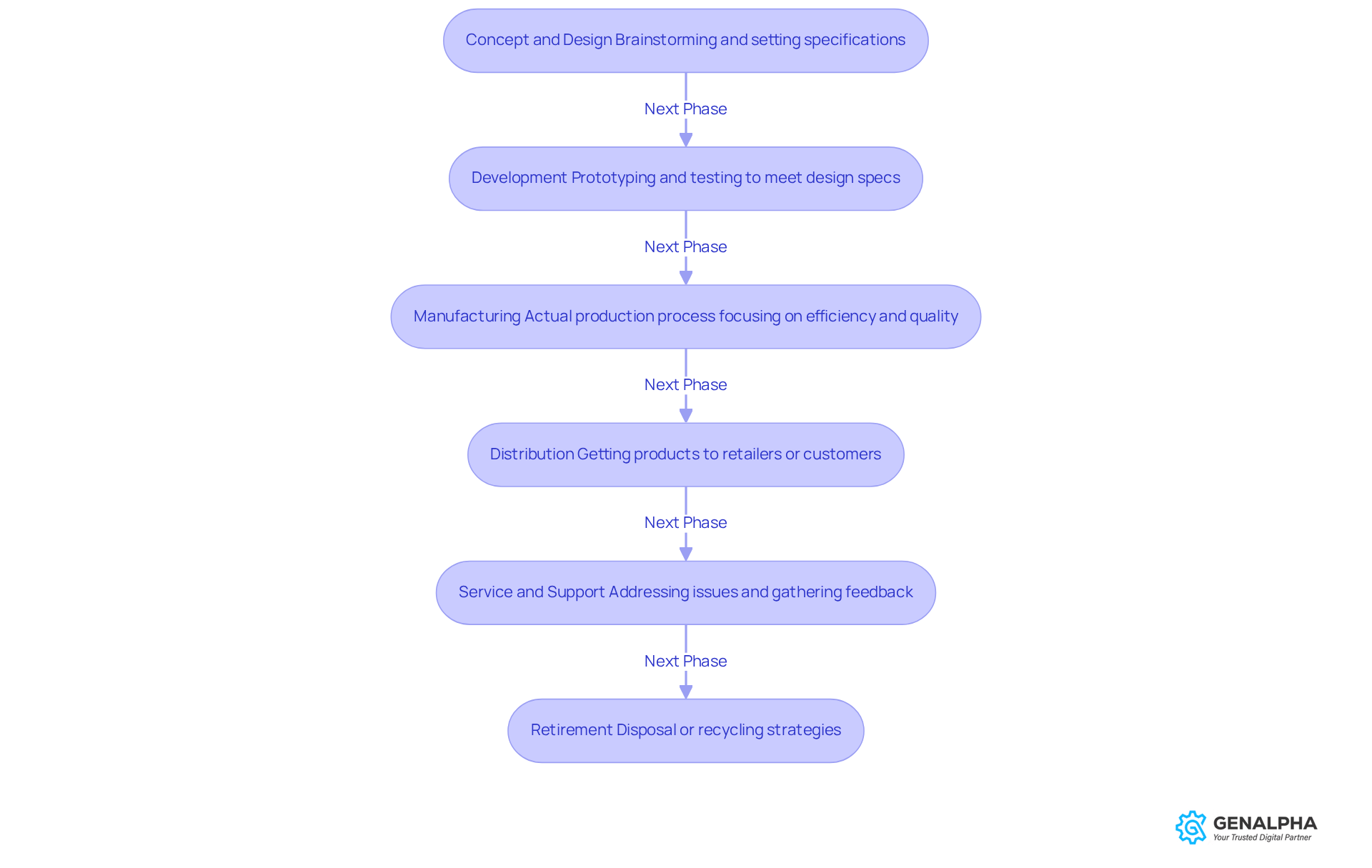

When we think about Product Lifecycle Management (PLM), it’s clear that certain elements and stages play a crucial role in boosting development and getting products ready for the market. Let’s break it down into phases that really matter:

-

Concept and Design: This is where the magic begins! It’s all about brainstorming and setting specifications that align with what the market needs. Have you ever thought about how important this phase is for a product’s success?

-

Development: Here, prototypes come to life, and testing kicks in to ensure everything meets those design specs. This step is key to avoiding costly rework down the line. Did you know that PLM systems can help cut down on mistakes? They do this through solid version control and detailed change tracking.

-

Manufacturing: Now we’re in the thick of it! This phase focuses on the actual production process, where keeping efficiency and quality in check is a must. Using PLM for manufacturing can really speed things up, reducing the time products spend here and lowering costs. For instance, after implementing PLM solutions like Enov8's, operational efficiency shot up by 30%!

