Introduction

Understanding the ins and outs of fixed operations is super important for equipment manufacturers who want to keep that revenue flowing and boost customer satisfaction. Think about it: these operations, which include maintenance and parts sales, are really the backbone of profitability in the manufacturing world. But here’s the kicker - managing these processes can be tricky, especially with rising costs and changing customer expectations. So, how can manufacturers tap into fixed operations not just to survive, but to really thrive in today’s competitive landscape?

Let’s dive into this together! What if we could turn these challenges into opportunities? By focusing on fixed operations, manufacturers can not only streamline their processes but also create a better experience for their customers. Imagine being able to anticipate customer needs and respond quickly - that’s the kind of service that builds loyalty and keeps customers coming back.

So, what’s the next step? It’s time to rethink how we approach fixed operations. Let’s explore some strategies that can help manufacturers not just meet expectations but exceed them. Are you ready to take your operations to the next level?

Define Fixed Operations: Core Concepts and Importance

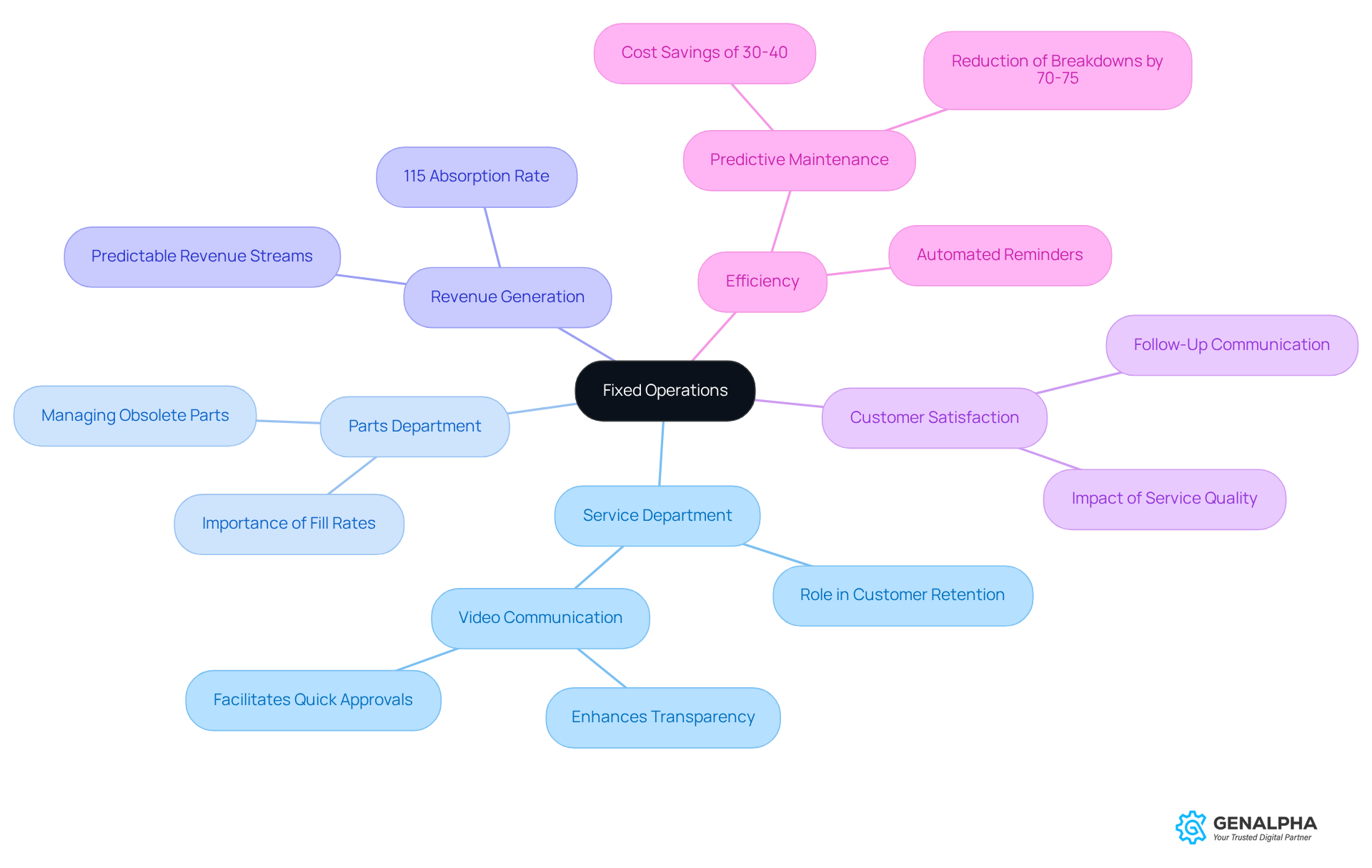

The fixed operations meaning encompasses those essential parts of production and dealership settings that help create steady and reliable income, mainly through maintenance and parts sales. Consider the service department, which manages maintenance and repairs, alongside the parts department that supplies the necessary components, as this illustrates the concept of fixed operations meaning. For equipment producers, understanding the fixed operations meaning of these steady functions is essential. Why? Because fixed operations meaning plays a key role in generating consistent revenue, boosting client satisfaction, and building long-term relationships with customers.

In fact, these set functions can lead to an impressive 115% absorption rate, which significantly boosts dealership profitability by exemplifying fixed operations meaning. By focusing on these processes, manufacturers can ensure efficiency and cultivate customer loyalty over time, reflecting the fixed operations meaning. And let’s not forget, unexpected downtime can cost manufacturers up to $50 billion each year, with equipment breakdowns accounting for 42% of those costs. So, managing established processes efficiently is more important than ever to grasp fixed operations meaning.

Investing in digital tools and strategies, like predictive maintenance - which can save businesses 30 to 40% in costs - can really enhance these processes. This ultimately turns stable functions into a solid foundation for profitability, highlighting the fixed operations meaning in the equipment manufacturing sector. As W. Edwards Deming wisely said, "Quality means doing it right when no one is watching." This highlights just how important dedicated management is in these processes. So, what steps can you take today to improve your operations?

