Introduction

In a world where efficiency and teamwork are key, Product Data Management (PDM) for CAD systems is more important than ever for manufacturers. This handy tool not only brings all product information together but also makes workflows smoother, so teams can always access the latest data. As companies tackle the challenges of modern manufacturing, you might wonder: how can PDM systems help not just to streamline processes but also to spark innovation and keep a competitive edge in a constantly changing market?

Think about it: when everyone’s on the same page with the latest info, it’s easier to collaborate and innovate. PDM systems can be the backbone of your operations, ensuring that your team has what they need, when they need it. So, how can you leverage this powerful tool to not only improve efficiency but also drive your business forward? Let’s explore!

Define Product Data Management (PDM) in CAD

Have you ever wondered how companies keep track of all their product information? Well, that’s where Product Information Management (PIM) comes into play! It’s a smart way to manage and control product-related info throughout its lifecycle, especially with the use of PDM for CAD environments. Think of PDM for CAD systems as the central hub for all item information, which includes CAD files, specifications, and documentation. This centralization means everyone involved has access to the latest info, which is super important for collaboration and cutting down on mistakes.

By organizing and monitoring product information systematically, PDM not only boosts operational efficiency but also helps companies stay compliant with industry standards. Fast forward to 2026, and you’ll see just how crucial PDM is for manufacturers and distributors. It streamlines operations and enhances customer satisfaction. Imagine how much smoother things could run when engineering, manufacturing, and procurement teams work together seamlessly - this can lead to fewer costly errors and quicker production cycles.

Experts agree that having a well-structured PDM framework, especially one that uses AI and machine learning for better accuracy, is key to keeping projects on track. Plus, automated workflows within PDM make processes easier and improve information management. But let’s not forget: proper training and user-friendly interfaces are essential for making it all work.

And here’s something to think about: when PDM integrates with Product Lifecycle Management (PLM) and ERP systems, it really takes collaboration to the next level and breaks down those pesky data silos. In today’s competitive manufacturing landscape, PDM isn’t just helpful - it’s a must-have tool!