-

Distribution: Once manufacturing wraps up, it’s time to get those products to retailers or directly to customers. A well-coordinated supply chain is essential for timely delivery and keeping customers happy. Have you ever experienced delays? It’s frustrating, right?

-

Service and Support: After the sale, support is vital for keeping customers satisfied. Addressing issues and gathering feedback can lead to future improvements. Jane Temov, an IT Environments Evangelist at Enov8, shared that customer satisfaction jumped by 40% thanks to new releases. That’s impressive!

-

Retirement: Finally, as products reach the end of their lifecycle, we need to think about disposal or recycling strategies that comply with environmental regulations.

Each of these phases is interconnected, and effective PLM for manufacturing ensures a smooth flow of information among them. This not only boosts operational efficiency but also helps businesses respond quickly to industry changes. Excitingly, the PLM sector is projected to hit a whopping USD 53.74 billion by 2034, showing just how important it’s becoming in our industry. So, what do you think? How can your organization leverage PLM to stay ahead?

Highlight Benefits of PLM for Manufacturers

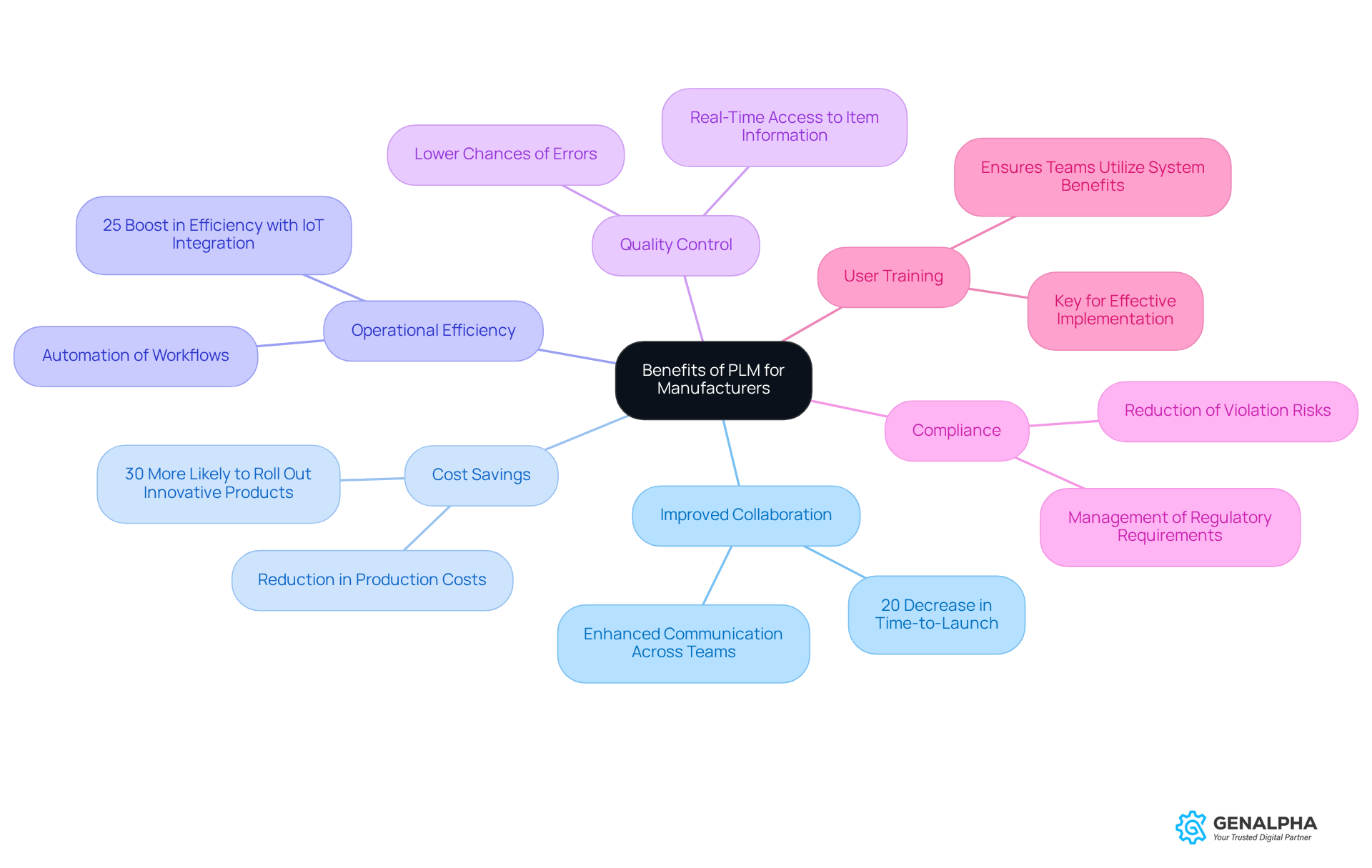

Implementing PLM for manufacturing can significantly change the game for producers, offering a variety of important benefits that can transform their operations. Have you ever thought about how much smoother things could run with better collaboration across teams? That’s one of the standout perks of using PLM for manufacturing. It fosters better communication and cuts down on the time spent sorting out misunderstandings. Companies using PLM software have reported a 20% decrease in time-to-launch, which means they can respond quickly to what consumers want.

But that’s not all! PLM for manufacturing also aids in identifying cost-saving opportunities by optimizing design and manufacturing processes. By automating workflows and getting rid of inefficiencies, manufacturers can see some serious reductions in production costs. For example, organizations that implement PLM for manufacturing are 30% more likely to roll out innovative products to market faster, which is significant for staying competitive. Plus, when companies integrate IoT into their strategies for PLM for manufacturing, they experience a 25% boost in operational efficiency. Talk about operational benefits!

And let’s not forget about quality. PLM ensures that everyone involved has real-time access to the latest item information and specifications. This centralized data approach significantly lowers the chances of errors, leading to better consistency and traceability of products. As a result, producers can maintain high standards of quality control, which is crucial for minimizing recalls and keeping customers happy.

On top of that, PLM for manufacturing helps with compliance to regulatory requirements, which is super important in today’s manufacturing world. By weaving compliance management into workflows, PLM for manufacturing ensures that products meet safety standards and regulatory obligations, reducing the risk of violations and the costs that come with them. And let’s not overlook user training - it’s key for effective PLM implementation, ensuring that teams can really tap into the system’s benefits.

