Introduction

Have you noticed how personalized products are becoming the norm? It’s a big shift in what consumers expect, and engineer-to-order (ETO) manufacturing is leading the charge in this exciting transformation. This innovative approach lets manufacturers whip up customized solutions that fit individual client needs perfectly. But here’s the catch: as the demand for these tailored offerings skyrockets, so do the challenges of keeping communication clear and projects on track.

So, what does this mean for the future of manufacturing? How can businesses tap into ETO processes to boost client satisfaction and drive success? Let’s dive into this together!

Define Engineer-to-Order Manufacturing

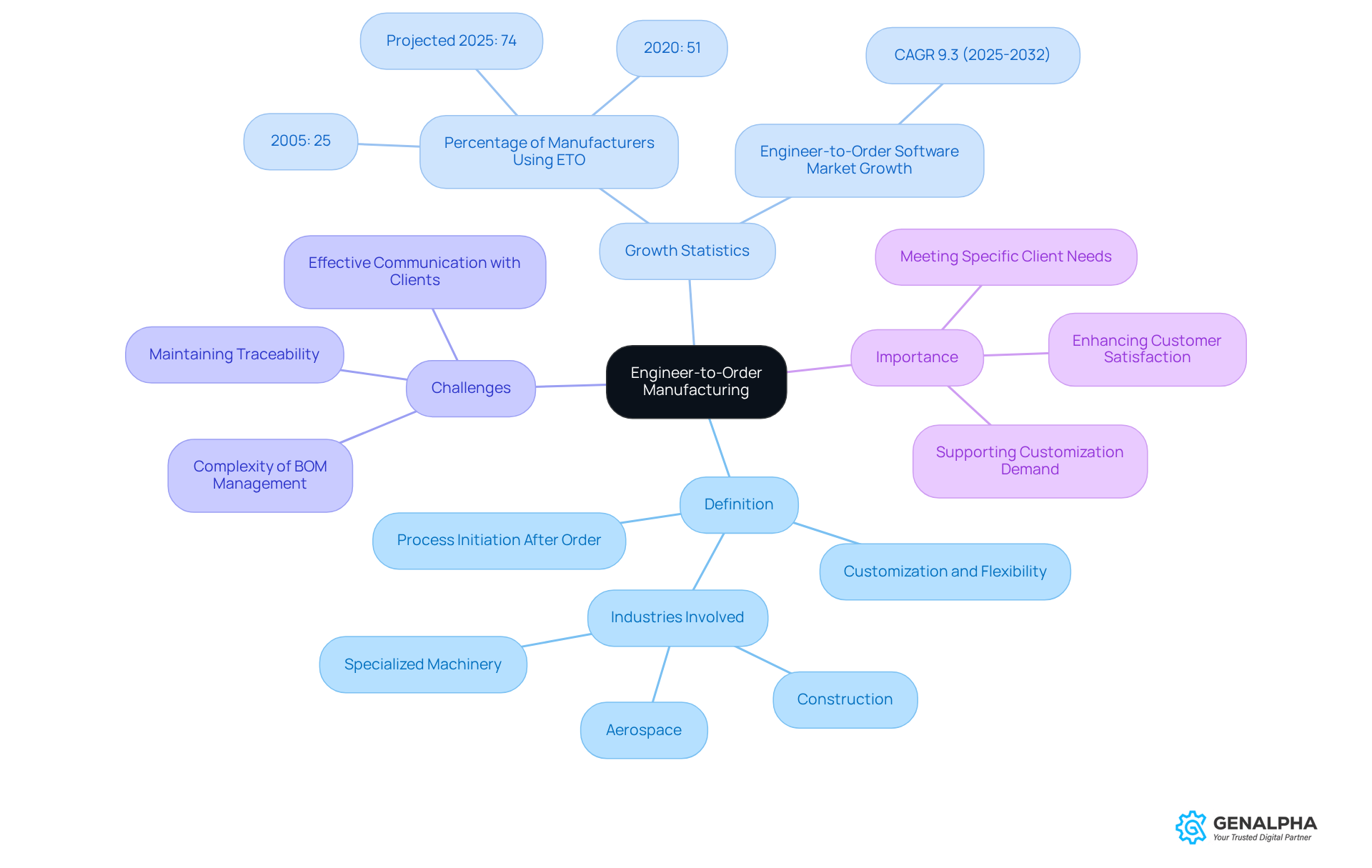

Have you ever thought about how some products are made just for you? That’s where the concept of engineer-to-order production comes in! This unique approach involves an engineer-to-order process, ensuring that items are specially designed, engineered, and created to meet the specific needs of individual clients. Unlike conventional manufacturing, which often relies on standardized items, engineer-to-order processes highlight customization and flexibility.

The process of engineer-to-order begins only after a customer places an order. This allows manufacturers to tailor each item precisely to what the client needs. It’s especially important in industries like aerospace, construction, and specialized machinery, where engineer-to-order products often involve complex engineering and design considerations.

Did you know that the percentage of manufacturers in the U.S. using ETO processes has jumped from 25% in 2005 to 51% in 2020? And it’s expected to reach a whopping 74% by 2025! Additionally, the engineer-to-order software market is anticipated to expand at a CAGR of 9.3% from 2025 to 2032. That’s a clear sign of strong demand for solutions that support this production model.

However, ETO manufacturers do face some challenges. They need to maintain traceability in their projects and ensure effective communication with clients to make sure everything goes smoothly. As industry leaders point out, "Creating a BOM organizes the materials and subassemblies needed to manufacture an item." This really highlights how crucial thorough documentation is in the engineer-to-order process.

So, what do you think? Is ETO production the future of manufacturing? Let’s keep the conversation going!