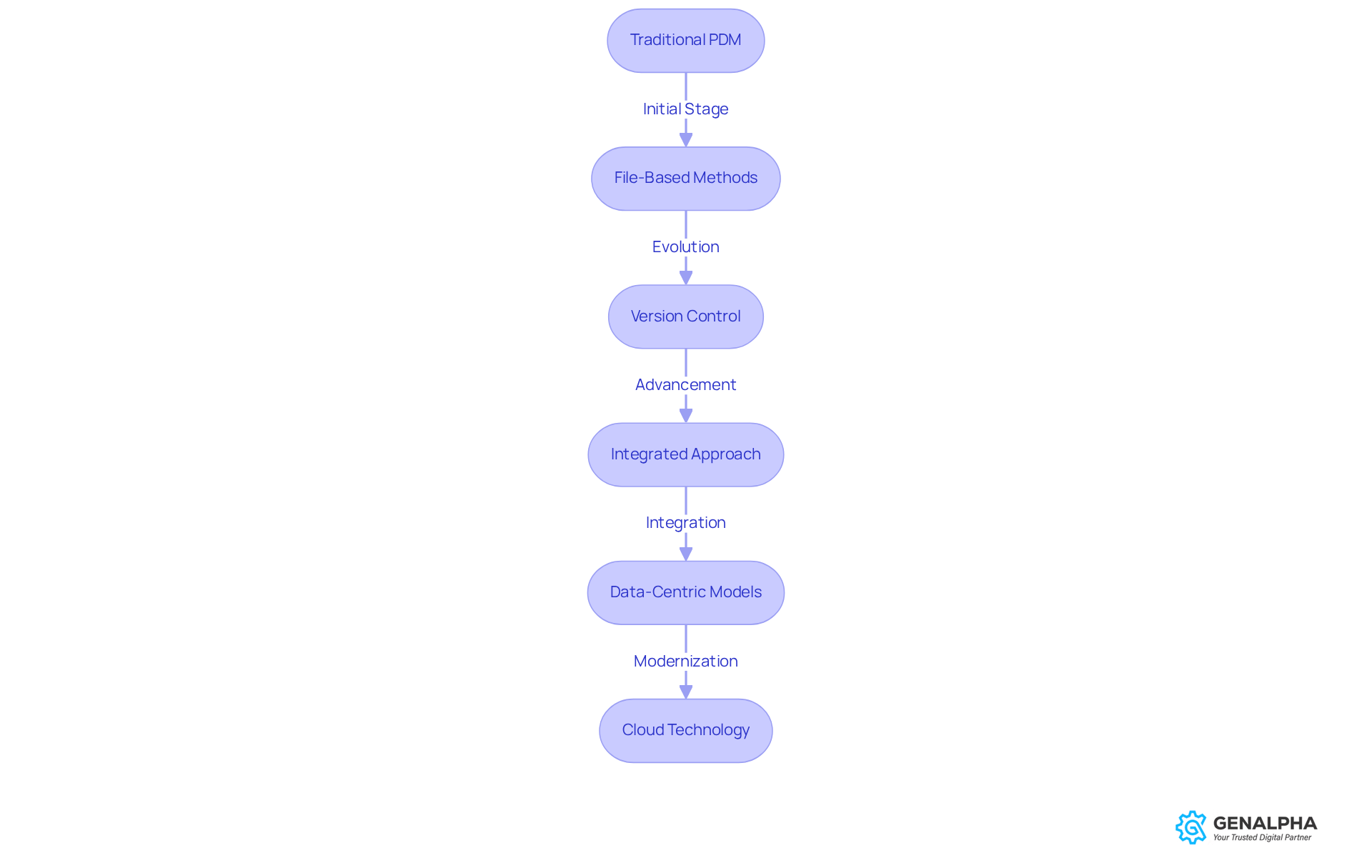

Trace the Evolution of PDM from Traditional to Data-Centric Models

Have you ever thought about how much Product Data Management (PDM) has changed over the years? It’s quite a journey, moving from those old-school file-based methods to today’s sleek, data-centric models. In the beginning, PDM for CAD focused on managing CAD files and keeping track of versions. But as manufacturing got more complex and interconnected, it became clear that we needed a more integrated approach. Now, modern PDM solutions do so much more than just handle design files; they also manage a whole range of product-related info, like bills of materials (BOMs), change orders, and compliance documents. This shift really shows how the industry is embracing digital transformation, where making decisions based on data is key to staying ahead of the competition.

Today’s PDM solutions are designed to manage a wide variety of digital assets, which is a big step up from what we had before. For example, traditional PDM for CAD platforms were primarily just storage spaces for CAD drawings. In contrast, contemporary solutions come packed with advanced features that promote collaboration, allow real-time data access, and ensure compliance with industry regulations. This change is especially important given the increasing complexity of product development, which now requires smooth integration across various fields like mechanical, electrical, and software engineering.

And let’s not forget about cloud technology! It’s really changed the game for PDM solutions, making remote collaboration a breeze and allowing integration with other enterprise platforms without the hassle of big IT projects. Because of this, manufacturers can now tap into data-centric PDM solutions that not only boost operational efficiency but also spark innovation and adaptability in a fast-paced market. The move from traditional to information-focused PDM models isn’t just about tech upgrades; it’s a fundamental shift in how organizations manage product information. It highlights the importance of being agile and responsive in today’s competitive landscape. So, how is your organization adapting to these changes?