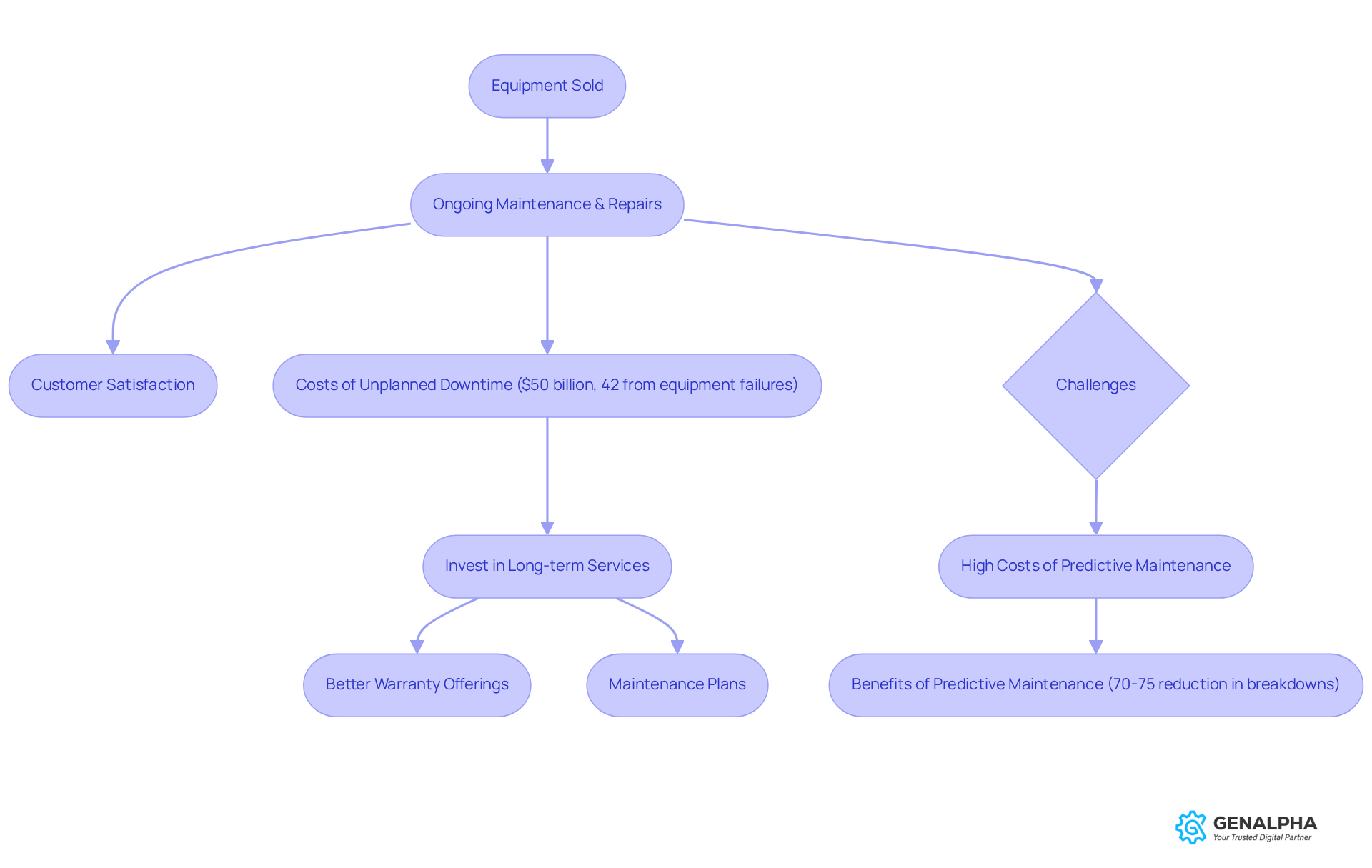

Contextualize Fixed Operations in Equipment Manufacturing

In the world of equipment production, there are some key processes that really make a difference. Think about it: from the moment a piece of equipment is sold to the ongoing maintenance and repairs, these activities are crucial. They not only help manufacturers keep a steady income but also boost customer satisfaction with reliable support. Did you know that unplanned downtime can cost manufacturers up to $50 billion each year? A staggering 42% of those costs come from equipment failures!

So, what can producers do? Investing in solid long-term services can lead to better warranty offerings and maintenance plans, which customers are starting to expect more and more. As Henry Ford wisely said, "Time waste differs from material waste in that there can be no salvage." This really underscores how important operational efficiency is. Companies that nail these processes often see better customer retention and loyalty, which is a huge win in a competitive market.

But it’s not all smooth sailing. Some manufacturers face challenges, like the high costs of implementing predictive maintenance, which can hold them back from reaping these benefits. However, a case study on predictive maintenance shows that companies using these strategies can cut breakdowns by 70 to 75%! That’s a significant impact from having efficient processes in place.

So, what do you think? Are you ready to explore how these practices could benefit your operations?

Trace the Evolution of Fixed Operations

Have you ever thought about how much technology has changed the way we think about equipment manufacturing? It’s pretty fascinating! Initially, the focus was all about basic upkeep and repairs. But now, things have evolved. We’re seeing advanced offerings like digital warranty management and predictive maintenance solutions popping up everywhere. This shift isn’t just a trend; it’s a reflection of what’s happening across the manufacturing sector. Improving client engagement and operational efficiency has become essential.

