Introduction

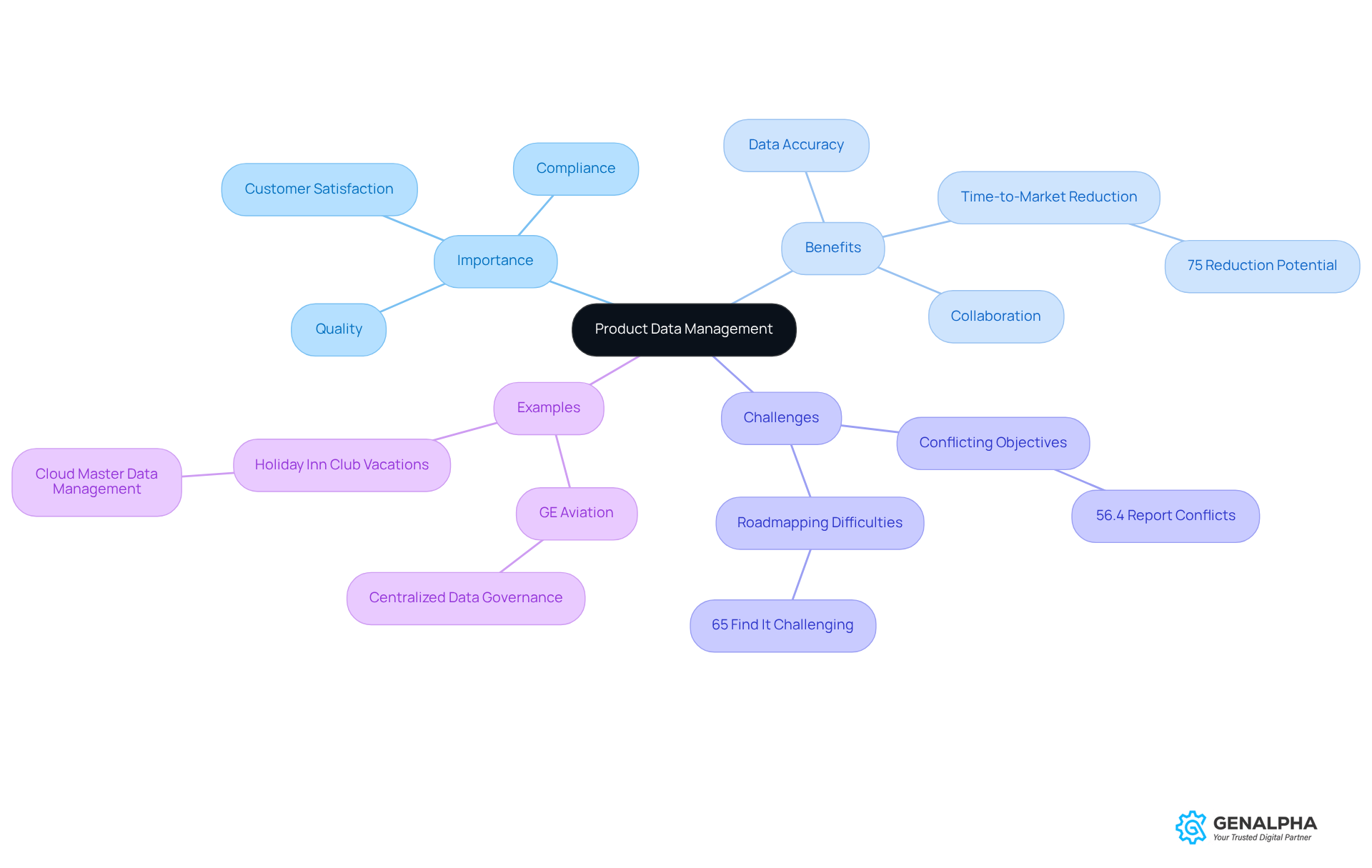

Optimizing how we manage product data in manufacturing isn’t just a passing trend; it’s essential for companies that want to keep up in today’s fast-paced market. Think about it: when product data is managed effectively, it can really boost quality, ensure compliance, and make customers happier. This, in turn, can lead to a significant drop in time-to-market. But here’s the catch - many manufacturers find themselves stuck between conflicting goals and operational hurdles that slow them down.