Context and Importance of ETO in Manufacturing

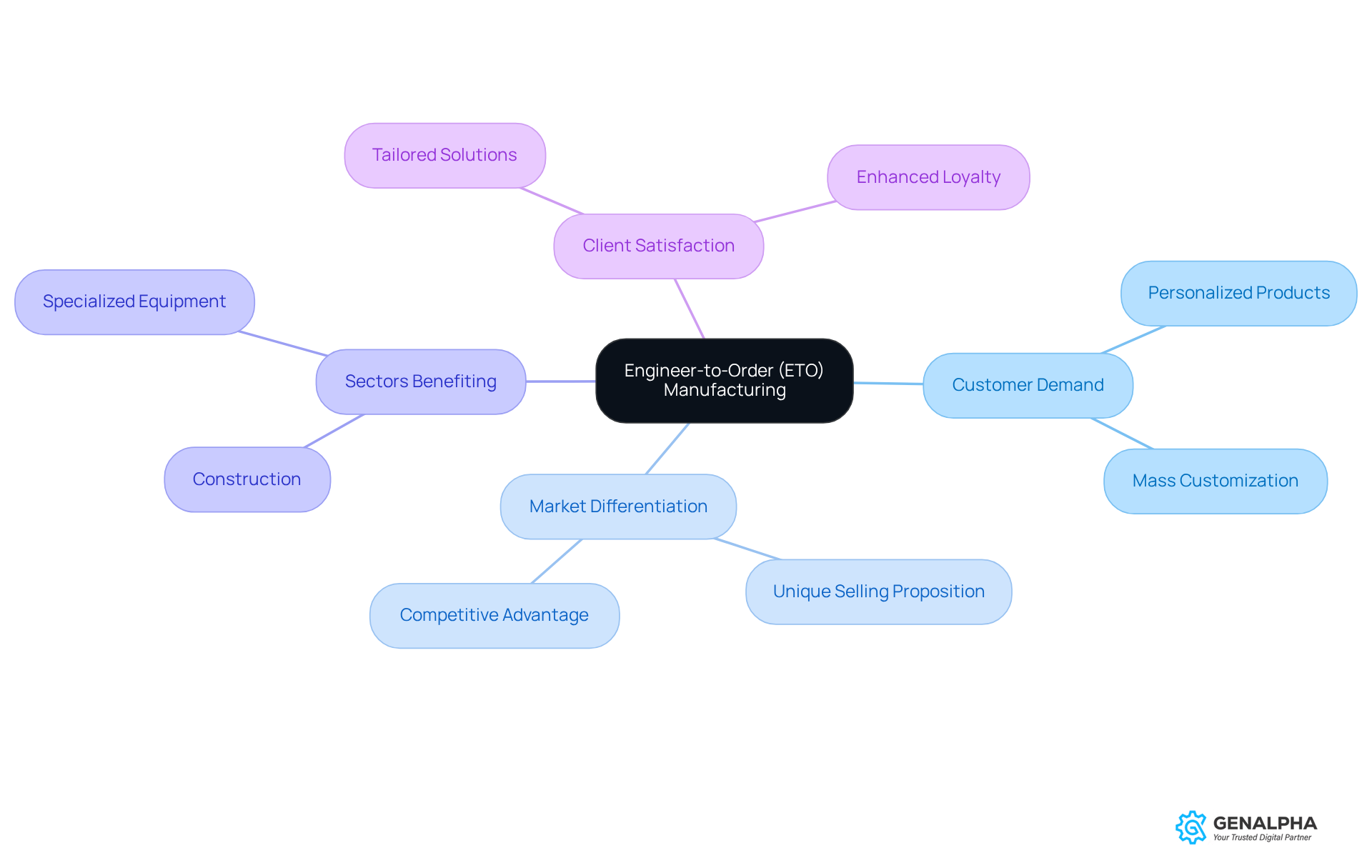

Have you ever noticed how much we crave personalized products these days? In the world of engineer-to-order (ETO) manufacturing, this demand is truly gaining momentum. As businesses look to stand out in crowded markets, the engineer-to-order approach offers a unique edge. It allows manufacturers to quickly adapt to specific customer needs, which is a game changer.

Think about sectors like construction or specialized equipment. Clients often need one-of-a-kind solutions that off-the-shelf items just can’t provide. This is where the engineer-to-order process shines! Plus, with the trend toward mass customization, consumers are expecting tailored products without having to wait ages or compromise on quality.

So, it’s no surprise that engineer-to-order production has emerged as a key player in modern manufacturing strategies. It’s all about boosting client satisfaction and loyalty. How can your business tap into this trend? Let’s explore the possibilities together!

Key Characteristics of Engineer-to-Order Manufacturing

When we think about Engineer-to-Order (ETO) manufacturing, a few key characteristics really stand out:

-

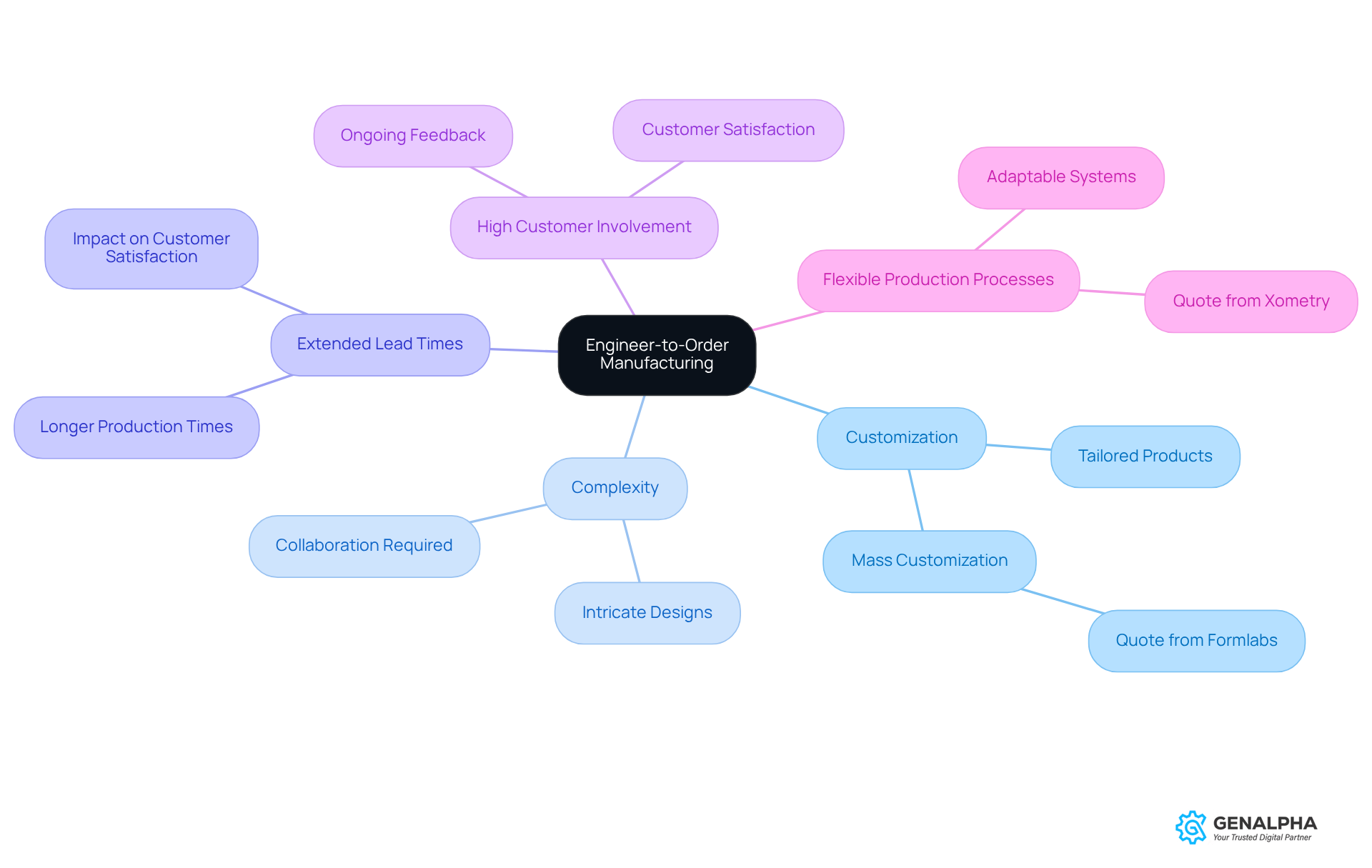

Customization: Imagine getting something made just for you-every detail tailored to your needs. That’s what engineer-to-order (ETO) is all about! Each item is designed as engineer-to-order to meet specific customer requirements, covering everything from dimensions to materials and functionalities. As Formlabs puts it, "Mass customization merges the adaptability of custom-made items with the low unit expenses realized in mass manufacturing."

-

Complexity: ETO items often come with intricate designs that require a lot of engineering know-how. This means that sales, engineering, and production teams need to work closely together to keep everything aligned and accurate. It’s a bit of a juggling act, especially when it comes to estimating costs, as various case studies have shown.

-

Extended Lead Times: Unlike make-to-stock methods, ETO production usually means longer lead times. Why? Because engineering and production kick off only after an order is placed, reflecting that custom touch. Interestingly, the engineer-to-order custom manufacturing market is expected to grow at a CAGR of 4.7%, showing that more folks are looking for these tailored solutions.

-

High Customer Involvement: Here’s where it gets personal-customers are deeply involved throughout the design and production phases. They provide ongoing feedback and make adjustments to ensure the final product meets their expectations. This level of involvement is key to achieving customer satisfaction in engineer-to-order processes.

-

Flexible Production Processes: ETO production thrives on adaptable systems that can handle design changes without causing major downtime or cost hikes. This flexibility is super important in industries where customization is a must, like aerospace, automotive, and specialized machinery. As Xometry highlights, "Xometry allows buyers to choose how and where their parts are produced, providing greater flexibility in global logistics."

So, what do you think? Engineer-to-order manufacturing truly demonstrates how customization can address specific needs while navigating the complexities of production. It’s a fascinating area that’s only going to grow!

Real-World Applications of ETO Manufacturing

When we think about engineer-to-order manufacturing, it’s fascinating to see how it is implemented across different industries, right? Let’s dive into some real-world examples that show just how versatile and effective engineer-to-order processes can be in delivering customized solutions.