In summary, adopting PLM for manufacturing not only boosts operational efficiency but also improves customer satisfaction and loyalty. This positions manufacturers for long-term success in a competitive marketplace. The history of PLM development, such as the launch of the first multi-tenant Cloud PLM solution in 2000, really highlights how these systems have evolved and their importance in modern manufacturing. So, are you ready to explore how PLM can benefit your operations?

Conclusion

Embracing Product Lifecycle Management (PLM) isn’t just a nice-to-have for manufacturers anymore; it’s a must if you want to thrive in today’s competitive landscape. Think about it: this all-encompassing approach ties together every stage of a product’s journey-from the initial concept to its retirement. It ensures that everyone on your team has the info they need to spark innovation and boost efficiency. By tapping into PLM, organizations can streamline operations, enhance collaboration, and ultimately get higher-quality products to market faster.

The article has highlighted just how crucial PLM is in manufacturing. It plays a key role in fostering collaboration across departments, improving operational efficiency, and ensuring compliance with industry standards. Each phase-whether it’s concept and design, development, manufacturing, distribution, service, or retirement-benefits from a solid PLM strategy. Plus, the real-world perks, like reduced time-to-launch, cost savings, and better quality control, show that PLM is a game changer in the industry.

As the manufacturing sector keeps evolving, the importance of PLM is only going to increase. Companies that invest in effective PLM strategies won’t just meet today’s market demands; they’ll set themselves up for future success. So, why wait? Now’s the time to explore and enhance your PLM strategy. The benefits are clear, and the opportunities are vast. Embracing PLM isn’t just a step toward operational excellence; it’s a commitment to innovation and long-term sustainability in manufacturing. What are you waiting for?

Frequently Asked Questions

What is Product Lifecycle Management (PLM)?

Product Lifecycle Management (PLM) is the process of managing an item's journey from its initial idea through design, manufacturing, service, and disposal. It involves collaboration among engineers, designers, and marketers to ensure everyone has access to the necessary information for making informed decisions.

How does PLM improve teamwork and processes?

PLM enhances teamwork by providing a centralized system where all stakeholders can access relevant information. This collaboration streamlines processes, leading to improved product quality and faster time-to-market.

Why is PLM important for manufacturers in 2026?

As manufacturers face increased competition and changing industry demands, effective PLM strategies will be crucial for managing development complexities. These strategies help ensure timely product launches that meet customer expectations.

How does PLM impact market entry speed?

PLM significantly affects how quickly products reach the market by aiding in schedule management and forecasting, which facilitates faster market entry.

What role do timely launches play in manufacturing?

Timely product launches are essential for maintaining competitiveness and maximizing revenue in the manufacturing sector. Embracing PLM is vital for achieving this goal in a fast-paced environment.