So, what can we do to tackle these challenges and truly harness the power of product data management? Let’s explore some strategies together!

Understand Product Data Management and Its Importance

Manufacturing product data management focuses on how we handle product-related data throughout its lifecycle. Think design specs, manufacturing details, marketing info, and even customer feedback. For manufacturers and distributors, understanding manufacturing product data management is super important. Why? Because it plays a huge role in quality, compliance, and keeping customers happy.

Imagine this: effective PDM can cut down time-to-market by a whopping 75%! That’s not just a number; it’s backed by industry studies. This kind of efficiency doesn’t just make operations smoother; it also boosts the overall customer experience. After all, who doesn’t want accurate and timely information at every stage of a product’s life?

By putting solid manufacturing product data management solutions in place, companies can improve collaboration across departments, enhance data accuracy, and ultimately drive up customer satisfaction. It really shows why investing in effective manufacturing product data management systems is a wise decision. But here’s the catch: goods managers often face challenges. In fact, 56.4% report conflicting objectives within their organizations. Plus, 65% of item managers say that roadmapping is the toughest part of their job.

Take GE Aviation, for example. Their centralized information governance initiative is a great case of successful PDM implementation. It streamlined their processes and made information more accessible. By identifying common pitfalls in manufacturing product data management execution, companies can avoid missteps and truly reap the benefits of efficient product information management. So, what’s holding you back from diving into PDM? Let’s chat about how you can make it work for you!

Implement Key Strategies for Effective Product Data Management

To boost how we manage item information, manufacturers can adopt a few key strategies that really make a difference:

-

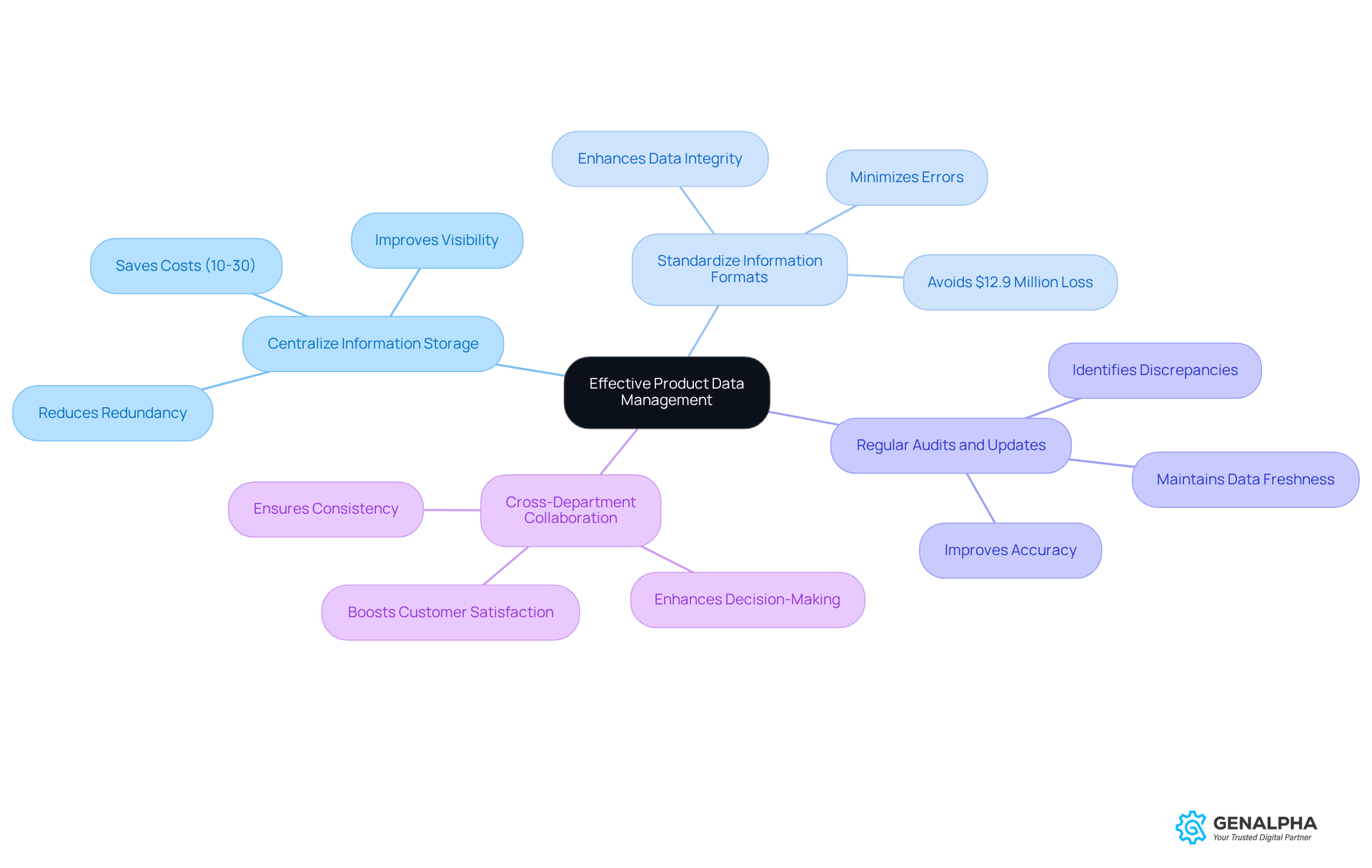

Centralize Information Storage: Imagine having all your product details in one place. By consolidating everything into a single repository, you cut down on redundancy and make sure everyone has access to the same info. This not only improves visibility but also simplifies decision-making. Companies that have centralized their information often report better operational efficiencies and lower costs. In fact, those transitioning from scattered to integrated information environments can save between 10% and 30% over three years. That’s some serious financial incentive!

-

Standardize Information Formats: Ever noticed how inconsistent formats can lead to confusion? Establishing uniform formats across all platforms helps minimize errors and boosts integrity. For instance, companies that use standardized formats for item codes, names, and dates can make more accurate comparisons and analyses. Poor information quality can cost businesses an average of $12.9 million each year! One organization even linked a staggering $110 million revenue loss to faulty info from a major client. Clearly, standardization is essential.

-

Regular Audits and Updates: Think of periodic reviews of product information as a health check-up. They help spot inaccuracies and outdated details, keeping your content fresh and reliable. Organizations that regularly review their information sources often find discrepancies and improve overall quality, which is crucial for maintaining operational efficiency. Those who conduct regular audits have seen significant boosts in information accuracy and reliability.

-

Cross-Department Collaboration: What if engineering, marketing, and sales worked together more closely? Promoting cooperation among these divisions creates a well-rounded approach to item information management. This teamwork leads to better decision-making and ensures everyone is on the same page regarding product information, ultimately enhancing quality and customer satisfaction.

By putting these strategies into action, manufacturers can significantly improve their operational efficiency and product quality, setting themselves up for success in a competitive marketplace. So, why not start today?

Leverage Technology and Tools for Enhanced PDM

To optimize manufacturing product data management, manufacturers should really consider adopting a mix of advanced technologies and tools.