-

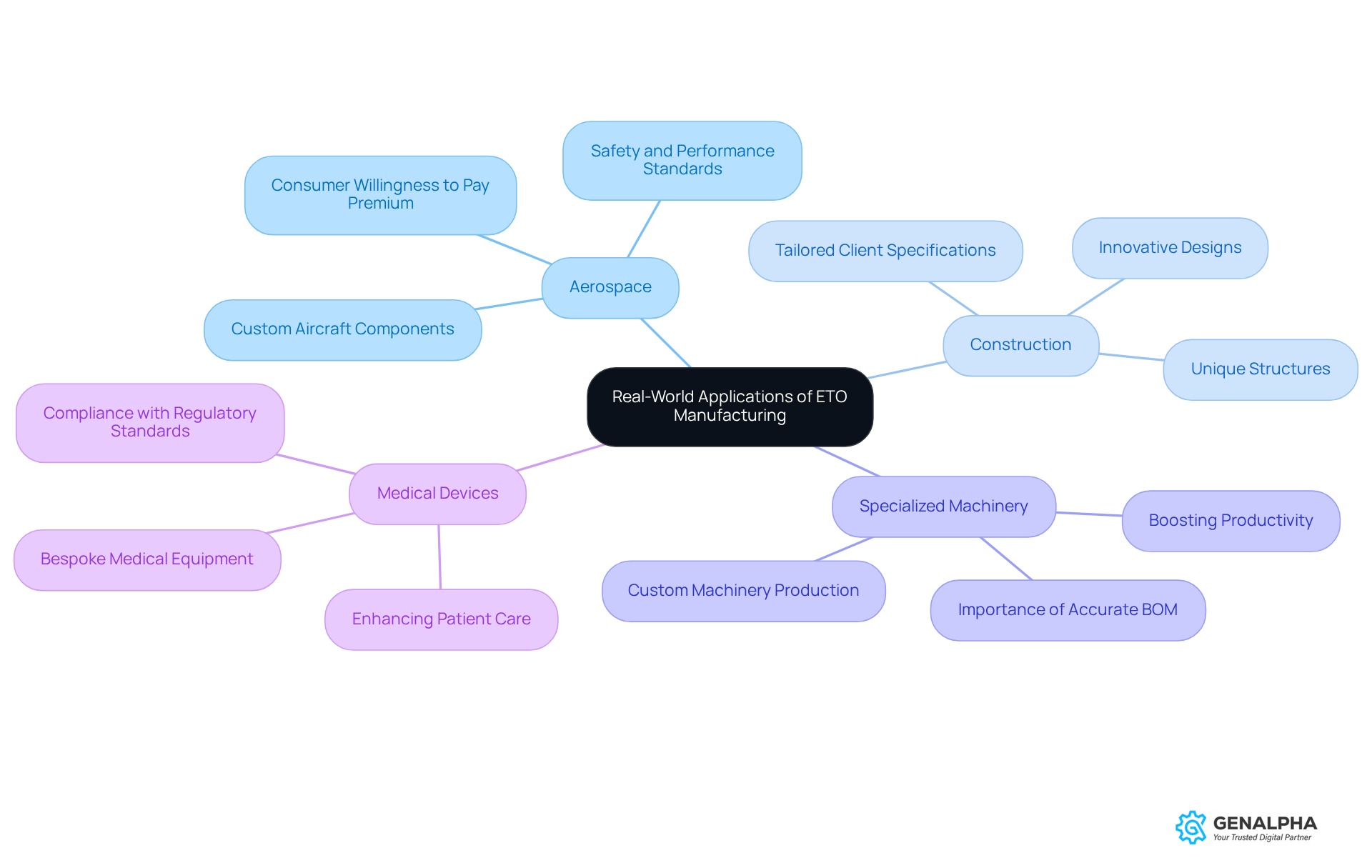

Aerospace: Take companies like Boeing and Airbus, for instance. They use engineer-to-order processes to create custom aircraft components that meet specific airline needs. This isn’t just about making something unique; it’s about ensuring safety and performance standards are met, which boosts operational reliability. Did you know that one in five consumers is willing to pay a 20% premium for personalized products? That’s a testament to how engineer-to-order solutions meet complex demands in the aerospace sector.