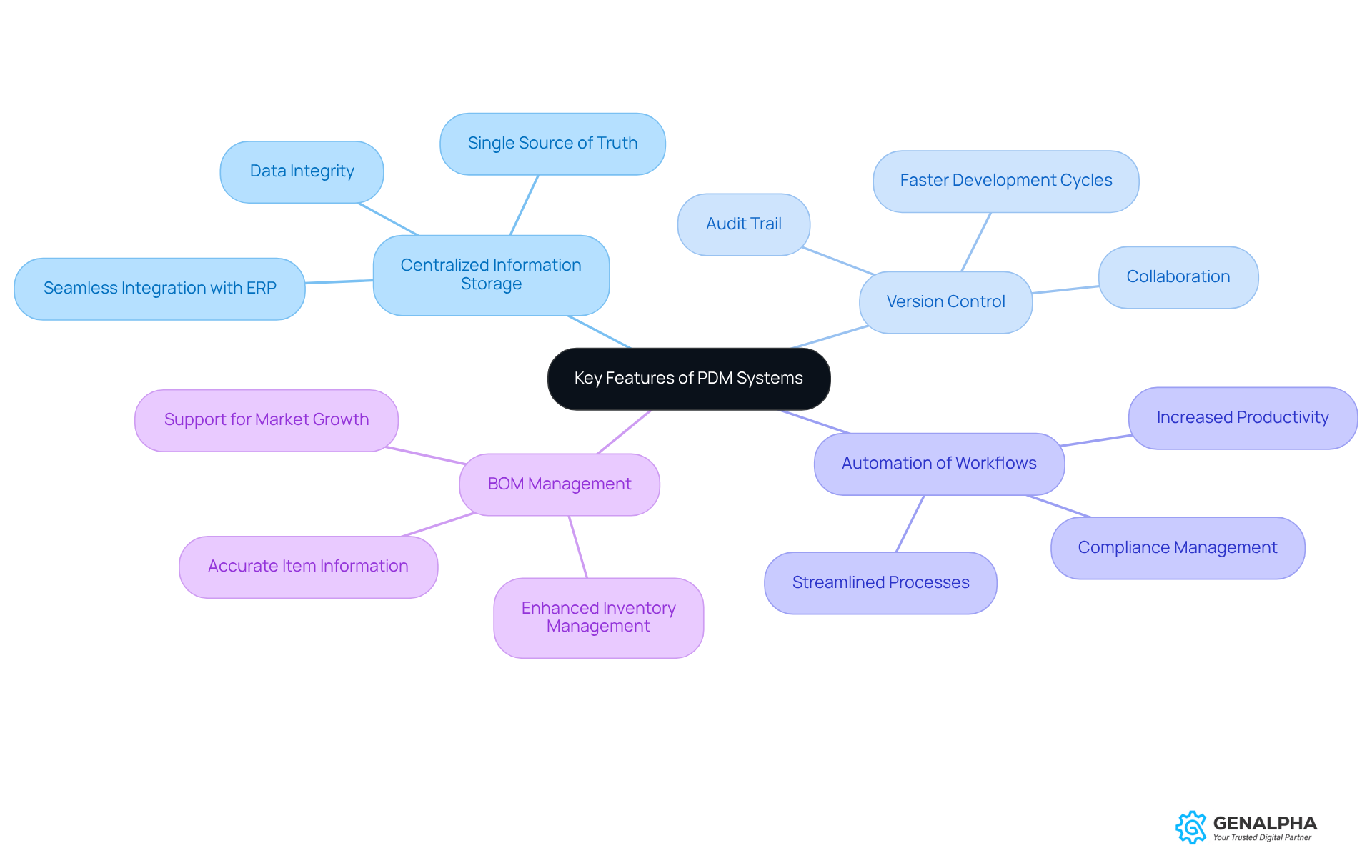

Identify Key Features and Capabilities of PDM Systems

When you think about Product Information Management (PIM) platforms, what comes to mind? Well, they’re all about keeping things organized and efficient. Key features like centralized information storage, version control, and strong security measures make them essential tools for businesses today. With centralized storage, you can easily access all product-related details, which really cuts down on mistakes and discrepancies. It’s like having a single source of truth that boosts data integrity and helps integrate seamlessly with other enterprise solutions like ERP. This is crucial for keeping accurate item information across all channels.

Now, let’s talk about version control. It’s super important because it keeps track of every change made to design files, creating a clear audit trail that enhances teamwork. Imagine several users collaborating on the same project without worrying about overwriting each other’s work-that’s a game changer! This kind of collaboration leads to quicker development cycles. For instance, companies utilizing PDM for CAD solutions have experienced better inventory management and faster time-to-market due to optimized workflows and accurate item information. A solid PDM for CAD solution can manage larger product catalogs without requiring a ton of extra management resources, which is fantastic for supporting market growth.