-

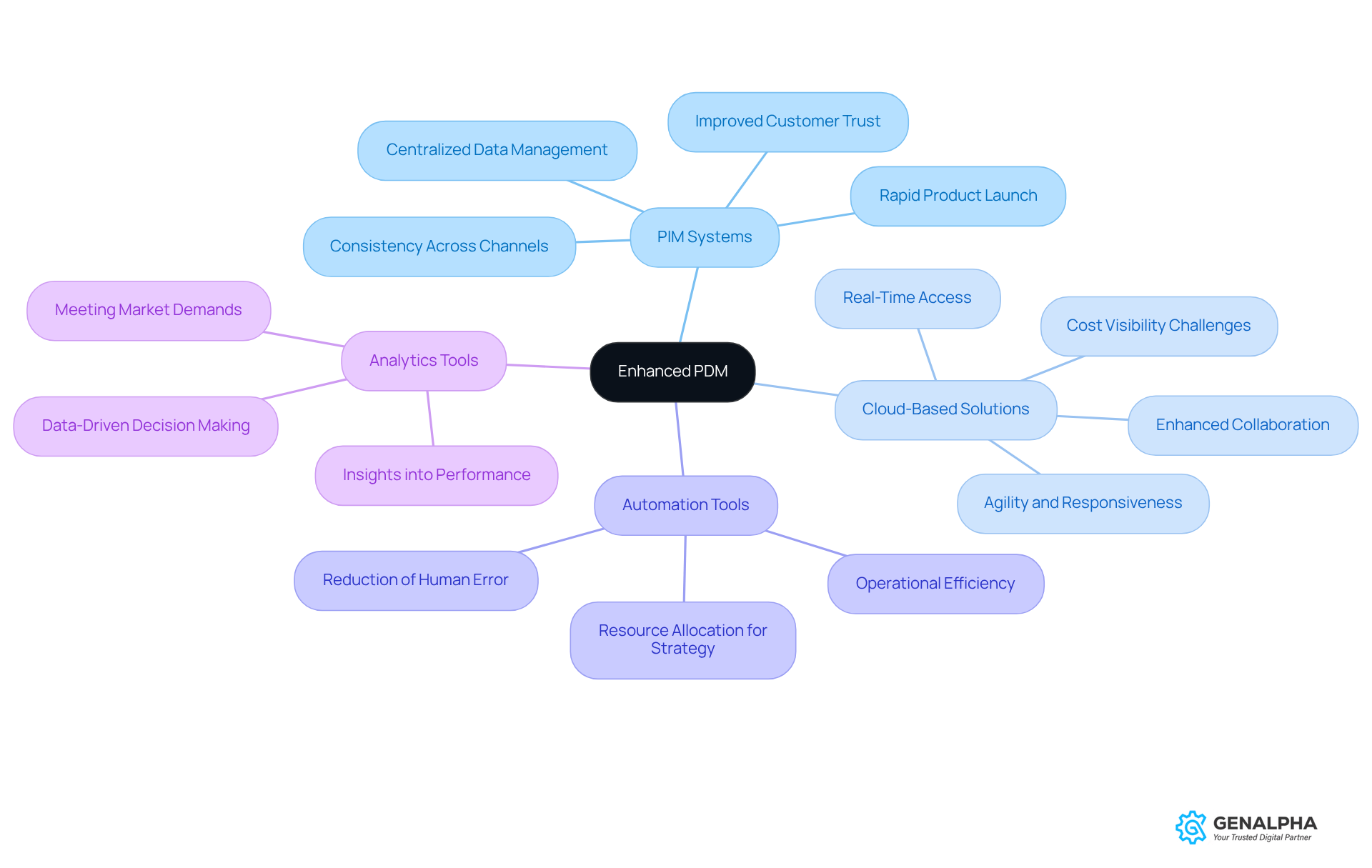

Product Information Administration (PIM) Systems: Think of PIM systems as a centralized hub for all your item information. They make it super easy to oversee and distribute data across various sales channels. This centralization is key for effective manufacturing product data management, which helps keep things consistent and accurate, thereby maintaining brand integrity and customer trust. As Shawn Griffin points out, manufacturing product data management enables producers to launch new items quickly, giving them a competitive edge in the market.

-

Cloud-Based Solutions: Now, let’s talk about cloud technology. It’s a game changer for manufacturing product data management, offering real-time access and collaboration. Did you know that 72% of global workloads are currently hosted in the cloud? This means producers can empower their teams to work effectively from anywhere, making them more agile and responsive to market changes. Just a heads up, though-54% of cloud waste comes from not having clear visibility into costs, so it’s something to keep in mind when adopting these solutions.

-

Automation Tools: Imagine cutting down on human error and operational inefficiencies-sounds great, right? By implementing automation for manufacturing product data management and updates, producers can achieve that. Automating routine tasks frees up resources for more strategic initiatives, ultimately driving growth and innovation.

