Introduction

Navigating the world of manufacturing today can feel like a maze, right? With rising costs and supply chain uncertainties, efficient parts ordering systems have become a must-have. Imagine being able to master inventory management, tap into innovative technologies, and harness the power of data analytics. Sounds great, doesn’t it? These strategies can really boost your operational efficiency and keep your customers smiling.

But let’s be real - optimizing these systems isn’t always a walk in the park. Many manufacturers hit roadblocks that can slow down progress. So, how can we tackle these challenges head-on? How can we turn our parts ordering processes into a competitive edge?

Let’s dive in and explore how we can make this happen together!

Understand Inventory Management Principles

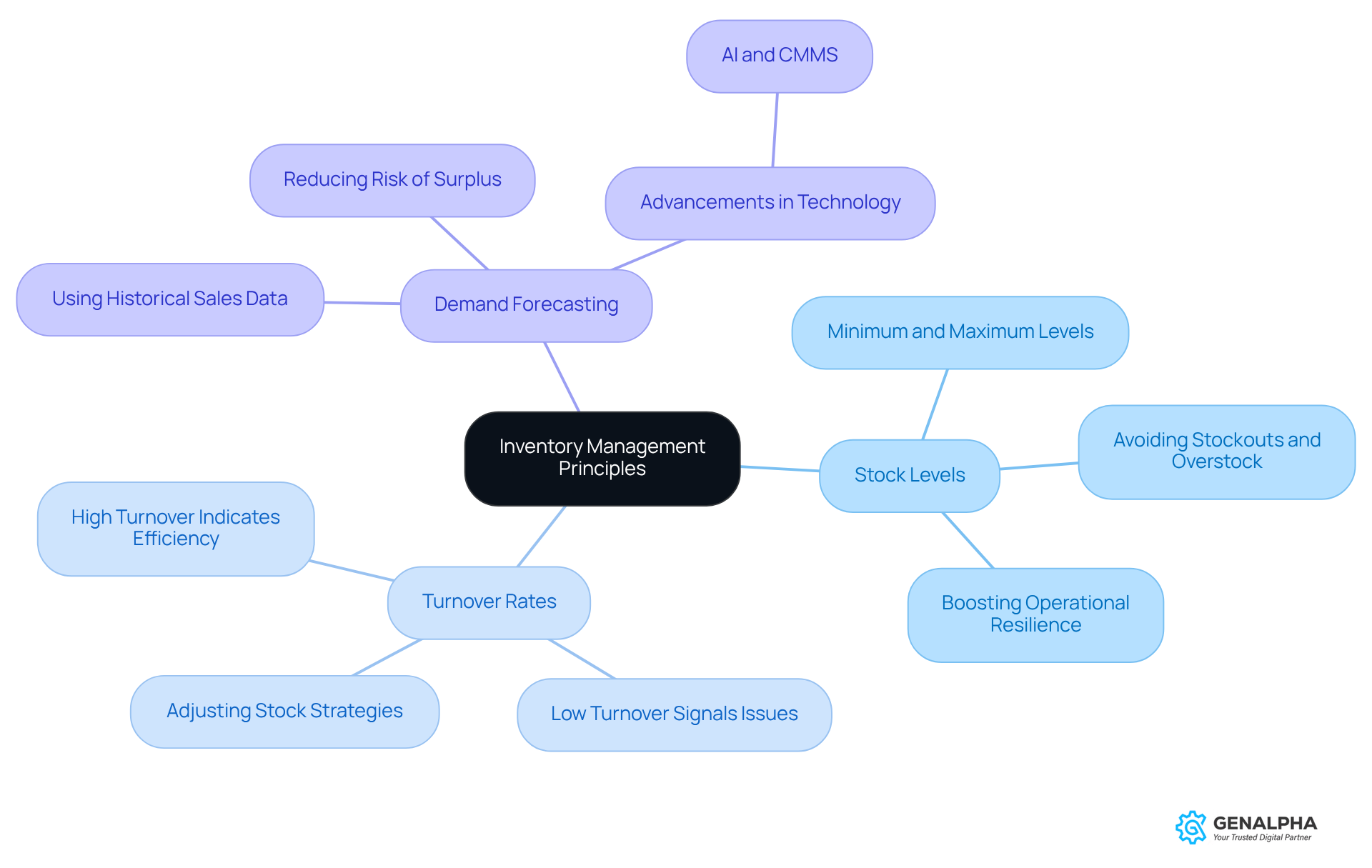

Efficient stock management truly serves as the backbone of a successful parts ordering system, particularly in light of the evolving challenges manufacturers will face in 2026. As companies focus on cost optimization and navigate geopolitical risks, grasping key principles like stock levels, turnover rates, and demand forecasting becomes even more crucial.

-

Stock Levels: Setting minimum and maximum stock levels is key to avoiding stockouts and overstock situations. This approach ensures that components are readily available when needed while keeping too much cash tied up in stock. In a world where supply chain uncertainties are the norm, maintaining optimal stock levels can really boost operational resilience.

-

Turnover Rates: Keeping an eye on turnover rates shows how quickly parts are sold and replaced. A high turnover rate means effective stock management, while a low rate might signal overstocking or sluggish sales. As businesses face rising costs and fluctuating demand, understanding turnover rates can help producers make quick adjustments to their stock strategies.

-

Demand Forecasting: Using historical sales data to predict future demand is essential. This strategy helps producers make informed decisions about which components to stock and in what quantities, reducing the risk of surplus. Thanks to advancements in technology, like AI and Computerized Maintenance Management Systems (CMMS), manufacturers can sharpen their forecasting accuracy, leading to better stock management outcomes.

By mastering these principles and being mindful of common pitfalls - like not adapting to changing market conditions or overlooking the role of technology - producers can craft a solid stock management strategy. This not only improves their parts ordering system but also increases operational efficiency and client satisfaction. So, how are you planning to refine your stock management approach?

Leverage Technology for Streamlined Ordering

Technology plays a crucial role in optimizing parts ordering systems, and there are some exciting innovations to consider:

-

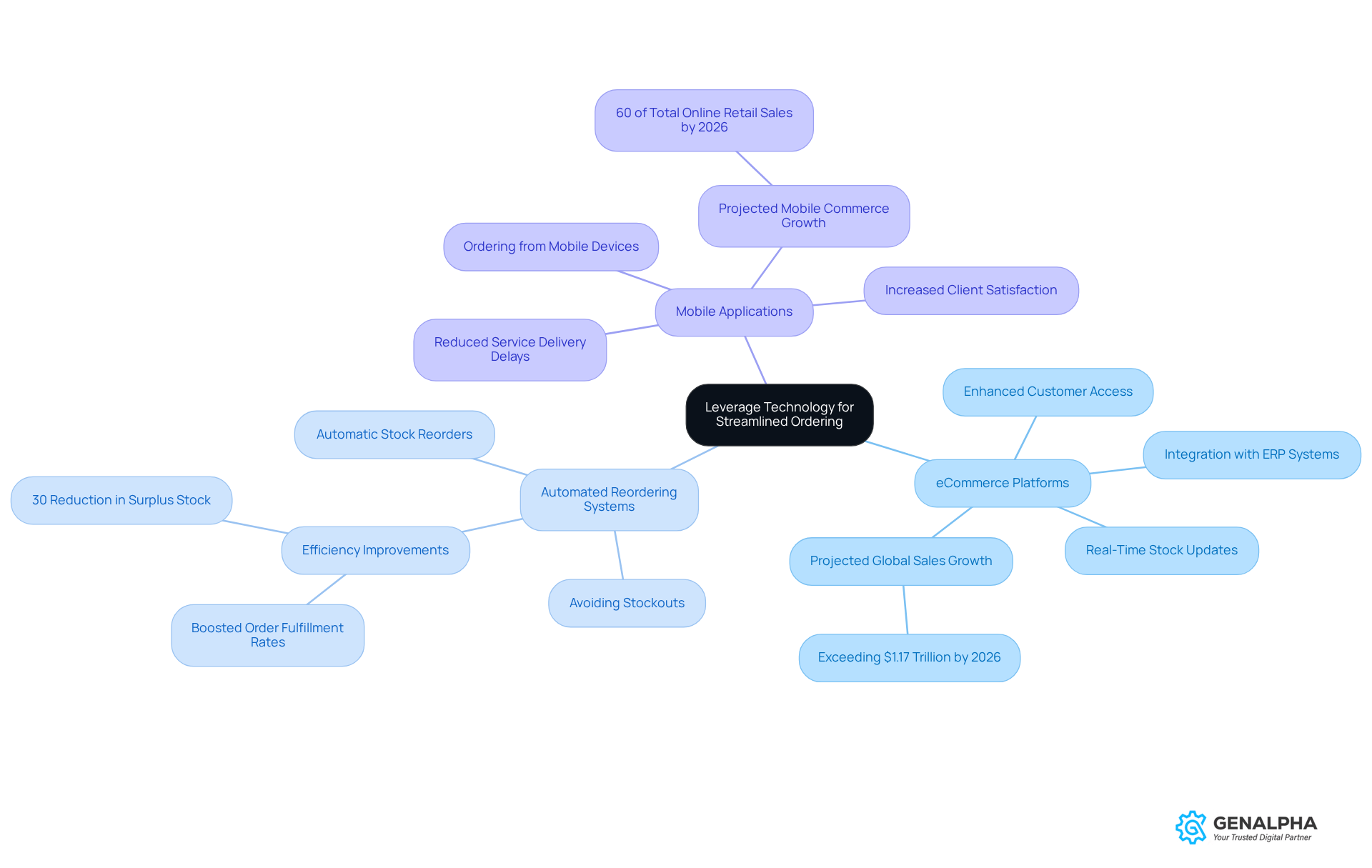

eCommerce Platforms: Think about implementing a solid eCommerce solution like Equip360. It seamlessly integrates with your existing ERP systems, allowing for real-time stock updates. This means your customers can easily access parts information, making their purchasing experience much smoother. With global social commerce sales projected to exceed $1.17 trillion by 2026, it’s clear that having a strong online presence is more important than ever.

-

Automated Reordering Systems: Have you ever run out of stock at the worst possible moment? That’s where automated reordering systems come in. These smart systems automatically trigger reorders when stock levels drop below a certain point, helping you avoid stockouts and ensuring you always have essential parts on hand. By 2026, producers using these systems can expect significant improvements in stock management efficiency. Studies show they can reduce surplus stock by up to 30% while boosting order fulfillment rates. As industry leaders say, "Automated reordering systems are transforming inventory management, enabling producers to operate more efficiently and responsively."

-

Mobile Applications: Imagine your field technicians being able to order parts right from their mobile devices. This capability can drastically cut down on service delivery delays. Not only does it enhance operational efficiency, but it also boosts client satisfaction by ensuring timely access to necessary components. With mobile commerce expected to make up nearly 60% of total online retail sales by 2026, investing in mobile applications is a smart move to stay competitive.

By embracing these technologies, producers can streamline their ordering processes, cut down on manual errors, and significantly improve customer experiences. So, why not take the leap and position yourself for success in this competitive marketplace?

Utilize Data Analytics for Informed Decisions

Data analytics is a game changer for manufacturers aiming to enhance their parts ordering system. So, how can they make the most of analytics? Let’s break it down:

-

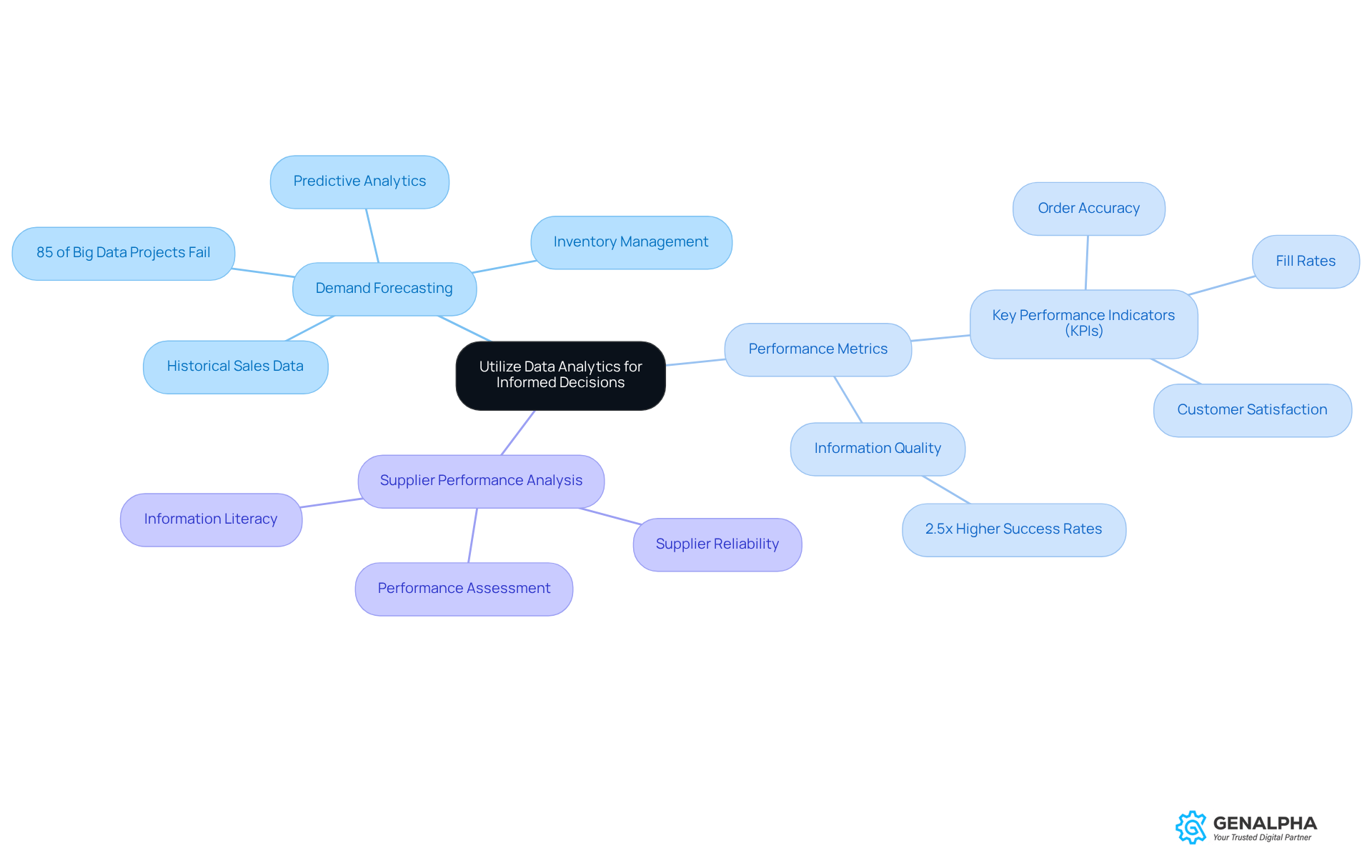

Demand Forecasting: Ever thought about how predictive analytics can help? By digging into historical sales data, manufacturers can forecast future demand with impressive accuracy. This not only keeps inventory levels just right but also cuts down on excess stock, which means lower carrying costs. And here’s a kicker: 85% of big data projects stumble due to technical hiccups and unclear goals. That’s why having a solid plan for analytics is key.

-

Performance Metrics: Keeping an eye on key performance indicators (KPIs) like order accuracy, fill rates, and customer satisfaction is crucial. By analyzing these metrics, manufacturers can pinpoint areas that need a little TLC in the ordering process, leading to smoother operations. Did you know that organizations that focus on information quality see 2.5 times higher success rates in transformations? It really shows how vital precise information is for making smart decisions.