Additionally, PDM systems often come with features for managing Bills of Materials (BOMs) and automating workflows, which really boosts productivity and compliance. Experts agree that effective version control not only fosters collaboration but also builds a culture of accountability among teams. Everyone can refer to the latest information, which is a huge plus. Tim King, Executive Editor, points out that keeping an eye on relevant information management news is key to understanding the ever-changing PDM landscape. By adopting a robust PDM for CAD solution, manufacturers can streamline their operations and remain competitive in a fast-paced market. So, are you ready to take the leap and optimize your processes?

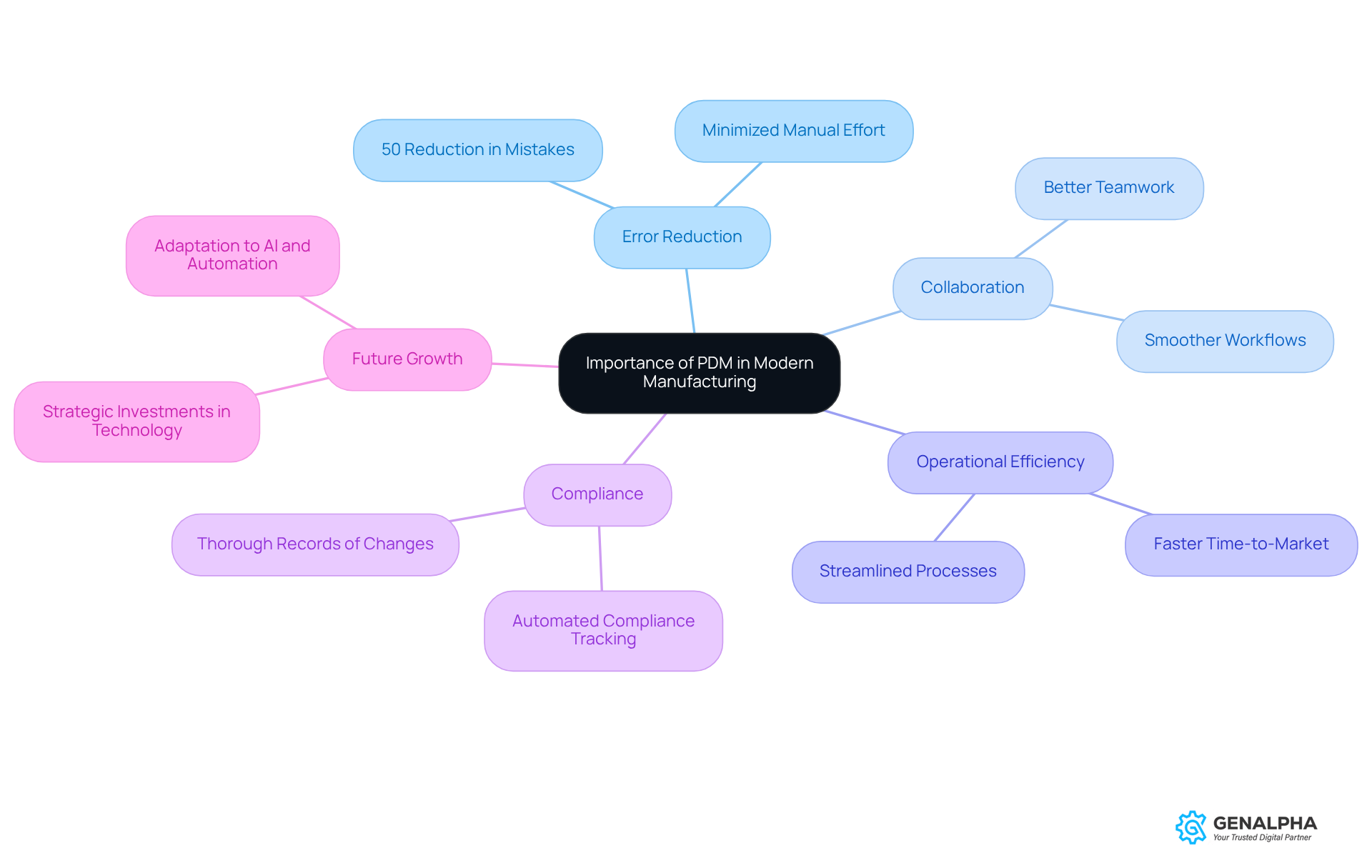

Explain the Importance of PDM in Modern Manufacturing

In the fast-paced world of manufacturing, have you ever considered how crucial PDM for CAD really is? PDM for CAD platforms consolidate all item information, ensuring that everyone involved has access to accurate and up-to-date details. This is key for effective collaboration and smart decision-making. By simplifying how we manage item data, PDM can cut down on human errors - studies show that using a PDM system can reduce mistakes by as much as 50%! That’s a big win for quality.

But it doesn’t stop there. Fewer errors mean quicker time-to-market and better compliance with industry regulations, thanks to thorough records of product changes and documentation. As more manufacturers jump on the digital bandwagon, PDM for CAD is becoming essential for boosting operational efficiency, sparking innovation, and building stronger relationships with customers. For example, companies that use PDM often see better collaboration among their engineering, manufacturing, and procurement teams, which leads to smoother workflows and projects that finish on time.

Looking ahead, by 2026, companies that don’t embrace AI might find themselves lagging in efficiency, precision, and responsiveness. This makes PDM for CAD even more essential as technology continues to evolve. In a competitive market, knowing how to use PDM for CAD effectively can position manufacturers for lasting growth and success, especially with the U.S. economy expected to grow by 2.3% in 2026. So, how are you planning to leverage PDM in your operations?

Conclusion

You know, the importance of Product Data Management (PDM) in CAD environments really can’t be overstated. Think of it as a vital tool for manufacturers - a centralized hub that makes managing product information a breeze. It enhances collaboration and cuts down on errors across different teams. This integration doesn’t just boost operational efficiency; it also helps ensure compliance with industry standards, making PDM an essential asset in today’s competitive manufacturing landscape.