-

Analytics Tools: And let’s not forget about analytics tools. They provide valuable insights into item performance and consumer preferences. This data-driven approach empowers businesses to make informed decisions, helping them meet market demands and boost customer satisfaction.

By combining these technologies, manufacturers can simplify their processes related to manufacturing product data management. This leads to enhanced operational efficiency and a stronger competitive advantage in the marketplace. Plus, the recognition of Viamedici's EPIM4 with the 2023 Frost & Sullivan Product Leadership award really highlights how effective PIM systems can be in improving item information oversight.

So, what do you think? Are you ready to take your product data management to the next level?

Overcome Challenges in Product Data Management

Manufacturers face significant challenges in manufacturing product data management, which can hinder smooth operations and profitability. Let’s break it down:

-

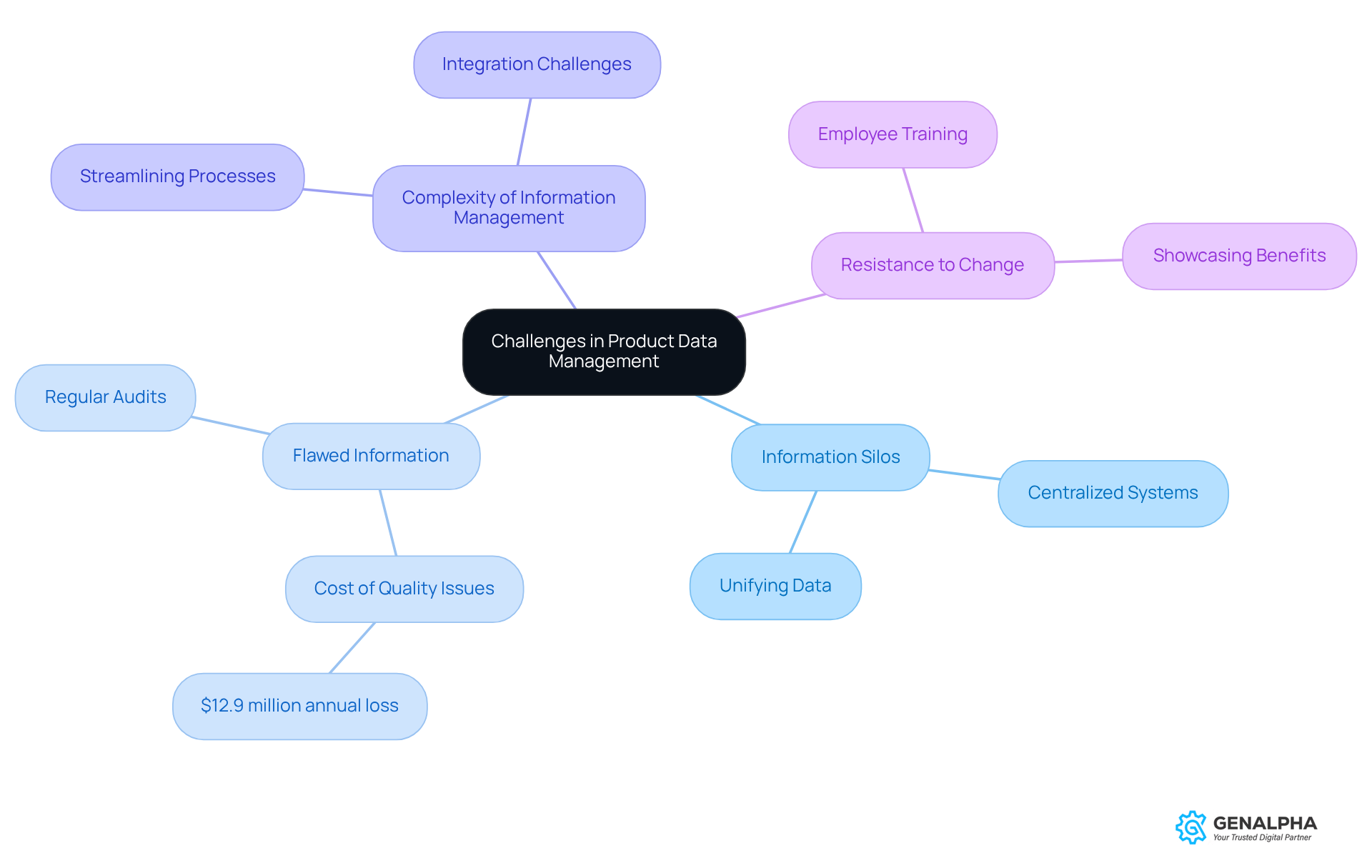

Information Silos: Ever notice how different departments often have their own isolated systems? This can lead to inconsistencies that are hard to manage. A centralized manufacturing product data management system can help unify everything, giving you a consistent view and reducing those pesky discrepancies.

-

Flawed Information: Mistakes in product details can be costly, impacting everything from production to customer satisfaction. Did you know that the average organization loses about $12.9 million each year due to quality-related issues? Regular audits and validation procedures are key to keeping your information accurate and reliable.

-

Complexity of Information Management: As your product lines grow, managing all that information can get complicated. That’s where manufacturing product data management systems come in handy, as they streamline the process, making it easier to handle and access information. Many manufacturers struggle with integrating data from various sources, which only adds to the complexity.

-

Resistance to Change: Change can be tough! Employees might hesitate to adopt new systems because they’re unsure or just not familiar with them. Providing thorough training and clearly showing the benefits of new tools can help ease this transition. As Matt Pacheco wisely points out, "If you don’t take the time to evaluate your data, you may lose your competitive edge to other manufacturing companies that take meaningful, decisive action on gathered insights."

By tackling these challenges head-on, manufacturers can really boost their manufacturing product data management processes, leading to better operational efficiency and improved business outcomes. So, what steps can you take today to enhance your PDM?

Conclusion