-

Supplier Performance Analysis: Let’s talk about suppliers. Using analytics to assess supplier reliability and performance can really pay off. This insight helps manufacturers prioritize the right suppliers, ensuring they work with those who consistently meet demand. As Piyanka Jain puts it, "Everybody needs information literacy, because information is everywhere." It’s like the new currency in business; we all need to be fluent in it.

Integrating analytics into operations allows manufacturers to make informed choices that enhance the efficiency of their parts ordering system. This not only drives growth but also keeps them competitive in the market. But here’s a reality check: 70% of digital transformation projects don’t hit their targets. That’s why careful planning and execution are essential. A case study showed that organizations that successfully embraced data analytics saw a 30% improvement in inventory efficiency. That’s a clear win for leveraging data effectively!

Enhance Customer Engagement and Satisfaction

Enhancing client engagement is crucial for optimizing the parts ordering system. So, how can we elevate customer satisfaction? Here are some effective strategies:

-

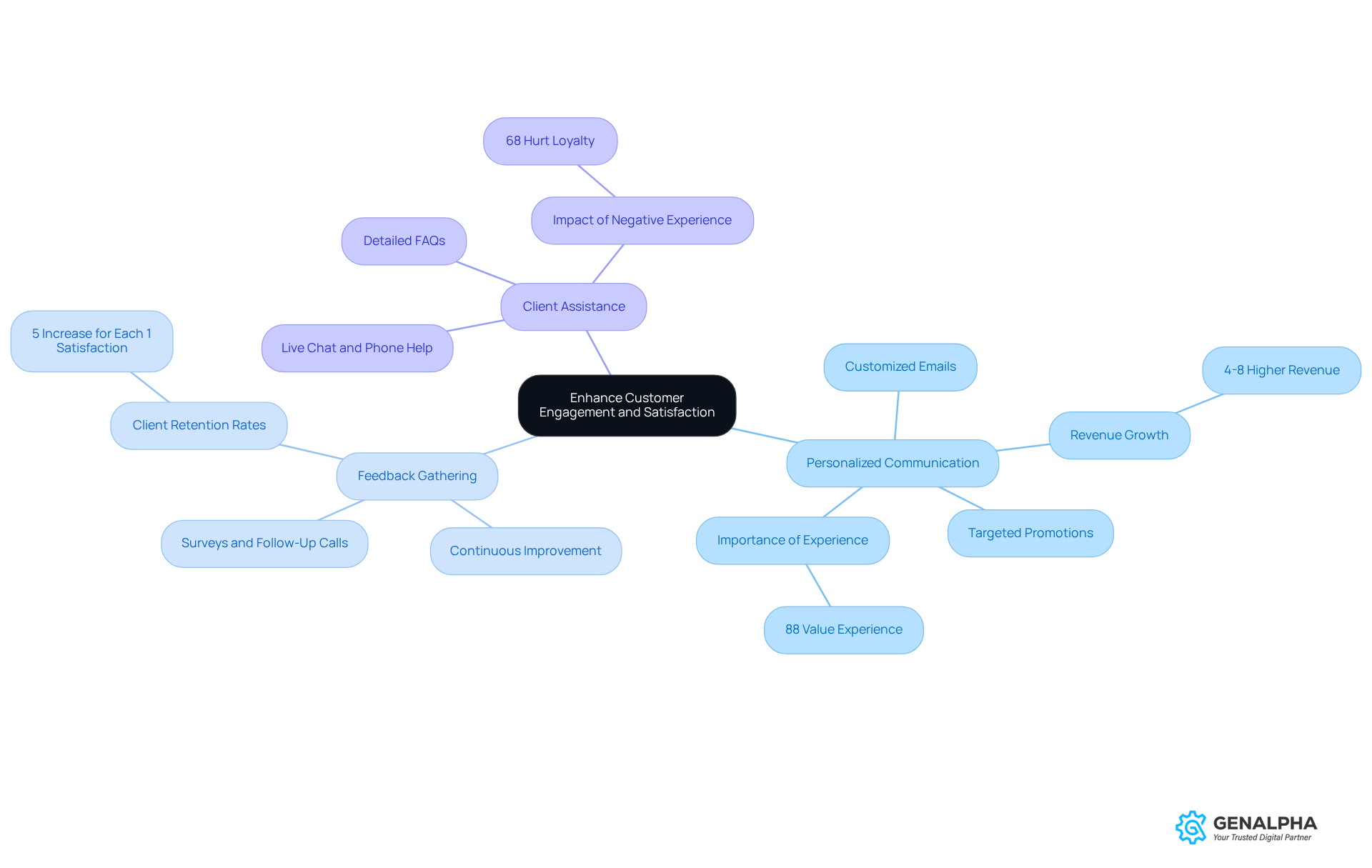

Personalized Communication: Let’s tap into client data to customize our communications and offers. Think about it-personalized emails and targeted promotions can really boost engagement. In fact, brands that nail their client experience strategies see revenue growth that’s 4-8% higher than the industry average! As KPMG points out, '88% say the experience a company provides is as important as its products or services.' This really highlights how vital personalized communication is for enhancing client satisfaction.

-

It’s crucial to set up a parts ordering system for gathering feedback from clients about their ordering experience. Using surveys or follow-up calls can help manufacturers pinpoint pain points and areas for improvement. This fosters a culture of continuous improvement. Plus, did you know that client retention rates rise by 5% for each 1% increase in client satisfaction? That’s a direct effect of addressing client feedback!

-

Client Assistance: Offering extensive client assistance options is key. Think live chat, phone help, and detailed FAQs. Quick and efficient assistance not only boosts satisfaction but also builds loyalty. In fact, 68% of clients say that a negative experience can really hurt their allegiance to a brand.

By implementing these strategies, manufacturers can create a more engaging and satisfying experience for their customers. This not only drives increased sales but also fosters long-term loyalty. So, what are you waiting for? Let’s get started!

Conclusion