Today, the fixed operations meaning revolves around a comprehensive approach to relationship management. We’re using data analytics and technology to not just meet client needs but to anticipate them. It’s like having a crystal ball for service delivery! As Sam Walton famously said, "To succeed in this world, you have to change all the time." This really highlights how crucial it is to adapt to changing client expectations.

And here’s something to think about: technician turnover is increasing by 12% year-over-year. That’s a big deal! Integrating technology doesn’t just streamline processes; it also fosters a culture of continuous improvement. This is essential for thriving in today’s competitive landscape. So, if you’re in manufacturing, embracing these advancements isn’t just a good idea-it’s crucial for meeting the evolving expectations of your clients and driving sustainable growth. What steps are you taking to adapt?

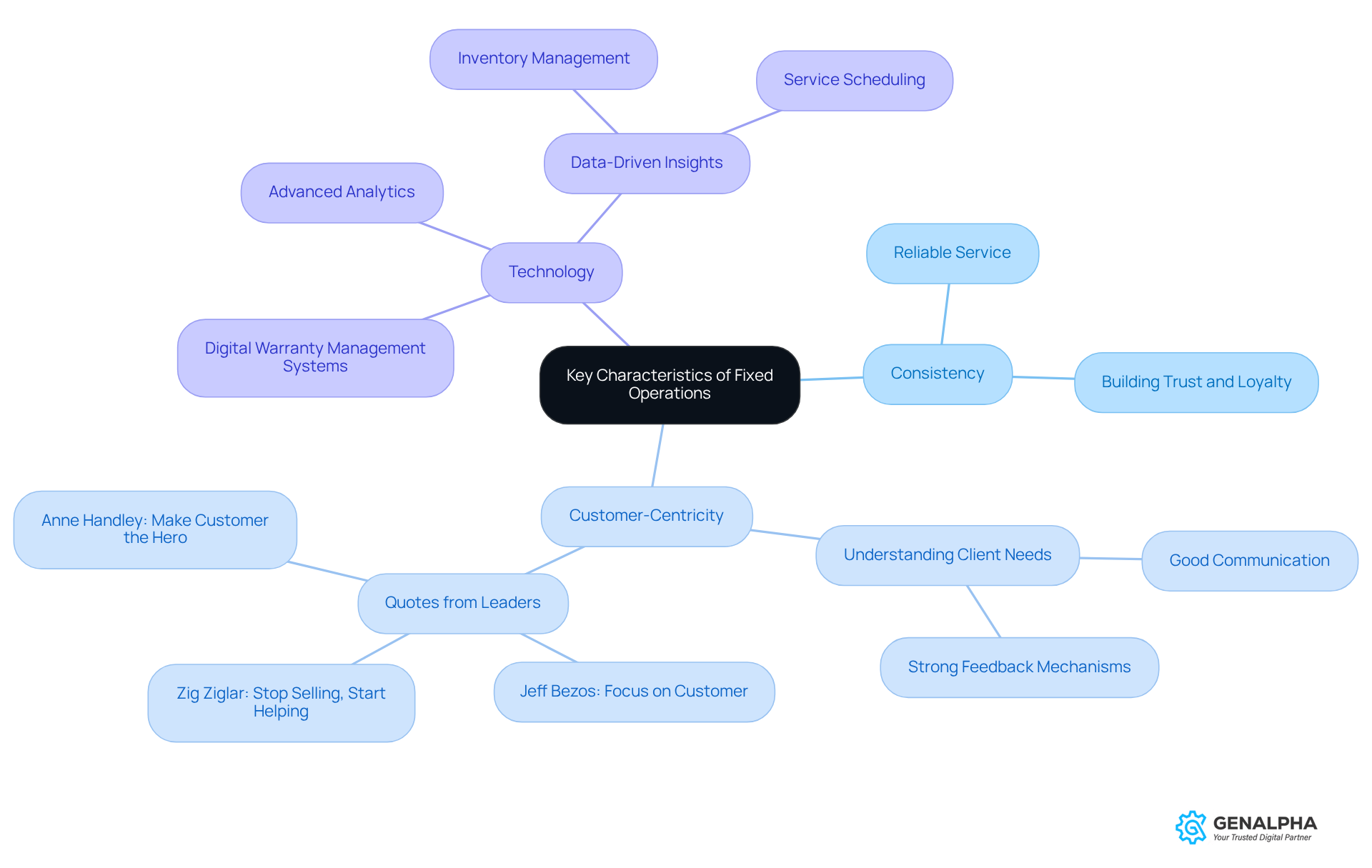

Identify Key Characteristics of Fixed Operations

When we think about effective fixed operations meaning, a few key traits come to mind:

- Consistency

- Customer-centricity

- A solid integration with technology

Let’s start with consistency. It’s crucial because it ensures that every time clients interact with the manufacturer, they receive reliable service. This builds trust and loyalty, don’t you think?

Now, consider what Jeff Bezos said about focusing on the client. It’s not just a nice idea; it actually boosts company resilience. This is where customer-centricity comes into play. It’s all about understanding and anticipating client needs, which can be achieved through good communication and strong feedback mechanisms.

Additionally, let’s talk about technology. Incorporating tools like advanced analytics and digital warranty management systems can really ramp up operational efficiency and enhance client satisfaction. For example, manufacturers that leverage data-driven insights can fine-tune their inventory management and service scheduling. This means shorter wait times and better service quality. Who wouldn’t want that?

Bill Gates once emphasized that clients ultimately decide what goes into products. This really underscores the importance of aligning our activities with client expectations. So, when we put all these characteristics together, we create a robust fixed operations meaning strategy that not only meets but consistently exceeds customer expectations. How can we apply these insights to our own operations?

Conclusion