Throughout this article, we’ve seen how PDM has evolved from those old-school file-based systems to modern, data-centric models. Features like centralized storage, version control, and automated workflows play a huge role in promoting collaboration and accountability among teams. Plus, with the rise of AI and cloud technology, PDM has become a powerful driver of innovation and agility, enabling manufacturers to quickly adapt to market demands.

So, why should you embrace PDM for CAD? It’s not just about keeping up with tech trends; it’s about setting your organization up for long-term growth and success. As the manufacturing sector keeps evolving, effectively leveraging PDM will be key to boosting efficiency, speeding up time-to-market, and building stronger relationships with customers. We encourage manufacturers to take a good look at their current systems and consider how PDM can transform their operations to thrive in this increasingly complex environment.

Frequently Asked Questions

What is Product Data Management (PDM) in CAD?

Product Data Management (PDM) in CAD is a system that manages and controls product-related information throughout its lifecycle, serving as a central hub for all item information, including CAD files, specifications, and documentation.

Why is PDM important for companies?

PDM is important for companies because it centralizes product information, ensuring that everyone involved has access to the latest data. This enhances collaboration, reduces mistakes, boosts operational efficiency, and helps maintain compliance with industry standards.

How does PDM benefit collaboration among teams?

PDM benefits collaboration by streamlining operations and enabling seamless teamwork between engineering, manufacturing, and procurement teams, which leads to fewer costly errors and quicker production cycles.

What role does AI and machine learning play in PDM?

AI and machine learning enhance the accuracy of PDM frameworks, making it easier to keep projects on track and improving overall information management.

What are the advantages of automated workflows in PDM?

Automated workflows within PDM simplify processes, improve information management, and contribute to operational efficiency.

What is the significance of training and user-friendly interfaces in PDM?

Proper training and user-friendly interfaces are essential for ensuring that PDM systems function effectively and that users can navigate them with ease.

How does PDM integrate with other systems?

PDM integrates with Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems, enhancing collaboration and breaking down data silos.

Why is PDM considered a must-have tool in manufacturing?

PDM is considered a must-have tool in manufacturing because it is crucial for maintaining competitiveness, improving operational efficiency, and ensuring accurate and timely product information management.