When we think about manufacturing product data management, it’s easy to see it as just a back-end process. But let’s be real - it’s a game changer that can really impact a company’s success and how happy customers are. By managing product-related data effectively throughout its lifecycle, manufacturers can streamline operations, boost product quality, and cut down on time-to-market. This all leads to a more competitive edge in the business world.

So, what are some key strategies to keep in mind?

- Centralizing information storage

- Standardizing formats

- Conducting regular audits

- Encouraging collaboration across departments

These are all essential practices for optimizing product data management. Plus, incorporating advanced technologies like Product Information Management (PIM) systems, cloud solutions, automation tools, and analytics can take these efforts to the next level, driving efficiency and accuracy in how data is handled.

Let’s not underestimate the importance of effective manufacturing product data management. It’s crucial for tackling common challenges like information silos, flawed data, and resistance to change. By addressing these issues head-on and implementing the strategies and technologies we’ve discussed, manufacturers can set themselves up for long-term success. Embracing these best practices now not only boosts operational efficiency but also opens the door for innovation and growth down the line. So, why wait? Let’s get started on this journey together!

Frequently Asked Questions

What is manufacturing product data management (PDM)?

Manufacturing product data management focuses on how product-related data is handled throughout its lifecycle, including design specifications, manufacturing details, marketing information, and customer feedback.

Why is understanding manufacturing product data management important for manufacturers and distributors?

It is crucial because it significantly impacts quality, compliance, and customer satisfaction, ultimately contributing to a smoother operation and enhanced customer experience.

How much can effective product data management reduce time-to-market?

Effective product data management can cut down time-to-market by up to 75%, according to industry studies.

What are the benefits of implementing solid manufacturing product data management solutions?

Benefits include improved collaboration across departments, enhanced data accuracy, and increased customer satisfaction.

What challenges do goods managers face in product data management?

Goods managers often report conflicting objectives within their organizations, with 56.4% experiencing this issue. Additionally, 65% of item managers find roadmapping to be the toughest part of their job.

Can you provide an example of successful PDM implementation?

GE Aviation is an example of successful PDM implementation, where their centralized information governance initiative streamlined processes and made information more accessible.

What should companies focus on to avoid pitfalls in manufacturing product data management execution?

Companies should identify common pitfalls in PDM execution to avoid missteps and fully reap the benefits of efficient product information management.