Understanding fixed operations is crucial for equipment manufacturers who want to grow sustainably and keep their customers coming back. Think about it: these steady functions - from maintenance to parts sales - are the backbone of reliable revenue and strong client relationships. You can’t underestimate their importance!

Throughout this article, we’ve highlighted some eye-opening insights, like the hefty costs that come with unplanned downtime and the perks of investing in predictive maintenance strategies. By focusing on consistency, customer-centricity, and tech integration, we’ve shown how these elements can boost operational efficiency and make customers happier.

So, here’s the deal: embracing the evolution of fixed operations isn’t just an option; it’s a must for manufacturers who want to thrive in today’s competitive landscape. By putting these practices front and center, businesses can cut costs and enhance their service offerings, ensuring they meet the ever-changing expectations of their clients. The message is clear: let’s take proactive steps today to optimize fixed operations and secure a bright future in the equipment manufacturing industry!

Frequently Asked Questions

What are fixed operations in the context of production and dealership settings?

Fixed operations refer to essential parts of production and dealership settings that generate steady and reliable income, primarily through maintenance and parts sales, including the service department and parts department.

Why is understanding fixed operations important for equipment producers?

Understanding fixed operations is crucial for equipment producers because it plays a key role in generating consistent revenue, boosting client satisfaction, and building long-term customer relationships.

What is the absorption rate associated with fixed operations, and why is it significant?

The absorption rate associated with fixed operations can reach an impressive 115%, significantly boosting dealership profitability by illustrating the importance of these steady functions.

What are the potential costs of unexpected downtime for manufacturers?

Unexpected downtime can cost manufacturers up to $50 billion each year, with equipment breakdowns accounting for 42% of those costs.

How can investing in digital tools and strategies impact fixed operations?

Investing in digital tools and strategies, such as predictive maintenance, can enhance fixed operations by saving businesses 30 to 40% in costs and turning stable functions into a solid foundation for profitability.

What quote by W. Edwards Deming emphasizes the importance of management in fixed operations?

W. Edwards Deming stated, "Quality means doing it right when no one is watching," highlighting the importance of dedicated management in fixed operations processes.