-

Construction: Now, let’s look at the construction industry. Here, engineer-to-order methodologies are frequently employed to design and build unique structures or components, such as bridges and specialized machinery, tailored to precise client specifications. This level of customization allows for innovative designs that truly meet project needs. Isn’t it amazing how engineer-to-order can provide such tailored solutions?

-

Specialized Machinery: Think about manufacturers of custom machinery, like CNC machines and industrial robots. They rely on engineer-to-order methods to meet the diverse requirements of their clients. This flexibility leads to tailored solutions that significantly boost productivity and operational efficiency. Plus, having accurate Bill of Materials (BOM) documentation is crucial for the success of these projects.

-

Medical Devices: In the medical field, engineer-to-order production is vital for creating bespoke medical equipment and devices that address the specific needs of healthcare providers and patients. This ensures optimal functionality and compliance with regulatory standards, ultimately enhancing patient care.

These examples really highlight how engineer-to-order manufacturing effectively delivers customized solutions that meet the unique demands of various sectors. It’s all about enhancing customer satisfaction and driving business success. So, what do you think? Could ETO be the key to unlocking new opportunities in your industry?

Conclusion

Engineer-to-order (ETO) manufacturing is really changing the game when it comes to how products are designed and produced. It’s all about creating tailored solutions that meet the specific needs of clients. This approach not only boosts customization but also builds a stronger bond between manufacturers and their customers, leading to greater satisfaction and loyalty.

Let’s dive into what makes ETO manufacturing so unique. It’s characterized by complexity, longer lead times, and the crucial role of customer involvement. Industries like aerospace, construction, specialized machinery, and medical devices are already using ETO processes to craft one-of-a-kind, high-quality products that not only work well but also align perfectly with what clients expect. The growing adoption of ETO practices really highlights its importance in today’s manufacturing world.

As the demand for personalized solutions keeps climbing, embracing engineer-to-order manufacturing could be a game-changer for businesses looking to stand out in competitive markets. By getting to grips with ETO strategies, manufacturers can tap into new opportunities and spark innovation, ultimately shaping the future of the industry. Engaging with this evolving approach doesn’t just meet the immediate needs of clients; it also sets businesses up for long-term success in a constantly changing marketplace.

So, are you ready to explore how ETO manufacturing can transform your business? Let’s take that step together!

Frequently Asked Questions

What is engineer-to-order manufacturing?

Engineer-to-order manufacturing is a production process where items are specially designed, engineered, and created to meet the specific needs of individual clients, starting only after a customer places an order.

How does engineer-to-order manufacturing differ from conventional manufacturing?

Unlike conventional manufacturing, which relies on standardized items, engineer-to-order manufacturing emphasizes customization and flexibility to cater to unique client requirements.

In which industries is engineer-to-order manufacturing particularly important?

Engineer-to-order manufacturing is especially important in industries like aerospace, construction, and specialized machinery, where products often involve complex engineering and design considerations.

What has been the trend in the usage of engineer-to-order processes among U.S. manufacturers?

The percentage of manufacturers in the U.S. using engineer-to-order processes has increased from 25% in 2005 to 51% in 2020, and it is expected to reach 74% by 2025.

What is the expected growth rate for the engineer-to-order software market?

The engineer-to-order software market is anticipated to expand at a compound annual growth rate (CAGR) of 9.3% from 2025 to 2032.

What challenges do engineer-to-order manufacturers face?

Engineer-to-order manufacturers need to maintain traceability in their projects and ensure effective communication with clients to ensure smooth operations.

Why is documentation important in the engineer-to-order process?

Thorough documentation, such as creating a Bill of Materials (BOM), is crucial as it organizes the materials and subassemblies needed to manufacture an item, facilitating effective project management.