Optimizing a parts ordering system is crucial for manufacturers who want to stay efficient and competitive in today’s fast-paced market. Have you ever thought about how understanding key inventory management principles, using advanced technologies, and tapping into data analytics can really boost your ordering processes? This multifaceted approach not only streamlines operations but also enhances customer satisfaction and loyalty.

Let’s break it down. The article pointed out three main areas for improvement:

- Mastering inventory management principles

- Embracing technology for smoother ordering

- Using data analytics for smarter decision-making

Think about strategies like setting optimal stock levels, adopting automated reordering systems, and focusing on personalized customer engagement. These are vital components of a successful parts ordering system. Plus, integrating analytics into your operations can help you anticipate demand and refine supplier performance, leading to more efficient inventory management.

In a world where customer expectations and market dynamics are always changing, it’s essential for manufacturers to prioritize these best practices. Why wait? By optimizing your parts ordering processes now, you can boost operational efficiency and build stronger relationships with your clients. The time to refine and innovate is now-let’s embrace these strategies and set your manufacturing operations up for future success!

Frequently Asked Questions

Why is efficient inventory management important for manufacturers?

Efficient inventory management serves as the backbone of a successful parts ordering system, helping manufacturers navigate challenges such as cost optimization and geopolitical risks.

What are stock levels and why are they important?

Stock levels refer to the minimum and maximum quantities of inventory that should be maintained. They are important for avoiding stockouts and overstock situations, ensuring components are available when needed while minimizing cash tied up in stock.

How do turnover rates impact inventory management?

Turnover rates indicate how quickly parts are sold and replaced. A high turnover rate reflects effective stock management, while a low rate may signal overstocking or sluggish sales, prompting businesses to adjust their stock strategies.

What is demand forecasting and why is it essential?

Demand forecasting involves using historical sales data to predict future demand for components. It is essential for making informed stocking decisions and reducing the risk of surplus inventory.

How can technology improve demand forecasting?

Advancements in technology, such as AI and Computerized Maintenance Management Systems (CMMS), enhance forecasting accuracy, leading to better stock management outcomes.

What common pitfalls should manufacturers avoid in inventory management?

Manufacturers should avoid not adapting to changing market conditions and overlooking the role of technology in their stock management strategies.